Businesses that entrust their data storage to the state-of-the art Novva data center outside of Salt Lake City will benefit from a location chosen for its many data center-friendly attributes. The area offers outstanding connectivity, low power costs, and a central-western site with easy access to a major international airport. In addition, the site’s climate Read more

Aquatherm

Businesses that entrust their data storage to the state-of-the art Novva data center outside of Salt Lake City will benefit from a location chosen for its many data center-friendly attributes. The area offers outstanding connectivity, low power costs, and a central-western site with easy access to a major international airport. In addition, the site’s climate and 5,000-ft. altitude allow for many hours of free cooling annually.

Just as important to Novva’s clients, the new data center has a low disaster risk. The area is not prone to earthquakes, floods, or adverse weather events such as hurricanes.

And finally, for the additional peace-of-mind that makes this data center truly start-of-the-art, the cooling system for the computer servers boasts Aquatherm PP-RCT piping that will provide virtually leak-free service for decades to come. The Aquatherm piping will never scale or corrode, and the cooling water flow will remain unchanged throughout the anticipated 50-year lifespan of the pipe. All of this data adds up to a win for Novva and its clients.

The “hyperscale” data center in Salt Lake City will be Novva’s flagship data center. The 100-acre Utah campus is planned to ultimately include more than 1.5 million square feet of data center space and will accommodate 250kW to 30 MW clients. The construction is taking place in four phases. The first phase, which includes a 300,000-sq.-ft. data center, a 120MW substation and an 80,000-sq.-ft. headquarters office building for Novva, was completed in December 2021.

Beating the Heat

Reliable cooling systems are an essential component of modern data centers. Computer servers are notorious for generating heat—and heat is notorious for being an enemy of computer servers.

The decision to install Aquatherm pipe as part of the new data center’s cooling system was driven by Steven Boyce, vice-president of infrastructure and design at Novva Data Centers. Boyce has been involved in the IT and data center space for more than 20 years, and has worked on multiple successful startups during that time.

When I first learned about Aquatherm, it was a no-brainer,” Boyce said. “I had been using steel pipes in my builds, which would corrode and rust, and in turn, fill my equipment with sediment and pieces of rust. Efficiencies would be diminished, and the pipes would eventually have to be replaced. Aquatherm’s total installed costs are lower, and their warranty is something that no steel vendor could match.”

Once the decision was made to trust the cooling system’s performance to Aquatherm pipe, Novva turned to the Salt Lake City branch of Harris Mechanical for the installation.

Harris had experience installing Aquatherm pipe, although the Novva data center represented the company’s largest data center Aquatherm installation to date. To handle the first phase of the Novva system, Harris installed a BASX custom chiller package (which included the pumps and controls), the Aquatherm pipe for computer system cooling, and the comfort system piping and plumbing. The piping work for phase 1 began in mid-May 2021 and was completed in October 2021. The system was commissioned and turned over to the owner in December 2021.

Fast and Furious

Jeff Reading, operations manager, construction, Harris Mechanical, explained that the Novva data center started out as a core and shell project, with the office built first and the data hall scheduled to be built out later. However, as anyone in construction work knows, it’s always best to expect the unexpected.

“We finished the core and shell construction in May 2021, and the data hall was right on its heels as a change order to the original project. So it came at us fast and furious,” Reading said. “The original plan was to complete the entire chilled water loop, which runs underneath the floor on both sides of the building. However, it was decided to install the piping in stages as the facility is built out. So far we have installed about half of the piping that will ultimately go in there.”

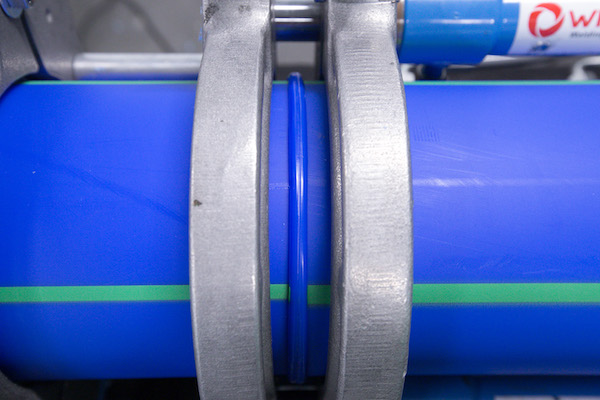

The installation to date has included 4,418 ft of Aquatherm Blue Pipe SDR 17.6. The main system piping is 10-in., and the takeoffs are 4-in.

Training Professionals

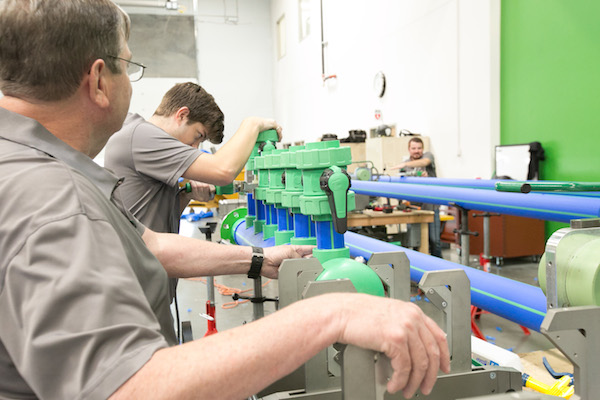

To handle such a large project. Harris Mechanical sent several installers to Aquatherm’s U.S. headquarters in nearby Lindon, UT, for training.

Having Aquatherm-trained technicians opens up new opportunities for HVAC and plumbing companies. The company gains differentiation in the market, and enjoys the time- and labor-savings associated with installing polypropylene pipe.

Aquatherm training is the most intensive, comprehensive training in the polypropylene piping industry. Attendees receive both classroom training and hands-on training with multiple fusion machines, and must pass a rigorous test using all the fusion tools correctly.

After the training, Harris completed the installation using McElroy fusion tools and a combination of socket fusion for the 4-in. pipe and butt fusion for the 10-in. pipe. The system runs at a low pressure (35 to 45 psi); the cooling system supply water runs at 55°F and returns to the chiller at about 60°F.

According to Reading, Harris Mechanical had a good experience with Aquatherm piping at the Novva data center, and the ease of installation compared to steel pipe helped Harris stay ahead of the project’s tight schedule.

“It was a smooth process,” he said. “We definitely gained experience and confidence with the pipe throughout the project, and our installers became accustomed to ‘leapfrogging’ and working with more than one [fusion] machine at a time.”

A Smooth Path

The underfloor piping system presented one of the major installation challenges at this project. The floor is raised 5-ft., and all of the facility’s piping, wiring, HVAC ducting, and utilities run through the raised space.

Aquatherm’s building information modeling (BIM) capabilities and Scan-to-Fab service helped ensure that the installation went smoothly by preventing underfloor conflicts and collisions.

“Using 3D BIM and Revit really helped with coordinating this installation,” said Autumn Turner, a fabrication drafter at Aquatherm. “Not only was all the HVAC and plumbing under the floor, there were floor stands every square foot. It took a lot of coordination to avoid all those potential obstacles.”

Turner noted that careful coordination enhanced the already-fast heat-fusion installation of Aquatherm pipe, and that less time and money spent on welders is a major benefit of choosing Aquatherm.

“Aquatherm is just easier work with than steel pipe,” she said. “It takes a lot less time to weld, and when you add in the BIM support and drafting it was easier for the installers to get situated into the floor and navigate the space.”

Turner added that Aquatherm’s BIM and Revit capabilities will ensure the future installation phases of the massive project also go smoothly.

Rhett Coles, Aquatherm’s fabrication drafting/scan-to-fab manager, said that Aquatherm’s Scan-to-Fab service and in-house fabrication makes any piping installation easier and smoother. Spools can be custom made in any size or configuration and shipped to the jobsite ready to install. In addition, any pieces fabricated by Aquatherm are covered by a comprehensive 10-year warranty.

“In the case of the Novva data center, we were in constant communication with Steven Boyce and the owner’s group,” Coles said. “We were not providing a cookie cutter system to them. They would tell us whatever they wanted or needed and we would work directly with them to help them fully accomplish their goals.”

A reliable, leak-free piping system with a long life span, and a smooth installation in any space, including challenging underfloor designs? The data are in: Aquatherm is the right choice for data centers.

Lindon, Utah — Aquatherm announced that it has added Southern Pipe & Supply as a distribution partner. Founded in 1901, Southern Pipe & Supply is one of the largest privately held, independent distributors of brand-name plumbing, HVAC, industrial, mechanical, and water works supplies in the Southeast, with more than 100 locations in Mississippi, Alabama, Louisiana, Georgia Read more

Lindon, Utah — Aquatherm announced that it has added Southern Pipe & Supply as a distribution partner.

Founded in 1901, Southern Pipe & Supply is one of the largest privately held, independent distributors of brand-name plumbing, HVAC, industrial, mechanical, and water works supplies in the Southeast, with more than 100 locations in Mississippi, Alabama, Louisiana, Georgia, Arkansas, Florida, and Tennessee.

“Southern Pipe has always aligned themselves with the brand leaders in the marketplace,” said William Jolly, Director of Purchasing – Southern Pipe & Supply. “We are honored to partner with Aquatherm, the leader in polypropylene piping systems.”

Glen Miller, Vice President of Sales, Aquatherm North America, said the company has been strategically adding distribution to support its contractor customers.

Glen Miller, Vice President of Sales, Aquatherm North America, said the company has been strategically adding distribution to support its contractor customers.

“Southern Pipe & Supply is a perfect fit with Aquatherm’s Culture of Excellence,” Miller said. “We are excited to have them as a distributor partner.”

This paper refers to legal professional cannabis growers complying with state/provincial laws. Professional cannabis growers are well aware that environmental conditions play a critical role in plant quality and overall yield. Most can recite the ideal temperature and humidity for their crops without missing a beat. But ask most growers which type of pipe is Read more

This paper refers to legal professional cannabis growers complying with state/provincial laws.

Professional cannabis growers are well aware that environmental conditions play a critical role in plant quality and overall yield. Most can recite the ideal temperature and humidity for their crops without missing a beat. But ask most growers which type of pipe is best and they’ll likely to refer you to the closest head shop. The fact is professional growers (of cannabis or otherwise) are generally unaware of the piping options they have or the extent to which these options impact structural costs, energy efficiency and overall sustainability. When these matters are given proper consideration, polypropylene emerges as a great choice for this burgeoning industry.

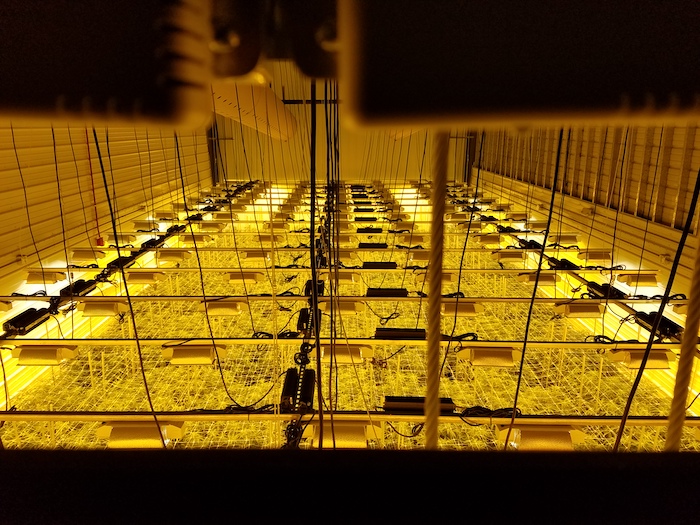

Cannabis growing facilities use a lot of energy and generate a lot of heat, making a reli- able cooling system essential.

Polypropylene pipe has been widely used for plumbing and hydronic heating in Europe since the 1970s. However, it was not introduced to North America until 2005. Since then, it has become increasingly popular for a wide range of applications, from radiant heating of sports fields to process applications in craft breweries. It is a lightweight yet highly durable thermoplastic pipe with pressure and temperature tolerances that make it suitable for hydronic heating and cooling, potable water, and industrial and food-grade applications.

Depending on size and wall thickness, polypropylene pipe can weigh up to 70% less than carbon steel pipe.

Unlike metal pipe, the installation of polypropylene pipe does not involve traditional torch welding. Instead it relies on a flameless heat-fusion method that’s easy to learn and highly reliable at creating virtually leak-free connections. When contractors become adept at heat fusion, they can typically install polypropylene piping much faster than welding copper, carbon steel and stainless-steel pipe.

An appealing characteristic of polypropylene is its chemical purity and inertness. It does not rust, scale or leach any impurities into to the fluids it transports, nor does it react with most chemicals. This not only improves its longevity over other piping materials, it also makes it suitable for a wide range of applications. Furthermore, unlike PVC or CPVC piping, polypropylene pipe does not become brittle or susceptible to cracking when exposed to cold temperatures. A full list of the physical/performance characteristics of polypropylene and associated benefits is shown in Table 1.

Where does polypropylene fit into the day-to-day operation of a grow facility? The answer is pretty much any application that requires the transport of fluids. But to truly understand the potential roles that polypropylene can play in the growing cannabis industry, one must first look at the special needs, challenges and values of the industry.

Where does polypropylene fit into the day-to-day operation of a grow facility? The answer is pretty much any application that requires the transport of fluids. But to truly understand the potential roles that polypropylene can play in the growing cannabis industry, one must first look at the special needs, challenges and values of the industry.

An Energy Intensive Industry

The electrical demand of cannabis grow facilities is staggering. According to the 2018 Cannabis Energy Report, legal cannabis cultivation in the U.S. consumes an estimated 1.1 terawatt-hours of electricity a year, enough to power all of Newark, New Jersey or Anaheim, California.[1] In indoor grow facilities — very often repurposed warehouses or other types of vacant buildings —this massive energy consumption is caused by the artificial light required to grow cannabis. Heat from these lights imposes another energy burden: cooling. Year-round cooling loads are unavoidable in indoor facilities since carefully controlled space temperatures are essential for growers to achieve maximum yields. Greenhouse facilities may avoid most of the need for artificial light, but still need heating, cooling and dehumidification. In either case, large facilities benefit from the long-term efficiency of centralized hydronic heating and/or cooling systems, which are typically about 15 percent to 20 percent more efficient than other HVAC options.[2] These systems utilize piping to transport the heating water to and from a central boiler system and to transport cooling water to and from a chiller and/or evaporative cooling equipment.

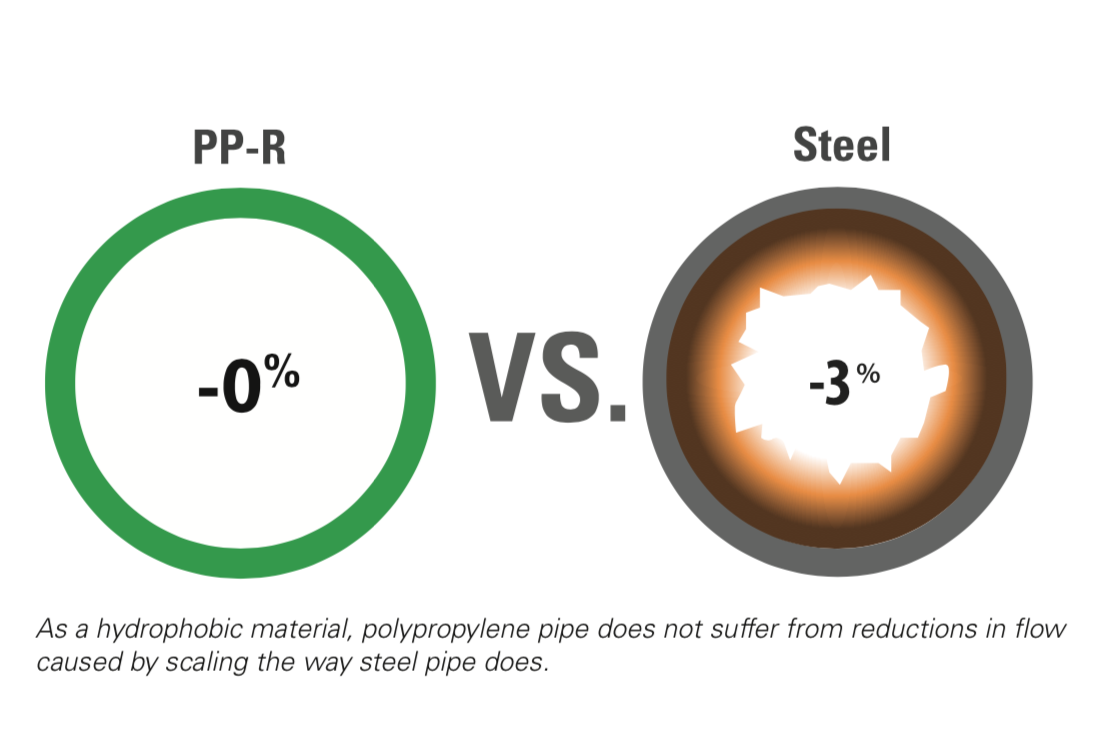

Polypropylene piping is ideal for these applications for reasons that directly impact the efficiency and longevity of a grow facility. First, the inner walls of polypropylene pipe are uniquely smooth, resulting in reduced friction losses, reducing pump energy consumption. The friction losses of polypropylene start out low and remain low for the life of the system because the pipe is not susceptible to rust or scale. Steel, copper and other metals do rust and corrode over time, increasing friction losses and the pump energy required to overcome those losses.

Socket fusion (shown here) is one method of heat-fusing polypropylene pipe and fittings.

Polypropylene pipe also can be used in conjunction with geothermal heat pump systems which are frequently applied in agriculture. Geothermal systems rely on the earth or a body of water as a heatsink and/or heat source for highly efficient transfer of heat to and from the growing spaces for space conditioning and agricultural processes. In these applications, polypropylene pipe transports the heating and/or cooling fluid from the central energy source to forced-air equipment or a radiant distribution loop. The pipe can be buried in the ground and/or concrete floors without the need for any protective sleeves or wrap.

Another strategy that grow facilities often use to reduce their energy consumption is heat reclaim. In these applications, polypropylene pipe can be used to transfer energy to or from process water, wastewater, or any other source that can be used to pre-heat or pre-cool water for other heating, cooling or process needs. This gives growers the opportunity to fully optimize whatever resources are available to them – whether it be the sun, a nearby lake, or even a nearby wastewater treatment plant. It’s all been done with polypropylene.

Specialized Growing Strategies

Not all commercial cannabis is grown in soil. Some is grown hydroponically with plant roots submerged in a nutrient-rich solution of water and fertilizers while others are grown aeroponically with roots suspended in air, drawing nutrients from a sprayed mist. These grow strategies very often rely on high purity water (typically reverse osmosis or deionized water) when existing water sources are determined unsuitable.

Versatile fusion tools allow polypropylene pipe to be heat- fused in spaces in which welding metal pipe would be difficult or impossible.

High purity water automatically limits piping options. Copper should never be used with deionized water because if the fluid’s pH levels fall below 6.5, corrosion may occur and copper molecules can leach into the supply. Although stainless steel piping is an option for these applications, it is often cost-prohibitive and it, too, will leach over time if the water should become too acidic or too alkaline. Polypropylene is ideal for these applications because it does not leach, and its installation never requires the use of any potential contaminants such as solder, flux or glue. It can even be used for potable water and food processing since it is available in formulations that meet both NSF 51 and NSF 61.

Facilitating Construction and Expansion

Growers and owners are typically under a lot of pressure to quickly get grow facilities operational so they can begin the journey from seed to profit as soon as possible. Construction schedules are always a challenge, particularly when it comes to mechanical components like piping. Installing metal pipe requires licensed welders (expensive and increasingly scarce) as well as special permitting for the use of open flames on a jobsite. In addition, maneuvering heavy sections of metal pipe into existing structures and then supporting it so it can be welded into place is both logistically and physically challenging. Under these circumstances, a seemingly trivial error like a miscalculation in metal pipe length can put a project several days (if not weeks) behind schedule.

Polypropylene pipe is hydrophobic and will never scale and corrode the way metal pipe does.

Opting for polypropylene pipe keeps these jobsite nightmares at bay for the following reasons:

- Polypropylene is lightweight – especially helpful in greenhouses where structural support is limited

- Polypropylene fittings can be prefabricated offsite in controlled areas so that jobsite fabrications are minimized – some manufacturers even offer fabrication services

- Improper lengths can usually be amended at the jobsite with little disruption to work schedules

- The pipe’s maneuverability compared to metal means it can be better negotiated in tight spaces

If an owner has hopes to expand the facility in the future (as many do), polypropylene piping systems are much easier to build out than metal pipe. Strategically located shut-off valves make it easy to isolate flow and cut into existing pipe to create new connections with minimal disruption to current operations. Fusion outlets allow for easy and relatively inexpensive expansions and one manufacturer offers a hot tap solution. Again, no flames or permits are required.

Beer There, Done That

If cannabis entrepreneurs need relevant examples of all that polypropylene can do, they need only look as far as the craft brewing industry. Craft brewers, an intensely collaborative group, have solidly embraced polypropylene for all that it has to offer, most notably its purity, sustainability, and fast and flexible installation – interests that closely parallel those of the cannabis industry.

“The word of mouth in the craft brewing industry is amazing, so we’ve had tremendous growth from breweries using it, not just for the glycol lines but in their heating and cooling applications, their geothermal applications, their domestic water supply, CO2, compressed air applications and beyond,” said Barry Campbell, VP of Marketing at Aquatherm, a leading manufacturer of polypropylene pressure piping systems.

A properly executed heat-fusion on polypropylene pipe creates a single piece with no leak paths.

According to Campbell, the fact that polypropylene is among the most environmentally friendly piping systems available has helped Aquatherm gain favor among craft brewers. One polypropylene pipe manufacturer has also done the certification work to allow the product to contribute to LEED v4 credits in the U.S. Green Building Council’s (USGBC) program.

An interest in sustainability is just one of the many commonalities that exist between the cannabis and brewing industries. Like so many newly incorporated cannabis growers, many craft brewers begin their entrepreneurial journey in the shell of a vacated building where existing infrastructure can challenge piping installations. The building or parking lot next door is “Phase II” of their venture. Finally, owners are often the same people brewing the beer or growing the cannabis, so they tend to be more hands-on in the selection of mechanical equipment. They do their own research and tend to look outside the box for ways to conserve energy.

Robert Millspaugh, operations supervisor at Flathead Lake Brewing Company in Bigfork, Montana, did extensive research on what piping to use for the process side of the brewery before ultimately choosing polypropylene. Flathead Lake, born from the ruins of an old bowling alley, installed several thousand feet of polypropylene to transport both heating water and glycol for heating, cooling, and process applications. Part of the system even uses clean effluent from a nearby water treatment plant to indirectly pre-temper process water for better efficiency.

“We were looking for products that would help us achieve a LEED certification and [polypropylene] had a lot to offer. I also came across an article on Epic [Brewing Company in Salt Lake City] and how they used [polypropylene] in a renovation and discussed the product with the brewer there,” said Millspaugh.

Polypropylene also has been used successfully in brewing applications that require piping for food-grade and potable water.

Avondale Brewing Co., in Birmingham, AL was the first North American brewery to use Aquatherm’s food-grade (NSF-51) polypropylene pipe to transport beer from vessels in the main brewery to its packaging building where it is kegged, canned and bottled. The piping, which also is NSF-listed for potable water, is cleaned and sanitized between uses. Of course, like all of the manufacturer’s polypropylene systems, the piping is guaranteed to be free of heavy metals and toxic chemicals.

Cleanliness is a high priority in breweries and is one of the main reasons Founders Brewing Co. in Grand Rapids, MI, decided to use polypropylene in a heat reclaim process that taps heat from the brewing process to pre-heat outdoor air before it enters the building’s HVAC system. The piping is wash-down rated, so the brewer can keep the brew facility sparkling clean.

Examples like these demonstrate the potential for polypropylene piping in the cannabis industry.

“The craft brewing industry and everything it has been able to do with our pipe has created an unexpected blueprint for cannabis growers and how they can use polypropylene to facilitate construction, save energy and be more sustainable,” said Campbell.

[1] New Frontier Data, 2018 Cannabis Energy Report. Scale Microgrid Solutions and Resource Innovation Institute, co-authors. https://newfrontierdata.com/product/2018-cannabis-energy-report/

[2] Surna, Sustainability for Your Indoor Garden (blog) https://surna.com/sustainability-for-your-indoor-garden/

Lindon, Utah—The tariffs on imported steel and aluminum recently imposed by President Donald Trump immediately raised concerns of an adverse effect on steel and aluminum prices. The American Institute of Architects issued a statement saying, “The administration’s announcement of new tariffs on steel and aluminum imports threatens to drastically increase the prices of many building Read more

Lindon, Utah—The tariffs on imported steel and aluminum recently imposed by President Donald Trump immediately raised concerns of an adverse effect on steel and aluminum prices. The American Institute of Architects issued a statement saying, “The administration’s announcement of new tariffs on steel and aluminum imports threatens to drastically increase the prices of many building materials specified by architects.” The Associated General Contractors of America warned that the tariffs “could wreck the budgets for numerous infrastructure projects and private nonresidential investments.”

The Associated General Contractors of America (AGC) warned that the tariff “could wreck the budgets for numerous infrastructure projects and private nonresidential investments.”

According to AGC, even before they took effect May 31, the tariffs had triggered a surge of orders that mills say exceeds their current capacity, a situation that threatens to produce construction delays, budget problems, and possibly cancellations for future construction projects.

“Considering the impact the mere threat of the tariffs have had on materials prices and demand, prices are likely to increase further as the new trade restrictions come online,” said Stephen E. Sandherr, AGC’s chief executive officer. “Forcing contractors to pay more for materials and wait longer to receive them will make construction more costly and slower.”

The American Supply Association’s (ASA’s) Industrial Piping Division noted that carbon steel pipe experienced “unprecedented” increases during the weeks following the president’s initial announcement of a tariff on imported steel in March. “[The announcement] caused an immediate increase of at least 25% on all imported steel pipe,” the ASA reports. “Domestic product has seen increases ranging from 22% to 60% depending on size.”

Given the ongoing turmoil the tariffs are likely to cause in the steel market, polypropylene-random (PP-R) pipe such as Aquatherm stands as a better option than ever for large-diameter mechanical piping systems.

PP-R pipe is not subject to the tariffs, and its price has remained stable and predictable over the years. Engineers planning mechanical systems, and contractors bidding on them, can rely on PP-R to remain a consistently priced piping system. By contrast, the metal piping market has fluctuated dramatically over that same time span, and in all likelihood is going to remain volatile because of the tariffs.

The predictable total installed cost of PP-R is a primary benefit versus steel. Heat fusion can be much quicker than welding or soldering and requires no hot work permit or fire watch, making considerable labor and total installed cost savings achievable.

Other benefits include much lighter weight (up to 70% less weight than carbon steel depending on size), a much longer life span of 60+ years, and virtually leak-free heat-fused connections that do not require any open flame or welding or release any volatile organic compounds (VOCs). PP-R pipe does not scale or corrode and is fully recyclable.

PP-R pipe is versatile and suitable for a wide variety of PHVAC and industrial applications, and possesses widespread code approvals. In addition, thanks to its light weight, PP-R pipe spools can be prefabricated and shipped directly to the jobsite, ready to hang.

In an ever-changing business climate where metal piping system prices are subject to uncertainty and volatility, price stability is just one more reason to consider PP-R for the piping system in your next project.

This edition of “They Said It” concentrates on prefabrication in construction of plumbing and hydronic systems. After attending numerous conventions and seminars over the course of the past six months, one topic resonated: prefab is the future of construction. We talked with industry experts from across the board—contractors and manufacturers—to share viewpoints on the benefits Read more

This edition of “They Said It” concentrates on prefabrication in construction of plumbing and hydronic systems. After attending numerous conventions and seminars over the course of the past six months, one topic resonated: prefab is the future of construction. We talked with industry experts from across the board—contractors and manufacturers—to share viewpoints on the benefits of prefabrication.

What are some of the major benefits of prefabrication?

Robert O’Brien, owner of Technical Heating Co. LLC, Mt. Sinai, NY.

Robert O’Brien, owner of Technical Heating Co. LLC, Mt. Sinai, NY.

Prefab speeds up installation time, shaves hours, and, quite often, a day from installation time. This is huge since all we do is replacements and not many homeowners want to spend a night or two without heat, particularly in the winter. We do in one day that others would take two days. Also, it is aesthetically pleasing, offers better serviceability. It has become a signature and a selling point.

Barry Campbell, vice president of marketing, Aquatherm

Barry Campbell, vice president of marketing, Aquatherm

Prefabrication can save time and money on the jobsite, as well as help ensure consistent, high quality assembly. Prefabrication services allow a manufacturer to serve as an essential extension of a contractor’s team, easing the workload and helping a project meet its deadlines.

Time is money—and nowhere is that more evident than in today’s construction industry. Since plumbing and mechanical profit margins are tighter than ever, contractors need solutions that separate them from their competition. A good manufacturing partner that offers prefabrication services can add value and help make a contractor’s job easier.

By having systems prefabricated and shipped directly to the jobsite, the labor savings compared to onsite fabrication can be significant, as prefabricated parts can simply be moved into place and connected together to form a system. In addition, safety can be improved by removing the fabrication work from the jobsite and outsourcing it to the manufacturer. The prefabrication process can be as simple or as extensive as a customer and a project requires.

Aquatherm, for example, can take a simple hand drawing and turn it into an intricate digital design document. Or, the company’s extensive engineering expertise and fabrication skill can be extended as a service to help show a customer the best way of designing a mechanical system and providing complete fabrication drawings. The Aquatherm team brings an array of building information modeling (BIM) tools to the table, including a full Revit library and a team with the skills to use it.

Shane Fink, owner, Triple H Hydronics, Calgary, Alberta, Canada

Shane Fink, owner, Triple H Hydronics, Calgary, Alberta, Canada

One of the most overlooked benefits is having detailed layouts and extensive system planning done well before construction ever starts. Many systems today are designed “as you go” in a mechanical room, and there are many mistakes made in the haste of designing and building the system at the same time.

Another major benefit is time savings. We are able to help design and prefabricate the systems, sometimes before the building structure is even standing. By having a well-executed layout and design, we are able to cut time on site by more that 50%. Many times this saves money on temporary heating costs, as well.

Another great benefit is workmanship and attention to detail. When we are in a controlled environment with all of our tools at our fingertips and not in the elements—cold winters—we are able to take the time required to do an excellent job. In the field there are many pressures to “get it done” and use what you have, so sometimes that attention to detail can slip away.

One of my favorite benefits would be quality testing. In our shop, we are able to test every system before it leaves from the loading docks. We have to ability to hydro-test the systems @ 5 times working pressure, to ensure the systems are leak-free. We are also able to electrically test the systems for proper operation and pre-program settings to save time and money in the field.

For custom-built hydronic panels, for instance, take me through the process. Are you onsite consulting with the client? (Measurements, heat load calcs, etc.)

O’Brien: We make site visits to take measurements, size boiler, water heater and accessories. We take pics to facilitate panel construction, and most importantly, sell the job!

Campbell: Customers contact their Aquatherm representative to initiate the process, then the Aquatherm Design & Fabrication team works directly with the customer to obtain drawings and walks them through all the steps necessary to deliver final drawings for approval. The pieces are then meticulously created and shipped to the jobsite.

Whether it’s a detailed spool, large diameter elbows, or complex manifolds, Aquatherm offers a dedicated and experienced professional staff and a vast collection of high-tech design and heat fusion equipment to create it. The company also produces unitary spool fabrications that can help reduce a project’s bottom line.

Prefabrication with Aquatherm often is possible where it would not be with other materials, as Aquatherm pipe is considerably lighter than metal pipe. This results in an easier prefabrication process and simplified transportation to the jobsite.

A proper heat fusion connection results in a joint as strong as the pipe itself. Additionally, PP-R is incredibly sturdy, yet slightly flexible. So after Aquatherm prefabrication services has meticulously created a custom spool, it will be carefully shipped to a jobsite anywhere in the U.S. or Canada, typically resulting in significant material and/or labor savings. Often, the prefabbed pieces are simply flanged into place.

Aquatherm’s design coordination and fabrication process cab help ensure a smooth job. With an extensive list of past projects, Aquatherm’s fabrication services team will find a solution to fit any project’s needs. For more information, www.aquatherm.com.

Fink: Most of our clients have either worked with us for years, have been referred by another client or find us on social media. In most cases the process is the same. First we start with the blueprints. Our clients send over architectural drawings of the building proposed. We do a heat loss/heat gain calculation and start working with the client to determine their needs. This usually involves laying out zones for heating, determining domestic hot water consumption demands, ventilation requirements and other items such as snowmelt, heated towel bars, pools, spas, etc. Once we determine what the client requires, we complete a loop layout for all the floor heating so that they can be submitted with the heat loss calculations and building permit applications.

After the panel has been built and polished, we start the wiring and controls. This can sometimes range from a couple hours to a week or more, depending on the size and complexity of the system.

At this point an estimate is produced for the manufacture of the hydronic heating panel. Once the client has approved the estimate, we go to work on the design of the panel itself. The panel design has many considerations and we do our best to ensure a smooth installation. This design includes boiler/venting locations, condensate drain locations, floor or wall mounted boilers, which side of the pre-fabricated panel will the boilers be, will the panel be shipped in one piece, two or more. This helps us as we start to physically lay out the system on a work bench. At this time we have hand drawn boiler panel layout with the basic information. Pipe size, hardware etc. Now we can build the system. Most systems we can build in a few days. Some of the simple panels can be built in a day or less.

After the panel has been built and polished, we start the wiring and controls. This can sometimes range from a couple hours to a week or more, depending on the size and complexity of the system. After all the wiring is done and sensors are attached, we can test the panel. Testing is always done with two or more people present. This helps to ensure that the entire checklist is done correctly. If the tests all check out, the panel is dressed with any loose accessories, labeled and serial numbered and is ready for shipping. For more info on Triple H Hydronics, www.triplehhydronics.com.