While hydronic system growth across most of the country is slow, Metro Detroit is seeing a bit of a water-side resurgence, at least in certain segments. And it’s appearing where people are demanding the best. “We’re installing more boiler systems now than ever before,” said Joe Sullivan, president of Paradigm Plumbing & Mechanical, Inc. “We’re Read more

Radiant Energy Systems

While hydronic system growth across most of the country is slow, Metro Detroit is seeing a bit of a water-side resurgence, at least in certain segments. And it’s appearing where people are demanding the best.

“We’re installing more boiler systems now than ever before,” said Joe Sullivan, president of Paradigm Plumbing & Mechanical, Inc. “We’re gaining market share, but the market is growing, too. Homeowners are demanding premium comfort with more regularity, and as a result, builders and architects are pushing hydronics. It’s the obvious answer.”

Paradigm Plumbing & Mechanical, Inc.’s niche is high-end new construction in the Detroit metro. During assembly of this mechanical room, the Aspen and Aspen Light Commercial boilers were installed early in the game.

Paradigm’s niche is high-end new construction. They call themselves a builder-based company. Founded 10 years ago, the ten-person company works exclusively for five or six general contractors. Radiant systems are common, and so are homes that require three or four different water temperatures.

“Our system designs might be a bit different that the competition, but we have a specific way we like to do things,” explained Sullivan. “Our market also allows us to install the best equipment available. We cut no corners. Comfort and reliability are the primary goals, and efficiency is close behind.”

Long timelines

Large custom homes are essentially small commercial projects. Paradigm’s involvement at a single residence can easily span two years, from design to start-up. They’ve partnered with rep HS Buy Van, and buy equipment through Hartsig Supply.

“HS Buy Van works on our piping and loop layouts,” said Greg Sharer, project manager and hydronic specialist at Paradigm. “With their help, we begin projects with a full MEP set. All of our electric and controls are done in-house.”

The 205 MBH Aspen boiler heats the home and provides DHW, while the 399 MBH Aspen Light Commercial provides heat for a snowmelt system.

Nearly a year ago, Paradigm started a new project with Eric Vogler on a 7,500-sq.-ft. residence in Orchard Lake, Mich., and they’ll be wrapping it up just before heating season this year.

Paradigm designed two separate hydronic systems for the home: one for in-floor radiant and DHW using a 205 MBH Aspen, and one for the snowmelt system, with heat provided by a 399 MBH Aspen Light Commercial. The home has a furnace in addition to radiant tubing throughout the floorplan, and a full tekmar control system.

https://youtu.be/u7RXZImuBOI

“Customers who’ve never experienced a well-designed radiant heating system are blown away when the first heating season rolls around,” said Sharer. “Every surface in the home is warm to the touch, even the countertops.”

Piped right

In the boiler room, mechanical components cover an entire 16-foot wall. The high-efficiency Aspen boilers are mounted next to an array of copper pipe and circulators.

“HS Buy Van recently changed hi-efficiency boiler brands, so when they picked up the US Boiler line, we gave the Aspen a close look,” said Sharer. “We still had access to our previous brand, but the appearance and the design of the Aspen are great, so we bought two for this project. They’ve proven easy to install, and we really like firetube heat exchangers.”

Paradigm is known for their meticulous installation of piping, pumps and controls.

The Aspen boiler offers up to 96% AFUE, comes in five sizes, and is available as a 155 MBH combi. The Aspen LC comes in two sizes and can be floor- or wall- mounted. Both units feature Sage2.3 controls and have a 10:1 turndown ratio.

The rest of the mechanical room is occupied by a 120-gallon Burnham Alliance SL tank, beautiful copper piping, a Caleffi hydro-separator and mixing valves, and numerous Grundfos circulators.

“Greg does phenomenal work,” said Sullivan. “He and I really love hydronics. We handle most of the boiler systems – which make up about 40 percent of our work – while the rest of the crew covers controls, electronics, plumbing and air-side.”

The system for the big custom home was built onsite, but Sharer and Sullivan often prefabricate systems at the company’s 5,000 square foot shop.

“Most of our manifolds are remote,” said Sharer. “We do this to keep loop lengths short, usually no more than 250 feet. And, despite what some people may think, we prefer to zone with pumps instead of zone valves. This offers a great deal of redundancy, but also makes balancing simple, as well as diagnosing issues after the fact.”

Half-inch Uponor PEX was used for the 12 zones of radiant, laid at six-inch centers. Most of the tubing is under tile, set in Portland cement. Plenty of care was taken to protect the tubing during construction, and the same attention to detail was given to the tubing outside.

Let it snow, just not yet

While high-end residential hydronics is an area of growth for Paradigm, so is one of its subcategories. The company has earned a reputation in the Detroit area as being a snowmelt specialist. Annual snowfall in the area is often between 45 and 100 inches.

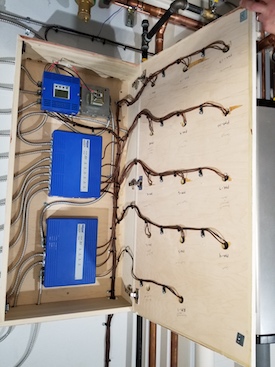

The home and snowmelt system are served by a full tekmar control system.

“There are plenty of wrong ways to install hydronic snowmelt systems, and a few ways to do it correctly,” said Sharer, who has been with the company for six years. “Over the years we’ve developed a method of designing, selling and installing these systems. All our systems operate as they should and offer great benefits to the owner. We’ve crunched the numbers thoroughly enough to give the perspective customer an accurate projection of operation expenses.”

The Paradigm snowmelt method includes years of experience, but there are a few rules of thumb they adhere to, some of which are universally accepted as best practice by the hydronic community, and some that aren’t.

“Maintaining proper loop length is one thing we’re careful about while installing tubing, and most everyone agrees on that,” said Sharer. “But our insistence on using individual pumps on all the zones in a snowmelt system is one that sometimes draws scrutiny. We have our reasons.”

“In the past, public opinion of snowmelt systems was that you had to be Bill Gates to own or operate one,” said Sullivan. “With the right design, piping, and control strategy, it can be cheaper to operate than most folks think.”

Sullivan admits that snowmelt systems are absolutely a luxury item, but clients still want to know what it’ll cost to run the system in addition to what it’ll cost to install. Of course, there’s a financial return on investment by offsetting salt and snow removal costs, but the true payoff is harder to quantify. Safety and convenience are difficult to assign dollar figures to.

The Aspen Light commercial was installed in early March, but the driveway work needed to wait several months until the weather improved. The two-zone snowmelt system included the concrete driveway and a paver walkway.

“High-end residential has been great for us, but we’re working on becoming more competitive, moving into lower-cost markets with hydronics,” said Sullivan. “It’s a slow transition, because we’re figuring out how to do that by eliminating a few bells and whistles without sacrificing any quality. It’s a marketing challenge as much as anything.”

But where there’s a will, Paradigm finds a way. They’ve proven this through their application of uncompromising hydronic system quality.

When Delta Electronics (Americas) expanded its headquarters in Fremont, Calif., they leaned on the company’s brand spirit: “Smarter. Greener. Together.” Founded in 1971, Delta’s mission is “To provide innovative, clean and energy-efficient solutions for a better tomorrow,” and the headquarters is a shining example of creative thinking paired with a desire to protect the environment Read more

When Delta Electronics (Americas) expanded its headquarters in Fremont, Calif., they leaned on the company’s brand spirit: “Smarter. Greener. Together.” Founded in 1971, Delta’s mission is “To provide innovative, clean and energy-efficient solutions for a better tomorrow,” and the headquarters is a shining example of creative thinking paired with a desire to protect the environment. The company takes advantage of the latest in advanced energy-efficient research and product development, and the American headquarters is their 13th green building worldwide.

To help meet the LEED Platinum and net-zero energy building standards, the company chose to go with a radiant heating and cooling system from Uponor. Originally specified for a conventional radiant tubing installation, the mechanical contractor, ACCO Engineered Systems, a contracting firm with locations throughout California, suggested changing the specification to Uponor’s Radiant Rollout Mats for a faster, more efficient and consistent installation. ACCO had recently completed several large commercial projects using the mats, including the Pier 15 Exploratorium in San Francisco and SMUD (Sacramento Municipal Utility District) building.

ACCO, in conjunction with Sean Timmons at Timmons Design Engineers—now ALFATECH-Timmons—and Osborne Company—an Uponor rep firm—designed the radiant heating and cooling system using the mats for the 178,000-square-foot campus that includes a 38,000-square-foot warehouse. The radiant slabs are the primary cooling and heating systems in the campus buildings so it was crucial for the design to ensure comfort as well as the desired energy efficiencies.

Due to their previous experience with the Radiant Rollout Mats, ACCO spent a considerable amount of time up front designing the slab construction, the sequence of the slab construction and how the mats would be fabricated to align with the installation thought process. “We eliminated a lot of potential problems up front – lessons that we learned on other projects,” said Jonathan Bell, ACCO project manager.

It took five months for three dedicated crew members plus one runner to install 138,000 feet of tubing with the Radiant Rollout Mats. It would have taken much more time—and labor—to install the tubing using conventional PEX rails or tie-down methods.

The installers needed a bit of onsite training to get up to speed, and the first couple of circuits went in a little slower while Osborne Company helped demonstrate efficiencies and effective ways to speed up the installation. “But it didn’t take long for the crew to have a full understanding of the processes, and they quickly picked up the pace for the rest of the installation,” Bell said.

The installers needed a bit of onsite training to get up to speed, and the first couple of circuits went in a little slower while Osborne Company helped demonstrate efficiencies and effective ways to speed up the installation. “But it didn’t take long for the crew to have a full understanding of the processes, and they quickly picked up the pace for the rest of the installation,” Bell said.

As with any project, there are challenges to overcome in buildings of this magnitude. “Having to accommodate physical building changes that occurred after we had procured the material was one of the challenges we had to work with,” Bell said. “And construction delays threatened to leave the tubing exposed to the sun for longer periods of time than we had anticipated. We had to do some quick thinking to make sure the tubing was protected from possible prolonged sun damage.”

Osborne, the Uponor rep firm, became an instrumental strategic partner in helping overcome and solve these unique challenges, and Bell is pleased with the process, the solutions and how quickly the crew installed the Radiant Rollout Mats.

“For large, open circuits, the installation of the Radiant Rollout Mats is much quicker than laying down regular tubing,” he said. “And the prefabricated and labelled mats allows for more efficient material handling onsite, which is very important in these large installations.”

According to a recent industry report, growth in radiant heating sales in the first quarter of this year was largely driven by sales of floor heating cables. WarmlyYours, a radiant heating company that specializes in electric floor heating systems, released their “Q1 2018 Industry Report ” earlier this week. Among other findings, the report showed Read more

According to a recent industry report, growth in radiant heating sales in the first quarter of this year was largely driven by sales of floor heating cables.

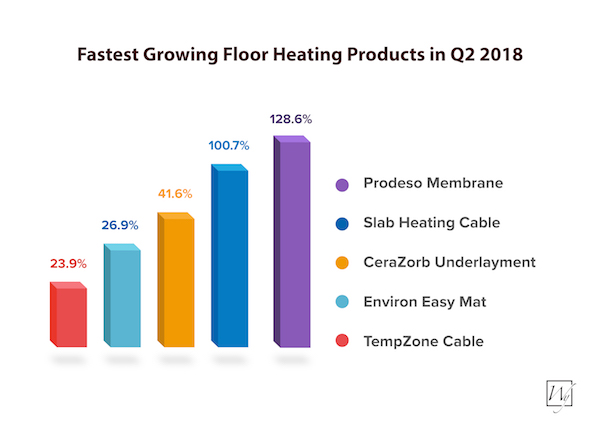

WarmlyYours, a radiant heating company that specializes in electric floor heating systems, released their “Q1 2018 Industry Report ” earlier this week. Among other findings, the report showed that electric floor heating cable sales were responsible for a large portion of the 24.5% growth in consolidated sales for the company. Sales of the TempZone Floor Heating Cable grew 23.9% in the second quarter, which translated to year-to-date growth of 16.1%.

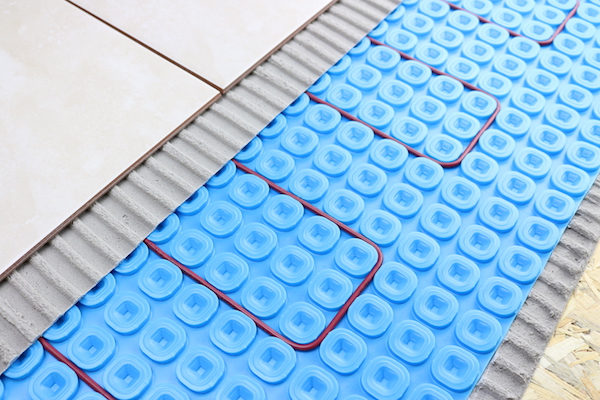

Pairing electric floor heating cable with an uncoupling membrane has become a very popular option for professionals and homeowners alike. In this picture you can see the various layers of a floor heating installation including the wood subfloor, thinset, the uncoupling membrane and heating cable, another layer of thinset, and the tile floor covering.

In addition, the Prodeso Membrane, an uncoupling membrane designed to accommodate the TempZone Floor Heating Cable product, has also increased significantly in sales in the second quarter (up 128%). When installed with the heating cable, the membrane significantly cuts down on installation time and provides long-lasting uncoupling benefits to relatively fragile floor coverings like tile. These features have helped grow the membrane from 45% of floor heating underlayment sales in the first half of 2017 to 57% in 2018.

A large part of the sales growth for both the TempZone Floor Heating Cable and the Prodeso Membrane is due to continued growth in the ecommerce channel. In fact, ecommerce now constitutes 19.4% of all WarmlyYours year-to-date sales, up from 8% last year. Most of this growth was with Amazon, which increased 349.8% in the second quarter. On Amazon, Q2 2018 sales of floor heating systems grew 427.9% and underlayment sales increased a whopping 3003.5%. The WarmlyYours report expects to see continued e-tailer sales growth well into 2019.

Infographic showing the fastest growing product lines for WarmlyYours floor heating sales in the second quarter of 2018. While the TempZone Cable’s growth rate isn’t as high as some of the other products, the increase in sales volume is by far the largest.

Despite the rapidly accelerating growth from digital avenues, Julia Billen, owner and president of WarmlyYours, stated in the report that the company will always place highest-priority on maintaining strong relationships with existing customers via direct sales.

“We’ve been in the radiant heating industry for a long time and some of our customers, from flooring installers to electricians, have been with us for nearly 20 years—in fact, they’re more like partners than customers,” said Billen. “And we will always place partners first because a website or app is never going to be able to beat the experience and knowledge of a professional.”

Here is a link to the report in full.

The Wasserman Eye Research Center is a culmination of a 50-year vision to house a world-class research and care center on the UCLA campus to preserve and restore eyesight. With offices in New York and Los Angeles, renowned architectural firm Richard Meier & Partners Architects designed the six-story, 100,000-square-foot Edie and Lew Wasserman building. Completed Read more

The Wasserman Eye Research Center is a culmination of a 50-year vision to house a world-class research and care center on the UCLA campus to preserve and restore eyesight. With offices in New York and Los Angeles, renowned architectural firm Richard Meier & Partners Architects designed the six-story, 100,000-square-foot Edie and Lew Wasserman building. Completed in April 2013, the three lower floors are dedicated to the expansion of the Jules Stein Eye Institute, making it a world-class research and treatment facility.

To accommodate for the Wasserman building, a plan was developed to demolish a seismically deficient portion of the adjacent Semel Institute building. Lead architect Michael Palladino was the principle-in-charge and Tom Goffigon, the project manager, worked closely with the Wasserman Foundation, overseeing the demolition project and design and construction of the new building. With a keen eye to detail, the architects kept sustainability top-of-mind. In fact, the University of California system recently became the first American university to have 100 LEED®-certified facilities – an impressive milestone and a testament to the university system’s dedication to responsible building practices.

To accommodate for the Wasserman building, a plan was developed to demolish a seismically deficient portion of the adjacent Semel Institute building. Lead architect Michael Palladino was the principle-in-charge and Tom Goffigon, the project manager, worked closely with the Wasserman Foundation, overseeing the demolition project and design and construction of the new building. With a keen eye to detail, the architects kept sustainability top-of-mind. In fact, the University of California system recently became the first American university to have 100 LEED®-certified facilities – an impressive milestone and a testament to the university system’s dedication to responsible building practices.

Radiant System Takes Load off Forced Air

The first three floors were specified to include radiant heating and cooling, and Uponor was asked to help with design and product guidance. Working closely with Circulating Air, a Los Angeles-based mechanical contractor, Uponor helped design the system in conjunction with engineers and architects.

The first three floors were specified to include radiant heating and cooling, and Uponor was asked to help with design and product guidance. Working closely with Circulating Air, a Los Angeles-based mechanical contractor, Uponor helped design the system in conjunction with engineers and architects.

“The contractor had not worked with Uponor prior to this project so we helped them get trained and comfortable with our system on site,” said Jacob Ford of Keyline Sales, a local Uponor rep firm. “It didn’t take long for them to catch on, and they quickly advanced and found innovative methods to speed up installation.”

According to Ford, the building’s southern facing is a wall of glass, and the radiant heating and cooling system takes a huge load off the forced air system.

According to Ford, the building’s southern facing is a wall of glass, and the radiant heating and cooling system takes a huge load off the forced air system.

The four-man Circulating Air crew worked closely with Keyline Sales to ensure they installed the 16,000 feet of Uponor’s Wirsbo hePEX™ tubing efficiently.

“We were truly amazed at how quickly and easily we installed the piping for the radiant heating and cooling system,” Matt Fitzgerald, Circulating Air job foreman, said. “Receiving training on site really helped us, and our crew felt up-to-speed very quickly.” Also, Fitzgerald said that prior to training he was unaware how easy it was to make the connections to the manifolds and fittings. “I love how fast and easy the system is,” he said.

Uponor’s Wirsbo hePEX tubing uses ProPEX® expansion fittings which require one simple expander tool to make fast, easy connections that hold tight with up to 1,000 pounds of radial force. For contractors familiar with traditional copper or other rigid pipe connections, the ProPEX fitting system is a much easier, more reliable connection method.

Uponor’s Wirsbo hePEX tubing uses ProPEX® expansion fittings which require one simple expander tool to make fast, easy connections that hold tight with up to 1,000 pounds of radial force. For contractors familiar with traditional copper or other rigid pipe connections, the ProPEX fitting system is a much easier, more reliable connection method.

The system hooked up to six manifolds and six cabinets divided between the three lower floors. “The installation was fairly straight forward,” Fitzgerald said. “And we didn’t encounter any obstacles that we couldn’t overcome.”

Another product innovation on display at this year’s AHR Expo in Las Vegas was Uponor’s Ecoflex pre-insulated PEX piping system. Here is a closer look at this insulated piping solution. https://www.youtube.com/watch?v=JEB-J1Kg3Es Read more

Another product innovation on display at this year’s AHR Expo in Las Vegas was Uponor’s Ecoflex pre-insulated PEX piping system. Here is a closer look at this insulated piping solution.

https://www.youtube.com/watch?v=JEB-J1Kg3Es