LENOX LXHT90551 10” V-Jaw Quick Adjust Pliers LENOX® Tools sent some new pliers and wrenches to Mechanical Hub a couple months ago. As always, we choose to use the tools we review on real job sites, in real life situations so we can report back to you. Whether we pay for a tool or product Read more

ProStaff Reviews

LENOX LXHT90551 10” V-Jaw Quick Adjust Pliers

LENOX® Tools sent some new pliers and wrenches to Mechanical Hub a couple months ago. As always, we choose to use the tools we review on real job sites, in real life situations so we can report back to you. Whether we pay for a tool or product or it is gifted to us, you will always get honest information that we hope will aid you in decision making when scouting out new tools. LENOX® is not new to hand tools or pipe wrenches, making these all updated designs worth a look. The following is a summary of our use of the 10” V-Jaw Quick-Adjust Pliers over three months of daily use.

Handles

If you read my review of the 10” Pliers Wrench or have used pliers with a cushioned grip, then you know the significance of this handle type and how it will benefit you over time and under high force. It’s not surprising LENOX chose this handle type as it is a favorite throughout the plumbing industry.

Jaws

The v-jaw geometry is one that grips, period. This is a proven jaw design that is meant to grip multiple shapes and sizes of materials. Performance on iron pipe, probably the most common material these pliers will work with, is reliable and exceptional. The v-jaw also allows the user to grip hex surfaces easily, although the aggressive teeth will mar softer metals like bras or finished surfaces like chrome so be aware.

Finish

The industrial chrome finish makes these pliers corrosion resistant which is an absolute must for plumbing and heating work. I also found that cleaning the pliers of pipe dirt was not difficult, I’d attribute that to the chrome finish as well.

Conclusion

If you’re like me and use pump pliers every day, I’d recommend giving the LENOX® 10” V-Jaw Adjust Pliers a try. The value when compared to higher price imported or domestic competitors is high. The quick-adjust feature is an absolute slam dunk in making these some of the nicest pliers I have used in my long career as a plumbing and heating contractor.

MSRP:

Availability: Now

Hilti’s newest laser entry into the cordless layout and measurement category comes with proven tech in a robust package. There is no shortage of line lasers on the market today. The PM 30-MG cordless multi-line laser from Hilti is 360 degree green beam laser powered by their Li-Ion B 12/2.6 battery. I have been working Read more

Hilti’s newest laser entry into the cordless layout and measurement category comes with proven tech in a robust package.

There is no shortage of line lasers on the market today. The PM 30-MG cordless multi-line laser from Hilti is 360 degree green beam laser powered by their Li-Ion B 12/2.6 battery.

I have been working with the PM 30 Hilti laser for a couple months, primarily using it for simple layout and leveling in different tasks like panel radiator installs or boiler piping layouts. I’ve used both the included wall mount bracket and magnetic base. The PM 30-MG has a very useful fine adjustment dial at the base that makes for quick alignment when rotated either direction.

Bracket alignment for hydronic panel radiators.

The Hilti PM 30-MG is intended for indoor use

Hilti has other laser models intended for outdoor use but as stated in the manual the PM 30-MG can be used outside if conditions are dry (manual pg 5, sec 3.2). Its intended use is to allow a single person to transfer right angles, level horizontally, carry out alignment work and plumb accurately.

The product has three green 360° laser lines, a reference point directed downward on the right-hand front of the measuring device, as well as four beam intersection points (front, back, left, right and above) with a range of approx. 65ft/20 m. Range depends on the brightness of ambient light.

How long will the battery last?

Runtime will vary based on laser projection. The ability to select plumb, level or cross-line (both plumb & level) beams depending on the job at hand will determine the battery life. Max operating time is published at 12 hours, I have used the PM 30-MG enough for one battery recharge but the bulk of my use has been in the cross-line mode. The selection of beam projection is easily done with a single button on the side of the laser housing.

Self-leveling or Locked

Self-leveling or Locked

The Hilti PM 30-MG can be set to auto-level or locked for use of setting slope. This is done with the sliding power button on the side of the unit. In the locked position the leveling pendulum is fixed allowing for grade or slope projection on a horizontal plane. Moreover, the unlocked (most used mode) will allow the pendulum to self-level. If the laser is not able to self level the projected beam(s) will blink rapidly until corrected.

The tool complies with Laser Class 2 in accordance with IEC / EN 60825-1: 2014 and in accordance with CFR 21 Sec. 1040 (FDA). These devices can be used without further protective measures. Nevertheless, as with the sun, do not look directly into the light source. If you do inadvertently look into the laser beam, immediately close your eyes and move your head clear of the laser beam. Do not aim the laser beam at persons.

Finally, the Hilti PM 30-MG is backed by Hilti’s 20 year materials and workmanship, 2 year wear & tear coverage and 1 day turnaround in the repair center warranty. The Hilti PM 30-MG laser was shared with mechanical-hub.com ProStaff member Eric Aune via Hilti’s tool lease program free of charge and will be returned after use required for full tool review. You can find more info for this and other Hilti products and tools on their website: hilti.com

Job site pics of the Hilti PM 30-MG

With a intended max working range of 65ft the line stays crisp at 40 in shaded daylight.

Same conditions and site as the 40′ measurement, at 80 feet the line is getting much thicker and less crisp.

Ah, the age-old question: is it duct tape or duck tape? Although often mispronounced, it’s actually duct tape (Duck is a brand of the tape) and covers a class of pressure-sensitive tapes that consists of three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. Yet, even with that clarification, the term “duct tape” can Read more

Ah, the age-old question: is it duct tape or duck tape? Although often mispronounced, it’s actually duct tape (Duck is a brand of the tape) and covers a class of pressure-sensitive tapes that consists of three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. Yet, even with that clarification, the term “duct tape” can still be a bit misleading – although it’s considered a fix-all that got its name from early-on usage in HVAC work, duct tape is, today, actually not recommended for use on ducts (though there are some versions that are approved for HVAC applications).

Here’s a rundown of tape types.

- General Purpose Duct Tapes: Typical Thickness: 6-9 mils, handy for DIY home projects or light duty patching and bundling for pros on the jobsite.

- Heavy Duty Duct Tapes: Typical Thickness: 10-17 mils, every tradesperson should keep at least one roll of heavy duty duct tape in the toolbox — and multiple widths or colors won’t hurt.

- Clear Repair Tapes: Typical Thickness: Approx. 7 mils, your go-to tape for airtight, waterproof repairs on any surface that needs to be seen.

- Structural Grade Duct Tapes: Typical Thickness: Approx. 17 mils, the most robust option for extreme jobs, including those that require a rope or chain.

Duct tape is undoubtedly one of those versatile items that’s earned a place in just about any toolbox. It’s flexible, resists tearing, and sticks to just about anything. As contractors know, when it comes to jobsite efficiency, having the right tools for the job at-hand makes all the difference—and saving time means saving money.

Duct tape is undoubtedly one of those versatile items that’s earned a place in just about any toolbox. It’s flexible, resists tearing, and sticks to just about anything. As contractors know, when it comes to jobsite efficiency, having the right tools for the job at-hand makes all the difference—and saving time means saving money.

The Mechanical Hub ProStaff team recently took on the challenge of trying out a new tape to see if it was the one to grab to ensure the fix doesn’t fail and can save time, money and a lot of space in the toolbox.

Traditionally, ropes or chains have been the only option for contractors and installers when they encounter jobsite tasks that require intense strength and durability. Until now as one 36-inch loop of new T-Rex® Brute Force® can hold more than 700 pounds of weight and offers superior adhesion, so you can quickly secure, fasten and hold loads that you wouldn’t dare attempt with other tapes.

The high-bond, double-thick adhesive allows the tape to stick to rougher, dirtier surfaces and offers a durable, waterproof backing suitable for all-weather performance. Brute Force® represents the next generation of high-performance duct tapes with patent-pending Forge-Link™ Technology.

ProStaffer Andy Mickelson of Mickelson Plumbing and Heating, Missoula, Montana, was impressed with the strength and said, “T-Rex Brute Force tape has an incredible tear-resistant design, so much so that you’ll require a blade to cut it. The adhesive layer is much thicker than any other tape I’ve used previously. The tape seems to hold well when bonded to itself and smooth surfaces alike, even when the surface is not completely dry. It will make a great addition to any travel box or tool box.”

ProStaffer Andy Mickelson of Mickelson Plumbing and Heating, Missoula, Montana, was impressed with the strength and said, “T-Rex Brute Force tape has an incredible tear-resistant design, so much so that you’ll require a blade to cut it. The adhesive layer is much thicker than any other tape I’ve used previously. The tape seems to hold well when bonded to itself and smooth surfaces alike, even when the surface is not completely dry. It will make a great addition to any travel box or tool box.”

“We have found a number of uses for T-Rex Brute Force! Someone didn’t judge the width of the truck while backing up and managed to rip off a side mirror. The mirror was put back into place and held there with the tape until we were able to get it into the dealership,” said Shay Shepston of Reimagined Renovations, Champaign, Illinois.

Shay added, “It’s been used to hold a foam base cove to metal before installing a pool liner, to hold PVC pipes in place while we work, and many other odd jobs. It has been added to all our trucks and toolboxes!”

According to our ProStaff team, the only drawback—and one they all mentioned—was that you cannot tear it; it must be cut. Contractors are so accustomed to just tearing tape, it required remembering to have a utility knife handy to cut it.

ProStaff member John Thompson with Thompson Family Plumbing & Rooter, with shops in California and Arizona, put it to work with his team and shared, “T-Rex Brute Force tape was fantastic to have on our work trucks. On multiple occasions it was used to build confinement areas with plastic, plus a last-minute repair to hold the casing together on my jackhammer because I broke it during a project. You never know when you might need something of this strength to get out of a jam.”

ProStaff member John Thompson with Thompson Family Plumbing & Rooter, with shops in California and Arizona, put it to work with his team and shared, “T-Rex Brute Force tape was fantastic to have on our work trucks. On multiple occasions it was used to build confinement areas with plastic, plus a last-minute repair to hold the casing together on my jackhammer because I broke it during a project. You never know when you might need something of this strength to get out of a jam.”

He joked, “I have never seen anything this durable. It’s truly remarkable to see the strength this tape has. I wish I could say that I’m putting together a zombie bunker, because I would seriously use it. It’s ‘Ferocious!’”

In addition to needing a utility knife to cut the tape, our ProStaff team suggested they would like to see the tape in more solid and neon construction colors such as red, white, green and possibly even reflective, as well as different roll size options.

T-Rex® Brute Force® is sold in 25-yard rolls and is available at national mass and hardware retailers. For more information, visit www.trextape.com/contractors.

Hands-on look at the new Makita Tools XRT01 Rebar Tool This week we traveled to the World of Concrete event at the Las Vegas Convention Center to see what’s coming from some of the biggest tool manufacturers in the construction industry. If you’ve never been to the WOC show, like myself, its huge and full Read more

Hands-on look at the new Makita Tools XRT01 Rebar Tool

This week we traveled to the World of Concrete event at the Las Vegas Convention Center to see what’s coming from some of the biggest tool manufacturers in the construction industry. If you’ve never been to the WOC show, like myself, its huge and full of hand-on displays for tool lovers of all types. We got our hands on a lot of tools, the Makita rebar tying tool was just one that left an impression.

Back in October, 2018 Makita announced the addition of 40 new tools to be available immediately. This announcement was made during the annual STAFDA convention in Atlanta and on the list of 40 new tools was the new XRT01 18V LXT Brushless Rebar Tying Tool. Normally a tool like this might slip by us here at MH but considering the usefulness to contractors tying radiant tubing to welded mesh or rebar for new installations, we wanted to get our hands on it.

Makita pulled out all the stops in designing and building their booth at WOC, they had literally dozens of tools powered up and ready to use in simulated scenarios. For the rebar tool they had two different forms built. When I first saw this tool back in October I immediately wondered how it would do for tying PEX tubing so I asked if they had any tubing around the booth to give it a try, they didn’t.

Get in the Uber and head to The Depot

The only way I was going to get first hand experience on whether my ideas for this tool would work was if I brought my own PEX to the show and tried it myself. So that’s what I did.

When I walked up to the concrete forms of rebar in the booth I got a lot of inquisitive looks, it only took about two minutes for nearly every one of the Makita employees to gather around and watch me as I began to test the XRT01 out as a true plumbing/heating contractor would on the job.

It worked flawless. All I did was adjust the torque setting to its lowest level and let’er rip. No kinking, not too tight, not too loose. The capacity of the tool is capped at tying two #5 bars together so the combination of the #5 bar they had and my 1/2″ PEX was well within that range. Check out the video from my tests, all tool specs included at the end of this post.

Makita Tools Rebar Tying Tool features:

Myself and mechanical-hub.com ProStaff contractor Andy Mickelson @mick_plumb have each been using the newest RIDGID tool to join their already mega huge offering. RIDGID’s thermal imagers are definitely well thought out and made with very high-end components, that’s good considering they carry the Lifetime Warranty @ridgidtools is famous for among plumbing and mechanical contractors. There Read more

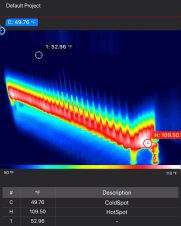

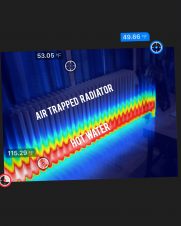

Myself and mechanical-hub.com ProStaff contractor Andy Mickelson @mick_plumb have each been using the newest RIDGID tool to join their already mega huge offering. RIDGID’s thermal imagers are definitely well thought out and made with very high-end components, that’s good considering they carry the Lifetime Warranty @ridgidtools is famous for among plumbing and mechanical contractors.

There are 4 imagers currently offered by RIDGID. All are point and shoot handheld models and range from high quality entry level (RT-3) to the fully featured RT-9X.

Andy and I have the fully loaded RT-9X. Like the others it has a rechargeable 3.7 Li-ion battery, super resolution capability and a rugged housing. In addition to other features the RT-9X has WiFi connectivity to the RIDGID Thermal mobile app which allows for fast and simple image sharing and saving across multiple devices.

There are so many features built in to this imager I simply cannot list them all. The standard 320×240 infrared resolution is clear and perfect for job site diagnosis. Turn on the Super Resolution mode and turbo charge the thermal image capturing to 640×480 and it’s operating at levels typically only ever seen by much higher priced units.

This is prime-time infrared season for Andy and I as we take on more heating calls and installs. I can speak for both of us when I say this technology has not only opened doors for our businesses but made us faster and more efficient when troubleshooting and diagnosing problems inside and outside the building. It’s like having a super power.