First technology to allow monitoring of every return circuit in a radiant system Viega LLC’s new Radiant Auto-Balancing System (RABS) delivers an unprecedented level of control and consistency in radiant heating systems. RABS gives users for the first time the ability to independently control each zone in a radiant heating system. Balancing valves are not Read more

Adam Botts

First technology to allow monitoring of every return circuit in a radiant system

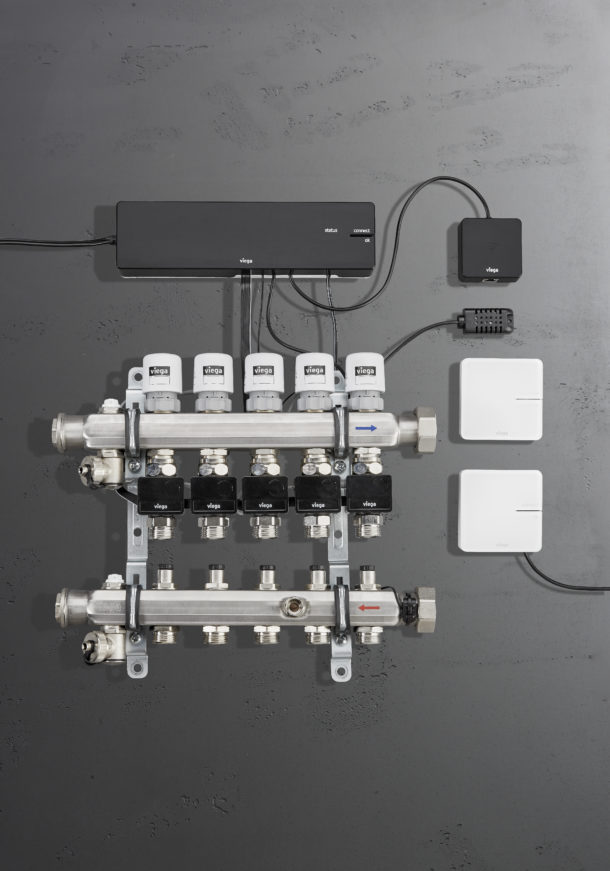

Viega LLC’s new Radiant Auto-Balancing System (RABS) delivers an unprecedented level of control and consistency in radiant heating systems.

RABS gives users for the first time the ability to independently control each zone in a radiant heating system. Balancing valves are not required and installers can commission as many as eight thermostats and 12 circuits per control unit. RABS achieves the desired temperature in each zone by analyzing the supply water temperature, each circuit’s return temperature and zone air temperatures where a wireless thermostat is used. The system offers four operation methods that complement each other.

“Achieving and maintaining consistent temperatures through multiple zones has been a challenge for radiant heating systems. RABS automates and digitizes the process, which helps installers and users alike,” said Adam Botts, Portfolio Manager.

RABS compensates for system inconsistencies and imperfections like:

- Different circuit lengths or tube sizes

- Varying installation clearances or tube depths/spacing

- Change of floor coverings

- Fluctuating supply temperatures, outdoor temperatures or external heat sources

In addition, a web-based app-enabled control lets users to manage the system from anywhere in the world. It allows remote control of power levels, thermostats and operation software. A local device can access the web app or it can be accessed remotely via the internet.

For more information about RABS, click here.

Viega LLC will reduce paper waste by 32 tons a year by eliminating printed instructions in favor of QR codes Beginning in October, the printed instructions inside the packages of most ProPress, MegaPress and PureFlow products made in the United States will be removed in favor of a QR code printed on the product label. A Read more

Viega LLC will reduce paper waste by 32 tons a year by eliminating printed instructions in favor of QR codes

Beginning in October, the printed instructions inside the packages of most ProPress, MegaPress and PureFlow products made in the United States will be removed in favor of a QR code printed on the product label. A scan of the code will send the user to the product instruction page on viega.us. It’s estimated that this will eliminate more than 6 million pieces of paper a year, paper which often wound up littering jobsites.

Having the instructions in digital format means any updates are immediately and automatically reflected, another benefit.

“Viega LLC is committed to reducing its environmental impact in ways big and small,” said Adam Botts, Portfolio Manager for piping systems. “This is an example of a simple measure that, in total, will save an enormous amount of paper without inconveniencing customers. This absolves them of having to recycle or dispose of the instruction sheets properly. We look forward to rolling out additional initiatives, both seen and unseen, that will have positive impacts on our company footprint.”

Earlier this year, Viega Holding GmbH & Co., parent company of Viega LLC, was named one of the 50 Sustainability & Climate Leaders by TBD Media Group.