Mechanical Hub continues with its 2023 Industry Forecast series with an exclusive interview with Caleffi North America’s president Mark Olson. Despite all of the negativity, Caleffi remains optimistic throughout all of the bumps in the road. MH: I’ve heard that the first half of 2023 might be a bit bumpy, how do you see Read more

air separator

Mechanical Hub continues with its 2023 Industry Forecast series with an exclusive interview with Caleffi North America’s president Mark Olson. Despite all of the negativity, Caleffi remains optimistic throughout all of the bumps in the road.

Mechanical Hub continues with its 2023 Industry Forecast series with an exclusive interview with Caleffi North America’s president Mark Olson. Despite all of the negativity, Caleffi remains optimistic throughout all of the bumps in the road.

MH: I’ve heard that the first half of 2023 might be a bit bumpy, how do you see 2023 shaking out and the short-term economy in the U.S.?

OLSON: The economy is slowing; however, orders are expected to remain healthy through Q1 as building projects are completed. In Q2, we expect orders to slow to probably a little less than last year’s intake rate. A primary factor is the abrupt drop in single-family construction from the quick rise in mortgage rates. However, we anticipate continued investment in homeowner refurbishment will be offsetting—there is still healthy excess personal savings out there for people to invest in their homes. Another additional factor is wholesalers are reducing their DOS as the supply chain is catching up on availability.

In the commercial marketplace, we expect activity will remain strong throughout 2023. Building projects have alternate sources of financing not constrained by high interest rates. Residential multi-family will stay robust before slowing some around the middle of the year.

MH: What causes you concern? (Steady inflation, materials pricing, supply chain, housing starts, interest rates, foreign factors, etc.)

MH: What causes you concern? (Steady inflation, materials pricing, supply chain, housing starts, interest rates, foreign factors, etc.)

OLSON: We do not have much concern honestly, outside of a belligerent foreign act that triggers a deep recession. The supply chain is healing and we expect inflation will continue falling through the year.

MH: Are you seeing any signs of positivity? If so, where?

OLSON: Yes! A consensus among manufacturers is that the long-term outlook for the economy remains good. Future infrastructure spending by the government such as enhanced electrical distribution and port infrastructure investments are examples. Reshoring manufacturing back to the U.S. will drive employment opportunities with product demand to follow.

MH: Obviously, Caleffi is dependent on a global market as well. What are some indicators globally that are cause for concern and/or optimism?

The global growth of Caleffi

OLSON: OPTIMISM wins! Our global rolling 2-month order intake rate exceeds 2022’s record pace. We are investing heavily in manufacturing expansion. Availability of energy in Europe is rapidly sorting out. In addition, the shift in Europe to electrification, accelerated by the Ukraine invasion, has created opportunities for new, innovative hydronic solutions. Caleffi is eager to meet this opportunity with energy savvy hydronic products.

MH: As it relates to contractors, what is your “message” to them as it relates to your company and its line of products and services?

OLSON: We pick up the phone! Engineers, wholesalers, reps, contractors, it does not matter! Our “Ask Caleffi” Technical support team, with over 150 combined years’ of experience in the industry, is available real-time to answer calls and emails. Caleffi wants to be a business partner of choice. Contractors can count on our level of experience, expertise and our commitment to Excellence in Education to help make their job easier!

OLSON: We pick up the phone! Engineers, wholesalers, reps, contractors, it does not matter! Our “Ask Caleffi” Technical support team, with over 150 combined years’ of experience in the industry, is available real-time to answer calls and emails. Caleffi wants to be a business partner of choice. Contractors can count on our level of experience, expertise and our commitment to Excellence in Education to help make their job easier!

MH: What specifically does Caleffi have its sights set on in 2023? (New products, working with associations, for workforce development, etc.)

OLSON: Caleffi is kicking off the year at AHR with the 536 Series PresCalTM HP which has been recognized by the Innovation Awards judges as the 2023 INNOVATIVE PLUMBING product winner! We’ll be exhibiting in our biggest Booth ever in Atlanta, where visitors can literally look inside of our quality products.

OLSON: Caleffi is kicking off the year at AHR with the 536 Series PresCalTM HP which has been recognized by the Innovation Awards judges as the 2023 INNOVATIVE PLUMBING product winner! We’ll be exhibiting in our biggest Booth ever in Atlanta, where visitors can literally look inside of our quality products.

Spoiler alert: We will be soon launching a revolutionary union sealing technology with Posi-StopTM (stay tuned!).

We are increasing investment in the professional development of our staff.

Did we mention that we are GROWING? In fact, we are nearly tripling our inventory carrying capacity in Milwaukee during the next phase of our building expansion starting later this year.

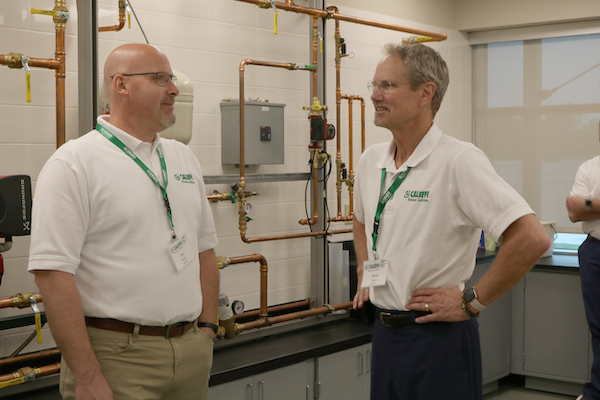

Dan Firkus (l) talks with the prez Mark Olson.

Caleffi is proud to expand its industry engagements with the American Society for Health Care Engineering (ASHE), American Backflow Prevention Association (ABPA) and the Advanced Water Heating Initiative (AWHI).

MH: Any unique training opportunities for 2023?

OLSON: Watch for training opportunities facilitated by our Caleffi staff and Manufacturer’s Representatives in YOUR neighborhood, making it easy to connect and learn with in-person and LIVE virtual settings.

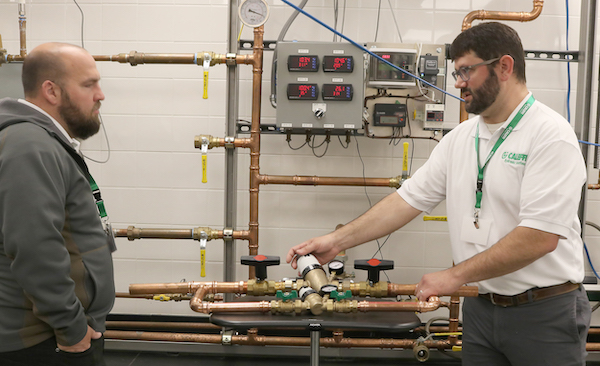

Gregg Tubbs (r) gives a demo to a visiting contractor.

In 2020, the heart of the latest expansion in Milwaukee was the incorporation of unique work environments that can be transformed into large spaces for training and workshop events. Caleffi will be offering Academy sessions in 2023 designed especially with the engineer and contractor in mind. Stay tuned!

And… don’t worry! The industry can count on the continuation of Caleffi’s commitment to Excellence in Education including idronicsTM, a complimentary design journal for hydronic and plumbing pros, with its just released 32nd edition: Troubleshooting Hydronic Systems.

Bob ‘Hot Rod’ Rohr during the wildly popular Coffee with Caleffi.

Coffee with CaleffiTM, a popular monthly webinar series that features our trainers and industry guest speakers, continues into its 14th year.

Our Ask Caleffi team hosts an engaging podcast series intended for contractors tasked with solving tricky system problems and are looking for answers!

The word separation was being used in hydronic circles back when I started in the business. Of course, I am old, so there is that. Many manufacturers and trainers are in the separation bandwagon now, rightfully so, from my view. Let’s take a look of how the word and the technology come together. The action Read more

The word separation was being used in hydronic circles back when I started in the business. Of course, I am old, so there is that. Many manufacturers and trainers are in the separation bandwagon now, rightfully so, from my view. Let’s take a look of how the word and the technology come together. The action of moving of being moved apart will work to describe the value of separation in hydronics or piping systems in general.

Photo: Bayshore House (Newport Beach, CA) Submitted by: David Mayo

Back in the day, we used a device called an air purger. We’ve all seen them, sometimes described as a camel hump. Commonly made from a casting, the “air purger” basically builds a wide spot in the road. As such, as fluid flows through it, the speed or velocity slows. Slowing the fluid allows air to rise up to the top of the “hump” to be vented away. It can, and does, some air removal in a system. A few important details. It likes to have some straight piping upstream, maybe 18” or so. This helps get the air going to where it can best be removed, at the top of the piping.

The velocity or speed is also critical. Water or fluids, flowing above 4 fps feet per second, tend to blow through the camel hump like bad leaves in the desert. Lastly, they have a tougher go grabbing the micro bubbles. If you fill a glass at the kitchen sink and notice cloudy water at first, those are micro bubbles. In your glass, since the top is open, this air escapes. It escapes quickly as the pressure has been taken off the fluid form when it was captive in the piping under 60 psi, or some pressure.

Some smart fellow decided there must be a better way to rid 95% or more of all air out of a closed loop piping system. The wide spot in the road had validity. Why not put something inside that wide spot to aid the collection. The microbubble resorber was born. The “stuff” in the chamber becomes a coalescing media. Simply the air bubbles, of all sizes cling to the media inside instead of blowing through like grass through a goose.

The concept works amazing well. Air can be successfully removed in a matter of minutes or hours on larger systems as it passes across the coalescing media. The microbubbles that were present in systems with camel humps, now have been captured and removed.

View this post on Instagram

Why all of a sudden is this so “in Vogue”? High efficiency boilers are one great reason to use microbubblers. The fluid content is way down, the HX metals are much thinner, and the flame is in close proximity to the boiler wall. As such, any layer of micro bubbles stuck on the metal surfaces reduce or impede the energy from the flame getting to the fluid. You have a miniature bubble wrap layer around the boiler surfaces if you are not getting the small air gone.

You may have seen failed mod con boilers. Darkened, brown or black metal instead of shiny stainless or aluminum. That HX has been overheated. Often lack of flow is to blame. And also, often the lack of flow is related to air bubbles slowing or stopping the perfect contract between fluid and hot metal surface. You take an efficiency hit also when you have this going on in your boilers. Circulators, the wet rotor type, especially like to be free of air, both from a performance and lubrication standpoint.

So, doesn’t it make sense that the same phenomena happen in your heat emitters? Microbubble air layers in your radiators, fin tube, air handler coil, coil in your indirect tanks.

Telluride Custom Home (Telluride, CO) Submitted by: Pete Cassidy

The microbubble resorbers aka air separators bring a few other advantages. They do not require straight piping upstream to work efficiently. This can be a big asset when you need to cram 10 lbs. of potatoes in a 1-pound sack, i.e., small mechanical closets. They are not as sensitive to over-pumped conditions, high velocities above 4 fps for example. The large chamber combined with the media inside work together to grab bubbles from speeding fluids. They are brass or composite construction, so corrosion issues are mitigated. Ever see a camel hump with the air vent port rusted close when you pull the 1/8 auto vent off the top? It was handicapped from first installation; the plugged vent hole renders it a “boat anchor.”

Yeah, I know they cost more than a chunk of iron than your great grandfather used his entire career, but times have change, my friends. Why not give your customers a system with the very best equipment and conditions to be highly efficienct. A simple device that removes 95% of air in systems almost instantly is what you need to consider.

So, you took my suggestion and STILL have an air/ noisy system. Now what? Look for places where air is getting in. Yes, air can enter a closed loop system, even a pressurized one. Those float type auto air vents allow air to move in both directions, in and out. IF one were to be installed in a point in the system that sees sub-atmospheric conditions you are seeping air into the loop. The most common occurrence is when you have the expansion tank misplaced. This can get worse with high heads circulators creating large pressure differential. The tank MUST be on or near the suction side of the circulator(s) to avoid pulling a vacuum in your system. Make it right or cap off auto vents in the negative pressure part of the system.

Taco Comfort Solutions® offers the 4900 Series magnetic dirt separator to provide dual-action dirt separation for closed loop hydronic heating systems. Both hydronic component lifecycle and efficiency are improved with the use of an effective dirt separation system. Taco’s 4900 Series magnetic dirt separator utilizes a powerful, 13,000 gauss magnet in addition to patented PALL Read more

Taco Comfort Solutions® offers the 4900 Series magnetic dirt separator to provide dual-action dirt separation for closed loop hydronic heating systems.

Taco Comfort Solutions® offers the 4900 Series magnetic dirt separator to provide dual-action dirt separation for closed loop hydronic heating systems.

Both hydronic component lifecycle and efficiency are improved with the use of an effective dirt separation system. Taco’s 4900 Series magnetic dirt separator utilizes a powerful, 13,000 gauss magnet in addition to patented PALL ring technology.

The 4900 Series magnetic dirt separator efficiently separates microscopic particles including dirt and magnetite from hydronic fluid with minimal pressure loss. The unit is easily blown down (cleaned) by opening a valve at the bottom of the vessel.

Available sizes range from ¾” to 2” NPT and from ¾” to 1-1/2” sweat. The unit’s maximum operating temperature is 250°F and maximum pressure is 145 PSI.

For more information, visit www.TacoComfort.com.