The versatile and space-saving 5517 Series DISCAL® brass air separator is ready to be installed in horizontal or vertical pipes with its industry exclusive rotating collar. It is a compact solution for installations with wall-mounted piping, especially when the pipes are closely-spaced. “We’re seeing significant field enthusiasm because of the 5517’s versatility and added benefit Read more

Whats New

The versatile and space-saving 5517 Series DISCAL® brass air separator is ready to be installed in horizontal or vertical pipes with its industry exclusive rotating collar. It is a compact solution for installations with wall-mounted piping, especially when the pipes are closely-spaced.

The versatile and space-saving 5517 Series DISCAL® brass air separator is ready to be installed in horizontal or vertical pipes with its industry exclusive rotating collar. It is a compact solution for installations with wall-mounted piping, especially when the pipes are closely-spaced.

“We’re seeing significant field enthusiasm because of the 5517’s versatility and added benefit of inventory reduction. Being able to accommodate tight spaces and varied piping layout with the separator is a game changer for installers,” asserts Kevin Freidt, director of product management and technical support.

The separator is available for 3⁄4” or 1” pipes sizes with sweat, press or NPT male connections. It features high capacity automatic air removal, down to the microbubble level, eliminates air-related corrosion and noise and improves water quality in hydronic systems. A removable top facilitates fast inspection and cleaning.

CALEFFI – Creating innovative, superior performance products that help customers live comfortably and economically, while softening their impact on the environment.

For more info, caleffi.com.

The Pennant line of fan-assisted, modular boilers and volume water heaters are among the industry’s most versatile and environmentally friendly commercial systems for hydronic and hot water applications. Available in seven sizes from 500 to 2000 MBH, Laars Pennant boilers/volume water heaters are fueled by natural or LP gas and deliver efficiency levels up to Read more

The Pennant line of fan-assisted, modular boilers and volume water heaters are among the industry’s most versatile and environmentally friendly commercial systems for hydronic and hot water applications.

Available in seven sizes from 500 to 2000 MBH, Laars Pennant boilers/volume water heaters are fueled by natural or LP gas and deliver efficiency levels up to 85%, with stage firing of up to 4:1, and cascade with auto redundancy. Pennant systems also qualify as low-NOx emission-rated, below 10 ppm.

The Pennant now has a substantial upgrade with its LAARS LINCTM Intuitive Control System. The controls include an auto cascade setup feature that easily configures lead lagging of up to eight Pennants. The color touchscreen home page displays key boiler performance measurements, easy to use and navigate control structure, USB input, easily connects to building automation systems via BacNet and a quick start option among many other features.

Pennants can be vented from the top, or back. They can also be installed indoors or outdoors and racked on top of each other for up to 4000 MBH in a small footprint.

Harol Harold Esmailka, 85, a native Athabaskan who grew up in the Alaskan tribe’s traditional nomadic lifestyle, is a true entrepreneur, having started a variety of businesses over the years. His bush plane service made him an aviation legend in the back country, and he and his wife still operate a general store out of his Read more

Harol Harold Esmailka, 85, a native Athabaskan who grew up in the Alaskan tribe’s traditional nomadic lifestyle, is a true entrepreneur, having started a variety of businesses over the years. His bush plane service made him an aviation legend in the back country, and he and his wife still operate a general store out of his hilltop home overlooking the Yukon.

The home/store is a typical remote Alaskan trading post; butter, blankets, bullets and beer. Lots of beer. It’s the next best thing to Walmart, which is 240 air miles away; the same distance to the nearest plumbing supply house.

For technicians at Rocky’s Heating Service in Fairbanks, AK, this is often how a morning commute starts.

The store’s old boiler started leaking from a cracked section, so Harold started looking for a solution over the summer. In the meantime, he had an oil-fired Burnham V85 shipped to Ruby on a barge, to await its coming installation. This boiler is popular in AK because it’s available as a “breakdown” boiler that can be assembled on-site – a big plus for remote applications which often require flying, barging, or snowmobile transportation of boilers.

After speaking with supply houses in Fairbanks, Harold learned that Rocky’s Heating Service, out of Fairbanks, had completed a boiler installation in the village where his daughter lives. A few more phone calls for references, and Rocky’s was called for the job.

The company was founded by Rocky and Catherine Pavey in 1994, and currently has 17 employees that serve most of the Alaskan interior. Robust hydronic systems comprise most of their work. Exceeding customer expectations is the ultimate goal of every Rocky’s technician.

One Tuesday morning in November, just as the Yukon started to freeze over, Pavey was able to make the flight out to Ruby himself.

It’s the logistics

Pavey packed 160 pounds of tools, pipe and parts to be flown out ahead of him on a dedicated freight flight. To conserve space, small diameter pipe was stashed inside larger pieces, and everything else was packed into one big tote. “You can’t get on a plane with MAPP gas, so I traded the torch for a press system and fittings,” he said.

The temperature dropped to -5°F the evening his plane touched down in Ruby. Not wanting to take Harold’s leaky boiler out of service overnight, he serviced three other boilers in town on Tuesday evening. Before going to bed, he added Fernox liquid cleaning agent to the four-zone hydronic system at the general store to circulate overnight.

On Wednesday morning he drained the system. The fluid looked like mud due to the constant addition of untreated makeup water. After tearing out the old unit, he moved the circulator from the return piping to the supply side.

“Once you’re there with all the tools and material, installing a V8 is a cakewalk,” said Pavey. “We use them because it’s a tough boiler that’s quick and easy to install. When we’re in the remote villages, time is of the essence, and durability is a huge factor.”

At 85% efficient, the Burnham V8 is a cast iron boiler built to offer low cost of ownership and easy drop-in replacement for most systems. Seven sizes are available, from .75-2.6 GPH.

“The zone valves and wiring were a bit messy, but Harold wanted to replace as little as possible,” said Pavey. “When I was pulling materials back in Fairbanks, he told me that the expansion tank was in good shape. I learned otherwise when I got there.”

Luckily, there was an air freight shipment headed to Ruby on the morning he was to fly home.

When the new boiler was installed, the owner insisted on changing the piping as little as possible to trim costs.

While Pavey was piping the new boiler and running fresh soft-copper, his guys back in Fairbanks took an expansion tank to the airport. Wednesday night, Pavey filled the new boiler and left the old expansion tank in place. What he hoped to accomplish on Wednesday drifted into Thursday. He still had an expansion tank to replace and glycol to add to the system. As a result, he moved his flight home from Thursday morning to the afternoon.

Insurance policy

When the morning’s first flight arrived from Fairbanks, Pavey met it at the airfield to get the new tank. At that point, the countdown began. He had exactly two hours to swap tanks and add antifreeze and corrosion inhibitor to the system before his flight back to Fairbanks departed.

“Harold decided he wanted antifreeze in the system,” said Pavey. “Good idea, but is came at a cost. The air freight alone on 30 gallons of 50/50 propylene glycol was $307.”

But according to Pavey, both the antifreeze and the Fernox corrosion inhibitor are an insurance policy, a guard against the worst Mother Nature can throw at a heating system. Nights dropping below -50°F and wicked winds to accompany it make for long runtimes in a long heating season.

Just before Pavey headed to the airfield, Harold stopped him to ask if the system was actually running. He was concerned because his baseboard wasn’t gurgling, despite the building being warmer than ever. After explaining that the hydronic system was meant to be silent, and that the noise he’d grown accustomed to was a result of air in the pipes, Pavey caught his plane with minutes to spare.

Hard knock life

“Folks out here don’t have a lot to spend, but nobody in the country is more cognizant of their heating system than interior Alaskans,” explained Pavey. “Last year, fuel oil was $6.00 per gallon in the villages, and it doesn’t matter what the current barrel price is in the Gulf.”

Oil is barged to Ruby in the summer. When the town’s 75,000 gallons of storage is topped off, the price doesn’t change till the following year.

Harold was thrilled—and a bit surprised—that a professional heating outfit would make the trip to Ruby. With any luck, his position in the tribe will help spread the word of a job well done.

“Not long ago, we were only doing about one remote boiler installation each year,” said Pavey. “Since then, that number has crept up. The native community is tight knit, and the word has spread that we’re helping extend the life of systems while also lowering fuel bills. It’s an area where we expect to see growth in the years to come.

Somewhere 37,000 feet above the Pacific Ocean, Eric Silva texted me that he had embarked on a journey of a lifetime. Chosen among a select group of contractors to accompany Navien execs to the company’s headquarters and production facilities in South Korea, Silva was excited, yet humbled, to visit the global HQ, take in some Read more

Somewhere 37,000 feet above the Pacific Ocean, Eric Silva texted me that he had embarked on a journey of a lifetime. Chosen among a select group of contractors to accompany Navien execs to the company’s headquarters and production facilities in South Korea, Silva was excited, yet humbled, to visit the global HQ, take in some sights and attend the 2018 Winter Olympics. “Who would have ever thought plumbing would take you to something like this?” asked Silva. “Why me? This is a very unique and humbling opportunity.”

Somewhere 37,000 feet above the Pacific Ocean, Eric Silva texted me that he had embarked on a journey of a lifetime. Chosen among a select group of contractors to accompany Navien execs to the company’s headquarters and production facilities in South Korea, Silva was excited, yet humbled, to visit the global HQ, take in some sights and attend the 2018 Winter Olympics. “Who would have ever thought plumbing would take you to something like this?” asked Silva. “Why me? This is a very unique and humbling opportunity.”

At the age of 17, Silva initially got into plumbing by digging basements for his uncle, who was a union residential contractor. A few months later—at the age of 18—Silva decided to apply to the local plumber’s union, at which he was initially rejected for what he says as being too “high profile.” Silva, outspoken on many topics in the trade, and rightfully so, indicated that union officials weren’t too elated with his “cockiness” when he responded, “in one of your chairs” when asked where he saw himself in 10 years.

Yet, Silva was just being forthright in his response. To be fair, Silva saw big picture: he also wanted his journeyman’s card and he wanted to own his own business one day. Realistically, Silva was confident and measured in his approach, and he was being honest, traits that he has carried with him to this day.

In 2000, Silva ultimately was accepted into the UA Local 98 Plumbers & Pipefitters, Madison Heights, Mich., to which he is eternally grateful for the education he received there. By 2005, Silva was running neighborhood service north of Detroit as a foreman for a large residential contractor, focusing on residential water heaters and boilers, hydronic and gas piping.

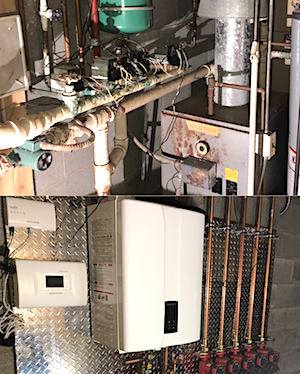

Fast forward to 2010—during the country’s economic downturn, Silva decided to go on his own to start Silva Mechanical LLC, Walled Lake, Mich., a one-man shop that specializes in tankless water heaters, hydronic heating, on-demand boilers and backflow testing. A difficult decision for sure, but one Silva may have been forced to make.

“When the economy went down, much like a lot of other guys, you didn’t have anything to fall back on but plumbing,” says Silva. “It was a sink- or swim-type deal. You never know what you are able to accomplish until your back is pushed up against the wall. We are all faced with adversity everyday; life obviously gives us a number of decisions,” says Silva.

Fortunately, in 2011, there was a resurgence in new residential construction, which gave him enough work to propel him forward, and Silva has not looked back since. “As workplaces continue to shrink, more and more people are starting on their own,” says Silva. “For those just getting into the trade, you have the ability to make it what you want it to be.”

A self-proclaimed enthusiast and believer in everything he sets out to do, Silva puts his best foot forward in servicing on-demand water heaters and boilers. In fact, a recent customer review of his work said, “We chose Silva Mechanical and its Navien package because of the company’s product knowledge, enthusiasm, and peace of mind knowing that the installer is the master plumber and mechanical contractor who’s doing the install, and it’s the most inclusive installation package.”

That is saying something, especially in a time when the plumbing industry faces a number of obstacles: DIYers, big box store renegades, bad installs and guys competing for work against those less experienced, or those not even licensed. According to Silva, bad installs and installers are the death sentence of the trade. In Michigan, says Silva, only one member of a plumbing shop needs to be licensed. “Wrong installations are killing the trades.” The concern then becomes underqualified workers overcharging customers. “I’m not going to sell you a high-dollar product and hope that it works,” says Silva. “Some companies are motivated by sales; I sell product lines at an affordable price.”

Everyday Silva crosses paths with somebody who knows someone who has had what Silva calls a “junk unit,” and his goal it to take that skeptic and make them a believer. “Every company believes they deserve the highest premium because of their ‘extensive training,’ yet we’re providing customers the highest quality materials, and still matching or beating our competitor’s price with a more inclusive package,” says Silva.

Everyday Silva crosses paths with somebody who knows someone who has had what Silva calls a “junk unit,” and his goal it to take that skeptic and make them a believer. “Every company believes they deserve the highest premium because of their ‘extensive training,’ yet we’re providing customers the highest quality materials, and still matching or beating our competitor’s price with a more inclusive package,” says Silva.

In a day and age when contractors look to diversify their business to increase income streams, Silva is doing just the opposite. As a licensed and insured master plumber and mechanical contractor, Silva has relied on his core competencies. “I’ve been installing on-demand water heaters for 12 years and never thought I could make it 100% a staple of my business, and realized that maybe I was too diverse,” says Silva.

In the end, it’s still comes down to relationships. For Silva, it’s the relationships he’s built, not only with Navien, but Rinnai, Nortiz, A.O. Smith and Triangle Tube that has allowed Silva Mechanical to stay ahead of the pack. In fact, the company is the first company in the U.S. as A.O. Smith approved for tankless products, says Silva.

In the end, it’s still comes down to relationships. For Silva, it’s the relationships he’s built, not only with Navien, but Rinnai, Nortiz, A.O. Smith and Triangle Tube that has allowed Silva Mechanical to stay ahead of the pack. In fact, the company is the first company in the U.S. as A.O. Smith approved for tankless products, says Silva.

Meanwhile, while other companies claim to be experts, Silva continues to accumulate the accolades. The local area rep, says Silva, coined the company as one of the “premier installers of our state.” A Navien engineer refers to Silva Mechanical as “premium installation, premium service,” and a Navien senior tech nominated him for the contractor of the year in 2017. “An expert is someone that excels in what they know. The only thing the folks in metro Detroit need to know is, ‘Silva Knows Tankless,’” says a confident Silva.

So to answer the original question, “Why Silva?” I have to believe it’s excelling at his job, confident and measured in his everyday approach to the trade, and being a loyal Navien enthusiast who promotes a good product at an affordable price. It’s also the dedication to the product line by continuing education and attending intensive training courses.

So to answer the original question, “Why Silva?” I have to believe it’s excelling at his job, confident and measured in his everyday approach to the trade, and being a loyal Navien enthusiast who promotes a good product at an affordable price. It’s also the dedication to the product line by continuing education and attending intensive training courses.

Ultimately, it is being damn good at what you do, would be my answer. Yet, perhaps it’s in the simplicity of Silva’s overall message to service contracting, “Give the customer a greater service than what they originally had.”

For more information on Silva Mechanical, www.silvamechanical.com.

Webstone, a brand of NIBCO, announces new vertical mount air separator and optional isolation accessories. A vertically mounted air separator can be conveniently placed beneath a wall hung boiler, upright in the system supply line. Available in ¾” or 1” with MIP, FIP, Sweat, or Press connections. Isolation accessories include full port ball valves and Read more

Webstone, a brand of NIBCO, announces new vertical mount air separator and optional isolation accessories. A vertically mounted air separator can be conveniently placed beneath a wall hung boiler, upright in the system supply line. Available in ¾” or 1” with MIP, FIP, Sweat, or Press connections. Isolation accessories include full port ball valves and Isolator® Uni-flanged ball valves. The G1 union connections simplify installation and prepare the air separator for future service. Install a G1 dual temperature gauge and verify boiler output right at the source.

Webstone, a brand of NIBCO, announces new vertical mount air separator and optional isolation accessories. A vertically mounted air separator can be conveniently placed beneath a wall hung boiler, upright in the system supply line. Available in ¾” or 1” with MIP, FIP, Sweat, or Press connections. Isolation accessories include full port ball valves and Isolator® Uni-flanged ball valves. The G1 union connections simplify installation and prepare the air separator for future service. Install a G1 dual temperature gauge and verify boiler output right at the source.

GUARANTEED FOR LIFE. Learn more at http://www.webstonevalves.com/airseparator