Four Larger Sizes added to New State-of-the-Art Boiler Line Featuring Industry-Leading Efficiency, Ease of Installation and Maintenance Hydronic comfort heating solutions leader Weil-McLain® has added four larger sizes to its advanced, energy efficient Stainless Vertical Firetube (SVF) boiler portfolio to accommodate large commercial applications. The new SVF boiler line has expanded to now include BTU sizes Read more

Product Spotlight

Four Larger Sizes added to New State-of-the-Art Boiler Line Featuring Industry-Leading Efficiency, Ease of Installation and Maintenance

Hydronic comfort heating solutions leader Weil-McLain® has added four larger sizes to its advanced, energy efficient Stainless Vertical Firetube (SVF) boiler portfolio to accommodate large commercial applications. The new SVF boiler line has expanded to now include BTU sizes of 1500, 2000, 2500 and 3000 MBH that join the existing 750, 1000 and 1100 BTU configurations.

The 1500 to 3000 MBH Stainless Vertical Firetube (SVF) boiler line features industry-leading thermal efficiency up to 96.8%, unrivaled ease of installation and maintenance, the intuitive and user-friendly Unity™ control system, and Weil-McLain boiler design reliability and longevity.

“With the addition of these four new sizes, we now have a complete line of SVF products ideal for both small and large commercial projects such as schools, colleges and other educational facilities, municipal buildings, multi-family, healthcare, churches and more,” said John Miller, senior product manager with Weil-McLain. “This design meets all market-driven bid specifications for new construction projects and also is ideal for hybrid applications and replacement boiler needs.”

The SVF line features a stainless-steel vertical fire tube and shell heat exchanger for best-in-class corrosion resistance, a new and bold exterior look, simple, user-friendly controls to make installation and operation easy and a long-term corrosion resistance solution in the form of a serviceable and replaceable condensate tray. With industry leading thermal efficiency performance, the SVF line offers annual operation cost savings and qualification for local utility rebates (where available).

“The SVF boiler line was developed with the contractor in mind and utilized feedback from our installer network to help shape design and functionality,” said John Miller, senior product manager with Weil-McLain. “The result is fire tube performance, perfected. The new SVF showcases the quality, durability, serviceability and innovation that our customers have come to expect from Weil-McLain, and demonstrates our commitment to industry-leading hydronic heating performance.”

Time-saving installation features include an integrated shipping ramp, heavy-duty roller casters for improved maneuverability in confined spaces, industrial-grade leveling legs mitigating the need for a concrete pad, integrated burner in cover plate for minimized 18” overhead space requirement, adjustable control panel height adjustment, and the advanced Unity control set-up wizard. The unit also is zero clearance, side-by-side installation capable to help make the most out of confined boiler room floor space.

“The Unity Controller is designed to reduce installation and set-up time for contractors, simplify boiler system design for specifying engineers, and improve control interface commonality and communication across the entire Weil-McLain high efficiency boiler line,” said Miller.

For ease of service, the SVF features a counter-balanced/hinged cover plate with hatch for quick access to the burner and fire tubes for simple heat exchanger wash-down and no need for additional disassembly. Easy access from the front/back of the boiler requires no side access for regular service intervals and the boiler also features a serviceable and replaceable condensate tray.

Other key features include:

- 70 to 3,000 MBH compatibility throughout the Weil-McLain Evergreen, SlimFit and SVF lines

- 160 psi working pressure

- Natural gas or propane fuel options

- Modbus communication with BACet/Lonworks compatibility

- Ultra-low emissions with SCAMD certification Commercial Energy Star Certification

- Up to 10:1 turn down ratio

- Full line of venting options

The SVF also is ideal for hybrid applications calling for a cast iron boiler complement, and joins the Weil-McLain family of boilers that includes the industry’s widest selection of high-efficiency gas and oil-fired boilers for residential, commercial and institutional needs.

The SVF expanded line became available in August 2019, with all models shipping from the Weil-McLain facility in Eden, North Carolina.

To learn more about the SVF Unity™ boilers, visit www.weil-mclain/svf or contact a Weil-McLain regional sales office.

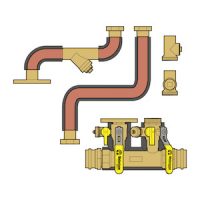

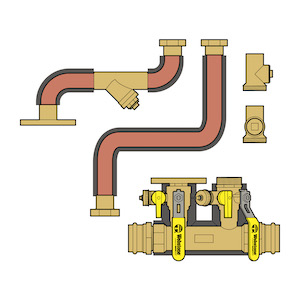

Worcester, Mass. — Webstone, a brand of NIBCO, announces Hydro-Core Complete Near Boiler Piping Kit designed in partnership with Lochinvar for their Noble NKB080, NBK110, and NBK150 boilers. Saves time, space and labor with expert-looking results. Fully-fabricated solution includes everything necessary for a successful installation, including insulated manifold with integrated purge and fill valves, copper Read more

Worcester, Mass. — Webstone, a brand of NIBCO, announces Hydro-Core Complete Near Boiler Piping Kit designed in partnership with Lochinvar for their Noble NKB080, NBK110, and NBK150 boilers. Saves time, space and labor with expert-looking results. Fully-fabricated solution includes everything necessary for a successful installation, including insulated manifold with integrated purge and fill valves, copper supply and return lines, boiler connections, and mesh “y” strainer. Choice of Press, FIP, or SWT manifold.

Worcester, Mass. — Webstone, a brand of NIBCO, announces Hydro-Core Complete Near Boiler Piping Kit designed in partnership with Lochinvar for their Noble NKB080, NBK110, and NBK150 boilers. Saves time, space and labor with expert-looking results. Fully-fabricated solution includes everything necessary for a successful installation, including insulated manifold with integrated purge and fill valves, copper supply and return lines, boiler connections, and mesh “y” strainer. Choice of Press, FIP, or SWT manifold.

Bosch Thermotechnology introduces the next generation of its premium air-source heat pump system – the Inverter Ducted Split (IDS) 2.0 system, offering a 20-plus seasonal energy efficiency ratio (SEER) inverter drive that precisely matches the heating/cooling load for greater efficiency The full IDS 2.0 product range is ENERGY STAR compliant and provides whisper-quiet operation – Read more

Bosch Thermotechnology introduces the next generation of its premium air-source heat pump system – the Inverter Ducted Split (IDS) 2.0 system, offering a 20-plus seasonal energy efficiency ratio (SEER) inverter drive that precisely matches the heating/cooling load for greater efficiency

The full IDS 2.0 product range is ENERGY STAR compliant and provides whisper-quiet operation – as low as 56 decibels. The accompanying air handler includes a two-stage x13 electronically commutated motor (ECM) blower for enhanced humidity control and an all-aluminum coil for superior corrosion resistance.

With a heating seasonal performance rating (HSPF) of 10.5 and heating operation down to temperatures of four degrees below zero, this heat pump yields highly efficient operation, even in cold-climate applications.

“As we continue to expand our air-conditioning portfolio, we’re thinking about what’s important for both our customers and contractors,” said Katie Woodling, product manager at Bosch Thermotechnology. “The IDS 2.0 is a next-level product that has it all: greater efficiency and better performance for customers, and easier serviceability and simplified control board maintenance for contractors.’”

Highlighted features include:

- Premium Efficiency: Up to 20.5 SEER, 10.5 HSPF

- Consistent Comfort: Inverter-driven pumps self-adjust, rather than cycling on and off

- Exceptionally Quiet: Integrated sound dampening, sound levels as low as 56dBA

- Energy Efficient: Full ENERGY STAR compliant product range

The inverter compressor offers 25% to 110% capacity with modulation in 1% increments. The unit’s compact footprint allows for easy installation and is compatible with most standard 24 VAC heat pump thermostats.

The Bosch IDS 2.0 outdoor unit can integrate with Bosch’s 96% AFUE gas furnace and cased coils for an exceptionally efficient dual heating and cooling system.

ALPHA 15-55 HWR-D reduces energy usage by 50% Grundfos Pumps Corporation, a world leader in innovative pump systems, is excited to introduce the ALPHA 15-55 HWR-D on-command pump, the most energy-efficient residential hot water recirculation system available in the United States. The system reduces homeowners’ energy consumption by up to 50%, saves thousands of gallons Read more

ALPHA 15-55 HWR-D reduces energy usage by 50%

Grundfos Pumps Corporation, a world leader in innovative pump systems, is excited to introduce the ALPHA 15-55 HWR-D on-command pump, the most energy-efficient residential hot water recirculation system available in the United States. The system reduces homeowners’ energy consumption by up to 50%, saves thousands of gallons of water per year per household, and meets regulations such as California Energy Commission Title 24 Building Energy Efficiency Standards.

“Reducing water and energy usage has always been a core value and ambition at Grundfos,” said Kirk Vigil, vice president of sales. “We are passionate about helping people live more sustainably and meet stricter standards with the latest innovation in our ALPHA line.”

Key Features and Benefits

- Plug and play design (115V)

- Designed with trusted ECM technology which has been used by Grundfos for more than 17 years

- LED light indicators for pump settings and alarms

- Easy to use push button control settings

- Accessories available for installation flexibility

- All components built by Grundfos

- Bluetooth signal range of up to 300ft (free air)

- Wireless communication, no wiring required

- Suitable for tankless water heater systems

The ALPHA 15-55 HWR-D system’s circulator includes plug-and-pump technology and the trusted Grundfos permanent magnet motor. When hot water is needed, a simple push-button control activates the pump via a Bluetooth signal. The pump then runs for five minutes or until the water entering the piping reaches 102°F, as indicated by an external temperature sensor.

To learn more about the ALPHA 15-55 HWR-D, visit Grundfos.us/hwrd.

Neutra-Safe introduces its new NSP-50 condensate neutralizing pump for improved reliability, ease of installation and service, and space savings in the mechanical room. The NSP-50 combines the functions of two accessories into one; high-efficiency gas appliance condensate neutralization and condensate pumping in one easily-maintained accessory. It is sufficient for appliances with input capacities up to Read more

Neutra-Safe introduces its new NSP-50 condensate neutralizing pump for improved reliability, ease of installation and service, and space savings in the mechanical room.

The NSP-50 combines the functions of two accessories into one; high-efficiency gas appliance condensate neutralization and condensate pumping in one easily-maintained accessory. It is sufficient for appliances with input capacities up to 500,000 BTU/h.

A transparent chamber top is provided for effortless visual inspection of the neutralizing chamber. The cover snaps on and off for easy replacement of neutralization media, which is contained in a disposable fabric sack for quick, simple recharging.

To save labor and material costs where both acidic and non-acidic condensate needs to be disposed of, the unit can accommodate more than one appliance. The NSP-50 features separate inlets for acidic condensate and non-acidic condensate. This allows the installer to use one device in place of two or more where both a gas-fired appliance and air conditioning unit may need to be drained.

The built-in pump is the popular and robust Little Giant VCMA series. This pump is known within the industry for its reliability.

Reducing the number of accessories needed in the mechanical room not only saves space, but also mitigates the risks of product failure, improper installation and negligent service.