Electrode boilers are ideal for quickly, efficiently supplying auxiliary steam and hot water to meet surges in demand In industry, fossil fuel-fired boilers are commonly used to produce steam or hot water for space and process heating. However, traditional boilers may not be flexible enough to respond quickly to demand surges during peak periods. To Read more

Acme Engineering

Electrode boilers are ideal for quickly, efficiently supplying auxiliary steam and hot water to meet surges in demand

In industry, fossil fuel-fired boilers are commonly used to produce steam or hot water for space and process heating. However, traditional boilers may not be flexible enough to respond quickly to demand surges during peak periods.

To compensate, processors and manufacturers often keep more than the required number of boilers running – usually at less than full capacity. When more steam or heat is required, the units are already in operation and so require less time to increase output. Even if burning at 75% however, fossil fuel boilers take time to heat up internally.

Using electrode boilers as an auxiliary system minimizes the number of gas-burning boilers on standby, provides greater operational flexibility, and reduces operating and maintenance costs.

“If you want to use a gas-fired boiler as an auxiliary, you’d better know in advance when you will need it since it takes time for the heat to rise and disperse before reaching the target output [of steam or hot water]. If you have gas-fired boilers run at 75% capacity and there is an increase in demand, you cannot quickly reach 100% capacity, says Robert Presser, Vice President of Acme Engineering, a manufacturer of industrial and commercial boilers with operations in the U.S., Canada, and Europe.

Today, a much more efficient and cost-effective approach is available: auxiliary electrode boilers. These modern electrode boilers can almost immediately provide supplemental steam or hot water as required. The approach minimizes the number of gas-burning boilers on standby, provides greater operational flexibility, and reduces operating and maintenance costs.

The components of these auxiliary high-voltage electrical systems – boilers, superheaters, secondary pressure vessels, and associated control systems – are readily available from experienced suppliers and can be customized to specific industrial needs.

“A gas-fired boiler cannot go from zero to 100% capacity in less than two minutes – but an electrode boiler can,” says Presser. He points out that modern electrode boilers are designed so temperature, pressure, and output can quickly rise or fall as needed with no “flywheel effect.”

Electrode boilers have existed in various forms for many decades. However, recent design improvements have closed the output gap while surpassing conventional units not only in terms of efficiency and simplicity but also responsiveness and safety.

Electrode boilers like those from Acme Engineering are ideal for quickly and efficiently supplying auxiliary steam and hot water to meet surges in demand.

Modern electrode boilers utilize the conductive and resistive properties of water to carry electric current and generate steam. In a jet boiler, water jets flow from a central column to electrodes of each phase, using chemicals in the water to create resistance and generate heat and steam as the water passes from ground to phase. More steam is produced as the water flows from the electrode to the counter electrode placed below the electrode box, before the water returns to the reservoir at the bottom of the vessel.

“The more current [amps] that flows, the more heat [BTUs] is generated and the more steam produced. Nearly 100% of the electrical energy is converted into heat with no exhaust stack or heat transfer losses,” says Presser.

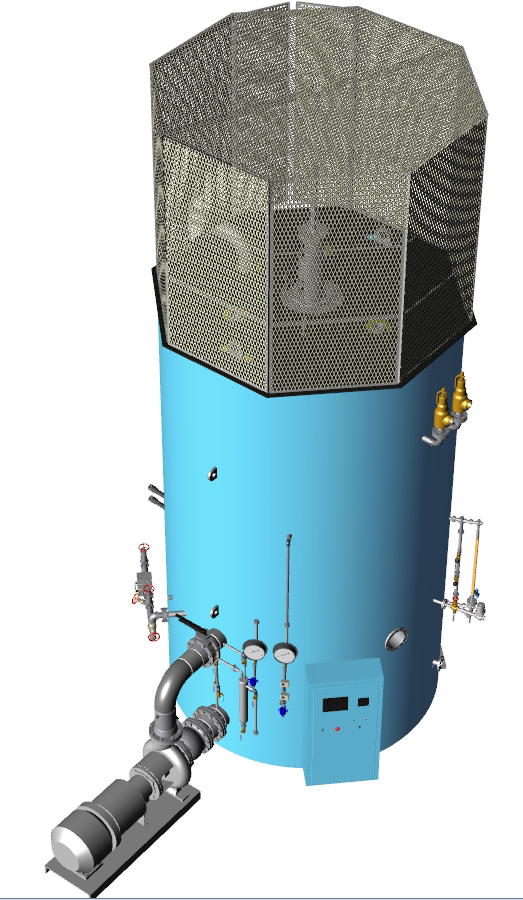

As an example, in the CEJS High Voltage Jet Type Steam Boiler from Acme Engineering, the electrodes are vertically mounted around the inside of the pressure vessel, which enables the unit to produce maximum amounts of steam in a minimum amount of floor space.

The electrode boilers operate at existing distribution voltages, 4.16 to 25 KV with exceptional efficiency – up to 99.9% efficient at converting energy into heat. The boilers can produce steam in capacities up to 270,000 pounds per hour, with pressure ratings from 75 psig to 500 PSIG. All CEJS boilers are designed to ASME Code or EU Pressure Vessels Directive and are certified, registered pressure vessels. Electrical standards meet CSA, UL, or CE requirements.

The advanced steam boilers have a 100% turndown ratio, the ratio between a boiler’s maximum and minimum output. Most gas boilers have a 10:1 or 5:1 ratio.

Modern electrode boilers can go from zero to 100% capacity in less than two minutes, almost immediately providing supplemental steam or hot water as required.

“The turndown means you can leave the boiler in standby at low pressure and, when needed, bring it to full capacity in about 90 seconds, which no other boiler type can achieve today,” says Presser. “With the electric boilers, the energy input and adjustment are very precise and virtually immediate.”

The ability to rapidly increase or decrease boiler capacity “on demand” can save industrial processors and manufacturers a substantial amount in operational and maintenance costs.

“Instead of running five gas-fired boilers on moderate capacity, you can run three or four boilers at full capacity, which maximizes their efficiency, and have an electrode boiler on standby. The electrode boiler can be used in short bursts only when you need peak performance. This is less expensive than running more gas-fired boilers,” says Presser.

The economics of using auxiliary electrode boilers further improve when utilizing discounted off-peak electricity at night when demand is low.

Electrode boilers also lower the costs of installation, operation, and maintenance. Gas-fired boilers require fuel lines, storage and handling equipment, economizers, and emission control equipment. Advanced jet type electrode boilers have a minimal number of components and electrical controls, with fewer parts. Under normal operation, the absence of excessive temperatures and electrode burnout assures long operating life.

Advanced jet type electrode boilers have a minimal number of components and electrical controls, with fewer parts, resulting in the absence of excessive temperatures and electrode burnout.

The units further lower operating costs with automatic controls that reduce the need for operating personnel.

Presser points out that the most advanced types of these boilers, such as Acme’s CEJS, also operate more safely than traditional fuel burning models.

“With the jet type electrode boilers, there are no combustion hazards because there are no flames, fumes, fuel lines, storage tanks, or hazardous emissions. There are no problems with heat buildup or electrode burnout even if scaling should occur, and thermal shock is eliminated. There is also no ‘low water’ danger since the current cannot flow without water,” says Presser.

With all the advantages of high-output auxiliary electrode boilers, industrial processors and manufacturers that utilize them will have a competitive advantage over rivals relying on gas-fired boilers alone.

The flexibility, precision, and responsiveness of electrode boilers will allow cost-effective “on demand” steam and process heating, eliminating the need for extra traditional units to be continually kept online at low capacity, ready to be “fired up” during peak periods. This approach will minimize operating costs including energy, labor, and maintenance.

For more info, contact Robert Presser at Acme Engineering via e-mail: rpresser@acmeprod.com; phone: (888) 880-5323 or (514) 342-5656; or web: https://www.acmeprod.com/jet-type-steam-boiler .

Advanced electric boilers offer output equal to fuel burning units with 100% energy efficiency, zero emissions, and minimal installation, operation, and maintenance costs In many areas of the U.S. and Europe, district heating remains popular for space and water heating of residential and commercial buildings. Although the source of the heat supplied can vary, one Read more

Advanced electric boilers offer output equal to fuel burning units with 100% energy efficiency, zero emissions, and minimal installation, operation, and maintenance costs

In many areas of the U.S. and Europe, district heating remains popular for space and water heating of residential and commercial buildings. Although the source of the heat supplied can vary, one common approach is to utilize fuel-burning boilers that produce steam. Unfortunately, conventional boilers present several challenges, including low efficiency when transforming fuel energy to heat; high installation, operating, and maintenance costs; environmental impact from harmful emissions; and some inherent safety issues.

There is growing interest in utilizing a new generation of jet type electrode boilers as an environmentally friendly solution. Due to considerable advances in the technology, these electric boilers can match the capacity (up to 65 MW) and output (270,000 pounds of steam per hour) of traditional gas or oil-fired boilers. When more output is required, multiple electric boilers can be connected to provide hundreds of megawatts of steam for district heating, and effectively replace gas fired boilers in a much smaller overall footprint.

There is growing interest in utilizing a new generation of jet type electrode boilers as an environmentally friendly solution. Due to considerable advances in the technology, these electric boilers can match the capacity (up to 65 MW) and output (270,000 pounds of steam per hour) of traditional gas or oil-fired boilers. When more output is required, multiple electric boilers can be connected to provide hundreds of megawatts of steam for district heating, and effectively replace gas fired boilers in a much smaller overall footprint.

There are a growing number of compelling reasons for municipalities to utilize high voltage, jet type electrode boilers for district heating, according to Robert Presser, Vice President of Acme Engineering, a manufacturer of industrial and commercial boilers with operations in the U.S., Canada, and Europe.

“Jet type electrode boilers can match the heating output of fuel burning boilers while converting almost all the energy to heat,” says Presser. “Electrode boilers also resolve many of the inherent drawbacks of fossil fuel burning boilers: they are much smaller, put out zero emissions, and minimize installation and maintenance costs.”

Today, the spiking cost of gas and oil is often a factor when considering an upgrade of an existing district heating system. In some cases, the concern is minimizing environmental impact. Natural gas-fired boilers and furnaces emit dangerous nitrogen oxides (NOx), carbon monoxide (CO), nitrous oxide (N2O), volatile organic compounds (VOCs), sulfur dioxide (SO2), particulate matter (PM), and the notorious greenhouse gasses carbon dioxide (CO2) and methane (CH4).

Regardless of the motivation, upgrading entails retrofitting or replacing boilers (the heat source) with cleaner, more efficient electric alternatives, along with the heat distribution network (pipes/heat exchanger stations).

Designed for Optimal Performance

Jet type electrode boilers have existed in various forms for many decades. However, recent design improvements have closed the output gap while surpassing conventional units in terms of efficiency, simplicity, responsiveness, and safety.

Modern jet type electrode boilers utilize the conductive and resistive properties of water to carry electric current and generate steam. An A.C. current flows from an electrode of one phase, through neutral, to an electrode of another phase using the water as a conductor. Since the water has electrical resistance, the current flow generates heat directly in the water itself.

“The more current [amps] that flows, the more heat [BTUs] is generated and the more steam produced. Nearly 100% of the electrical energy is converted into heat with no exhaust stack or heat transfer losses,” says Presser.

As an example, in the CEJS High Voltage Jet Type Steam Boiler from Acme Engineering, the electrodes are vertically mounted around the inside of the pressure vessel, which enables the unit to produce maximum amounts of steam in a minimum amount of floor space. The units operate at existing distribution voltages, 4.16 to 25 KV with exceptional efficiency – up to 99.9% efficient at converting energy into heat. Models can produce steam in capacities up to 270,000 pounds per hour, with pressure ratings from 75 psig to 500 PSIG. All CEJS boilers are designed to ASME Section VIII Division1 and are certified, registered pressure vessels.

The advanced steam boilers also have a 100% turndown ratio, the ratio between a boiler’s maximum and minimum output. Most gas boilers have a 10:1 or 5:1 ratio.

“The turndown means you can leave the boiler in standby at low pressure and, when needed, bring it to full capacity in about 90 seconds, which no other boiler type can achieve today,” says Presser.

“With the electric boilers, the energy input and adjustment are very precise and virtually immediate. In contrast, increasing or decreasing the temperature in a gas fired boiler is a slower process because it takes time for the heat in the boiler to rise or dissipate before reaching the targeted output,” he adds.

Jet type electrode boilers also lower costs for installation, operation, and maintenance. Gas-fired boilers require fuel lines, storage and handling equipment, economizers, and emission control equipment. Advanced jet type electrode boilers have a minimal number of components and electrical controls, with fewer parts. Under normal operation, the absence of excessive temperatures and electrode burnout also assures long operating life.

The units further lower operating costs with automatic controls that reduce the need for operating personnel.

Presser points out that the most advanced types of these boilers, such as Acme’s CEJS, also offer greater safety than traditional fuel burning models.

“With the jet type electrode boilers, there are no combustion hazards because there are no flames, fumes, fuel lines or storage tanks. There are no problems with heat buildup or electrode burnout even if scaling should occur, and thermal shock is eliminated. Also, there is no low water danger since the current cannot flow without water,” says Presser.

Communities utilizing district heating appreciate the eco-friendly nature of these boilers as well. Without combustion, jet type electrode boilers are clean and emission free. The design also eliminates many environmental issues associated with fuel burning boilers such as fuel fumes, fly ash, and large obtrusive exhaust stacks.

Finally, the electric units are exceptionally quiet compared to fuel fired boilers. Unlike gas-powered burners that throttle like turbine engines almost continually, electric boilers keep operational noise levels down. Because the loudest boiler component is a circulating pump motor, it is easy to have a conversation next to one without having to raise your voice.

With all the advantages of high output jet type electrode boilers, a growing number of communities are selecting them for district heating.

Presser concludes, “We have spoken to utilities with massive boiler plants that are traditionally stuck feeding steam lines all over major city cores like New York City. In urban centers, they really want to get away from the associated emissions. A large utility has been talking to us about putting a 60 MW steam boiler in the center of Manhattan to replace gas-fired boilers, providing a centralized theme to several buildings.”

For more info, contact Robert Presser at Acme Engineering via e-mail: rpresser@acmeprod.com; phone: (888) 880-5323 or (514) 342-5656; or web: https://www.acmeprod.com/jet-type-steam-boiler