https://youtu.be/G6oOo1OBQDw Mechanical Hub is proud to present its continuing Onsite Video Series. In this video, we feature Jason Ridgeway, owner of Ridgeway Home Services, as he talks about this 24,000-sq.-ft. custom residential geo/radiant project, which features Caleffi products Read more

Hydronics

Mechanical Hub is proud to present its continuing Onsite Video Series. In this video, we feature Jason Ridgeway, owner of Ridgeway Home Services, as he talks about this 24,000-sq.-ft. custom residential geo/radiant project, which features Caleffi products.

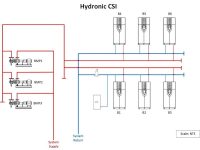

Mechanical Hub and Lochinvar are proud to team up to bring you the second feature in our Hydronics CSI series. Hub friend Paul Rohrs, design and application specialist for Lochinvar, has produced a hydronics design with intentional flaws in it. There are multiple mistakes with this diagram and it is up to you to Read more

Mechanical Hub and Lochinvar are proud to team up to bring you the second feature in our Hydronics CSI series. Hub friend Paul Rohrs, design and application specialist for Lochinvar, has produced a hydronics design with intentional flaws in it. There are multiple mistakes with this diagram and it is up to you to use your hydronics knowledge to figure out what they are.

PROBLEM

This was to be a Full Flow/Variable Primary System. Problem with current boiler piping: New install with six boilers, three boilers on one housekeeping pad, three boilers on another housekeeping pad that is across from it. Find all flow related and other potential issues.

The contestants who come closest to the answers will be put into a drawing to win a jacket from Lochinvar.

Good luck!

Recently, Toronto has had more high-rise construction projects underway than any other North American city. Last year alone, according to Canadian media, there were 130 high-rise buildings in progress. In the first quarter of 2015, the trend seems to continue. So it’s no surprise that Toronto’s suburbs are alive with the sounds of saws and Read more

Recently, Toronto has had more high-rise construction projects underway than any other North American city. Last year alone, according to Canadian media, there were 130 high-rise buildings in progress. In the first quarter of 2015, the trend seems to continue.

So it’s no surprise that Toronto’s suburbs are alive with the sounds of saws and pounding hammers. Within a half-hour drive from the heart of Toronto, custom home construction remains high.

Tim Rickards (l) and Fernando Valadai, of The Hydronics Group, deliver HDPE pipe and a Triton pipe fusion system.

As residential construction expenditure in Ontario and Quebec have pulled back only slightly since the record high in 2012, the custom home market retains its momentum. Enough so that some companies have made it their focus.

“We started to concentrate on the custom home market about a year ago,” said Bob Williams, VP of Tropical Heating and Air Conditioning. The 14-person firm used to serve a wide range of residential customers in the greater Toronto area — and still does when it comes to service work — but new installations are almost entirely in the half-million plus home market.

Bob Williams, owner and manager of Tropical Heating and Air Conditioning, gets ready to fuse an HDPE join as part of the home’s multi-unit geothermal system.

“Our staff has a wide knowledge base, especially in regard to hydronic applications,” continued Williams. “That specialty allows us to offer a great deal to clients seeking a more complex system, or systems, as is often the case.”

Concrete and complex

Custom work goes hand-in-hand with longer timelines. A project doesn’t need to be in the “starter castle” range to progress gradually, as the professionals at Tropical have learned. This is evident through ongoing work at a 5,000-square-foot modern residence between Toronto and Mississauga. Tropical started the job in 2012.

“This has been an on and off project,” said Williams. “But it includes some elements that stretch out the timeline, from concrete construction to geothermal.”

Adrian Navarette, senior installer for Tropical, uses The Triton pipe fusion system to join HDPE pipe and fittings after they’ve been dry-fitted.

Four ground-source heat pumps draw from 10 vertical bore holes to supply both hydronic and forced air systems. Polished concrete floors throughout the home include 8,600 lineal feet of half-inch Watts Radiant oxygen barrier RadiantPERT tubing. A 175 MBH NTI condensing boiler provides backup heat, DHW and heat for a snowmelt system. In all, 22 zones of radiant heat and three zones of air conditioning come out of two mechanical rooms; the main room downstairs and a smaller room on the second level.

“Space for components is the biggest challenge here,” said Williams. “And running all that pipe and ductwork through a solid concrete structure takes a lot of foresight. You need to use the available space as efficiently as possible.”

Close quarter connections

Geothermal Solutions, the drilling subcontractor, ran all the HDPE tubing from the exchange field to the mechanical room, where Tropical took over. The main flowcenter circulates the water/alcohol solution through the field and into a 26-gallon hydro separator. From here, flowcenters on each of the four heat pumps draw fluid as needed to condition the home. As a result, the room has one-and-a-quarter-inch HDPE pipe running in all directions.

Bob Williams, owner and manager of Tropical Heating and Air Conditioning, dry-fits an HDPE joint before fusing.

“To us, professional appearance is second only to functionality, and that’s hard to maintain with HDPE pipe,” said Williams. “A socket iron fusion system limits you to measuring, cutting and fusing pipe one piece at a time. We really wanted a system that allowed us to dry-fit an entire loop to make sure it’s all square, plumb and level, before fusing any fittings.”

While looking for a solution, Williams spoke with Tim Rickards, at The Hydronics Group, a Toronto-based wholesaler. In addition to supplying most of the equipment on the job, Rickards suggested that Tropical look at the Triton pipe fusion system, which uses radio frequency (RF) electromagnetic technology to fuse pipe instead of a hot iron.

The system is the HVAC industry’s first application of RF technology; a method of welding plastic pipe that’s been trusted in medical and industrial applications for decades. Radio frequency energy is emitted from the system’s portable control unit, and literally “excites” a thin strip of reactive metal that’s molded into each Triton fitting. The material heats up to the point of fusing the pipe and fitting together to form a joint that’s stronger than either the pipe or fitting alone.

With standard socket iron-fusing, two pieces of pipe are individually melted, then pressed together and allowed to cure. The Triton system allows the user to dry fit the pipe and fitting together, position them as desired, then simply clamp the tool around the fitting to complete the weld — with no risk of burns.

“The system really allowed us to tidy up the geothermal piping,” said Williams. “But it also cut our labor hours down. For example, while a technician is fusing one line, he can be simultaneously dry fitting the next one.”

Overload

According to Williams, Toronto’s geothermal installations are few and far between, as a result of small lot sizes. “Most of the geothermal work in Ontario is in more rural areas, where bigger yards are conducive to drilling or trenching exchange fields.”

At the concrete home, there was room enough in the yard to drill 10 bore holes, for a total 10-tons of geothermal exchange. But, the heat pumps in the home total 16 tons. As a result, BK Consulting Engineers — with input from Rickards and others at The Hydronics Group — designed a flexible system that overcomes the challenge.

The home’s main mechanical room includes three geothermal heat pumps; water-to-air units of two and four tons, and a six-ton water-to-water unit for the home’s extensive radiant floor system. An additional, four-ton water-to-air unit is on the home’s second story.

(L-R) Bob Williams of Tropical Heating and Air Conditioning, Tim Rickards of the Hydronics Group, and Mike Breault, Watts product manager HVAC Canada, look at building blueprints.

“We’re able to accommodate more installed capacity than the exchange field can supply based on two factors,” said Rickards. “First, the home is rarely, if ever, going to call for maximum input from all four units at once. Also, the condensing boiler is backup for the radiant system, which handles the brunt of the heating demand.”

To avoid getting what geothermal specialists call a “cold field” — where the exchange field becomes depleted of energy to the point that it can’t produce enough heat for the structure – the incoming water temperature is monitored. An aquistat on the main line into the mechanical room is programmed to shut off the water-to-water unit if dips below 32°F. At this point, the natural gas boiler supplies heat to the radiant system as well as an 80-gallon DHW tank and 1,200 square feet of driveway snowmelt.

In the summer, with the smaller cooling load and the water-to-water unit out of service, there’s no concern of overtaxing the exchange field’s ability to reject heat into the ground. While the home’s design heat load is 150,000 BTU, the cooling load is only 75,000.

“What this design does,” explained Rickards, “is cut down on exchange field expense, while using it to its full capacity without ever having to worry about overdrawing it.”

Double duty radiant

Each room in the home is an independent heating zone. Radiant tubing was installed on nine-inch centers, except where exterior walls consist of large expanses of glass. Here, six-inch centers were used on the perimeter.

“Right now, the system is supplying 100°F water to the radiant loops,” said Williams. “Once the home is occupied, that’ll fluctuate depending on the desired indoor temperature and outdoor ambient temperature.”

The owner also wanted the option to use the radiant system for cooling. The way the air conditioning system is designed, the water temperature in the slab can be dropped to 70°F without risking condensation on the floors.

“We’re able to focus on the custom home market because we can offer unique solutions,” said Williams. “And that’s a result of experience, relationships with other professionals, and a willingness to adapt to emerging technologies and practices.”

When most people think of radiant heat or hydronic snow melt, the usual applications come to mind: warm floors, heated sidewalks and snow-free driveways. The Big Bear Area Regional Wastewater Agency (BBARWA) in Big Bear, Calif., contacted Viega Radiant Design Services with a project that needed an innovative solution. A byproduct of the water treatment Read more

When most people think of radiant heat or hydronic snow melt, the usual applications come to mind: warm floors, heated sidewalks and snow-free driveways. The Big Bear Area Regional Wastewater Agency (BBARWA) in Big Bear, Calif., contacted Viega Radiant Design Services with a project that needed an innovative solution. A byproduct of the water treatment process is sludge which must be hauled by a truck to an off-site disposal area. BBARWA needed to reduce the water content and weight of the sludge, making it less expensive to haul. BBARWA tried several different methods to dry the sludge with only marginal success, so they decided to devise a new system that would be more effective, more efficient and would reduce the odor complaints.

Viega Radiant Design Services worked on the specifics of the slab-heating system design, focusing on what would be required to generate enough heat from the slab to meet the sludge-drying objectives. Viega design engineers used finite element analysis (FEA) to determine the optimum tubing size, spacing and install-depth in the slab based on the water temperature supplied from the diesel generator’s exhaust. Due to the shape and size of the 315- by 60-foot heated slab, it was clear that this project was an excellent application for Viega’s revolutionary Viega Climate Mat® system.

Within the first year alone, the new system saved approximately $200,000 in transportation and fuel costs. Additionally, the project received the California Water Association Desert Mountain Award for Innovation.

For more information on Viega system solutions, visit Viega.us.

BOSCH THERMOTECHNOLOGY INTRODUCES FLOOR STANDING MODEL WITH AFUE 95% RATED EFFICIENCY Bosch Thermotechnology’s Greenstar gas condensing boiler for residential applications is now available in a floor standing (FS) version for all eight regular (heat) and combi (heat+hot water) models. With its sleek appliance-like design and small footprint, Greenstar FS models are ideal for use in Read more

BOSCH THERMOTECHNOLOGY INTRODUCES FLOOR STANDING MODEL WITH AFUE 95% RATED EFFICIENCY

Bosch Thermotechnology’s Greenstar gas condensing boiler for residential applications

is now available in a floor standing (FS) version for all eight regular (heat) and combi

(heat+hot water) models. With its sleek appliance-like design and small footprint,

Greenstar FS models are ideal for use in applications where wall-mounting options are

not available or a floor standing unit is preferred. Greenstar FS boilers are fully

modulating condensing boilers that are CSA and ASME approved and have an

ENERGY STAR Most Efficient rating of 95%. www.boschheatingandcooling.com