The NEW Model 7899 Gas Sniffer from E Instruments is a portable, rugged & VERY easy-to-use leak detection tool ideal for any industrial or HVAC Professional. The 7899 is equipped with a highly sensitive tip to Pin-Point small leaks of any Combustible gases & Hydrocarbons from piping and/or appliances. (Natural Gas, Methane, Propane, Butane, LPG Read more

Toolbox

The NEW Model 7899 Gas Sniffer from E Instruments is a portable, rugged & VERY easy-to-use leak detection tool ideal for any industrial or HVAC Professional.

The 7899 is equipped with a highly sensitive tip to Pin-Point small leaks of any Combustible gases & Hydrocarbons from piping and/or appliances.

(Natural Gas, Methane, Propane, Butane, LPG, etc.)

The 7899 Gas Sniffer Includes:

- Economical, Hand-Held & VERY Easy to Use!

- 11” Fully Flexible Probe for Hard-to-Reach Places

- Auto Zero-Drift Adjustment

- LARGE Visual LCD and Bar Graph Display

- Audio Alarm

- HOLD Function

- Readings in PPM, %vol, %LEL

- Range: 0 to 10,000 ppm

- Quick Response Time

MILWAUKEE, WI – The leading jobsite lighting provider in the industry, Milwaukee Tool, continues to expand their Lighting Solutions with the introduction of the M18 RADIUS™ Compact Site Light w/ Flood Mode. Building off the popularity of their other industry-leading RADIUS™ site lights, Milwaukee’s newest light provides a more compact solution for users who require the Read more

MILWAUKEE, WI – The leading jobsite lighting provider in the industry, Milwaukee Tool, continues to expand their Lighting Solutions with the introduction of the M18 RADIUS™ Compact Site Light w/ Flood Mode. Building off the popularity of their other industry-leading RADIUS™ site lights, Milwaukee’s newest light provides a more compact solution for users who require the versatility of two lights in one. With 2,200 lumens of light output in area mode and 1,000 lumens of flood lighting, the light can easily handle both large work areas and smaller task situations.

The dual function of the M18 RADIUS™ Compact Site Light w/ Flood Mode allows users to carry less to the jobsite. The main body of the light provides 360° of area light, while an independent array of LEDs on the side provide 90° of task lighting. Additionally, its compact size makes it easy to transport to and from the jobsite.

The dual function of the M18 RADIUS™ Compact Site Light w/ Flood Mode allows users to carry less to the jobsite. The main body of the light provides 360° of area light, while an independent array of LEDs on the side provide 90° of task lighting. Additionally, its compact size makes it easy to transport to and from the jobsite.

The new M18 RADIUS™ Compact Site Light w/ Flood Mode can illuminate large and smaller task workspaces for up to 24 hours on a single charge. The light features TRUEVIEW™ Technology, which utilizes the most advanced LED technology and optical designs to deliver a consistent beam, optimized color temperature, and true representation of colors and detail leading to a more productive work area.

Equipped with a 4-1/4” self-centering metal hook, users can hang the unit overhead on studs and piping. An AC inlet also allows the user the option of plugging in the light for extended run-time.

A durable high impact polycarbonate lens design can survive harsh jobsite conditions, and is impact and chemical resistant, delivering superior impact durability. Similar to all of Milwaukee’s high output LED lights, the new Site Light also features a limited lifetime LED warranty, and a 5-year warranty on the light.

Powered by Milwaukee REDLITHIUM™ batteries*, the new M18 RADIUS™ Compact Site Light w/ Flood Mode is compatible with the M18™ cordless system, now offering more than 150 power tool products. Committed to its focus on the user and investment in game-changing technology, Milwaukee® will continue to design and develop lighting solutions with the ability to adapt, perform and survive the demands of professional use.

*batteries sold separately.

Specifications

M18 RADIUS™ Compact Site Light w/ Flood Mode (2144-20)

Area Lighting:

- 2,200 Lumens on high (7 hours*/ 4 hours**)

- 1,100 Lumens on Medium (15 hours/ 8 hours)

- 550 Lumens on Low (30 hours/ 16 hours)

Flood Lighting:

- 1,000 Lumens on high (10 hours*/ 6 hours**)

- 500 Lumens on Medium (22 hours/ 12 hours)

- 250 Lumens on Low (43 hours/ 24 hours)

AC inlet

4-1/4” hanging hook

4.3 lbs.

*Run-time with the M18™ REDLITHIUM™ XC 5.0 Battery

** Run-time with the M18™ REDLITHIUM™ HIGH DEMAND™ 9.0 Battery

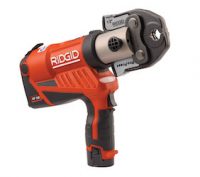

The only tool on the market that lets contractors press black steel pipe between two-and-a-half and four inches, the new RIDGID® Press Booster for use with Viega® MegaPress® XL Jaws and Rings, builds on the power of the RIDGID RP 340, attaching to the tool to multiply its output for fast connections on larger diameter Read more

The only tool on the market that lets contractors press black steel pipe between two-and-a-half and four inches, the new RIDGID® Press Booster for use with Viega® MegaPress® XL Jaws and Rings, builds on the power of the RIDGID RP 340, attaching to the tool to multiply its output for fast connections on larger diameter pipe.

The only tool on the market that lets contractors press black steel pipe between two-and-a-half and four inches, the new RIDGID® Press Booster for use with Viega® MegaPress® XL Jaws and Rings, builds on the power of the RIDGID RP 340, attaching to the tool to multiply its output for fast connections on larger diameter pipe.

“We heard from contractors that they wanted to leverage our current Standard Tool platform to make press connections on black pipe over 2 inches,” said Marcus Borman, RIDGID Global Marketing Manager. “The MegaPress XL Booster & Rings provide the ideal solution. The new tool will make press connections on 2.5”, 3”, and 4” black pipe in under 25 seconds—welding those same connections can take over 30 minutes. We worked closely with Viega to develop a program that would meet the strict demands of the contractors we serve. As market leaders in pressing, we’re both truly proud to introduce yet another industry-first.”

MegaPress XL makes connections in under 25 seconds, saving time and enhancing efficiency. Simply attach the booster to the end of the RP 340, press the trigger on the tool three times, and you have a secure press connection. Hard-to-reach angles are a breeze with an actuator that can rotate 180-degrees on the press ring.

Weighing less than 22 pounds and coming with built-in carrying handle and strap, the MegaPress XL Booster is designed for portability and easy transport between jobs. The primary kit includes the XL Booster, 2.5” ring, 3” ring, 4” ring, and high quality carrying case.

After success in Europe, RIDGID and Viega introduced ProPress® to North America in 1999 and continue to have a strong partnership to this day, resulting in continuous tool innovation and design. RIDGID press tools are unsurpassed in making quick and reliable connections on copper, stainless steel, black steel, PEX and multi-layer tubing.

All RIDGID press tools come backed by the RIDGID Full Lifetime Warranty.

To purchase or learn more about MegaPress XL or other pressing solutions contact your local distributor, visit RIDGID.com.

DEWALT® launches its Jobsite WiFi Access Points (DCT100) which are Made in the USA with global materials. First announced in May 2017 at ENR FutureTech, where leading construction teams learn about today’s innovative applications of technology, DEWALT Jobsite WiFi Access Points are built to withstand tough construction site conditions. Reliable internet access is a necessity Read more

DEWALT® launches its Jobsite WiFi Access Points (DCT100) which are Made in the USA with global materials. First announced in May 2017 at ENR FutureTech, where leading construction teams learn about today’s innovative applications of technology, DEWALT Jobsite WiFi Access Points are built to withstand tough construction site conditions.

Reliable internet access is a necessity on residential and commercial construction sites large and small. DEWALT Jobsite WiFi Access Points utilize the user’s existing ISP to provide jobsite wireless internet coverage. With an operating temperature of -4°F to 122°F, the Access Points are IP67 rated to protect against dust and water submersion. In addition, the Jobsite WiFi mobile app, coming soon, will provide detailed steps to guide users through the simple setup process without requiring a technician. With both vertical and horizontal mounting options, DEWALT Jobsite WiFi Access Points can be installed to a user’s optimal orientation on a carabiner, anchor, tripod, or wall mount (not included). As the jobsite changes and progresses, the DEWALT Jobsite WiFi Access Points self-heal and adapt, retaining connectivity on site and helping to keep users connected to their data.

DEWALT Jobsite WiFi Access Points provide increased productivity and profitability* by providing access to 3D models, construction software, RFI’s, change orders, punch lists, collaboration tools, and photo documentation. Each Access Point operates off of 120V AC power and provides WPA2 encryption via SSL interfaces for security. One DEWALT Jobsite WiFi Access Point is available for $1,499 MSRP. For more information, visit dewalt.com/jobsitewifi.

*Based on actual case study findings.

The RIDGID®RP 240 joins the RP 241 to expand its line of smaller, lighter and stronger next generation compact press tools. The tool is ideal for contractors accessing the tightest of spaces without sacrificing the quality of press on copper, stainless steel, black steel and PEX. “RIDGID has nearly 20 years of leadership in pressing Read more

The RIDGID®RP 240 joins the RP 241 to expand its line of smaller, lighter and stronger next generation compact press tools. The tool is ideal for contractors accessing the tightest of spaces without sacrificing the quality of press on copper, stainless steel, black steel and PEX.

The RIDGID®RP 240 joins the RP 241 to expand its line of smaller, lighter and stronger next generation compact press tools. The tool is ideal for contractors accessing the tightest of spaces without sacrificing the quality of press on copper, stainless steel, black steel and PEX.

“RIDGID has nearly 20 years of leadership in pressing, starting with our ProPress®in 1999,” said Marcus Borman, RIDGID Global Marketing Manager. “We’re continuing to set the standard for contractors by developing products that meet their needs without compromising pressing power. Our new RP 240 and RP 241are no exception, both purpose built smaller and lighter to maximize productivity and minimize contractor fatigue.”

The RP 240is13 inches long and weighs only7.4 pounds with battery and jaws included, making it 15 percent smaller and 10% lighter over earlier models. TheRP 241 is 25 percent smaller and 10 percent lighter than its predecessor.

Both tools feature a new 12V battery platform for 140 presses per charge –more crimps than contractors need per day -and come standard with RIDGID Link to track key tool data including crimps completed, service history and more. In addition,they include a brighter LED display,180-degreehead rotation, and bolt sensor to prevent tool use without proper form, helping to ensure a quality press. Each are also backed by the RIDGID Full Lifetime Warranty.

RIDGID and Viega, industry leaders in pressing technology, introduced the ProPress joining system in North America in 1999 and have had a strong partnership ever since. This strong partnership has resulted in continuous innovation and design in press connections. RIDGID pressing tools are unsurpassed in making quick and reliable connections on copper, stainless steel, black steel, PEX and multi-layer tubing.

To purchase or learn more about the RP 240, RP 241 and other pressing tools contact your local distributor, visit RIDGID.com, or call toll-free: 1-800-769-7743