When people think of Alaska, they think of cold weather, vast expanses of wilderness and small communities. While they’re correct about the wilderness and weather, there are a few communities in the state that can’t possibly be called “small.” Anchorage is home to almost 300,000 people, or roughly the size of Cincinnati, Newark or Pittsburgh Read more

Alta Boiler

When people think of Alaska, they think of cold weather, vast expanses of wilderness and small communities. While they’re correct about the wilderness and weather, there are a few communities in the state that can’t possibly be called “small.”

Anchorage is home to almost 300,000 people, or roughly the size of Cincinnati, Newark or Pittsburgh. But unlike its Lower-48 counterparts, the city stands apart with its weather.

While not the coldest region in Alaska, Anchorage typically experiences between 7,000 to 8,000 heating degree days per year. Cincinnati, for comparison, averages 3,000 to 3,500 heating degree days.

“We install about four boilers per week,” said Thomas Jurancich, plumbing manager at Extreme Heating & Air. The 40-person mechanical company is the largest contractor in the Anchorage area, and likely in the state.

The biggest little state

Like all big cities, Anchorage has its bedroom communities, such as Eagle River.

When Shane Thom founded Extreme Heating & Air in Eagle River in 2009, it was after serving a four-year Air Force enlistment, where he learned the HVAC trade.

Almost all of the residential boilers installed by Extreme Heating & Air are 180 MBH, a product of Alaska’s severe winter conditions.

“I was in the civil engineering department and left the service as a Senior Airman,” said Thom. “Our primary task was setting up temporary cities, whether in Okinawa, Japan, Texas or Alaska.”

When Shane hung his shingle in 2009, Extreme was strictly focused on HVAC installations. Two years later, he added a plumbing department, and in 2013, he opened the company’s service department, along with their supply house and retail store. They serve all sorts of customers within a 300-mile radius.”

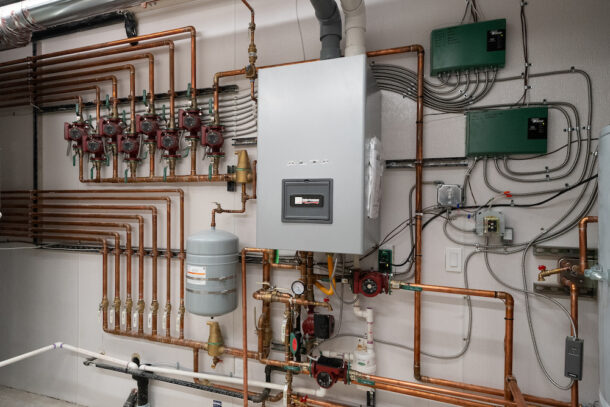

A 180-MBH Alta condensing boiler is used to supply all heat and domestic water to the large home.

Alaska’s remoteness (from supply chains), vast coverage areas, and the extreme cold temperatures (often dipping below -30°F), are the greatest challenges. Boilers are quite popular, thanks to the severe winter conditions.

Custom residential

“Our plumbing division is the largest segment of the company,” said Thomas Jurancich, plumbing manager. “Boiler work is big business here, both residential and commercial.”

Extreme has great relationships with most of the custom homebuilders in the Anchorage area. One of those, Michelsohn & Daughter, is the source of half a dozen hydronic projects each year. These homes are typically $1 million or more.

Thomas Jurancich, plumbing manager at Extreme Heating & Air, opens the Alta 180 boiler.

“New homes in Alaska with a seven-figure budget typically feature in-floor heat, and maybe snowmelt, too,” said Jurancich. “Both were included in our most recent Michelsohn project.”

The 4,7000-sq.-ft. home includes an art studio and three bay-garage, one of which is large enough to park the family’s RV. In-floor heat is used throughout, and the front walkway accounts for one small zone of snowmelt.

“All told, we have 11 zones here, including the snowmelt and 85-gallon indirect water heater, which is needed for multi-head showers and a giant freestanding tub,” said Jurancich. “We added a Rheem air handler for AC and to circulate environmental air through a Lifebreath HRV, but the only source of heat is the boiler.”

Nate Uson, territory manager with Ridgeline Mechanical Sales (left), walks Thomas Jurancich through various features of the USB-Connect Bluetooth adaptor.

A 180-MBH Alta condensing boiler, made by U.S. Boiler Company, is used to supply all heat to the home and DHW.

“We’ve been installing the Alta since Nate Uson, territory manager at Ridgeline Mechanical Sales introduced it to us,” said Jurancich. “We probably have 200 of them in the field, almost all of which are 180 MBH. New product releases are always a little worrisome with our winters, but the Alta has been exceptional.

Jurancich is quick to admit that the gas-adaptive technology and the rate-based reset features of the Alta—both new to the hydronic industry in North America—felt “too easy.” It took a few installations before the Extreme technicians felt comfortable trusting the technology, but there’s never a second thought anymore.

Thomas Jurancich, plumbing manager at Extreme Heating & Air, connects his phone to the Alta boiler via the USB-Connect Bluetooth adaptor.

Hot water is distributed to remote manifolds throughout the house. The radiant zones require 80°F at outdoor design temperature, and the snowmelt zone, isolated by a heat exchanger, calls for 110°F water. Chad Moore, lead boiler installer, and Joe Potter, apprentice, built the entire boiler room in three days.

“The homeowner loves the system,” said Jurancich. “He told me he takes guests into the mechanical room to show it off. I can’t think of a better endorsement of our work!”

Supply chain: end of the road

Jurancich was an outside sales rep for Ferguson before joining Extreme in 2017. This put him in frequent contact with Uson and others at Ridgeline, and that relationship has served them both well for years.

“Shane and Thomas have been great customers, and we’ve done our very best to support them, especially through the pandemic,” said Uson. “Contractors in the Lower-48 had supply chain issues, but not as bad as those in Alaska. We’re at the end of the proverbial road. Extreme has never been one to complain about price. Availability is the key concern here.”

Ryan Beck, service technician, pulling product from the Extreme warehouse.

Ridgeline helped ensure that Extreme had boilers to install throughout the supply chain crunches of the past few years. Other times, Extreme reaped the benefits of their own deep warehouse. In 2016, Extreme opened their own supply house and retail store.

“We’re halfway between Anchorage and the Matanuska-Susitna Valley,” explained Thom. “Alaska is different from other states in that people here are very independent, and there’s a long way to go between supply houses. Some of our competitors buy product from us. So do plenty of DIYers.”

Extreme Heating & Air has 40 employees that serve a 300-mile radius of Eagle River, AK.

With good manufacturer’s reps, a fleet of roadworthy vans and a stout supply of plumbing and heating products in-house, Extreme keeps a lot of Alaskans warm throughout the winter. And none so much as in their own little town of Eagle River.

Not all residential new construction

In the 1950s, back before the roads in Eagle River were paved, activity in town revolved around the grocery/general store. That building still stands, though it’s been expanded and modified an untold number of times. It’s now a strip mall, housing a tax preparation office, dry cleaner, and more, having been converted to the Eagle River Shopping Center in the 1990s.

Two, 399 MBH Alpine condensing boilers are used to heat the Eagle River Shopping Center.

Extreme Heating & Air has serviced the facility’s central hydronic system for almost a decade. Doing so has always been a challenge. Its two condensing boilers were a constant source of headache, requiring nearly $10,000 worth of parts over the years. Because the building had been remodeled, changed and retrofitted so many times, zoning was less than straightforward.

The USB-Connect Bluetooth adaptor connected to one of the shopping center’s modulating boilers.

In May of 2023, the shopping center’s owner decided to fix the problems for good. Extreme was hired to gut the mechanical room and replace it with a properly sized, newly piped system.

Extreme installed two U.S. Boiler Company Alpine 399 MBH modulating boilers in lead-lag operation. The entire building uses 15 zones of fin-tube baseboard radiation and a 119-gallon indirect tank supplies hot water to each retail space.

(Left to right) Nate Uson and Thomas Jurancich in the boiler room at the Eagle River Shopping Center.

“We’re fairly young guys, so we’re always looking for the newest technology to try,” said Jurancich. “Last year, Nate showed us the USB-Connect Bluetooth smartphone app, and the shopping center was the first job we tried it on. We connected the Alpine to the adaptor with a Cat 5 cable and adjusted the flow rates and supply temperatures on my phone. The guys love it for the Alpine and the Alta, so our service manager, Jacob Way, ordered eight more.”

Nate Uson, territory manager with Ridgeline Mechanical Sales (left), changes boiler setpoint temperatures using the USB-Connect Bluetooth adaptor.

Over the course of three days, four Extreme technicians straightened out the piping issues and replaced the entire mechanical system. The main challenge was that the boiler room was tucked in the back of the building, separate from the retail spaces. After a full season in operation, Extreme has only received good feedback.

“They love the system because it finally works as intended,” said Jurancich.

Steady growth despite challenges

Extreme Heating & Air is growing, keeping pace with the city.

“Our biggest challenges are procuring material and manpower,” said Thom. “We’ve largely resolved our material inventory by dealing with good reps and owning our own warehouse. The manpower struggle isn’t unique to Alaska, by any means, but we’re taking that challenge head-on, too.”

(Left to right) Nate Uson and Thomas Jurancich, their most recent custom home project with local builder Michelsohn & Daughter.

The company recruits in cold climates in the Lower 48, hoping to draw young adventure-seekers to Alaska. There are great opportunities for those looking to relocate.

Jacob Way, Extreme Heating & Air service manager.

“We’re booked out for more than a month.” said Jurancich. “Next week we have five combi boilers going into a 5-plex apartment downtown. It’s a good problem to have. Much better than the opposite.”

Anyone with a military background will recall the U.S. Government’s penchant for acronyms. MREs, BDUs, MRAPs, the list goes on. Unfortunately, this dynamic is also present when discussing the efficiency enhancing feature known as outdoor reset. ODT, SWT, LWT, etc. It’s enough to cause a BM in your BVDs! Well, U.S. Boiler Company has once Read more

Anyone with a military background will recall the U.S. Government’s penchant for acronyms. MREs, BDUs, MRAPs, the list goes on. Unfortunately, this dynamic is also present when discussing the efficiency enhancing feature known as outdoor reset. ODT, SWT, LWT, etc. It’s enough to cause a BM in your BVDs! Well, U.S. Boiler Company has once again developed a solution to make all this NBD.

First a few simple facts.

1. Flue gas will condense when temps are at or around 130° or less.

2. When vapor contained in flue gas condenses it releases a significant amount of heat.

3. Without question, optimal efficiency is achieved by heating a home using the lowest possible water temperature that will maintain the desired indoor target temperature, usually the thermostat set-point.

4. Using a Mod-Con, or high efficiency, gas boiler like the ALTA can take full advantage of the condensing action allowed by low water/flue temps.

Outdoor reset sensors do a wonderful thing. They enhance efficiency by matching water temperature to varying conditions. For example, one would want to maintain indoor design temp, normally 70°, during outdoor design temps (in CT normally 7-10 degrees.) Assume a 7° ODDT, and required SWT of 180. This means the boiler must deliver 180° supply water consistently at a 7° outdoor design temperature to maintain the desired indoor temp (IDT). This all simply means we need the hottest water when it’s coldest outside. Good so far?

As Paul Harvey used to say, “And now-The rest of the Story!” We now all understand (hopefully) what happens in our heating systems on the coldest day of the year. What about the rest of the time? Sure, that 180° water will heat the house just fine on a 50 degree day. But what about all the energy used to unnecessarily heat the water way past what would be required to keep the home comfortable? This is a net negative on many fronts, but most significant is the increased wear and tear on the heating unit.

So, your now asking “Tom, how low can my water temp be?” The answer will likely surprise you. Standard fin tube radiation works ok down to 130° water temps in most applications. Same with cast iron radiators. For the fin tube baseboard system in my house the minimum boiler water temp on my ALTAC-136 is 125 degrees. Hydro-air (hydronic coils added to or contained within hot air furnaces or air handlers) can often be run around 130° as well, depending on the occupant’s expectations. Remember, these SWT’s are typically targeted when the ODT is ~70°. We don’t need to transfer much heat to maintain indoor setpoints at these conditions. How does all this magic happen? Outdoor reset. Using a thermistor mounted outside, typically out of the sun on the north facing wall we monitor ODT and adjust SWT temp accordingly. So my personal curve used to be 180° SWT @ 7° ODT, and 125°SWT@70° ODT, but no more. My ALTA figures this out automatically without an outdoor reset sensor.

While outdoor reset simply monitors outdoor temperatures, rate-based reset works by looking at boiler run time, firing rate, and other parameters and adjusting accordingly. Here’s a few examples. Say it’s a beautiful spring day. Nice and sunny with a gentle breeze and 50° outdoor temperatures. The boiler run times are likely short, and the firing rate is likely low. The boiler knows from these conditions the heat loss from the house is minimal, and adjusts, incrementally dropping the boiler water temp until the minimum setpoint is reached, or our algorithm (the “secret sauce”) calculates that based on run time and firing rate the water temp will deliver enough heat to match the rate of heat loss and maintain indoor temp setpoints at the lowest possible SWT. As night rolls in and the temperature drops, average run times and firing rates increase, and once again, rate-based reset will adjust (increase) SWT’s to maintain indoor comfort and optimal efficiency. “Brilliant!” you say. I agree. But wait-there’s more!

Conventional ODR has limitations. Say the calculated water temp for a 45 degree day is 142°. It’s a moderately windy day. Consider two different houses, both 2,500 ft. The first has a well-sealed envelope, double pane windows, and effective insulation. The second has old single pane windows, minimal (or no) insulation, and is as drafty as old fence. The boiler doesn’t know what the indoor conditions are, just that it must target 142 degrees. That 142° SWT might be fine for the first, but far too low for the second. Now to be fair, all U.S. Boiler products with outdoor reset offer a “boost” feature that will automatically bump the temperature up every “X” (boost time value) minutes, default being 20. This means every 20 minutes with an uninterrupted call, the SWT will rise 10 degrees until the max setpoint is reached. The benefit of rate-based reset is we are always looking at indoor conditions and adjusting accordingly. Rate-based reset always uses the lowest possible water temp that will maintain the desired indoor temp, and then has the boost feature if an increase above the calculated target temp is required. Like a samurai sword: simple, elegant, and effective!

There are other benefits as well. Remember the test I mentioned? Here it is. What factors showcase the benefits of rate-based reset? See the answers below. Correct your test answers accordingly…

1. No sensor to install. Rate-based wins!

A) No sensor for landscape professionals to damage.

B) No sensor for contractor to install (or throw away!)

C) No wire required from boiler to sensor.

D) No worries about where the contractor will mount the sensor, if it will be impacted by the sun, or heat migration from the interior affecting the sensor calibration.

E) Enabled from the factory. No worries for homeowner regarding whether the contractor enabled ODR. The Alta boiler is set up for maximum comfort and efficiency right out of the box!

2. No Lemon Faces! Rate-based wins!

A) Always monitoring indoor temp. Onboard algorithms are constantly at work to meet heating demands while maintaining maximum efficiency. Tens of thousands of units installed with zero complaints about indoor temperature. When not writing informative and engaging articles such as this, I am a member of the renowned U.S. Boiler tech support team. I’ve honestly never received one complaint regarding rate-based reset. If you have, please contact me.

B) Not reliant on a technician with advanced, comprehensive knowledge of ODR curves. Works fine out of the box with no programming in most applications, and, where required, only minimal adjustments for almost all applications, including low temp radiant.

C) If the homeowner is made aware that during mild temperatures the radiators will not be the same temperature as the skin of the space shuttle during re-entry, and that these cooler temperatures mean more money in their pocket for candy/wine/shuffleboard, they will instead have smiles every time they touch the radiator. Or better yet, they will abandon the practice entirely…

3. Takes full advantage of condensing aspect of mod con boilers. Again, rate-based wins!

Regardless of ODT, rate-based reset always targets the lowest possible temp, thereby maximizing the potential for the boiler to run cool enough to operate in a range where flue gas condensation occurs.

I can almost feel grizzled old contractors firing up HP 386’s and waiting for the comforting squawk of their dial up modems connecting. I imagine most of the responses will begin with:

“Dear factory stooge/shill. Your article may fool the unwashed masses, but not me. My mom’s uncle’s grandmother has a hunting cabin with 1 radiator and 600 feet of ¾” pipe to connect the boiler to the house (it’s in the barn where we milk the squirrels). How does your new-fangled boiler work in my application? Hah!!! Gotcha!!!”

It will be this, or something substantially similar. There’s always at least one. For the rest of the world (and fortunately, most of the squirrels) these anomalies are rare. There is no magic solution for a poorly designed or installed system. But when a competent, capable, and progressive contractor is installing a new or replacement system, the advantage of rate-based reset over conventional sensor-based reset is clear. Reduced (or no!) programming required, no wires to pull, and no exposed exterior sensor susceptible to damage. Save time, money and aggravation. Go ahead and skip a step with ALTA.

For more information on the Alta boiler, visit our Alta Product Page.

GUEST BLOGGER: Tom Secondino is a Technical Sales Support Specialist for U.S. Boiler Company, a manufacturer of residential and commercial heating products, including condensing, non-condensing and electric boilers.

GUEST BLOGGER: Tom Secondino is a Technical Sales Support Specialist for U.S. Boiler Company, a manufacturer of residential and commercial heating products, including condensing, non-condensing and electric boilers.

Yes! (If the boiler does it for you) Of all the commodities available to us, time is the most precious. As humans have done for eons, we all trade in the commodity of time. Successful contractors regularly step back to assess whether they are getting the most out of the hours they’ve bartered. This is Read more

Yes! (If the boiler does it for you)

Of all the commodities available to us, time is the most precious. As humans have done for eons, we all trade in the commodity of time. Successful contractors regularly step back to assess whether they are getting the most out of the hours they’ve bartered.

This is where the team at U.S. Boiler Company was determined to add value with the high efficiency Alta boiler. Innovation at U.S. Boiler goes beyond durability and performance to saving your most precious resource: a skilled tradesperson’s time.

Gas analyzers should always make their way to the jobsite.

What are the most time-consuming and painful steps of installing or servicing a boiler? The Alta boiler addresses several steps near the top of your list, but it doesn’t just make them easier. You can skip them. Let’s start with combustion setup.

First, we can all agree that combustion setup takes time, and that improper setup can lead to big problems. What are the biggest challenges with combustion set up?

Ambient Temperature

If you have a passion for all things measured in horsepower, you know that your car, boat, motorcycle, etc. runs best on cool fall nights. This is because the cooler air is denser. That is, it contains more oxygen per cubic foot. The more oxygen in the cylinder, the more power generated.

Contractor conducts setup of the Alta boiler by U.S. Boiler using the USB-Connect phone app.

With boilers, we face a similar dynamic. Most of us perform preventative maintenance during the summer months. At this time of year, air temps can range from 50°F to 100°F or more, depending on your location.

Once winter rolls around and the outdoor temps drop, those combustion targets we worked so hard to achieve go right out the window. The dense air will skew your combustion to the leaner side of the spectrum (not enough fuel for the oxygen present) because your calibration was conducted when the ambient temperature was higher.

The problem gets worse if the combustion check was skipped altogether. If the boiler is already too lean, you might be required to pay a free visit to the site during the colder months and encounter the homeowner sporting what is colloquially known in the industry as “lemon face” due to a no heat call.

Well … It’s Complicated

Technicians face the daunting task of working on a wide variety of equipment and trying to keep pace with industry advancements. When setting the combustion on most high efficiency boilers, proper setup requires tuning at both high and low fire. This means knowing which screw to adjust, how to lock the boiler in high and low fire, and hoping the system has enough capacity to dissipate the heat generated during testing to keep the boiler running. That’s a lot to expect of a seasoned tech, much less some of the newer faces joining our industry.

What Analyzer?

Like fishing, combustion testing is frequently accompanied by “far away eyes and bold-faced lies.” I’m constantly amazed by the number of technicians who share the following comments with such a level of innocence, sincerity and/or ignorance that I’m not always sure how to respond.

- “We don’t have an analyzer. Never have! Boss says we don’t need one.”

- “We don’t have an analyzer. Boss keeps it in the office…”

- “We have an analyzer, but the last time it was calibrated was during the Nixon administration…”

- “We have an analyzer, but it doesn’t work. Ever since we left it in the truck last winter the numbers are all wonky.”

- “We have an analyzer, but I’m not trained on it.”

These are just a small sample of the excuses I’ve heard. There are many, many more, some of which deserve an A+ for creativity. Long story short, there’s cause for concern on whether the boiler was set up correctly, if at all. Which brings us to the Alta.

Alta Does It for You

The gas train in the Alta boiler utilizes an adaptive combustion system. Unlike a simple pneumatic gas train, gas adaptive technology uses the flame signal to constantly tune combustion. What does this mean to homeowners, contractors, and technicians?

Everyone is familiar with the K.I.S.S. concept. We use it in a slightly different manner for the Alta. Keep It Sweet and Simple!

Sweet—Alta’s adaptive system constantly tunes burner combustion, keeping the boiler consistently in the sweet spot, maintaining the cleanest heat exchanger possible while achieving optimal efficiency.

Simple—Because the Alta adaptive combustion system uses basic components and a time-tested method of monitoring, the Alta solution is elegant and ingenious, without being complex. No more worries about changing combustion air temperatures or watching over techs as they adjust combustion.

Alta does the heavy lifting for you by tuning itself to site conditions. The boiler runs its own combustion setup, so you don’t have to.

Technology should not replace knowledge of hydronic systems, but it should make your life easier. You should own and be competent in the use of a combustion analyzer so you can be sure there are no installer-induced failures like reversed low profile termination fittings (it’s happened) or wads of insulation that inadvertently get lodged in the combustion air piping (yep, this happened too!), or cross contamination at the vent termination (the list goes on).

Adaptive combustion delivers faster installations and fewer callbacks on combustion issues. That’s how you do more with the time you have. So go ahead, skip combustion setup with Alta.

Tom Secondino is a Technical Sales Support Specialist for U.S. Boiler Company, a manufacturer of residential and commercial heating products, including condensing, non-condensing and electric boilers. For more information on the Alta boiler, visit our Alta Product Page

“Commercial Condos” are gaining popularity nationwide for small businesses in the service industry. These spaces, typically found in large post-frame buildings, offer a workshop atmosphere perfect for a company with a small fleet of vehicles that’s in need of garage bays, storage space and an office. Property developers and managers have seen increased demand for Read more

“Commercial Condos” are gaining popularity nationwide for small businesses in the service industry. These spaces, typically found in large post-frame buildings, offer a workshop atmosphere perfect for a company with a small fleet of vehicles that’s in need of garage bays, storage space and an office.

Aune installed the combi boiler in a closet below the staircase, protecting the mechanical equipment from activity within the shop.

Property developers and managers have seen increased demand for medium-sized commercial space, and that constructing a large, simple building and dividing it into several smaller spaces has presented a new development option for bare commercial property when a town is already saturated with storage units. For professionals in a variety of trades, the buildings offer everything they need and nothing they don’t, and the spaces can often be rented, leased or purchased outright.

Late last year, Aune Plumbing & Heating was hired to install a hydronic heating system and a plumbing system at a commercial condo in Monticello, Minn. A refrigeration contractor bought the building as a well-insulated shell and required further build-out.

“This was a very simple project,” said Eric Aune, owner of Aune Plumbing & Heating, in Elk River, Minn., and co-owner of Mechanical-Hub.com. “It started like any other hydronic job, with a heat load calculation.”

The spray foam insulation, insulated slab and two walls that are shared with other conditioned spaces kept the heat load low, relative to the condo’s 4,000 square feet and 20-foot ceilings. There’s only one restroom and no full-time occupants.

Combi Is Key

Because the single shower, utility sinks and heated indoor hose bib are used only occasionally, it would have been a waste of space to install a tank-style water heater, especially considering that all mechanical components had to fit under a stairway.

“We suggested the use of a combi boiler,” said Aune. “A tank wasn’t necessary, and there simply wasn’t space for it in the mechanical room, meaning it would have been outside in the garage bays and susceptible to damage.”

The 136 MBH Alta Combi is used to produce DHW for one full bathroom, a utility sink and a heated indoor hose bib, in addition to heating the space.

The system Aune designed includes a single zone of Smith low-temp baseboard radiation paired with a 136 MBH Alta condensing combi boiler made by U.S. Boiler Company, the industry’s first and only 10:1 gas-adaptive combi boiler.

“The 50 feet of baseboard receives a maximum water temperature of 130°F on a design day with an outdoor temperature of -15°F,” said Aune. “When possible, I like to use low-temp baseboard with high-efficiency boilers because it keeps the boiler in condensing mode for as long as possible, similar to in-floor radiant, though not quite to that degree.”

Tight Fit

All mechanical components are contained in a closet under the staircase leading to a storage loft. Even using a small, wall-hung boiler, Aune was cramped during the single-day boiler installation. The system includes a Taco 007e pump for the system and a Caleffi AngleMix thermostatic mixing valve on the domestic hot water side.

“The Alta fit nicely on one wall, but what really helped was the FastPipe premanufactured primary/secondary piping kit that U.S. Boiler Company includes with the boiler,” said Aune. “That reduced the amount of time I spent crammed in the closed. It all installed very quickly.”

Aune found that the FastPipe premanufactured primary/secondary piping kit installs very quickly and easily.

The high efficiency Alta line includes 136 and 200 MBH combi models, as well as heat-only boiler models of 120, 150 and 180 MBH capacities. Its best-in-class gas adaptive technology provides simplicity and rapid installation and optimal efficiency in all variety of outdoor conditions. This technology also provides “no touch” adaptive combustion setup, with no manual throttle or offset adjustments.

The boiler self-calibrates in response to component wear, variation in fuel, environment and vent air pressure. No additional parts are required to convert from natural gas to propane.

Shockingly Simple

“I had never installed an Alta Combi before, so a few things came as a surprise,” said Aune. “I’m very accustomed to installing an outdoor reset sensor, and this boiler doesn’t have one. Instead, the Alta features sensor-less reset, and the boiler modulates water temperature perfectly. I think the unit is running more often than not, which is exactly what a condensing boiler is intended to do. It just runs almost continuously on low-fire.”

The Alta’s sensor-less reset monitors home heat load rather than outdoor air temperature. It assesses home heat input (firing rate) patterns. Monitoring heat load allows boiler water temperature setpoint to be responsive to everything impacting home heat loss, including outdoor air temperature, wind, rain, clouds, home occupancy, and activities like cooking and showering. Once home heat loss is known, the boiler water temperature can be set in very much the same way that outdoor air reset adjusts setpoint.

“The touchless works perfectly, but after installing condensing boilers for years, it definitely felt odd firing this boiler and walking away,” said Aune. “I didn’t have to input any information, and the unit just works as intended. It’s that simple and straightforward.”

Maintaining Temperature

The customer maintains the building at 68°F, and every time Aune has checked, the farthest from setpoint he’s ever seen the temperature is half a degree.

“We also found that the Alta produces domestic hot water very quickly,” said Aune. “There’s never been a complaint about the speed of hot water delivery or hot water volume. I think the owner would literally have to run the shower, the hose bib, and all sinks simultaneously to see the water temperature begin to drop off.”

The boiler has only been running for a month, and an unseasonably warm month at that, but based on how much time the unit spends on low-fire, Aune is confident the owner isn’t going to have any issues with his gas bill.