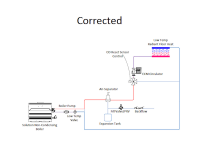

1) The closely spaced tee’s separating the boiler loop from the secondary loop do not isolate the differential pressure from the boiler pump. In short, the boiler pump was in series with the zone pump. 2) The boiler is a non-condensing boiler and the (typical) low-return water temperatures from the radiant floor heat would cause Read more

Radiant Energy Systems

1) The closely spaced tee’s separating the boiler loop from the secondary loop do not isolate the differential pressure from the boiler pump. In short, the boiler pump was in series with the zone pump.

2) The boiler is a non-condensing boiler and the (typical) low-return water temperatures from the radiant floor heat would cause the boiler to condense. Sustained flue gas condensation would over-time cause the heat-exchanger in the boiler to fail and the vent could degrade and allow CO to fill the structure. The LTV (Low Temp Valve) will ensure the water temperature entering the boiler will be 140°F or higher.

3) The boiler will produce temperatures above that of low temperature radiant floor heat requirements. The use of a 3rd party mixing valve to provide outdoor reset will allow the proper mixing. (One of several methods of OD reset mixing)

Lebanon, Tenn. — Lochinvar has announced the second wave of winners in its VIP Contractor Program for the 2014-2015 heating season. Jamie Whitehead of Cooper Plumbing & Heating in Calgary, Alberta, Canada was named the November winner of the VIP Installation Showcase, and Aaron Jazynka of Master Mechanical in Papillion, NE was selected in the Read more

Lebanon, Tenn. — Lochinvar has announced the second wave of winners in its VIP Contractor Program for the 2014-2015 heating season. Jamie Whitehead of Cooper Plumbing & Heating in Calgary, Alberta, Canada was named the November winner of the VIP Installation Showcase, and Aaron Jazynka of Master Mechanical in Papillion, NE was selected in the second monthly VIP drawing. As their prize, both contractors receive an all-expenses-paid trip for two to Nashville, as part of Lochinvar’s renowned Nashville Experience, for the world’s largest country music festival in June 2015.

For the VIP Installation Showcase, which is housed on Lochinvar’s Facebook page as well as on www.knightheatingboiler.com, Whitehead submitted an entry detailing the installation of a KNIGHT® Heating Boiler for a snowmelt system at a custom home in Calgary. The home’s steep driveway demanded a reliable snowmelt system and Whitehead chose the KNIGHT WHN199 model for the job. His entry received numerous votes and was ultimately selected by a panel of Lochinvar judges as November winner.

“I’m thrilled to have won the VIP Installation Showcase,” said Whitehead. “At Cooper Plumbing & Heating, we’re committed to offering our customers top-quality, high-efficiency heating systems. We install many KNIGHT Boilers for snowmelt and heating systems, and it’s an honor to have Lochinvar recognize our work.”

Through April 2015, approved contractors can upload a photo and brief description of any eligible boiler installation to the contest interface. Qualified products include the high-efficiency KNIGHT® (55,000 – 399,000 Btu/hr models), Solution™ and Cadet® Boilers, as well as the Squire® Indirect Water Heater.

Once an entry has been submitted, it is featured in a gallery where Facebook users can vote for their favorite installations. Each month of the Showcase, the top three entries with the most votes are selected as finalists, and a panel of Lochinvar judges chooses the winner.

If an Installation Showcase entry is not named a winner in the month it was registered, there’s still a chance it may win in a later month. While VIP Contractors can only win the Nashville Experience once per year, submissions continue to be eligible to win even after the first month they are entered.

Rewards for Registrations

In addition to Whitehead, Jazynka will be among the VIP Contractors attending the 2015 Nashville Experience. Jazynka was randomly selected in the monthly drawing for approved VIP Contractors. Every approved VIP Contractor is entered into a monthly drawing to win the Nashville Experience. For every qualified boiler registration, VIPs receive a Visa® Reward Card pre-loaded with $25 value. Each registration of the Squire Indirect Water Heater earns a card pre-loaded with $10 value.

“Winning a spot on the Nashville Experience next summer is an exciting surprise,” said Jazynka. “I’ve heard great things about the trip and Lochinvar headquarters, and I look forward to checking it out for myself!”

During the all-expenses-paid trip for two, winners and their guests will stay at Nashville’s Omni Hotel, a short walk from the ultimate experience for any country music fan. As part of the Nashville Experience, the winning VIP Contractors will also tour Lochinvar’s world headquarters and take part in a round-table discussion where they can share insights and information with Lochinvar executives.

For more information about the VIP Contractor Program, visit knightheatingboiler.com.

To repair Calvary Lutheran Church’s heating system — in a two week period of time — it would be necessary to strip out pipe layers, pumps and inefficient compression tanks. With a clean slate, the system was redesigned so that the existing distribution piping and new boilers would work in unison without air or flow Read more

To repair Calvary Lutheran Church’s heating system — in a two week period of time — it would be necessary to strip out pipe layers, pumps and inefficient compression tanks. With a clean slate, the system was redesigned so that the existing distribution piping and new boilers would work in unison without air or flow issues thanks to Caleffi’s superior performance products. Kurt Koegel’s design was the October winning entry in the Caleffi Excellence contest. A HydroCal™ hydraulic separator was used to protect the system from dirt resident in existing pipe. QuickSetter™ balancing valves insure accurate monitoring and balancing. The AutoFill™ filling valve maintains steady system pressure.

Pictured (l) Dave Skindelien (Midwest Sales & Marketing) and Kurt Koegel (Koegel Plumbing & Heating Solutions)

Koegel Plumbing & Heating’s winning entry was determined by most audience votes received during a recently held Coffee with Caleffi™ webinar. Mr. Koegel was presented with an iPad™ mini by Dave Skindelien, Midwest Sales & Marketing, and is now a contender for the grand prize: a trip to Italy to our global headquarters. After 12 months, the grand prize winner will be chosen from the 12 monthly winners by a panel of industry experts and Caleffi executives.

Share your mission possible hydronic and plumbing system design. You could win a trip to Italy! Visit us.caleffiexcellence.com for contest details.

• Annual Energy Use with Geothermal Heat Pumps is 44% Less than with a Variable Refrigerant Flow System Dec. 15 – Definitive scientific research has shown that a geothermal heat pump system offers far more efficiency in a large commercial building than a variable refrigerant flow system. In January 2013, the Geothermal Exchange Organization (GEO)—with Read more

• Annual Energy Use with Geothermal Heat Pumps is 44% Less than with a Variable Refrigerant Flow System

Dec. 15 – Definitive scientific research has shown that a geothermal heat pump system offers far more efficiency in a large commercial building than a variable refrigerant flow system.

In January 2013, the Geothermal Exchange Organization (GEO)—with financial assistance from Southern Company—contracted a research team from Oklahoma State University and Oak Ridge National Laboratory to evaluate the relative performance of GHP vs. VRF heating and cooling systems installed at the American Society of Heating Refrigeration and Air-conditioning Engineers (ASHRAE) International Headquarters Building in Atlanta, GA. (ASHRAE provided data for this study, but the organization does not endorse, recommend or certify any equipment or service used at ASHRAE International Headquarters).

When ASHRAE contracted a major renovation of their two-story, 31,000-sq.-ft. building in 2008, they established a “living lab” to offer the chance to evaluate commercial building energy and sustainability performance. In addition to improvements to its envelope, floor plan and sustainability features such as lighting, the building uses three separate heating, ventilation and air-conditioning (HVAC) systems:

· A variable refrigerant flow (VRF) system for spaces on the first floor;

· A geothermal heat pump (GHP) system, primarily for spaces on the second floor; and,

· A dedicated outdoor air system (DOAS), which supplies fresh air to both floors.

The GEO research team studied the relative performance of the GHP and VRF systems, determining energy consumption of each, and heating and cooling required by the building.

“There’s no question about it – GHPs trump VRF systems for efficiency and cost savings,” said GEO President and CEO Doug Dougherty. “Our study of heating and cooling performance at the ASHRAE Building proves that over a two-year period—with all variables accounted for—energy use by the geothermal system averaged 44% less than the VRF system.”

The first-floor VRF system includes three dedicated split systems and two multi-zone inverter driven heat-recovery units. The multi-zone heat-recovery units are connected to a total of 22 fan coil units (FCUs). Cooling capacity of the heat-recovery units is 28 tons, while the three dedicated systems have an additional 10 tons of capacity. The second-floor GHP system includes 14 individual water-to-air heat pumps (two ¾-ton units, six 2-ton units and six 3-ton units) connected to a ground loop heat exchanger consisting of twelve 400-ft. deep vertical boreholes, for a total of 31.5 tons of cooling capacity.

To facilitate efficiency studies like that performed by GEO, the ASHRAE Building renovation included an array of 1,600 sensors that monitor heating, ventilation and air-conditioning operations and conditions in each building zone.

Historical and current data from these sensors were available to the GEO research team, led by Dr. Jeff Spitler, Regents Professor of Mechanical Engineering at Oklahoma State University. His colleagues Included Dr. Xiaobing Liu, Staff Scientist at Oak Ridge National Laboratory and Laura Southard, Oklahoma State Mechanical Engineering graduate student. Southern Company provided the services of a power engineer to assist with onsite data measurements.

The researchers concentrated on determining actual heating and cooling provided by the GHP and VRF systems; data analysis; and computation of measured and experimental metrics. They collected two years of operational data (July 1, 2011 – June 30, 2013) for the HVAC systems. Data points included operating mode (off/heat/cool); zone temperature; and discharge air temperature for each individual FCU or heat pump. The researchers gathered data on ground loop water supply, return temperatures and flow rates for the geothermal system.

The team also collected metered energy used by each system. For the GHP system, that included power for all 14 heat pumps, as well as the ground loop water circulation pumps. For the VRF system, power is metered and recorded only for the two heat-recovery units and the 22 FCUs connected to them. Power for the three dedicated split systems is metered through a different panel that also includes power used for computer servers and other equipment. All such differences were taken into account for comparison.

“Though the energy consumed by each system is affected by several factors—including floor space; heating and cooling loads; control strategies; and operating conditions/efficiencies—the efficiency implications of each system are clear,” said Spitler. “Raw data show that the VRF system used twice as much energy as the geothermal system during the two-year study period.”

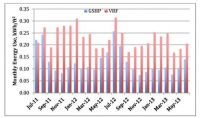

Total monthly energy use by each HVAC system

The areas served by the GHP and VRF systems have different heating and cooling loads, so the research team estimated the loads provided by each based upon individual unit air flows. The graph below shows that when differences in floor space were normalized, energy use (kWh/sq. ft.) by the GHP system was an average 44% less than the VRF system.

Normalized monthly energy use per square foot

“During the two-year study period, the GHP system used 29% less energy in the summer and 63% less energy in the winter/shoulder seasons than the VRF system, while maintaining similar zone temperatures,” said Spitler.

“The underlying difference between the geothermal system and the air-source VRF system lays in the heat sink and source—ground vs. ambient air,” Spitler explained. “Though the control strategy for the VRF system resulted in longer runtimes compared to the geothermal system, it is clear that ground loop water supply temperatures were more favorable than ambient air temperatures for heat pump operation. This allows the geothermal equipment to operate at higher efficiencies.”

“Final Report, Performance of the HVAC Systems at the ASHRAE Headquarters Building” is available at the GEO website, here. Two peer-reviewed articles by Spitler et al. describing the project and its results were published this year in the ASHRAE Journal (September and December2014 issues). The articles can be accessed online at the ASHRAE website, here, and here. GEO will offer a free webinar about the research in early February 2015. (Editor’s Note: ASHRAE stipulates that anyone publishing links to their Journal articles include the following statement: “Use of the data published in ASHRAE Journal regarding performance of ASHRAE International Headquarters may not state nor imply that ASHRAE has endorsed, recommended, or certified any equipment or service used at ASHRAE International Headquarters.”)

Mechanical Hub and Lochinvar are proud to team up to bring you a new feature called “Hydronics CSI.” Hub friend Paul Rohrs, design and application specialist for Lochinvar, has produced a hydronics design with intentional flaws in it. There are multiple mistakes with this diagram and it is up to you to use your hydronics Read more

Mechanical Hub and Lochinvar are proud to team up to bring you a new feature called “Hydronics CSI.” Hub friend Paul Rohrs, design and application specialist for Lochinvar, has produced a hydronics design with intentional flaws in it. There are multiple mistakes with this diagram and it is up to you to use your hydronics knowledge to figure out what they are.

The contestants who come closest to the answers will be put into a drawing to win a jacket from Lochinvar.

The above is our first installment. Good luck!