Taco Comfort Solutions® has expanded its family of easy-to-use, ECM high-efficiency circulators with the addition of the 0034e® and 0034ePlus® models. With a maximum of 34 feet of head and 50 GPM, the new circulators offer up to 85 percent energy savings over a conventional circulator. The 0034e and 0034ePlus circulators are available with cast Read more

Taco Comfort Solutions

Taco Comfort Solutions® has expanded its family of easy-to-use, ECM high-efficiency circulators with the addition of the 0034e® and 0034ePlus® models. With a maximum of 34 feet of head and 50 GPM, the new circulators offer up to 85 percent energy savings over a conventional circulator.

The 0034e and 0034ePlus circulators are available with cast iron or NSF/ANSI 61 & 372 certified stainless steel volutes, so they are ideal for closed-loop hydronic heating systems as well as domestic hot water recirculation systems. Both circulators also offer a convenient, rotatable control box cover for a professional look, no matter the orientation of the installed circulator.

The 0034e features an easy-to-use dial with five operating modes, including constant pressure, fixed speed, Taco’s exclusive TacoADAPTTM self-adjusting proportional pressure, and 0-10V capability. The 0034ePlus adds proportional pressure and more constant pressure settings as well as a digital display with real-time feedback, including watts, GPM, feet of head, and RPM. Both circulators are dual-voltage 115V/230V.

The new circulators come with exclusive features that make Taco’s ECM high-efficiency circulators so easy to use, including SureStart® automatic unblocking and air purging, BIO Barrier® black iron oxide protection, dual electrical knockouts, and recessed flange nut-grabbers.

For more information, visit www.TacoComfort.com

Taco Comfort Solutions has partnered with Contractor Rewards, a free program designed to reward professional contractors, plumbers, builders, and remodelers for buying the industry’s leading products. Customers earn points on Taco’s heating and plumbing products that can be redeemed for thousands of possible rewards – anything from movie tickets to tools or live events and Read more

Taco Comfort Solutions has partnered with Contractor Rewards, a free program designed to reward professional contractors, plumbers, builders, and remodelers for buying the industry’s leading products.

Customers earn points on Taco’s heating and plumbing products that can be redeemed for thousands of possible rewards – anything from movie tickets to tools or live events and vacations. Taco’s full catalog of residential heating and plumbing products is eligible. Points are earned on circulators, zone valves, or switching relays that were going to be purchased anyway.

Enroll today and use the bonus code GreenRewards to earn 200 points, free. This jumpstart is Taco’s way of saying “thank you” to loyal customers. Signing up is free and only takes a minute. Just go to ContractorRewards.com and answer a few questions.

For questions, email ContractorSupport@ContractorRewards.com or call 1-877-286-7064.

Taco Comfort Solutions has expanded its family of easy to use, high-efficiency ECM circulators with the addition of the 0026e. With a maximum of 26 feet of head and 44 GPM, the new variable-speed circulator offers up to 85 percent energy savings over a conventional circulator. The 0026e circulator is available with cast iron or Read more

Taco Comfort Solutions has expanded its family of easy to use, high-efficiency ECM circulators with the addition of the 0026e. With a maximum of 26 feet of head and 44 GPM, the new variable-speed circulator offers up to 85 percent energy savings over a conventional circulator.

The 0026e circulator is available with cast iron or NSF/ANSI 61 & 372 certified stainless steel volutes, ideal for either closed-loop heating systems or domestic hot water systems. It also offers a convenient, rotatable control box for a professional look, no matter the orientation of the installed circulator.

The easily-installed, easily-programmed 0026e circulator features five simple settings; low, medium, high, Taco’s exclusive activeADAPT® self-adjusting proportional pressure, and 0-10v control. Its variable speed performance curves are equivalent to Taco’s 0010, 0011, 0012, 0012 and 0014 models.

Hydronic system designers and installers will find that the new circulator is ideal for large residential and light commercial heating, chilled water cooling and domestic hot water systems. The 0026e is dual-voltage 115V/230V, and the 6.5” rotated flange-to-flange dimension retrofits most circulators in its class.

The new circulator includes exclusive features that make Taco’s ECM high-efficiency circulators easy to use, including SureStart® automatic unblocking and air purging, BIO Barrier® black iron oxide protection, dual electrical knockouts, and recessed flange nut-grabbers for easier fit up.

For more information, visit www.TacoComfort.com

Taco Comfort Solutions donated $25,000 to Tunnel to Towers Foundation during an event held on June 15 at Wales Darby’s Islandia, N.Y. facility. Taco teamed up with their New York manufacturer’s rep, Wales Darby, to run a contractor promotion in the Long Island area supporting Tunnel to Towers. Taco donated proceeds from Taco heating circulators Read more

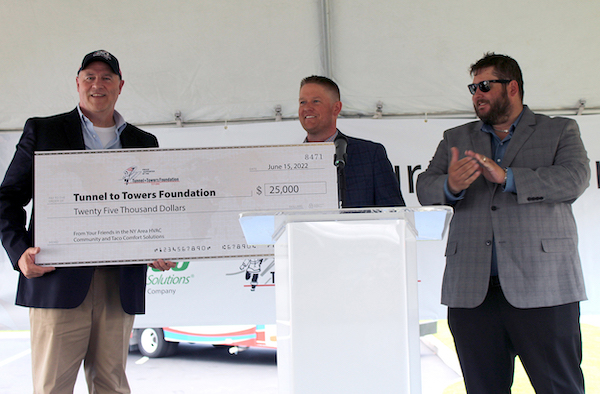

Taco Comfort Solutions donated $25,000 to Tunnel to Towers Foundation during an event held on June 15 at Wales Darby’s Islandia, N.Y. facility.

From left to right, Tunnel to Towers Foundation representative Andrew McClure receives a check for $25,000 from Taco Comfort Solutions’ Benjamin White, Manager, Supply Chain, and John White, III, Sr. Vice President, OEM Sales.

Taco teamed up with their New York manufacturer’s rep, Wales Darby, to run a contractor promotion in the Long Island area supporting Tunnel to Towers. Taco donated proceeds from Taco heating circulators sold during a four-month period to Tunnel to Towers.

Tunnel to Towers Foundation supports families of fallen and severely injured military and first responders by providing mortgage-free homes.

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions. MH: What are some of the driving forces behind heat pump technology? Chaffee: The Read more

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

MH: What are some of the driving forces behind heat pump technology?

Chaffee: The key, driving factor is a desire for CO2 reduction by using less fossil fuel. The world’s leading cultures and political forces have chosen to pursue beneficial electrification as a key component to achieve reduction goals. So, how is it that we can most quickly, substantively reduce our dependence on fossil fuels—a key contributor to carbon emissions? Heat pump technology is the HVAC industry’s best foot forward in achieving this today.

The effort to accomplish decarbonization is broken into two primary camps: a.) at the grid (source) level, and b.) equipment (local).

At the grid level, our 50 states are all at different places in implementing this. And, for the technology that’s involved residentially, and commercially, the ability of heat pumps to deliver COP’s (coefficient of performance) of 3, 4 and 5—meaning operational efficiencies of 300, 400 and 500 percent, or more— can’t be ignored. In comparison, fossil fuel burning equipment can achieve efficiencies of maybe 92 to 98 percent at best.

The goal: clean, efficient grid energy in combination with the highest efficiency HVAC solutions possible. Then install some solar panels on your house or commercial building (distributed green energy) for another win. Heat pumps measure up effectively as viable equipment solutions to keep people comfortable year-round.

MH: What are the benefits of heat pump technology?

Chaffee: At Taco Comfort Solutions, we believe that the best, no-compromise product offering comes from air-to-water systems; we want to be sure they have a seat at the table. They offer extreme energy efficiency, and the finest heating and cooling solutions with the greatest options and flexibility for delivery of that comfort—such as low-temperature radiant heat and towel warmers, etc. And: cooling, too. Hydronic technology is the undisputed king of comfort for humans.

With so many other heat pump technologies (for instance, mini splits, VRF or split system HVAC equipment), refrigerants are the means of thermal exchange across all facets of the distribution network. Refrigerant lines may pierce roofs, and course their way through attics and walls from condensing units to air handlers or terminal units. We prefer the much improved means of using water as the primary source of distribution; it’s safer, less expensive and more efficient. We know water to be the cleanest and most efficient medium of thermal exchange. Simply, more BTUs can be transported by water than by refrigerant compounds or by forced air.

With so many other heat pump technologies (for instance, mini splits, VRF or split system HVAC equipment), refrigerants are the means of thermal exchange across all facets of the distribution network. Refrigerant lines may pierce roofs, and course their way through attics and walls from condensing units to air handlers or terminal units. We prefer the much improved means of using water as the primary source of distribution; it’s safer, less expensive and more efficient. We know water to be the cleanest and most efficient medium of thermal exchange. Simply, more BTUs can be transported by water than by refrigerant compounds or by forced air.

We aren’t comparing heat pumps with boilers here. For generating high temperature water, there’s nothing better than a sturdy boiler. On the other hand, we are comparing air-to-water heat pumps with forced air systems and traditional ground-sourced geothermal systems, the latter of which can also consistently provide efficient, decarbonized comfort, though with substantial up-front costs to accomplish geoexchange.

Air-to-water heat pumps are a viable solution and can deliver no-compromise, year-round comfort without wells, deep and grouted boreholes, trenches, or underwater heat exchangers.

Heat pumps offer extreme efficiency, with heating and colling for year-round comfort. Some of them, like ours, also provide super-efficient heating of domestic water—all from a single appliance-like device.

MH: Do you see demand for Heat pumps more on the residential side than commercial? What’s the ratio?

Chaffee: We’ve all seen the explosive growth of mini-splits in the US residential market. To a large extent, homeowners have accepted and appreciate them. In the commercial sector, VRF technology has also seen broad acceptance, but there’s a tougher battle for dominance of the market—including the hydronic technology that we at Taco have invested in heavily.

Air-to-water systems represent a small percentage of both markets—residential and commercial—though with great potential for growth. After all, their superior comfort and technology offerings is matched with the ability to decarbonize. They can also handle the domestic hot water loads as part of a singular system.

Consider, too, that a lot of refrigerant compounds have come and gone in the last couple of decades. As increased regulatory and environmental efforts removed more from the market, the long-term viability of distributed refrigerant-based systems comes into question. Why rip out and replace an existing system just because refrigerant laws change? Hydronics has always been able to adapt and upgrade to environmental, regulatory or technology changes.

I hope we see a great deal more demand for water-based systems in both the commercial and residential markets to help meet the demands for a low carbon society.

A ratio? Right now, the growth trend is affecting both markets equally, though overall—the residential market has seen faster growth initially.

MH: Can the grid support a HP transition?

Chaffee: Probably not, in its current state. But that won’t stop anyone from trying to achieve 100 percent clean energy. But, there’s a lot of work to be done to improve grid conditions before this can accomplished.

MH: Is a different skill set required for installation?

For the most part—no. Most trade professionals in the market today have everything they need—from expertise on tap, skills and tools—to accomplish proper installation of heat pumps. Those who already have a refrigerant license have a step up. Though, what little refrigerant there is within our System M is fully sealed at the factory in the outdoor unit, so no refrigerant license is needed to install the unit.

There are two types of heat pumps as defined by refrigerant technology:

- Monobloc—all refrigerant and the compressor are within the exterior unit, factory-sealed; refrigerant-to-water is the medium for thermal exchange. Only water moves to and from the exterior unit to the home or business for space conditioning.

- Split—these systems move refrigerant from the outside condensing unit to the inside of a structure in the process of air-to-refrigerant, or refrigerant-to-air thermal exchange.

MH: Life expectancy compared to boilers?

Chaffee: Nothing lasts like a boiler. Though many improvements have been made to boilers through the years, chiefly to enhance efficiency, their ability— by design—to heat water and transport it out for distribution, and then back again, is unsurpassed. In round numbers, a boiler’s lifespan is about 30 years.

Now, consider the rate new HVAC technology introductions over the past decade or so. In that same 30 years, a lot of new technology will emerge to supplant any appliance on the market today, and some will see the influence of refrigerant compounds that will be legislated-out, making them obsolete. It’s become broadly accepted that if an appliance lasts 15 to 20 years, its met its expectation.

Essentially, today’s air-to-water heat pump systems are appliances— considering their construction and durability. With proper installation and routine maintenance, they should last 15 to 20 years.

MH: Will you offer training for these products?

Chaffee: Yes. Taco provides training for all of the technology it offers to the market. We’re passionate about the support we offer to installers and system designers, the System M air-to-water heat pump will allow us to continue to educate on products and system design, especially as we look to implement high performance, energy efficient HVAC system.

MH: Other thoughts?

Chaffee: Glad you asked! We’ve heard this question on many occasions from a wide range of trade professionals: “Why does Taco want to offer this technology?”

The answer stems from our combination of expertise in hydronics, thermal distribution and comfort. These different facets meet and combine uniquely in our newest technology—the System M. It’s a single-source, air-to-water, turnkey heat pump system designed and built to meet the comfort and efficiency needs of a low-carbon society.

If we at Taco can help the trade to accomplish this, all the better. After all, that’s been an important part of our makeup dating back more than 100 years now. In the past decade or so, we’ve made a concerted effort to move from our role as a component manufacturer to that of a systems provider. With System M, we’ve combined no-compromise comfort with environmental benefits. And, considering that the technology is easy to size and install, it’s a win-win from many perspectives.