Epoch Senior Living Inc. operates 10 Bridges by Epoch Memory Care Assisted Living Facilities throughout New England. Over the years, management has sought to provide the highest level of resident comfort and environmental sustainability. Partnering with architects, designers and mechanical system installers that understand these priorities has lead the company to continuous growth.

At nearly all the Bridges locations, consulting engineer Wozny Barbar & Associates (WB&A) has been hired for the mechanical system design. The 27-year-old firm specializes in assisted living facilities, with an impressive list of projects completed throughout the Northeast.

“We have 37 employees,” said Casey Archacki, PE. “As the market has changed and grown, so has our stake in the industry. We’ve done work for EPOCH specifically since 2011.”

In 2016, construction began on the newest facility, Bridges by EPOCH at Sudbury (MA). With help from manufacturer’s representatives at Emerson Swan, WB&A specified a mechanical system that has performed exceptionally well at other EPOCH properties: a cooling tower and boiler system providing heating and cooling capacity to a variable-speed loop for water source heat pumps, along with an extensive ventilation system.

Comfort and control

“The heat pump systems provide a high level of control and zoning throughout the building,” said Archacki. “At EPOCH, comfort is the main priority, followed by efficiency and lifecycle cost.”

Bridges at Sudbury is a 45,000 square-foot, single-structure facility with 54 resident apartments. An 85-ton cooling tower and two redundant 650 MBH condensing boilers serve the collection of water source heat pumps. Whalen vertical-stack heat pumps are used in tenant rooms, while horizontal heat pumps made by Florida Heat Pump are used in common areas.

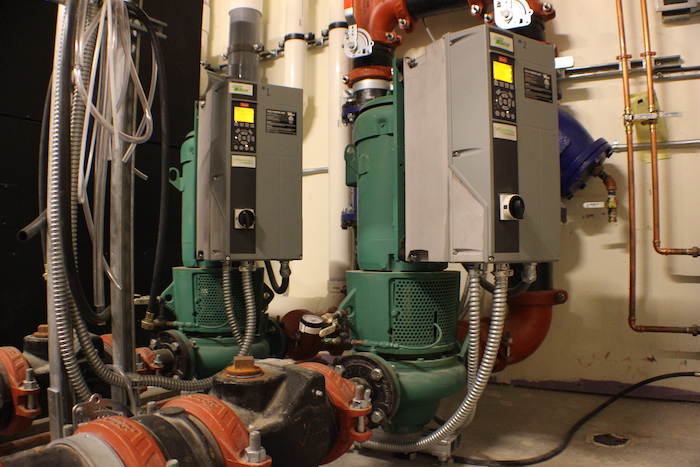

The building loop serving the heat pumps is served by a pair of redundant Taco SelfSensing pumps, with a max 210 GPM and 70 ft. head. The use of SelfSensing pumps eliminates the need for pressure sensors within the hydronic loop, and speeds up the commissioning and balancing process.

“To improve the indoor air quality of the building, the owners request that all of the spaces be mechanically ventilated,” said Archacki. “In order to accomplish this, all the bathroom exhaust has to be mechanically balanced with ventilation air. Since each resident has a private bathroom, this means that outdoor air and exhaust air requirements are quite high for the building. In order to maximize the energy load, we provided a single energy recovery ventilator to handle all of the outdoor and exhaust air.”

EPOCH has hired WB&A for numerous projects in part because the engineering firm comes highly recommended by architects. Their systems continuously perform. Each time they’ve approached a new EPOCH design, WB&A has drawn on the experience of Emerson Swan.

Smart choice in pumps

Emerson Swan has supplied the pumps, cooling towers and heat exchangers, along with assistance during specification, since WB&A was founded.

Emerson Swan has supplied the pumps, cooling towers and heat exchangers, along with assistance during specification, since WB&A was founded.

“Wozny Barbar is self-sufficient, but we help in any we can,” said Bill Arscott, sales engineer at Emerson Swan. “WB&A has been installing these heat pump systems before my time at Swan, and precedes the release of the Taco SelfSensing pumps that have simplified installation of the systems. Back then, conventional pumps with pressure sensors were used.”

Taco’s SelfSensing line of VFD-driven pumps not only eliminate the need for pressure sensors, but the VFDs are pre-programmed at the factory.

“The challenge we faced when using conventional circulators with sensors was picking a location for the sensor early on in the design phase,” said Archacki. “This was tough because the piping was subject to change, meaning sensor placement would no longer be ideal. Not needing sensors has been a big advantage.

Because Taco installs the VFDs on the pumps at the factory, on-site programming is not needed. The engineer provides a nominal pressure drop measurement, and the factory programs the units to 10 steps below nominal. Once installed, a balancing team fine tunes the pumps.

“We’ve always specified Taco in part because they’re a local company,” said Archacki. “When the SelfSensing product line came out, I attended a lunch-and-learn hosted by Rich Medairos at Taco. “That was several years ago, and we’ve now installed the pumps at nine properties without a single issue.”

Modulation

Because the SelfSensing line of pumps can sense and respond to pressure changes within a hydronic system, DDC controls are eliminated from the picture. The big advantage is that the capability is all found in a single pump, as opposed to fishing wires, paying the set-up and maintenance contract for controls, and installing pressure sensors throughout the loop.

Because the SelfSensing line of pumps can sense and respond to pressure changes within a hydronic system, DDC controls are eliminated from the picture. The big advantage is that the capability is all found in a single pump, as opposed to fishing wires, paying the set-up and maintenance contract for controls, and installing pressure sensors throughout the loop.

When compared to fixed-speed, centrifugal pumps – which are specified for maximum flow rate – the savings provided by SelfSensing pumps are even greater. Fixed-speed pumps spin literally non-stop, regardless of whether there’s a call or not. By slowing or stopping the pumps, literally millions of revolutions per heating season are eliminated. This dramatically extends the life of pumps, seals and bearings and translates into a very big savings in wear and tear.

A 1750 RPM design pump will save at least 225,000,000 cycles every heating season.

From a design standpoint, SelfSensing pumps provide more leeway in pump selection, since the pump will adjust to the need.

Continuing success

“At most senior living facilities, residents don’t pay utilities, so they expect a lot, and that typically means very warm spaces,” said Archacki. “In addition to the high ventilation rate, we must be able to maintain 80°F at an outdoor design temp of 0°F.

Bridges By EPOCH has considered installing a VRF system at one of the properties in place of the heat pump design, but the systems typically have lower performance in the middle of winter. Discharge air temperatures can drop, resulting in lower comfort levels.

“In general, natural gas costs in this area have been stable and very cheap when compared to electricity,” said Archacki. “Massachusetts pays some of the highest electricity rates in the country. This, along with high comfort levels, is one of the main reasons we continue installing heat pump systems for EPOCH.”

The success that EPOCH has had since its inception is evident. Roughly one new property is constructed and occupied each year. Currently, WB&A is designing systems for two coming EPOCH facilities simultaneously, one in MA and one in NY.