Bradford White Water Heaters introduces streamlined product label designed to elevate brand awareness and reinforce message of support for pro contractors and distributors Bradford White Water Heaters, an industry-leading manufacturer of water heaters, boilers and storage tanks, introduces a new primary branding label for the company’s range of storage tanks and tank-style water heaters. “The new label clearly and Read more

Industry News

Bradford White Water Heaters introduces streamlined product label designed to elevate brand awareness and reinforce message of support for pro contractors and distributors

Bradford White Water Heaters, an industry-leading manufacturer of water heaters, boilers and storage tanks, introduces a new primary branding label for the company’s range of storage tanks and tank-style water heaters.

“The new label clearly and consistently communicates the Bradford White Water Heaters brand with customers and elevates brand awareness with end users,” said Neal Heyman, director of marketing for Bradford White Water Heaters. “Our previous labels had been developed at different times and for a variety of applications, and as a result did not offer a consistent presentation of our brand. Now, we’re confident that our label effectively highlights the Bradford White brand and reinforces the message of our commitment to professional installation.”

The new label will be featured across Bradford White Water Heater products as well as all Bradford White technical documents and marketing collateral, including the Bradford White Water Heaters website.

For more information about Bradford White Water Heaters, visit https://www.bradfordwhite.com.

Dynamic training in Seneca Falls offers interactive demonstrations and hands-on learning experience At the forefront of industry training, Goulds Water Technology, a Xylem brand, has released the 2023 third quarter course schedule for its training facility in Seneca Falls, New York. Product, application and troubleshooting courses will be offered from August through the end of Read more

Dynamic training in Seneca Falls offers interactive demonstrations and hands-on learning experience

At the forefront of industry training, Goulds Water Technology, a Xylem brand, has released the 2023 third quarter course schedule for its training facility in Seneca Falls, New York. Product, application and troubleshooting courses will be offered from August through the end of September at the Goulds Water Technology Factory School covering commercial/industrial pumps, residential water systems and wastewater pumping.

Taught by full-time instructors and experienced Xylem staff, courses cover an extensive range of product lines and related systems. In addition to applications, markets, troubleshooting and system components, students will gain hands-on learning through interactive demonstrations of pumps and controls in the lab facility. Most classes also include a tour of Xylem’s manufacturing facility in Auburn, New York.

“Goulds Water Technology Factory School is a fierce advocate of the importance of immersive, hands-on training for industry professionals,” said Tom Stephan, training manager, Goulds Water Technology. “Our interactive sessions allow distributors, dealers and engineers to experiment and troubleshoot various scenarios in a low-risk academic setting, ultimately fostering their success in real-world applications. Our staff is eager to welcome a new class to the Factory School later this summer.”

For more than three decades, Goulds Water Technology Factory School has been a trusted source of knowledge for water industry professionals, offering training on the newest developments in commercial, residential and agricultural applications. In-person sessions held at the Campbell Education Center include modernized classrooms and laboratories equipped with interactive touch boards and flexible configurations, allowing for dynamic demonstrations, as well as digital-forward training activities.

The Goulds Water Technology Factory School is open to distributors, dealers and Original Equipment Manufacturers with at least one year of industry experience.

Q3 2023 Goulds Water Technology Factory School schedule:

- Commercial/Industrial Pump Product & Application School: Aug. 21-24

- Residential Water System Product Application & Troubleshooting School: Sept. 11-14

- Wastewater Pumping Product & Application School: Sept. 25-28

Detailed class descriptions for Factory School courses are available here.

To register for an in-person course, or learn more about Goulds Water Technology learning opportunities, visit the updated website at https://goulds.com/factory-school. For e-learning courses and other virtual training resources, visit https://goulds.com/e-learning.

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers. Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million Read more

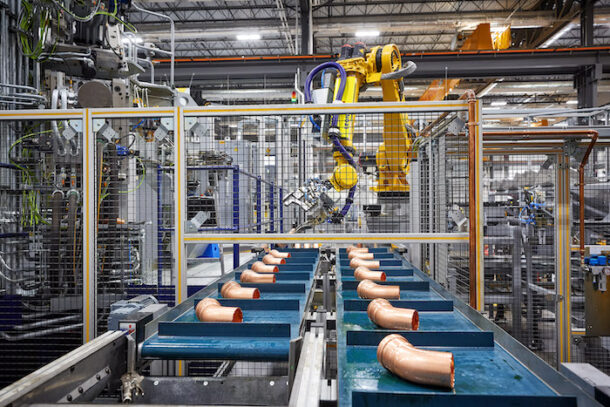

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers.

Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million and will increase the U.S. production of its industry-leading ProPress® products.

“As we continue to grow the business, we are bringing more production to the United States,” said Markus Brettschneider, CEO and President of Viega LLC. “These investments in our U.S. footprint will further support demand and leverage the talented U.S. manufacturing workforce, starting with the expansion of production capacity in Kansas.”

The McPherson manufacturing and distribution center is currently around 1 million sq. ft, with the facility more than doubling its footprint and workforce since opening in 2008. The new ProPress equipment is expected to be in production by the end of Q3 2023, with additional investments to come.

“We are proud to produce our fittings right here in Kansas. As we increase our U.S.-made products, we remain committed to creating highly skilled jobs in America, building out more sustainable manufacturing processes, and developing tomorrow’s workforce,” said Marki Huston, Head of Manufacturing for Viega LLC.

In addition to its McPherson, Kansas facility, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with further North American expansion planned for 2024 and 2025.

Once again, the employees of Uponor North America have placed the company on the Star Tribune Minnesota Top Workplaces list as well as the Top Workplaces USA list. The ranking is based on survey feedback received by Energage, a research company with 17 years of experience assessing more than 27 million employees at 70,000 organizations. Uponor was also awarded three Culture Read more

Once again, the employees of Uponor North America have placed the company on the Star Tribune Minnesota Top Workplaces list as well as the Top Workplaces USA list. The ranking is based on survey feedback received by Energage, a research company with 17 years of experience assessing more than 27 million employees at 70,000 organizations. Uponor was also awarded three Culture Excellence awards focusing on Compensation and Benefits, Innovation, and Work-Life Flexibility.

Once again, the employees of Uponor North America have placed the company on the Star Tribune Minnesota Top Workplaces list as well as the Top Workplaces USA list. The ranking is based on survey feedback received by Energage, a research company with 17 years of experience assessing more than 27 million employees at 70,000 organizations. Uponor was also awarded three Culture Excellence awards focusing on Compensation and Benefits, Innovation, and Work-Life Flexibility.

This is the ninth year Uponor has received a ranking in the top 200 or better. It is also the second year in a row the company has achieved the Top Workplaces USA and Culture Excellence recognitions.

“Being named a top workplace by our employees in the state of Minnesota and also the U.S., and having them recognize our unique People First culture that we all work so hard to maintain, is a testament to the strength of our corporate values that drives how we do business every day,” says Uponor North America President Andres Caballero. “Gaining and retaining top talent in the industry and throughout North America is vital to our success. These recognitions highlight the quality work environment Uponor provides and showcases us as an employer of choice.”

In addition to receiving the Top Workplaces awards, Uponor has also been recognized this year with two Minnesota Governor’s Safety Awards, the David Weekley Homes National Preferred Partner Award, and the Plastics Pipe Institute Project of the Year Award in the Building and Construction Division.

Interplay Learning, the leading provider of immersive training solutions for the skilled trades, announced the launch of its new driving safety training. Designed to address the crucial need for workplace safety among trades companies worldwide, this innovative training can equip employees with the necessary skills to be safe and secure while driving on the job Read more

Interplay Learning, the leading provider of immersive training solutions for the skilled trades, announced the launch of its new driving safety training. Designed to address the crucial need for workplace safety among trades companies worldwide, this innovative training can equip employees with the necessary skills to be safe and secure while driving on the job.

Interplay’s newly introduced driving safety training offers courses tailored to the specific needs of trades companies. Employees will have access to training modules covering critical topics such as Aggressive Driving, Controlling Your Speed, Distracted Driving, Pre-Trip Vehicle Inspections, Vehicle Backing Safety, Vehicle Incident Response, and more. By addressing these key areas, Interplay Learning helps employees drive more safely and confidently, minimizing the risk of accidents and injuries.

Employees can access the driving training from their phone, tablet, or desktop computer, allowing them to learn at their own pace and in their preferred environment. By offering flexible learning options, Interplay Learning sets a new standard for convenient and effective training delivery.

“We’ve learned from our customers that there are more safety incidents to and from the jobsite than on the jobsite. That’s why we are thrilled to introduce our driving safety training for the skilled trades,” said Dan Clapper, HVAC and Facilities Maintenance Market Director at Interplay Learning. “By equipping trades professionals with the necessary knowledge and skills to drive safely, we empower them to succeed both on the job and on the road. With this new offering, Interplay Learning solidifies its position as the go-to resource for comprehensive training solutions for the skilled trades.”

Interplay’s commitment to comprehensive training is further highlighted by its one-stop-shop approach. In addition to driving safety training, Interplay offers an extensive array of hands-on technical training courses, including HVAC, Electrical, Plumbing, Multi-Family, and Facilities Maintenance, as well as other on-the-job safety-related training. By combining safety training with specialized skill development, Interplay Learning ensures that employees receive a holistic training experience to excel in their respective trades.

To learn more about Interplay Learning’s driving safety training and explore their full range of online training solutions, please visit www.interplaylearning.com.