For the company’s 85th anniversary, Freeborn Mower Electric Cooperative in Albert Lea, Minn., decided to build a brand-new facility to house all their equipment, trucks, and employees in one location. The new 97,000-square-foot, $17 million structure featured several high-tech, sustainable building practices, including radiant floor heating throughout the entire building.

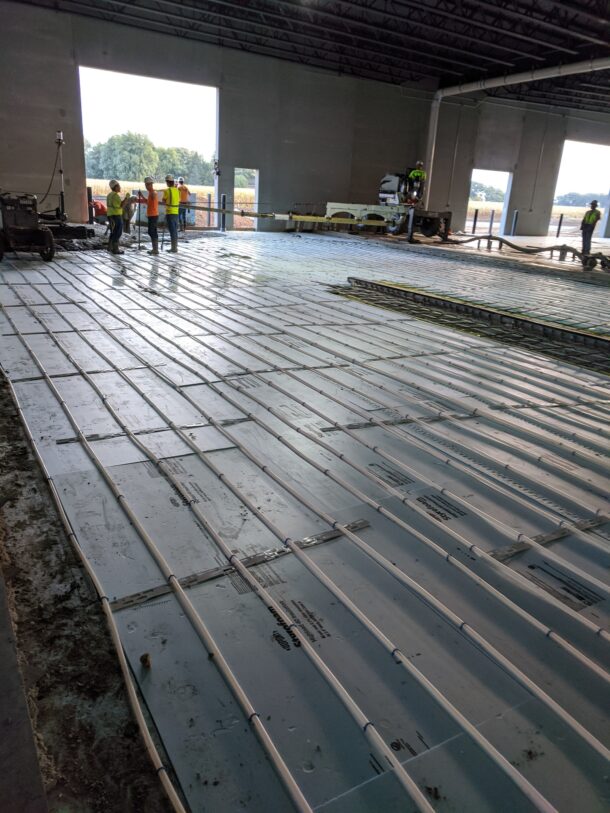

Being an electric cooperative that serves 21,045 members in two counties with 2,950 miles of line, they wanted the most energy-efficient method for heating their structure, which meant a radiant floor heating system using Wirsbo hePEX™ pipe along with an underground distribution system using Ecoflex® pre-insulated piping.

Despite construction being done during the height of the COVID-19 pandemic in 2021, all the construction partners came together to complete the project quickly and under budget. This was thanks, in part, to the efficiency of the Uponor Radiant Rollout™ Mats for the radiant heating system, which saved significant install time and labor costs.

Taylor Bestor of Valor Mechanical, the radiant contractor, had been installing commercial systems since 2007, but had always used traditional methods of wire ties or foamboard staples. When the engineer’s specification called for preassembled radiant mats, Taylor was curious about how the installation would go, knowing he needed to align with concrete-pour schedules to stay on the customer’s tight timeline.

To learn more about these preassembled radiant mats, Taylor met with Ryan Swanson of FourMation Sales, an Uponor manufacturer rep firm. Ryan told Taylor about the Uponor Radiant Rollout Mats and how they could “cut labor by one third.” Of course, after hearing about the incredible installation efficiencies, Taylor was interested in how this technology worked.

Once he learned that the mats are custom designed by Uponor Construction Services to fit the space and come to the job site preassembled and pre-pressurized, ready for installation, Taylor was on board with moving forward.

Paul McCulloch from Uponor, along with Ryan, were there for the first install to guide Taylor and his team with the mats. The crew made a plan to complete the radiant tubing install in thirds to work with the concrete pours.

“We started out by training about 10 guys to get an understanding of how the mats worked,” says Taylor. “By the last third of the project, we were able to do the entire install with three guys in one day. Using traditional wire ties or staples would have taken more than double the workers and triple the time.”

Because the project included complete layout designs from Uponor Construction Services, Taylor and his team were able to efficiently and effectively install the Radiant Rollout Mats as well as the radiant perimeter, which used a staple-down method. They also installed Ecoflex pre-insulated pipe for the underground piping to the Uponor TruFLOW™ manifolds, which, Taylor says, “worked out perfectly for the install”.

After his experience with the extreme efficiency of the Radiant Rollout Mats, along with the support from the Uponor sales team and Uponor Construction Services, Taylor is convinced of their effectiveness and is anxious to use them again in a future large commercial radiant project.

To learn more about Uponor Radiant Rollout Mats or other radiant installation methods, visit www.uponor.com.

Join the conversation: