In today’s competitive market, it’s important to choose products that improve productivity and profitability. PEX isn’t a new pipe material, but more plumbers are choosing it as their preferred pipe type — and for good reason too. Explore the key reasons PEX is the best tubing to use for your next plumbing installation.

1. It’s more versatile

The initial cost of PEX is already budget-friendly, but its flexibility makes it even more so. The bendable tubing can maneuver around corners without the use of elbows or other additional fittings, making it easier for getting into places where rigid pipe isn’t easy to use.

Because its flexibility helps reduce the number of connections, PEX helps lower the cost of materials and minimizes potential leak points. Plus, you can install PEX pipe in longer runs with the use of coils that come in lengths up to 1,000 feet.

2. It’s quicker to install

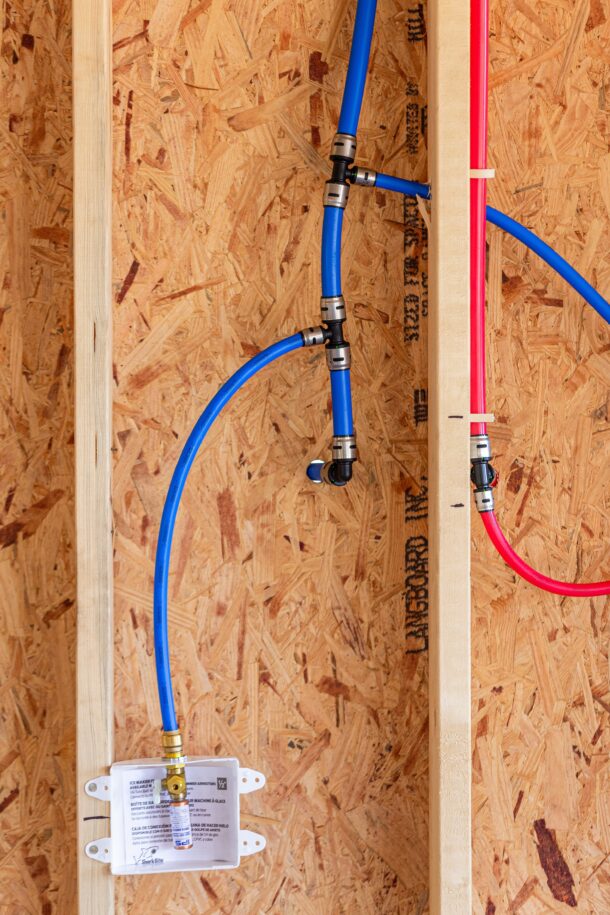

One of PEX’s biggest draws is that it’s compatible with quick-installing plumbing solutions like SharkBite EvoPEX push-to-connect fittings that help you stay on schedule. In today’s labor market, that’s no small thing. Here’s why,

You need less labor. When you plumb PEX with push-to-connect fittings, you don’t need glue, solder, solvents or torches. These traditional techniques often require you to start and stop during installation, wait for glue or for water to dry before testing the plumbing system, or spend extra time cleaning up scrap material.

Bypassing these time-consuming processes means you can complete your installation with fewer people and without ever needing to pause your work. It also keeps potentially dangerous chemicals out of plumbing systems and removes the potential risk of fire from using torches on the job site.

You don’t need a specialized toolbox. Since they don’t require special tools, push-to-connect PEX systems give you more mobility compared to a two-hand system like crimp/clamp, while also significantly reducing the chance of installation errors and leaks. This in turn lessens the risk of water damage and mold.

As an advanced PEX push-to-connect plumbing system, SharkBite EvoPEX fittings even display a green visual indicator to assure you that a proper and permanent connection has been made. Plus, you can immediately test the plumbing system once the installation is done.

3. It performs better in the winter

The chemical composition of cross-linked polyethylene, the synthetic material PEX pipe is made from, allows the structure of the pipe to have more freeze resistance and elasticity under pressure. That means PEX will expand if water within the pipe freezes, and it’ll contract to its original shape when it thaws. This can help prevent other plumbing issues in the winter.

Additionally, the tubing has a host of other attractive features:

- It’s chlorine-resistant and resists scale buildup, which is common in copper pipe. Corrosion resistance facilitates more water pressure and better hot water delivery.

- You can find PEX that is tested to the highest level of chlorine resistance (100% chlorine at 140°F) and is certified to meet ASTM F876 oxidative-resistance requirements for continuous recirculation.

- PEX can withstand not only extreme low temperatures, but also extreme high temperatures too.

4. It’s sustainable

As the world focuses more on sustainable building practices, there’s a growing emphasis on reducing the long-term impact of building materials, including pipes. The good news is PEX addresses all three pillars of sustainability: environmental, economic and social impact.

Environmental. Polyethylene is a byproduct of oil or natural gas that’s already being extracted for other energy use, so PEX doesn’t require the extraction of natural resources just to make the tubing. It also doesn’t take a lot of energy to create PEX.

When the pipe is installed, it saves energy too. Polyethylene is a non-conductor and has insulation properties, which means PEX plumbing systems require less energy than copper systems to achieve a desired water temperature. And at the end of its life, the tubing can be ground up and used as a filler in composite lumber, playground equipment, traffic barriers and more.

Economic. Not only is PEX cheaper than other piping materials, but its bendability and compatibility with efficient plumbing solutions like push-to-connect fittings help save on parts and labor costs. Because it’s flexible and corrosion-resistant, it also has a long lifespan (about 50 years per PPI TR-3). This reduces costs, increases customer satisfaction and lessens waste.

Social. PEX and the innovative plumbing systems that it can be used with help address the industry’s labor shortage. It supports pros who have limited help in the field by making installations faster, safer and more reliable. Some other social benefits include:

- PEX is joined using mechanical fittings rather than soldering, which creates a potential fire hazard during installation.

- PEX systems are certified to NSF/ANSI/CAN 61, so they’re approved for potable water application.

- PEX is resistant to leaching, pitting and mineral buildup.

When picking a PEX manufacturer to work with, consider one that offers the highest-rated chlorine resistance and six-month UV resistance, such as SharkBite PEX-B. This tubing is also made in the U.S. — right in Cullman, Alabama — which creates and maintains jobs that boost the national economy.

Join the conversation: