On the opening day of the AHR Expo in Chicago—Monday, January 22—the crew from Mechanical Hub was fully immersed in the very first Coffee with Caleffi Live from the Caleffi booth. There, emcees John Mesenbrink and Tim talked with industry powerhouses John “Siggy” Siegenthaler, Bob “hot Rod” Rohr, Eric Aune and Andy Mickelson about the Read more

Andy Mickelson

On the opening day of the AHR Expo in Chicago—Monday, January 22—the crew from Mechanical Hub was fully immersed in the very first Coffee with Caleffi Live from the Caleffi booth. There, emcees John Mesenbrink and Tim talked with industry powerhouses John “Siggy” Siegenthaler, Bob “hot Rod” Rohr, Eric Aune and Andy Mickelson about the lifelong learning in the trades.

From l to r: Emcee John Mesenbrink, John Siegenthaler and Bob Rohr

In the first half of the presentation, the hosts asked “Siggy” and “Hot Rod” where they go to find the resources they need to keep up in today’s contracting world. Having forgotten more than most have learned in a lifetime, where do these legends go to learn?

From l to r: Emcee John Mesenbrink, Eric Aune and Andy Mickelson

Part two featured Eric Aune and Andy Mickelson as they shared their point of view from the eyes of a business owner and working contractor, and discussed the importance of social media and its impact on learning.

As you read this, thousands of American families are considering a move to less densely populated areas. Towns and cities within the Rocky Mountain States – Idaho, Montana and Wyoming specifically – are seeing unprecedented population growth. The idea of living in rural and suburban areas is gaining a lot of interest among residents of Read more

As you read this, thousands of American families are considering a move to less densely populated areas.

Towns and cities within the Rocky Mountain States – Idaho, Montana and Wyoming specifically – are seeing unprecedented population growth. The idea of living in rural and suburban areas is gaining a lot of interest among residents of the country’s more populated regions.

Popular opinion in these scenic areas attribute the migration to three major factors: social unrest in urban areas, prevalence of COVID-19 cases, and the ability for more people to telecommute, professionally.

The owner of a moving company in Cody, WY, noted that they had relocated a dozen families from California in May alone. Real estate prices are rising, counter to what would be expected during a recession. Similar stories come from Montana.

“A customer of mine who is a real estate agent just sold a $700,000 home sight unseen to a family from back East,” said Andy Mickelson, owner of Mickelson Plumbing and Heating Inc. in Missoula, MT. “He took them through the home via Skype just before a contract was signed. Migration is extreme. Houses are selling fast, and high.”

Earlier this year, the same real estate agent referred a recent homebuyer to Mickelson for boiler replacement. Not surprisingly, the house was purchased in a hurry.

“The homeowner ran out of domestic hot water a week after buying the home, so we replaced the igniter on the mod-con boiler which was supplying heat to an indirect tank,” said Mickelson. “We also found that the heat exchanger had failed, so we returned to replace the boiler as soon as we could.”

Mickelson is a Montana native who started his own company in 2011, after 13 years at a large mechanical firm. Today he employs two full time technicians and has the work for more – if only he could find the right people. He’s a self-proclaimed wet-head, but his skill set also includes commercial controls, plumbing and air conditioning.

While Mickelson’s work can be seen in commercial buildings and full-blown mountainside mansions (he’s done work for some of the world’s most famous musicians), this specific home was average in every way.

Smart components

The 2,500-square-foot bi-level was constructed in the 80s, and the aluminum-block condensing boiler he found in the house was, to his knowledge, boiler number two. Installing boiler number three, a 199 MBH Aspen Combi made by U.S. Boiler Company, would have been pretty straightforward if not for several messy system changes that had been done in the past.

“The system was a result of 30 years of additions and haphazard corrections,” explained Mickelson. “At one point a water softener had been added, and an irrigation system was tee’d into the domestic piping. On top of that, the first retrofit was a hack job.”

At least the three zones of fin-tube baseboard were in good condition; one downstairs and two upstairs. By the time he started to cut the supply and return piping out of the closet mechanical room, he already had a plan for the new system.

“I pair a heat load calculation with a radiation measurement,” said Mickelson. “This not only tells me the supply water temperatures I’ll need for proper outdoor reset programming, but it gives me the flow and head I’ll need out of my system pump. This is valuable information to optimize comfort and efficiency with two components I used on this job.”

“A Taco 0018e circulator allows me to precisely set my flow rate for a 20°F Delta-T, and paired with U.S. Boiler’s Sage Zone Control, the pump will respond perfectly as zones open and close.”

Without the help of a buffer tank, the Sage Zone Control allows the boiler to start at low fire and only increase to the firing rate needed for the zone (or zones) calling. Mickelson inputs the size of all three zones, and the boiler fires accordingly, never exceeding the actual load, and the ECM circulator responds by modulating the flow rate across the system.

“A single circulator with baseboard and zone valves is perfect for this setup,” said Mickelson. There’s never a concern about being over- or under-pumped. This house needs about five feet of head and five GPM with all zones open.”

“Both the Sage Zone Control and the 0018e are very easy to program,” he explains. “The panel is accessible through the boiler’s Sage Control, which is connected to the boiler via a CAT 5 cable. I access the pump via a Bluetooth app on my phone. It has a number of different modes; constant speed, proportional pressure, and constant pressure, as well as a self-adjusting proportional pressure mode.”

The perfect fit

For simplicity and space savings, Mickelson installed the Aspen Combi instead of adding an indirect tank. The house only has two occupants, so there’s never a concern of running more than two showers at a time.

Connections to the combi boiler were very easy to make from the bottom side of the unit, even in the cramped closet. Adjusting the burner for Missoula’s 3,200 foot elevation was simple. The factory-supplied exhaust fitting has a built-in test port for a combustion analyzer, and the boiler cabinet has a side access panel for easy access to the gas valve.

“Taco’s mobile app for Bluetooth connection to the circulator makes changing modes, etc., very easy, and all feedback from the Aspen boiler and the Sage Zone Panel read out in plain English on the boiler’s touchscreen display,” said Mickelson. “I didn’t need a secret decoder ring to set the unit up.”

The homeowner’s frustration at buying a property that immediately needed a new boiler came at least with a silver lining. The new system is comfortable and reliable. Ignition is smooth, and the loudest noise that the system makes is the baseboard heating up. That’s a very good thing, considering that the mechanical closet is adjacent to the owner’s home office.

As working from home in the Rocky Mountains becomes more popular, the mechanical contractors who’re best suited to provide the right solutions will benefit while western towns grow.

Mickelson Plumbing & Heating, Missoula, Montana, specializes in plumbing, HVAC and boiler service, and high-efficiency systems. Starting his own business out of necessity, or perhaps the illusion of it, Andy Mickelson (@mick_plumb) launched Mickelson Plumbing & Heating New Year’s Day, 2011. I guess you could say it’s all part of Mickelson’s fabric and mental make-up—there Read more

Mickelson Plumbing & Heating, Missoula, Montana, specializes in plumbing, HVAC and boiler service, and high-efficiency systems.

Starting his own business out of necessity, or perhaps the illusion of it, Andy Mickelson (@mick_plumb) launched Mickelson Plumbing & Heating New Year’s Day, 2011. I guess you could say it’s all part of Mickelson’s fabric and mental make-up—there is no end result other than success. “I am a terrible loser; I hate not winning daily,” says Mickelson.

Turning the clock back to where it all began, Mickelson was eight years old when he got his taste of real hard work, helping out his father, a remodeling contractor. “It was easy to have my brothers and me helping out, and at that time, we were eager to get dirty and learn how to build things, and THAT has never stopped,” says Mickelson.

Soaking up knowledge whenever he had the chance, Mickelson has had many great mentors in his first shop, and the UA produces an incredible brotherhood of knowledgeable folks. “Dick Darne was one of the Journeyman that I learned the most from; he had a hip replacement, and a few weeks later I began my service career, carrying his tool bag and being his hands in the field when he couldn’t. All I had to do was listen to directions and retain the methods of his madness. The troubleshooting tactics I learned in a roundabout way were invaluable.”

Today’s Landscape

Nearly 10 years after venturing on his own, who could’ve ever foreseen the situation we are faced with today? “The first quarter was one of the best we’ve ever seen, but April produced only 68% of the average business produced in the first three months of the year,” says Mickelson.

Thankfully, Montana has seen fewer COVID-19 cases than the rest of the country, and the state has re-opened for business. But that’s not to say Mickelson isn’t taking the necessary PPE precautions, and Mickelson is screening all customers at this time. “For the most part, we are not taking on work that can be postponed.”

In general, needless to say, Mickelson loves what he does—creating solutions for his customers. “Service work allows me to do that several times a day. It’s a good thing.”

But thinking of going out on your own? A heavily-involved Boy Scout leader, Mickelson suggests taking its motto to heart—Be Prepared. “Plan, Plan, Plan. There are fantastic resources available to help people prepare to start a business. USE THEM! Also, you have to answer the simple question, am I ready to be a business owner first and a plumber second? If yes, then proceed. If no, rethink the approach get your mind right. Businesses hire good plumbers, not the other way around.”

And those who are thinking of getting into the trades? “Do it, unless you have a better plan that actually pays,” says Mickelson, but he stresses that we need to kill the stigma that the trades are all about hard work. Concerning to Mickelson, those who discourage others from entertaining the idea of becoming a tradesman based on the work being too tough or man’s work. “Anyone who indulges in this tactic is merely afraid of their own deficiencies and nervous about being replaced by someone who may work smarter or harder.”

Sure, there are aspects that are hard, continues Mickelson, but with continued education and exerting oneself, reaching a higher level of employment in the trades is a real possibility. Good work ethics and attitude are noticed—one may not hear about it—but it doesn’t go unnoticed. And, share the knowledge others have shared with you. “I have always found that it is far easier to share knowledge with a willing listener than it is to intentionally with hold it,” says Mickelson.

Mickelson’s career has afforded him a good life with his wife and two kids. “Family time is my favorite. Second would be exercising my 2nd Amendment rights. Both of which usually occur outdoors.”

Yet balancing work/family life is a careful endeavor for Mickelson. “It’s really easy for family to take a back seat and be lost in the hustle. I traditionally try to make sure that work is done during the day and that my ‘Night Shift’ doesn’t start until everyone has begun to wind down for the night. All in all, business has taught me to use my time efficiently, and set priorities, Family, friends, money, seems to be a good flow.

All in all, waking up every day is a blessing for Mickelson. “I’ve told my kids for years that they are the only person who can make their day a bad day, so go into battle and aim for a great day, and worst-case scenario it’ll be OK.”

Ah, the age-old question: is it duct tape or duck tape? Although often mispronounced, it’s actually duct tape (Duck is a brand of the tape) and covers a class of pressure-sensitive tapes that consists of three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. Yet, even with that clarification, the term “duct tape” can Read more

Ah, the age-old question: is it duct tape or duck tape? Although often mispronounced, it’s actually duct tape (Duck is a brand of the tape) and covers a class of pressure-sensitive tapes that consists of three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. Yet, even with that clarification, the term “duct tape” can still be a bit misleading – although it’s considered a fix-all that got its name from early-on usage in HVAC work, duct tape is, today, actually not recommended for use on ducts (though there are some versions that are approved for HVAC applications).

Here’s a rundown of tape types.

- General Purpose Duct Tapes: Typical Thickness: 6-9 mils, handy for DIY home projects or light duty patching and bundling for pros on the jobsite.

- Heavy Duty Duct Tapes: Typical Thickness: 10-17 mils, every tradesperson should keep at least one roll of heavy duty duct tape in the toolbox — and multiple widths or colors won’t hurt.

- Clear Repair Tapes: Typical Thickness: Approx. 7 mils, your go-to tape for airtight, waterproof repairs on any surface that needs to be seen.

- Structural Grade Duct Tapes: Typical Thickness: Approx. 17 mils, the most robust option for extreme jobs, including those that require a rope or chain.

Duct tape is undoubtedly one of those versatile items that’s earned a place in just about any toolbox. It’s flexible, resists tearing, and sticks to just about anything. As contractors know, when it comes to jobsite efficiency, having the right tools for the job at-hand makes all the difference—and saving time means saving money.

Duct tape is undoubtedly one of those versatile items that’s earned a place in just about any toolbox. It’s flexible, resists tearing, and sticks to just about anything. As contractors know, when it comes to jobsite efficiency, having the right tools for the job at-hand makes all the difference—and saving time means saving money.

The Mechanical Hub ProStaff team recently took on the challenge of trying out a new tape to see if it was the one to grab to ensure the fix doesn’t fail and can save time, money and a lot of space in the toolbox.

Traditionally, ropes or chains have been the only option for contractors and installers when they encounter jobsite tasks that require intense strength and durability. Until now as one 36-inch loop of new T-Rex® Brute Force® can hold more than 700 pounds of weight and offers superior adhesion, so you can quickly secure, fasten and hold loads that you wouldn’t dare attempt with other tapes.

The high-bond, double-thick adhesive allows the tape to stick to rougher, dirtier surfaces and offers a durable, waterproof backing suitable for all-weather performance. Brute Force® represents the next generation of high-performance duct tapes with patent-pending Forge-Link™ Technology.

ProStaffer Andy Mickelson of Mickelson Plumbing and Heating, Missoula, Montana, was impressed with the strength and said, “T-Rex Brute Force tape has an incredible tear-resistant design, so much so that you’ll require a blade to cut it. The adhesive layer is much thicker than any other tape I’ve used previously. The tape seems to hold well when bonded to itself and smooth surfaces alike, even when the surface is not completely dry. It will make a great addition to any travel box or tool box.”

ProStaffer Andy Mickelson of Mickelson Plumbing and Heating, Missoula, Montana, was impressed with the strength and said, “T-Rex Brute Force tape has an incredible tear-resistant design, so much so that you’ll require a blade to cut it. The adhesive layer is much thicker than any other tape I’ve used previously. The tape seems to hold well when bonded to itself and smooth surfaces alike, even when the surface is not completely dry. It will make a great addition to any travel box or tool box.”

“We have found a number of uses for T-Rex Brute Force! Someone didn’t judge the width of the truck while backing up and managed to rip off a side mirror. The mirror was put back into place and held there with the tape until we were able to get it into the dealership,” said Shay Shepston of Reimagined Renovations, Champaign, Illinois.

Shay added, “It’s been used to hold a foam base cove to metal before installing a pool liner, to hold PVC pipes in place while we work, and many other odd jobs. It has been added to all our trucks and toolboxes!”

According to our ProStaff team, the only drawback—and one they all mentioned—was that you cannot tear it; it must be cut. Contractors are so accustomed to just tearing tape, it required remembering to have a utility knife handy to cut it.

ProStaff member John Thompson with Thompson Family Plumbing & Rooter, with shops in California and Arizona, put it to work with his team and shared, “T-Rex Brute Force tape was fantastic to have on our work trucks. On multiple occasions it was used to build confinement areas with plastic, plus a last-minute repair to hold the casing together on my jackhammer because I broke it during a project. You never know when you might need something of this strength to get out of a jam.”

ProStaff member John Thompson with Thompson Family Plumbing & Rooter, with shops in California and Arizona, put it to work with his team and shared, “T-Rex Brute Force tape was fantastic to have on our work trucks. On multiple occasions it was used to build confinement areas with plastic, plus a last-minute repair to hold the casing together on my jackhammer because I broke it during a project. You never know when you might need something of this strength to get out of a jam.”

He joked, “I have never seen anything this durable. It’s truly remarkable to see the strength this tape has. I wish I could say that I’m putting together a zombie bunker, because I would seriously use it. It’s ‘Ferocious!’”

In addition to needing a utility knife to cut the tape, our ProStaff team suggested they would like to see the tape in more solid and neon construction colors such as red, white, green and possibly even reflective, as well as different roll size options.

T-Rex® Brute Force® is sold in 25-yard rolls and is available at national mass and hardware retailers. For more information, visit www.trextape.com/contractors.

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.” On a custom home Read more

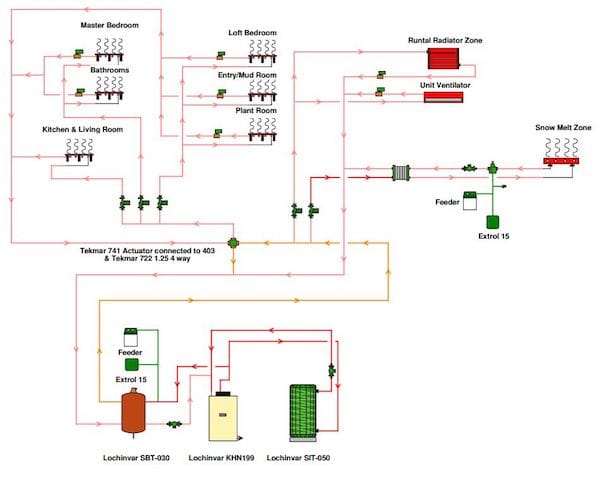

Complex hydronic systems are so 2008, at least according to Mechanical-Hub ProStaffer Andy Mickelson, who owns Mickelson Plumbing and Heating in Missoula, Mont. His three-man shop does plenty of high-end residential work, and even here—no—especially here, their recipe for success, serviceability and efficiency includes a heavy dose of “keep it simple.”

On a custom home, where some contractors may be tempted to stack the material list high and deep, Andy does the opposite. He takes a step back from the blueprints and figures out how to use the fewest components needed without any compromise. Numerous zones, DHW production, multiple supply temperatures and snowmelt loops can and are all handled without making things more complicated.

“There are a number of things you can do to keep systems simple,” said Mickelson. “I make sure to avoid ‘inadvertent’ redundancy: that is, two products that accomplish the same task.

Proper sizing of radiation, pipe, pumps and boilers accurately is obviously important, too. Picking a control system that accomplishes what you need and nothing more is helpful.

Another thing we began doing a few years ago—and have noticed an improvement since – is sizing and grouping our zones to the capacity of a specific pump, instead for creating a zone with no real parameters, and trying to find a pump that fits the zone or zone group.”

Like a round peg in a round hole, selecting your circulator first can save a lot of trouble, as well as the issues that come with over- or under-pumping a system.

Starting in late October of last year, Mickelson was hired for a job that would test his ability to “keep it simple.”

Mickelson’s work included installation of a mod-con boiler, seven zones of in-floor radiant, a hydronic unit ventilator, high-temp baseboard and 400 sq.-ft. of snowmelt.

Just out of town, the customer had purchased a nice lot with an older, 800-sq.-ft. home. The house was leveled and the basement foundation was re-used. The plan was to build a new 5,000-sq.-ft., two-story home on top of and around the original foundation.

Pick the pump first

“Like we do on all our jobs, I interviewed the homeowner long before we started the work, in order to really understand what they wanted,” said Mickelson. “Comfort was paramount, and budget not as much. So a thin concrete slab covers all radiant tubing, which is set at nine-inch centers.”

Before Mickelson started his loop layouts, he chose the Taco VT2218 variable speed circulator to serve all of the zones, with a total of six pumps. Additionally, Taco 007e single-speed ECM circulators are used on the 200 MBH fire-tube boiler and the indirect water heater.

“I like a Delta-T pump on a job like this, but another reason I used the VT2218 is for its broad pump curve, and we made use of it,” explained Mickelson. “It’s also very easy to program. Each radiant pump serves a group of zones. The zones are paired up according to the pump’s capacity, in terms of both head loss and flow rate. That way there aren’t any extra, underutilized circulators.”

Once the pump has been selected and the heat loss has been completed, the zones can be designed to fit the home. A common misconception about radiant circuits is that they must be as close to 300 feet long as possible, this just isn’t true. By dropping the length of each circuit, the head loss can be comfortably managed. The downfall to this is that the zone may require more circuits, but honestly the difference between five circuits and seven is minimal. It’s the same amount of tubing, no real noticeable increase in labor, just a larger manifold and a manageable head loss.

Low temp

Through zone valves, each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold, located remotely. Half-inch Watts RadiantPERT tubing was laid out before the gypcrete was poured.

“We chose the PERT instead of PEX because the radiant work was done throughout the winter. With spells of sub-zero weather, the increased flexibility of PERT was a huge benefit, especially considering our tight tube spacing.”

Because of the hydronic radiators, unit ventilator and snowmelt, the boiler maintains the buffer tank at 140°F at an outdoor design condition of -15°F. To make low temp water for the radiant zones, a Watts 4-way mixing valve with a tekmar 741 actuating motor was used. The 741 communicates with a tekmar 402 House Control in order to supply the exact radiant temperature need based on the outdoor temperature.

“The mixing valve sets the final delivery temp to all the low-temp zones,” said Mickleson. “It’s one of three elements at play here that really allow us to provide the exact temperature and flow rate to the radiant zones, so we’re really capitalizing on the primary/secondary piping, and squeezing every last ounce of comfort and efficiency out of the system. The other two elements are the outdoor reset on the higher temp boiler zones, and the variable-speed, Delta-T pumps. They all work hand in hand.”

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

The home has several areas with structural elements which made installing some of the tubing a challenging. Because of this, Mickelson had no choice but to run PEX supply and return piping through exterior walls. As a guard against the challenge of Montana winters, he wanted to run a glycol solution in the system. He installed a Neutra-Safe system feeder, which is an all-in-one reservoir, pump and control.

High temp

The fourth and fifth VT2218 circulators serve the home’s three high-temp zones directly out of the buffer tank. In the basement, where the existing, uninsulated slab is still in place, Runtal baseboard was used in lieu of radiant tubing. Mickelson had considered ceiling radiant, but there wasn’t enough height to allow it. The circulator used for the baseboard zone also supplies water to the 12,000 BTU Smith Environmental unit ventilator in the garage attic.

The last variable-speed circulator serves as the snow melt system pump on the loop side of the brazed-plate heat exchanger. Mickelson uses a tekmar 654 Snowmelt Control to manage automatic operation and maintain a 25°F Delta-T across the 400 square-foot zone. This control features a snow and ice sensor that’s set in concrete when poured. The snowmelt loops also utilize a second Neutra-Safe System Feeder.

“Because of the components used and a thoughtful design, we’re covering five different loads with one boiler while installing it in a relatively tight space, all without being overly complicated,” said Mickelson.

Each pump supplies the appropriate amount of water and heat to a Watts Radiant stainless steel manifold.

“In the case of an emergency, I only have to deal with a single control system or one replacement pump,” he added. And with all that said, I can’t think of a quieter, more comfortable, or higher efficiency heating system.”

Mickelson is now going over a punch list, and looking forward to the feedback from the customer. He’s expecting rave reviews about the comfort level, and complete satisfaction when the owner receives their first propane bill.