Nestled in the beautiful rolling hills of Northern Lancaster County sits a beautiful, spacious house that was confronted with a very nasty problem. The homeowners were facing uncomfortable temperatures in both the heating and cooling seasons. The summers here can become hot and humid and the winters at times can be brutal with chilling winds Read more

Heating & Cooling

Nestled in the beautiful rolling hills of Northern Lancaster County sits a beautiful, spacious house that was confronted with a very nasty problem. The homeowners were facing uncomfortable temperatures in both the heating and cooling seasons. The summers here can become hot and humid and the winters at times can be brutal with chilling winds and abusively cold temperatures. Thomas Soukup, Patriot Water Heater Co., Kirkwood, Pa., was contacted by the homeowner to come in and investigate these issues and come up with a custom solution to alleviate these pain points.

The Situation

Right off the bat, Soukup was presented with end-of-life, direct expansion, refrigerant-based heat pumps. With the tremendous amount of electric backup heat, the customer experienced bills exceeding one thousand dollars a month. The three-story house is 4500 sq. ft. of an open floor plan, contemporary design.

Anyone who has dealt with these types of homes before knows that when dealing with open staircases it creates a very efficient pathway for the conditioned air to go where it does not belong. All the hot air from the lower rooms chimneys upstairs when you do not need it to and vice versa with the cool air. This creates many challenges in creating a space that is comfortable. Also, to top it off, the house has many windows which creates tremendous solar gain and air infiltration.

Pinpoint zoning and control in the different living areas becomes a headache. In the winter months, homeowners could wear tropical clothing on the third floor but need a snow suit on when on the main floor. Obviously, the customer wanted this problem rectified.

The Design

The Design

First step was the math. Soukup provided a heat loss and heat gain calculation. The calculations were performed on a granular basis: doing the math on a per room basis. Measurements were taken of the available duct work and registers to figure out if they would be able to provide the correct amount of heating and cooling.

Soukup sat down with the customer and figured out how the house was originally zoned with three separate air handlers. Each handler was controlling multiple areas across different floors and the layout was scattered and improperly designed. It also was clearly not the most efficient way of zoning out the structure.

A kitchen and solarium remodel were in planning stage at the time of the calculations. Soukup learned that all the current ductwork on the registers were going to be covered by cabinetry. For the remodeled solarium and cabinet design, there would be no way to add additional ductwork to handle the load. Other solutions would need to be considered due to this.

The customer also brought to my attention in the planning phase of our project that their pool heater had failed, and swimming was a very important part of their daily regimen. While this slightly altered the design somewhat, it did cement the idea that a high-efficiency hydronic system was by far the best solution for both the heating and the cooling.

The Solution

The Solution

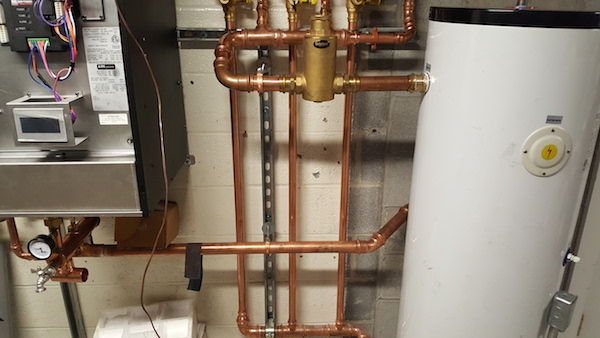

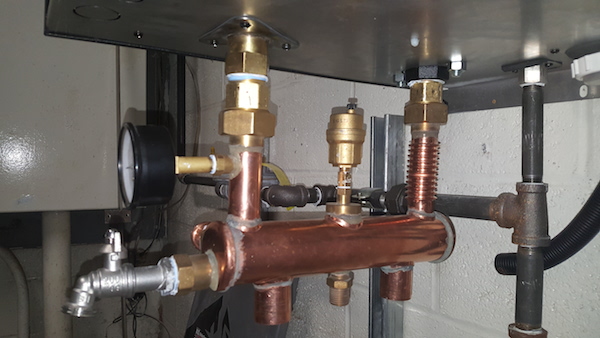

Soukup chose a reverse cycle chiller for cooling and heating. Also installed was a mod-con boiler for the higher heating demands. One of the unique challenges was being able to run the chillers in cooling mode while running the mod-con boiler in heating mode to heat the pool and domestic hot water. A point of demarcation was created to separate the cooling system and the heating system. That was done with a buffer tank that the chillers were piped into and off that tank the circulator pumps were piped for the heating and cooling zones.

This also gave the advantage that when the chillers were used in heating mode and not able to keep up with demand, the boiler would provide that supplemental heat to the buffer tank. This was done with careful hydronic design and strategic placement of pumps.

In the solarium, due to the remodel, additional heating and cooling needed to be added to accommodate the new layout. A hydronic high-wall emitter was installed on the wall in an inconspicuous location where the kitchen met the solarium in a large opening. That gave that pinpoint cooling and heating needed and gave the customer the ability to control the level of comfort at will.

Additional air flow was needed to the bedroom side of the house as well as the master bedroom on the third floor. To make this a non-invasive install and to reuse as much of the previously installed ductwork, the decision was made to block off the vents in the lowest portion of that zone (an exercise room). Since that lowest room had the lowest requirements another hydronic high-wall emitter in that area. This opened the air flow to go to the critical rooms.

Additional air flow was needed to the bedroom side of the house as well as the master bedroom on the third floor. To make this a non-invasive install and to reuse as much of the previously installed ductwork, the decision was made to block off the vents in the lowest portion of that zone (an exercise room). Since that lowest room had the lowest requirements another hydronic high-wall emitter in that area. This opened the air flow to go to the critical rooms.

This was a perfect solution to go with ECM pumps and Soukup chose Grundfos Alpha2 ΔP. This created the opportunity to use less pumps and get the flow where it was needed, when it was needed.

Spacepak Chiller Control was installed to allow for the switch between heating and cooling based on thermostat demand. It also allowed to bring the boiler online to satisfy additional demand based on the outdoor temperature.

This is where the math is critical. Based on the loss calculations and the EDR (equivalent direction radiation) it allows it to know at what point additional water temperature was needed to satisfy the demand. This situation required 40-degree outdoor temperature for the boiler to come online and the chillers to go offline. Soukup arrived at this by looking at the temperature curves of the chillers based on the ambient outdoor temperature. The boiler was set up on an outdoor reset curve as well.

The Result

The Result

As a professional in the industry, when Soukup is presented with unique situations, he looks outside of the box to provide custom solutions. A large focus is put on looking at a problem analytically: marrying mathematics with proper products and equipment. Even if he’s used a product before and trust it, he always makes sure to study the manufacturer specs to know its strengths, weaknesses and what other auxiliary systems he needs to make it operate at peak efficiency.

The customer was satisfied and happy. Soukup walked away knowing he had taken the time to listen to their needs, see where the previous system had failed and give them something flexible and reliable, they could enjoy year after year. No matter how hot the summer, or how biting the winter they now have what everyone deserves. Comfort in their homes.

Information was provided by Thomas Soukup, Patriot Water Heater Co. Please visit www.patriotwaterheater.com.

While hydronic system growth across most of the country is slow, Metro Detroit is seeing a bit of a water-side resurgence, at least in certain segments. And it’s appearing where people are demanding the best. “We’re installing more boiler systems now than ever before,” said Joe Sullivan, president of Paradigm Plumbing & Mechanical, Inc. “We’re Read more

While hydronic system growth across most of the country is slow, Metro Detroit is seeing a bit of a water-side resurgence, at least in certain segments. And it’s appearing where people are demanding the best.

“We’re installing more boiler systems now than ever before,” said Joe Sullivan, president of Paradigm Plumbing & Mechanical, Inc. “We’re gaining market share, but the market is growing, too. Homeowners are demanding premium comfort with more regularity, and as a result, builders and architects are pushing hydronics. It’s the obvious answer.”

Paradigm Plumbing & Mechanical, Inc.’s niche is high-end new construction in the Detroit metro. During assembly of this mechanical room, the Aspen and Aspen Light Commercial boilers were installed early in the game.

Paradigm’s niche is high-end new construction. They call themselves a builder-based company. Founded 10 years ago, the ten-person company works exclusively for five or six general contractors. Radiant systems are common, and so are homes that require three or four different water temperatures.

“Our system designs might be a bit different that the competition, but we have a specific way we like to do things,” explained Sullivan. “Our market also allows us to install the best equipment available. We cut no corners. Comfort and reliability are the primary goals, and efficiency is close behind.”

Long timelines

Large custom homes are essentially small commercial projects. Paradigm’s involvement at a single residence can easily span two years, from design to start-up. They’ve partnered with rep HS Buy Van, and buy equipment through Hartsig Supply.

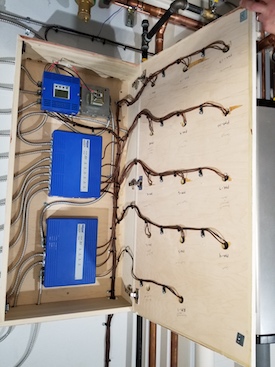

“HS Buy Van works on our piping and loop layouts,” said Greg Sharer, project manager and hydronic specialist at Paradigm. “With their help, we begin projects with a full MEP set. All of our electric and controls are done in-house.”

The 205 MBH Aspen boiler heats the home and provides DHW, while the 399 MBH Aspen Light Commercial provides heat for a snowmelt system.

Nearly a year ago, Paradigm started a new project with Eric Vogler on a 7,500-sq.-ft. residence in Orchard Lake, Mich., and they’ll be wrapping it up just before heating season this year.

Paradigm designed two separate hydronic systems for the home: one for in-floor radiant and DHW using a 205 MBH Aspen, and one for the snowmelt system, with heat provided by a 399 MBH Aspen Light Commercial. The home has a furnace in addition to radiant tubing throughout the floorplan, and a full tekmar control system.

https://youtu.be/u7RXZImuBOI

“Customers who’ve never experienced a well-designed radiant heating system are blown away when the first heating season rolls around,” said Sharer. “Every surface in the home is warm to the touch, even the countertops.”

Piped right

In the boiler room, mechanical components cover an entire 16-foot wall. The high-efficiency Aspen boilers are mounted next to an array of copper pipe and circulators.

“HS Buy Van recently changed hi-efficiency boiler brands, so when they picked up the US Boiler line, we gave the Aspen a close look,” said Sharer. “We still had access to our previous brand, but the appearance and the design of the Aspen are great, so we bought two for this project. They’ve proven easy to install, and we really like firetube heat exchangers.”

Paradigm is known for their meticulous installation of piping, pumps and controls.

The Aspen boiler offers up to 96% AFUE, comes in five sizes, and is available as a 155 MBH combi. The Aspen LC comes in two sizes and can be floor- or wall- mounted. Both units feature Sage2.3 controls and have a 10:1 turndown ratio.

The rest of the mechanical room is occupied by a 120-gallon Burnham Alliance SL tank, beautiful copper piping, a Caleffi hydro-separator and mixing valves, and numerous Grundfos circulators.

“Greg does phenomenal work,” said Sullivan. “He and I really love hydronics. We handle most of the boiler systems – which make up about 40 percent of our work – while the rest of the crew covers controls, electronics, plumbing and air-side.”

The system for the big custom home was built onsite, but Sharer and Sullivan often prefabricate systems at the company’s 5,000 square foot shop.

“Most of our manifolds are remote,” said Sharer. “We do this to keep loop lengths short, usually no more than 250 feet. And, despite what some people may think, we prefer to zone with pumps instead of zone valves. This offers a great deal of redundancy, but also makes balancing simple, as well as diagnosing issues after the fact.”

Half-inch Uponor PEX was used for the 12 zones of radiant, laid at six-inch centers. Most of the tubing is under tile, set in Portland cement. Plenty of care was taken to protect the tubing during construction, and the same attention to detail was given to the tubing outside.

Let it snow, just not yet

While high-end residential hydronics is an area of growth for Paradigm, so is one of its subcategories. The company has earned a reputation in the Detroit area as being a snowmelt specialist. Annual snowfall in the area is often between 45 and 100 inches.

The home and snowmelt system are served by a full tekmar control system.

“There are plenty of wrong ways to install hydronic snowmelt systems, and a few ways to do it correctly,” said Sharer, who has been with the company for six years. “Over the years we’ve developed a method of designing, selling and installing these systems. All our systems operate as they should and offer great benefits to the owner. We’ve crunched the numbers thoroughly enough to give the perspective customer an accurate projection of operation expenses.”

The Paradigm snowmelt method includes years of experience, but there are a few rules of thumb they adhere to, some of which are universally accepted as best practice by the hydronic community, and some that aren’t.

“Maintaining proper loop length is one thing we’re careful about while installing tubing, and most everyone agrees on that,” said Sharer. “But our insistence on using individual pumps on all the zones in a snowmelt system is one that sometimes draws scrutiny. We have our reasons.”

“In the past, public opinion of snowmelt systems was that you had to be Bill Gates to own or operate one,” said Sullivan. “With the right design, piping, and control strategy, it can be cheaper to operate than most folks think.”

Sullivan admits that snowmelt systems are absolutely a luxury item, but clients still want to know what it’ll cost to run the system in addition to what it’ll cost to install. Of course, there’s a financial return on investment by offsetting salt and snow removal costs, but the true payoff is harder to quantify. Safety and convenience are difficult to assign dollar figures to.

The Aspen Light commercial was installed in early March, but the driveway work needed to wait several months until the weather improved. The two-zone snowmelt system included the concrete driveway and a paver walkway.

“High-end residential has been great for us, but we’re working on becoming more competitive, moving into lower-cost markets with hydronics,” said Sullivan. “It’s a slow transition, because we’re figuring out how to do that by eliminating a few bells and whistles without sacrificing any quality. It’s a marketing challenge as much as anything.”

But where there’s a will, Paradigm finds a way. They’ve proven this through their application of uncompromising hydronic system quality.

When Delta Electronics (Americas) expanded its headquarters in Fremont, Calif., they leaned on the company’s brand spirit: “Smarter. Greener. Together.” Founded in 1971, Delta’s mission is “To provide innovative, clean and energy-efficient solutions for a better tomorrow,” and the headquarters is a shining example of creative thinking paired with a desire to protect the environment Read more

When Delta Electronics (Americas) expanded its headquarters in Fremont, Calif., they leaned on the company’s brand spirit: “Smarter. Greener. Together.” Founded in 1971, Delta’s mission is “To provide innovative, clean and energy-efficient solutions for a better tomorrow,” and the headquarters is a shining example of creative thinking paired with a desire to protect the environment. The company takes advantage of the latest in advanced energy-efficient research and product development, and the American headquarters is their 13th green building worldwide.

To help meet the LEED Platinum and net-zero energy building standards, the company chose to go with a radiant heating and cooling system from Uponor. Originally specified for a conventional radiant tubing installation, the mechanical contractor, ACCO Engineered Systems, a contracting firm with locations throughout California, suggested changing the specification to Uponor’s Radiant Rollout Mats for a faster, more efficient and consistent installation. ACCO had recently completed several large commercial projects using the mats, including the Pier 15 Exploratorium in San Francisco and SMUD (Sacramento Municipal Utility District) building.

ACCO, in conjunction with Sean Timmons at Timmons Design Engineers—now ALFATECH-Timmons—and Osborne Company—an Uponor rep firm—designed the radiant heating and cooling system using the mats for the 178,000-square-foot campus that includes a 38,000-square-foot warehouse. The radiant slabs are the primary cooling and heating systems in the campus buildings so it was crucial for the design to ensure comfort as well as the desired energy efficiencies.

Due to their previous experience with the Radiant Rollout Mats, ACCO spent a considerable amount of time up front designing the slab construction, the sequence of the slab construction and how the mats would be fabricated to align with the installation thought process. “We eliminated a lot of potential problems up front – lessons that we learned on other projects,” said Jonathan Bell, ACCO project manager.

It took five months for three dedicated crew members plus one runner to install 138,000 feet of tubing with the Radiant Rollout Mats. It would have taken much more time—and labor—to install the tubing using conventional PEX rails or tie-down methods.

The installers needed a bit of onsite training to get up to speed, and the first couple of circuits went in a little slower while Osborne Company helped demonstrate efficiencies and effective ways to speed up the installation. “But it didn’t take long for the crew to have a full understanding of the processes, and they quickly picked up the pace for the rest of the installation,” Bell said.

The installers needed a bit of onsite training to get up to speed, and the first couple of circuits went in a little slower while Osborne Company helped demonstrate efficiencies and effective ways to speed up the installation. “But it didn’t take long for the crew to have a full understanding of the processes, and they quickly picked up the pace for the rest of the installation,” Bell said.

As with any project, there are challenges to overcome in buildings of this magnitude. “Having to accommodate physical building changes that occurred after we had procured the material was one of the challenges we had to work with,” Bell said. “And construction delays threatened to leave the tubing exposed to the sun for longer periods of time than we had anticipated. We had to do some quick thinking to make sure the tubing was protected from possible prolonged sun damage.”

Osborne, the Uponor rep firm, became an instrumental strategic partner in helping overcome and solve these unique challenges, and Bell is pleased with the process, the solutions and how quickly the crew installed the Radiant Rollout Mats.

“For large, open circuits, the installation of the Radiant Rollout Mats is much quicker than laying down regular tubing,” he said. “And the prefabricated and labelled mats allows for more efficient material handling onsite, which is very important in these large installations.”

Our complimentary educational series, Coffee with Caleffi™, is an online technical training webinar and is intended for contractors, designers and wholesalers. What’s next? Maintaining High Fluid Quality in Modern Hydronic Systems (Part 2) Thursday, April 27 12 noon – 1:00pm CDT Fluid problems can cause loss of efficiency, comfort fall-off and/or premature equipment failure. This Read more

Our complimentary educational series, Coffee with Caleffi™, is an online technical training webinar and is intended for contractors, designers and wholesalers.

What’s next?

Maintaining High Fluid Quality in Modern Hydronic Systems (Part 2)

Thursday, April 27

12 noon – 1:00pm CDT

Fluid problems can cause loss of efficiency, comfort fall-off and/or premature equipment failure. This webinar picks up where Part 1 left off (refer to: Maintaining High Fluid Quality, February 2017 in our online archive). Bob “Hot Rod” Rohr, our training and education manager, will focus on glycol systems, sediment formation and fluid quality measurement instruments. You’ll learn:

→ Is municipally treated water good enough for my system?

→ What can cause glycol to degrade over time?

→ Is using only the minimum glycol needed for freeze protection the only factor to consider?

→ Why is the TDS reading of a glycol fluid a meaningless value?

→ Does a pH value within the glycol manufacturer’s acceptable range ensure freeze protection?

→ Low hardness but high TDS. Is my fill water good?

→ My system water is slightly grey. I’m good right?

→ What are some potential mistakes in measuring pH, TDS, hardness or freeze point?

For over 30 years Hot Rod has installed plumbing, radiant heat and renewable energy jobs. As a regular contributor for several industry publications, he puts his rubber-to-the-road experiences to pen. A familiar and favorite speaker at our Coffee with Caleffi webinars, he is sure to delight with his expertise and quick wit.

A Certificate of Participation is emailed to all attendees following the webinar.

All Coffee with Caleffi webinars are free, but registration is required. After registering, you will be immediately forwarded a confirming email containing login details for attending the webinar. When training time comes, grab a coffee, tune in and learn more about Caleffi’s innovative products and how they can add value to your work.

Energy-efficient, reliable, space-saving unit features leading-edge condensing technology for residential applications Burr Ridge, Ill. – Weil-McLain® introduces the new AquaBalance™ combination boiler featuring leading-edge hydronic technology for smaller space residential applications. The state-of-the-art unit combines the warmth of high-efficiency space heating and the convenience of on-demand domestic hot water in a reliable, space-saving, easy-to-install package Read more

Energy-efficient, reliable, space-saving unit features leading-edge

condensing technology for residential applications

Burr Ridge, Ill. – Weil-McLain® introduces the new AquaBalance™ combination boiler featuring leading-edge hydronic technology for smaller space residential applications. The state-of-the-art unit combines the warmth of high-efficiency space heating and the convenience of on-demand domestic hot water in a reliable, space-saving, easy-to-install package.

With a capacity of 155,000 BTUH input, the AquaBalance combi-boiler produces a constant supply of hot water with up to four gallons per minute (GPM) at 70 degrees F. temperature rise.

Featuring 94.4% AFUE energy efficiency, and the industry’s latest stainless steel, titanium-infused heat exchanger technology, the AquaBalance is ENERGY STAR®-rated to deliver maximum operational cost savings to homeowners and provide qualification for local utility rebates, if available.

The unit is ideal for retrofits or new construction in single-family homes, apartments or condominiums.

“The AquaBalance has a wide range of advanced features to deliver energy efficient, worry-free space heat and domestic hot water in a sleek, compact design that’s small enough to fit in a closet,” said Mike Boyd, product manager with Weil-McLain. “The unit’s high-efficiency condensing technology has the power to supply hydronic heat for up to a 2,500 square-foot home and enough hot water to run two showers and a dishwasher simultaneously.”

The combination boiler features an aesthetically pleasing design and simple, user-friendly controls to make installation and operation easy for contractors and homeowners.

“The AquaBalance unit also streamlines the installation process as it eliminates the need to hook up a separate boiler and hot water tank,” said Boyd. “Fewer pipes and less connection points translate into reduced set up time and a more efficient installation.”

Other features of the AquaBalance include:

· Low NOx rated – low emissions level achieved South Coast certification

· Proven Honeywell® boiler controls with digital display

· Unique 3-in-1 vent adapter approved to accept PVC, CPVC, stainless steel or polypropylene vent materials

· Easy electrical connection points and plug in cord

· Heavy gauge insulated jacket for quiet operation

· Removable sides for easy service

· Available as natural gas or propane (LP) gas operation with conversion kit

The AquaBalance joins the Weil-McLain family of boilers that includes the industry’s widest selection of high-efficiency gas and oil-fired boilers for residential and commercial needs.

To learn more about the AquaBalance boiler, visit http://www.AquaBalanceboiler.com or contact a Weil-McLain regional sales office at www.weil-mclain.com/en/weil-mclain/about-us/locations/.