Water pressure is a key part of any plumbing system, but there is potential for too much of a good thing. The 535/536 Pressure Reducing Valve Kit is a problem solving assembly for applications where a single valve won’t cut it. Simplified, two-stage pressure reduction can save the day when high incoming water pressure puts Read more

Toolbox

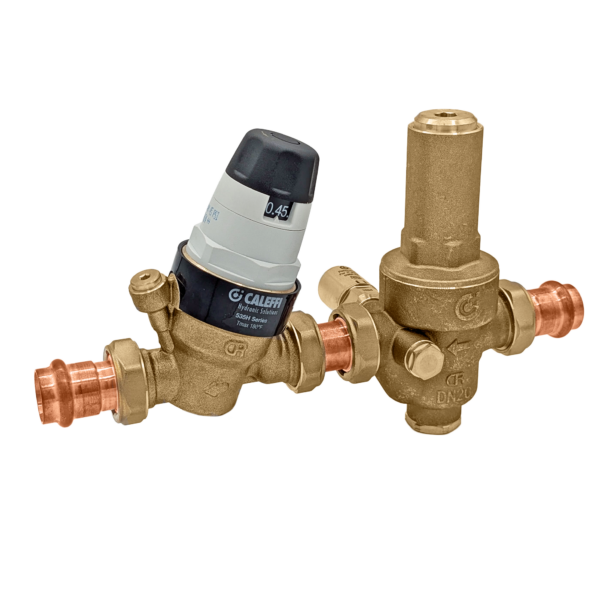

Water pressure is a key part of any plumbing system, but there is potential for too much of a good thing. The 535/536 Pressure Reducing Valve Kit is a problem solving assembly for applications where a single valve won’t cut it. Simplified, two-stage pressure reduction can save the day when high incoming water pressure puts extra stress on your system components.

For high-pressure plumbing systems, controlling water pressure is crucial to prevent damage and ensure reliable operation. When supply pressures exceed 200 psi, typically in high-rise buildings or systems with booster pumps, but also in water districts with high street pressures, a single Pressure Reducing Valve (PRV) may struggle to reduce pressure to a safe level. This can lead to issues like noisy and destructive cavitation, and ultimately damaging the other components all the way down to the faucet.

The 535/536 Pressure Reducing Valve Kit offers a solution with a two-stage pressure reduction system. The kit includes the Caleffi 536 PresCal HP piston-type PRV, perfect for the initial high-pressure stress and the 535 PresCal diaphragm-type PRV to dial in the perfect pressure at the taps.

This two-stage approach not only prevents cavitation but also extends the lifespan of the valves and other system components. It provides a reliable and efficient way to manage high-pressure scenarios, ensuring quiet and safe operation in even the most demanding plumbing environments. Whether dealing with inconsistent municipal supplies or high-rise booster systems, the 535/536 kit is a robust solution for maintaining optimal pressure levels.

Viega is the first U.S. manufacturer to make a transition coupling with press technology to join dissimilar materials Viega continues to find innovative solutions for piping systems with a new line of MegaPress® Transition Couplings that can be used to transition between galvanized or carbon steel pipe and copper, PEX, or stainless steel in seconds Read more

Viega is the first U.S. manufacturer to make a transition coupling with press technology to join dissimilar materials

Viega continues to find innovative solutions for piping systems with a new line of MegaPress® Transition Couplings that can be used to transition between galvanized or carbon steel pipe and copper, PEX, or stainless steel in seconds. Viega is the first press fitting manufacturer to offer a press coupling of this kind that can be used in commercial, residential, and

industrial applications.

The company will be offering three products available in ½” to 2” sizes:

- Viega MegaPress ZL Bronze IPS to CTS Transition Coupling (Model: 4813.4ZL) – This transition coupling includes a factory-installed EPDM sealing element and is ideal for transitioning between IPS and CTS piping systems, including PEX.

- Viega MegaPress ZL Bronze IPS Transition Coupling (Model(s): 4815ZL and 5915ZL) – These couplings include an option for factory-installed EPDM or FKM sealing elements and are ideal for joining carbon steel to stainless steel or galvanized steel to stainless steel.

All of the Viega MegaPress Transition couplings are made of zero-lead (ZL) bronze that can be used to connect dissimilar metals while reducing the risk of galvanic corrosion. The MegaPress Transition Couplings also feature Smart Connect® technology to quickly detect and resolve unpressed connections.

The couplings with EPDM sealing elements carry an NSF-61 rating for potable water.

”Customers have been asking us for this type of product that uses press technology,” said Will Schneider, Product Manager at Viega. “Up until now, transitioning from one type of pipe to another has been challenging and time-consuming with the use of cumbersome traditional joining methods. Now, our

customers have a quick and secure option to connect dissimilar materials.”

Schneider continued, “These transition couplings allow our residential customers to easily retrofit homes with old galvanized potable water lines. They can now use our IPS x CTS transition coupling on the galvanized pipe and add a ProPress® fitting to the street end, to transition to copper, or a ProPress by

PureFlow® adapter to transition to PEX. They are also available in IPS x IPS models with EPDM or FKM seals, allowing commercial or industrial customers to transition from Carbon or Galvanized Steel to Stainless Steel with ease for a variety of applications.”

Product will be available to order starting in late fall 2024. To learn more about Viega’s transition couplings, visit viega.us/press-transition.

Sellars Absorbent Materials, a Milwaukee-based manufacturer of wipes, absorbents and towel and tissue products, is extending its TOOLBOX® WaterWeave line with the addition of its multipurpose T500 wiper. The light-duty T500 is a solvent resistant and contaminant-free wiper that combines strength, durability and absorbency and can be used for a variety of applications. The versatile Read more

Sellars Absorbent Materials, a Milwaukee-based manufacturer of wipes, absorbents and towel and tissue products, is extending its TOOLBOX® WaterWeave line with the addition of its multipurpose T500 wiper. The light-duty T500 is a solvent resistant and contaminant-free wiper that combines strength, durability and absorbency and can be used for a variety of applications.

The versatile T500 can clean equipment and handle maintenance and repair jobs. The hydro-entangled substrate retains its strength, even when wet, so it can also be used on rough surfaces when wet or dry.

In addition, the WaterWeave T500 is a low linting and latex-free product that can soak up oil and solvents and clean dirt and grime from surfaces without leaving particles behind. Since the wipers are contaminant-free, they are a safer alternative to laundered rental shop towels and cloth rags, which studies show contain residual oils, chemicals and metal shavings.

The white WaterWeave T500 wiper is available in an interfold pop-up box. The WaterWeave line now includes the T500, T600, T700 and T800 that provide light, medium and heavy-duty wipers.

For more information on the TOOLBOX T500 WaterWeave wipers from Sellars, visit sellars.com.

Photo Caption: Sellars is extending its TOOLBOX® WaterWeave line with the addition of the light-duty T500 wiper.

Taco Comfort Solutions’ new Project Builder 2.0 design tool – developed by Taco engineers in close collaboration with sales reps, product managers and HVAC engineers – dramatically increases HVAC system design productivity and accuracy. By design, Project Builder 2.0 helps commercial hydronic engineers and designers to quickly select the right products and assemble all related Read more

Taco Comfort Solutions’ new Project Builder 2.0 design tool – developed by Taco engineers in close collaboration with sales reps, product managers and HVAC engineers – dramatically increases HVAC system design productivity and accuracy. By design, Project Builder 2.0 helps commercial hydronic engineers and designers to quickly select the right products and assemble all related documents into one complete project file.

With all features in one platform portal, its built-in configurator offers a broader, faster and feature-rich means of product sizing and selection, document comparisons and quote development. With one click, all PDFs and Revit files are co-joined in a customized submittal, which can be saved or e-mailed. The dynamic platform offers new, compelling graphics, full customization and avails one-click response from quote recipients.

With the free, cloud-based Project Builder 2.0, there’s no software to download, and the resource is always up to date for real-time collaboration.

Selecting a product in any of the upgraded Taco selection apps automatically opens Project Builder 2.0, where users can choose to add products to an existing project, create a new project, proceed to other product selections, or just browse. Also, engineers and designers can invite other users to share and collaborate on any product selection or configuration.

Project Builder revisions include new navigation with faster access to product information and tools to allow easier analysis and evaluation. The shared goals for Taco’s new website and Project Builder include saving time, improving productivity and ensuring information accuracy.

For more information, visit www.TacoComfort.com

Focused on increasing productivity, cut quality and capacity, Milwaukee introduces the new M12™ Brushless 1-¼”-2” Copper Tubing Cutter. Delivering the fastest, clean cuts, the M12™ Copper Tubing Cutter provides high performance without sacrificing quality and automatically adjusts diameter to cut Type K, L, and M copper pipes from 1-3/8 ” to 2-1/8” (OD). Eliminating the Read more

Focused on increasing productivity, cut quality and capacity, Milwaukee introduces the new M12™ Brushless 1-¼”-2” Copper Tubing Cutter. Delivering the fastest, clean cuts, the M12™ Copper Tubing Cutter provides high performance without sacrificing quality and automatically adjusts diameter to cut Type K, L, and M copper pipes from 1-3/8 ” to 2-1/8” (OD).

Eliminating the need for manual cutting and reducing user fatigue, the M12™ Brushless Copper Tubing Cutter delivers over 100 cuts on a singular charge from a Milwaukee XC 4.0 battery. Featuring a rotating head, the copper tubing cutter allows for faster cut speeds and superior access with as little as 1.7” clearance. The inline design allows for better balance and control for one-handed operation.

Producing quality, square cuts, the M12™ Brushless Copper Tubing Cutter benefits productivity by reducing the amount to deburr. Paired with a patented cutting mechanism, the copper tubing cutter is the first battery powered tool with the capacity to cut up to 2” copper pipes. The built-in LED light and view window illuminate the line of cut for better visibility when working in confined spaces.

The new M12™ Brushless Copper Tubing Cutter joins the M12™ Cordless System, the largest sub-compact system on the market, focused on delivering industry-leading durability and the ability to complete applications in the tightest spaces. Currently, the M12™ System is made up of more than 150 solutions.

Specifications

M12™ Brushless 1-1/4″ – 2″ Copper Tubing Cutter (2479-20)- $399

- Pipe Capacity: 1-¼”- 2”

- Pipe Types: K, L, and M Copper

- Blade Material: Steel

- Maximum Cutting Diameter: 2”

- Maximum RPM: 325

- Minimum Cutting Diameter: 1.25”

- 5 Year Tool Warranty