It’s easy to become overwhelmed when thinking about the Internet of Things (IoT) and the complexities of smart home appliances and products. However, it’s never too late to educate yourself on the smart HVAC features and products that are sought by today’s customers. Before the dawn of the smart age, HVAC controls were synonymous with Read more

Industry Blogs

It’s easy to become overwhelmed when thinking about the Internet of Things (IoT) and the complexities of smart home appliances and products. However, it’s never too late to educate yourself on the smart HVAC features and products that are sought by today’s customers.

Before the dawn of the smart age, HVAC controls were synonymous with a simple thermostat that provided comfort from a system designed to focus only on heating or cooling a space. Functionality and practicality were the most vital roles of an HVAC system. With the increased role that technology plays in our daily lives, a lot has changed.

It’s no secret that smart home technology has reshaped the way consumers interact with their homes on a day-to-day basis. Now more than ever, consumers demand the ability to change their home’s climate with the push of a button or a simple voice command – without ever touching the thermostat and from anywhere, whether sitting on a couch or away on vacation. The focus has gone from practicality to the accessibility and convenience that come with an integrated smart HVAC system. Simply put, consumers demand more from their HVAC systems.

Considering this smart home revolution, technology advancements have allowed for HVAC systems to evolve faster than can be absorbed by those in the field who must explain the functionality of the systems they are selling. How can one fully learn and understand the value of today’s smart HVAC? Dedicated time to learn about this rising tide of technology is important, but equally as helpful is to install and use similar HVAC-connected smart products within your own home. First-hand experience and determining how it can benefit your life will simplify explaining the value proposition to customers.

Considering this smart home revolution, technology advancements have allowed for HVAC systems to evolve faster than can be absorbed by those in the field who must explain the functionality of the systems they are selling. How can one fully learn and understand the value of today’s smart HVAC? Dedicated time to learn about this rising tide of technology is important, but equally as helpful is to install and use similar HVAC-connected smart products within your own home. First-hand experience and determining how it can benefit your life will simplify explaining the value proposition to customers.

While the smart home revolution has markedly changed the products, services, and accessibility HVAC dealers can offer, making the sale comes back to the homeowner’s perceived financial outlay and return on investment. Knowing how to explain the value in energy savings and diagnostic capabilities throughout the life of the product can help make the case for the more costly, higher efficiency system. Similarly helping consumers understand the value of convenience from a connected systems, such as voice interactions through Alexa, or even Geofence-based set points through the app, are paramount to moving customers up to a connected system.

It also provides an avenue to become a trusted advisor for your customers while building lifelong relationships for not only yourself, but also for the brands you’re selling. While a robust consumer value proposition is key to making the initial sale, the long term value to a contractor of a connected customer is even more impactful. Using remote diagnostic capabilities, servicing dealers can better maintain the customer relationship over time, deliver more efficient service when required, and be in the best position for a proactive replacement at the end of the product lifecycle.

By being transparent and showcasing factors such as energy savings, user experience, cross-device capabilities, etc. dealers can leverage the smart home revolution to position themselves as knowledgeable and trustworthy.

Because smart home technology has reshaped the way HVAC systems are viewed within the greater home ecosystem, it should be noted that not everyone (or every home) is right for a smart HVAC installation. Consumers often do their own research before consulting dealers about whether a technologically advanced HVAC system is right for their home. In the end, an educated consumer can be the best barometer for whether upgrading to a smart HVAC system makes the most sense.

George Land, Connected Home Solutions General Manager for Ingersoll Rand Residential HVAC

George Land, Connected Home Solutions General Manager for Ingersoll Rand Residential HVAC

The difference between cast iron soil pipe and plastic is easily understood when it comes to sound. Cast iron drain waste and vent pipe systems are superior when it comes to sound attenuation. For commercial office buildings, hospitals, high-rise condominiums or high-end hotels, no one wants to listen to the flowing of fluids when a Read more

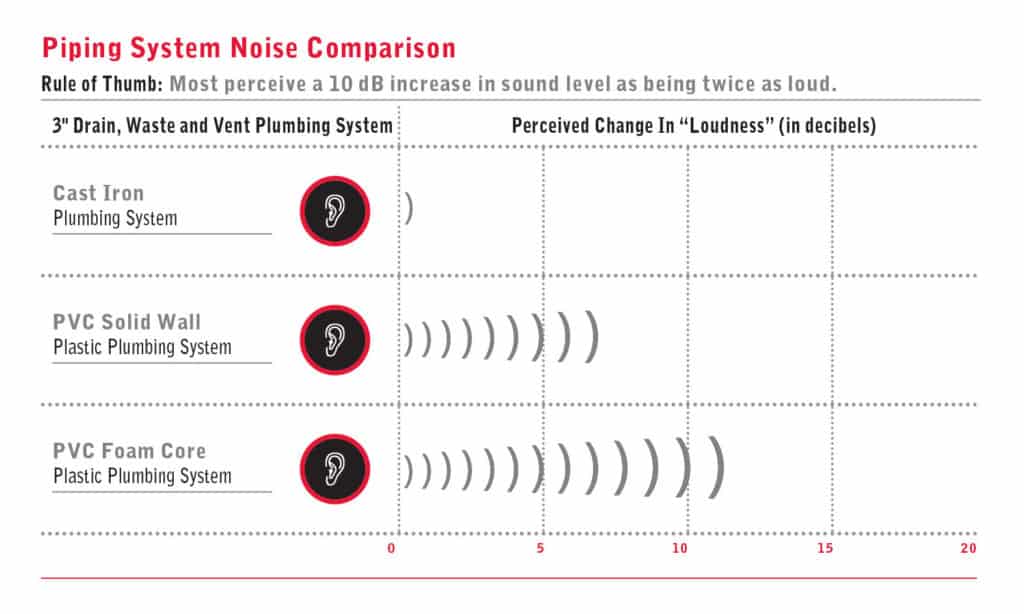

The difference between cast iron soil pipe and plastic is easily understood when it comes to sound. Cast iron drain waste and vent pipe systems are superior when it comes to sound attenuation. For commercial office buildings, hospitals, high-rise condominiums or high-end hotels, no one wants to listen to the flowing of fluids when a toilet is flushed from the floor above.

Specifying cast iron for waste piping provides a plumbing system that is up to 11 times quieter than an all-plastic system. This is how it got its name – the Quiet Pipe®.

A primary factor in cast iron’s sound-dampening quality is its microstructure. Graphite flakes absorb and dampen vibration applied to the iron. The microstructure isn’t the only advantage when it comes to noise.

Cast iron installation plays a primary role in sound attenuation. The use of neoprene rubber gaskets to join sections of cast iron pipe provides additional sound dampening. Sections of pipe do not touch as the rubber gasket creates a buffer, and so contact-related sound is eliminated. In contrast, plastic systems are installed as rigid systems that are solvent cemented. Noise is created as the rigid system expands and contracts with heating and cooling.

A frequently used tactic attempts to create a solid barrier between the pipe and the wall: wrapping plastic pipe in insulation to muffle the sound of rushing water and fluids through pipes. An insulated plastic pipe, however, can be sound-enhancing rather than sound-deadening. The “fix” results in additional installation costs incurred for both product and labor.

A frequently used tactic attempts to create a solid barrier between the pipe and the wall: wrapping plastic pipe in insulation to muffle the sound of rushing water and fluids through pipes. An insulated plastic pipe, however, can be sound-enhancing rather than sound-deadening. The “fix” results in additional installation costs incurred for both product and labor.

Specify cast iron soil pipe and enjoy the benefits of the Quiet Pipe®.

Check out cast iron soil pipe’s other benefits.

Dave Parney is the Executive Vice President of the Cast Iron Soil Pipe Institute (CISPI) and a former Master Plumber in the Chicago area.

Dave Parney is the Executive Vice President of the Cast Iron Soil Pipe Institute (CISPI) and a former Master Plumber in the Chicago area.

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from. The shortage of skilled workers in the trades is severe and getting worse. Seventy percent of construction companies nationwide are having trouble finding qualified workers, according to the Associated General Contractors of Read more

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from.

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from.

The shortage of skilled workers in the trades is severe and getting worse. Seventy percent of construction companies nationwide are having trouble finding qualified workers, according to the Associated General Contractors of America.

And if Congress ever does approve a much-needed infrastructure package, the need will be even greater.

We in the trades can hope parents will stop pushing the necessity of a four-year degree to every child, regardless of interest or qualifications, but there are more practical measures we can take in the meantime.

Last year, Viega LLC launched the Viega Trades Education Network (VTEN) to boost the ranks and skills of students studying the design, installation and function of plumbing and hydronic systems. Viega is partnering with trade schools, community colleges and the UA in the United States and Canada to subsidize and provide training on mechanical systems.

VTEN is about providing a better education for those already enrolled and supporting the schools and instructors that are training the next generation of workers. Like all educational institutions, these schools don’t have the budgets and resources to deliver everything they’d like to give their students.

As members of VTEN, schools get comprehensive curriculum modules that easily integrate into existing programs. The modules include Hydronics 101, Piping & Controls, Radiant Design, Trades Math, Blueprint Reading, CAD and BIM, and more. In addition, Viega provides functional demonstration units supported by lesson plans and projects and a complete tooling package.

Educators receive admission to an annual VTEN conference in Colorado or New Hampshire, including hotel, airfare, food and admission; Viega and direct vendor support of BlueVolt® eLearning platform; hands-on tool demonstrations and LoopCAD® license options and instructor training.

The LoopCAD package includes on-site orientation to the network and a Zoning Demonstration Board and Mixing Demonstration Board to give students hands-on experience in troubleshooting systems.

And, of course, VTEN offers credentialed classes for Viega products, including ProPress® and MegaPress®.

But the program doesn’t stop there. Schools also receive a RIDGID® RP-340 tool or Milwaukee M18® Force Logic Press Tool with a set of jaws for metal and PEX, as well as samples of various types of pipe and couplings for each student.

The first students in VTEN will graduate soon and we welcome them to the ranks of the trades. We invite other companies to follow suit and join us in building the workforce of the future.

Lino Santoro is Viega Trades Education Network (VTEN) Manager.

Lino Santoro is Viega Trades Education Network (VTEN) Manager.

We are approaching the end of the 2018-2019 heating season in North America, although homeowners in the colder northern sections of the United States and throughout Canada will likely need their heating systems for another two, maybe even three months. As you know, our long cold seasons can take a heavy toll on hydronic heating Read more

We are approaching the end of the 2018-2019 heating season in North America, although homeowners in the colder northern sections of the United States and throughout Canada will likely need their heating systems for another two, maybe even three months. As you know, our long cold seasons can take a heavy toll on hydronic heating systems. Here’s a rundown on some of the more common boiler and component problems facing home and business owners and what can be done to remedy them.

Radiator cold spots

Radiator cold spots

If your home’s or business’s radiators are not uniformly hot throughout, the following could be the culprit:

- air in the piping and components;

- a malfunctioning component or part, such as a circulator or a valve; and, finally, our “favorite” villain —

- rusty or corroding system pipes that ultimately fill the radiators with magnetite.

What is magnetite? As air and water mix inside the pipes of an untreated hydronic heating system, an iron oxide sludge, called magnetite, forms. As these small (.0003-micron) particles circulate and accumulate inside the system, they begin to adversely affect heat-transfer rates and boiler efficiency. Eventually, iron oxide buildup can lead to equipment damage and/or failure, resulting in costly repairs. Just how extensive is this problem? A recent study analyzing returns to European pump manufacturers found that nearly 70 percent of circulator returns consisted of failures triggered by iron-oxide buildup. The study also showed that more than 95 percent of the debris in hydronic heating systems consists of iron oxide*.

The fix? To eliminate air in the system, first try bleeding your radiators. But if the cold-spot problems persist, bring in a professional plumbing and heating contractor to:

- conduct a full system inspection;

- upgrade failing parts;

- fully cleanse the system with a magnetic dirt filter, as well as a chemical cleaner, such. This maintenance should remove not only the rust, but also all the other debris.

Noisy system

Maybe your boiler rattles every time it rolls into action. Maybe you are routinely treated to a chorus of bangs, gurgles, whistles and rumbles from elsewhere in the system. Regardless, such noise goes beyond mere annoyance; it might indicate more serious problems. Once again, air as well as a buildup of limescale are the most common culprits.

The fix? To eliminate the pipe noise, get rid of any trapped air by bleeding your radiators. If that doesn’t work, call a professional to flush the entire system of limescale and air. If the noise originates in your boiler, your service technician will work to remove limescale in the heat exchanger.

Leaks and drips

Water leakage from your boiler is never a good sign. Leakage usually means a breakdown is imminent. It’s a simple problem to spot. Is there any water beneath the boiler or around its pipes and tank? Causes can range from broken parts to corroded pipes.

The fix? Whether the problem stems from a damaged component or simple wear and tear, there’s only one answer for leaks and drips: Call a professional to check your boiler.

On the subject of leaks, it is often questioned whether cleaning chemicals cause leaks within hydronic systems. The answer to this is — no, if, of course, you are using correctly formulated chemicals, which includes surfactants, dispersants, and inhibitors that make it pH neutral. The surfactants and dispersants help dislodge, lift and move the corrosion, while the inhibitors protect the vulnerable metals during cleaning.

Complete protection

Complete protection

The rising popularity of high-efficiency boilers and the increased use of high-efficiency ECN (electronically commutated motors) pumps with these boilers, have helped lower fuel bills. That’s the good news. The downside: both of these positive trends can also create system-performance headaches for home and business owners. We will explore the why behind these problems in a future blog. For now, understand that both trends can lead to premature system and component failure because of the buildup of iron oxide sludge (magnetite) and other nonmagnetic debris. Both can rob hydronic heating systems of their high efficiency and superior performance.

The solution is magnetic dirt filtration, along with regular and proper system cleansing and protection. This is the only way to prevent the buildup of magnetite and the costly problems it can cause.

GUEST BLOGGER: Brian Salem, ADEY Western/Central North America area sales manager.

Growing up in his Dad’s plumbing company, Brian has a wealth of experience within the HVAC/P industry. Professionally, Brian has been in the industry since 2004 and joined ADEY in 2017 – his role began as OEM Manager for North America but due to ADEY’s growing network of North American Reps, Brian has now taken the reigns as ADEY’s Western/Central North America Area Sales Manager. Brian Salem: brian.salem@adey.com, (847) 440-6665

Growing up in his Dad’s plumbing company, Brian has a wealth of experience within the HVAC/P industry. Professionally, Brian has been in the industry since 2004 and joined ADEY in 2017 – his role began as OEM Manager for North America but due to ADEY’s growing network of North American Reps, Brian has now taken the reigns as ADEY’s Western/Central North America Area Sales Manager. Brian Salem: brian.salem@adey.com, (847) 440-6665

Some time ago, I was asked by a colleague to comment on a story that was being written about the growth of the geothermal HVAC industry. Across Canada and through the United States, government and private entities have embraced the environmental and financial wisdom of clean heating and cooling. Technical trainings classes, informational programs and Read more

Egg Family in front of Egg Geothermal Systems, Tampa, FL

Some time ago, I was asked by a colleague to comment on a story that was being written about the growth of the geothermal HVAC industry. Across Canada and through the United States, government and private entities have embraced the environmental and financial wisdom of clean heating and cooling. Technical trainings classes, informational programs and trade conferences were being hosted across the U.S. and people like my husband, Jay Egg, were asked to come and share information and knowledge with the mechanical industry. I was asked why I insisted that Jay travel up to New York the day after my first open cranial surgery. Here’s what I remember:

Some people know, but many likely do not that it started back in September 2017 (This is a link to the Egg Family Blog for the whole back-story). I was suddenly diagnosed with multiple brain aneurysms that would require a lengthy and dangerous open-cranial surgery to treat the largest and most dangerous. Once completed, there would be several smaller surgeries scheduled to deal with the remaining aneurysms. The largest surgery was scheduled for the October 16, the day before my husband was scheduled to travel to New York to attend and speak at the 2017 International Energy and Sustainability Conference located near Farmington State College from October 17-19.

Kristy Egg, Before, During and After Surgery

Jay’s first response was to cancel the trip that would require him to fly out early on the morning of the 17th, the day after the brain surgery. I argued with him for days about the trip and eventually, as expected, I won. I talked him into going up to the Energy Conference with the following arguments:

My surgery started at 7 a.m. and was anticipated to be completed by 3 p.m. on October 16, 2017. Considering an hour or two for recovery, I was expected to be in my ICU room by evening. He would know by then what the prognosis was, and if anything had changed. He could then make the calls to his associates to firm up his travel to New York.

Anticipation of Surgery, October 16, 2017

If something did go wrong, as amazing as he is at being a consultant and mechanical professional, he is not a brain surgeon. Although I have been known to describe the flow of blood to my students using a “water piping system” metaphor, with drains and valves, the truth is that it’s a bit more complicated. Even with Jay’s knowledge of heat transfer and fluid flow, he was unlikely to be able to scrub in and assist in re-engineering my cerebral artery blood flow. He stayed with me in ICU overnight and around 5 a.m., he kissed me goodbye and asked me to behave and rest. I told him that I would as long as he promised to go to New York and do a good job. And then he headed to the airport, keeping his end of the bargain.

I believe in what the good folks in this industry are doing and striving to accomplish. For the past 20 years I have watched as my husband worked tirelessly to make the Geothermal HVAC industry a more utilized and promoted entity. Now more than ever, I am convinced that I made the right decision; I wasn’t trying to become some self-sacrificing martyr. I just knew that some things are worth doing right. If problems with my recovery did arise, my parents and children were going to be by my side; I needed him to be where he could do the most good.

Jay still travels often; teaching, consulting and often collaborating with other like-minded clean energy organizations. Although it hasn’t always been easy, we also learned a great deal about the compassion and generosity of the geothermal & mechanical community.

NYSERDA Technical Committee Image circa 2016

I have remained sidelined with continuing and persistent seizures, but my hope shines bright for the future. There are many times that Jay could have taken a position for a company and worked the steadier and less traveled path than we have chosen.

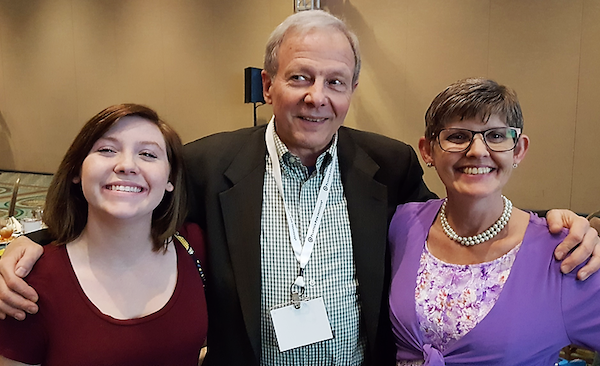

Bill Nowak with Kristy (r) & Hannah Egg at 2018 IGSHPA Conference

His unwillingness to bend is one of the reasons that I sent him to New York the morning after my surgery. He believes in clean heating and cooling enough to promote its use, even when sometimes that belief causes discomfort in his own plans or desires.

Jay doesn’t work for a specific manufacturer, nor does he endorse one brand over another. He works for the industry, to grow the consumer base and increase uptake & use. He works with whatever brand will best accommodate the project and showcase the best that the geothermal industry has to offer governments, communities, commercial projects and residences that are wise enough to listen.

Kristy Egg is a Registered Nurse, mother of six, grandmother of four.