The difference between cast iron soil pipe and plastic is easily understood when it comes to sound. Cast iron drain waste and vent pipe systems are superior when it comes to sound attenuation. For commercial office buildings, hospitals, high-rise condominiums or high-end hotels, no one wants to listen to the flowing of fluids when a toilet is flushed from the floor above.

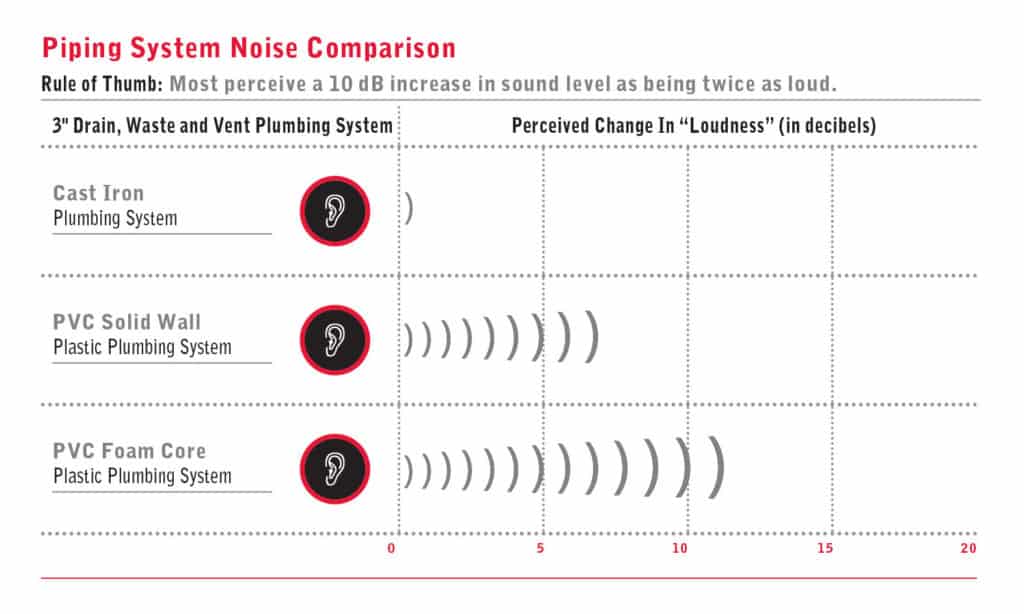

Specifying cast iron for waste piping provides a plumbing system that is up to 11 times quieter than an all-plastic system. This is how it got its name – the Quiet Pipe®.

A primary factor in cast iron’s sound-dampening quality is its microstructure. Graphite flakes absorb and dampen vibration applied to the iron. The microstructure isn’t the only advantage when it comes to noise.

Cast iron installation plays a primary role in sound attenuation. The use of neoprene rubber gaskets to join sections of cast iron pipe provides additional sound dampening. Sections of pipe do not touch as the rubber gasket creates a buffer, and so contact-related sound is eliminated. In contrast, plastic systems are installed as rigid systems that are solvent cemented. Noise is created as the rigid system expands and contracts with heating and cooling.

A frequently used tactic attempts to create a solid barrier between the pipe and the wall: wrapping plastic pipe in insulation to muffle the sound of rushing water and fluids through pipes. An insulated plastic pipe, however, can be sound-enhancing rather than sound-deadening. The “fix” results in additional installation costs incurred for both product and labor.

A frequently used tactic attempts to create a solid barrier between the pipe and the wall: wrapping plastic pipe in insulation to muffle the sound of rushing water and fluids through pipes. An insulated plastic pipe, however, can be sound-enhancing rather than sound-deadening. The “fix” results in additional installation costs incurred for both product and labor.

Specify cast iron soil pipe and enjoy the benefits of the Quiet Pipe®.

Check out cast iron soil pipe’s other benefits.

Dave Parney is the Executive Vice President of the Cast Iron Soil Pipe Institute (CISPI) and a former Master Plumber in the Chicago area.

Dave Parney is the Executive Vice President of the Cast Iron Soil Pipe Institute (CISPI) and a former Master Plumber in the Chicago area.

Join the conversation: