Just in time for heating season, Weil-McLain® has updated its ProTools™ App with enhanced features to provide contractors and service technicians with the support they need to streamline customer visits and provide clients with a premium experience. Available for iOS and Android devices, the app now allows heating professionals to work virtually with Weil-McLain’s Tech Support team to Read more

hot water

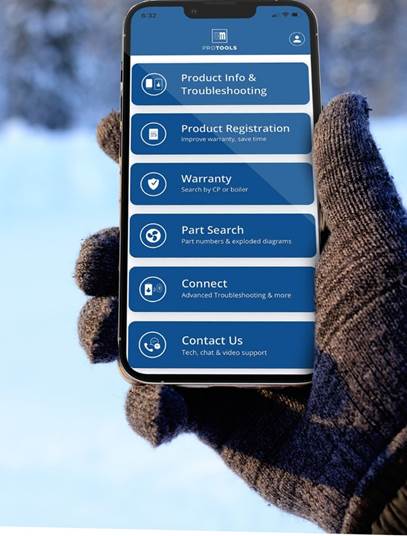

Just in time for heating season, Weil-McLain® has updated its ProTools™ App with enhanced features to provide contractors and service technicians with the support they need to streamline customer visits and provide clients with a premium experience. Available for iOS and Android devices, the app now allows heating professionals to work virtually with Weil-McLain’s Tech Support team to problem-solve issues as they occur on the job site.

“Our goal is to continuously optimize this platform by adding additional features that make service technicians’ and installing contractors’ jobs easier – especially during the busy heating season period,” said David DeVries, Director of Product Management with Weil-McLain. “The new Site-Call video assistance opens new opportunities for service technicians to receive instant support from our Tech Support team.”

Service technicians who run into complications while on the job can contact Weil-McLain Tech Support for Site-Call video and receive immediate real-time assistance. After requesting support, they simply accept the call from Tech Support on their smartphone and share a live video of the issue they are experiencing on the job site. Tech Support will then highlight the issue on the service technician’s screen and propose corrective action to solve it.

“This new feature provides heating professionals with immediate access to our support team and also allows them the opportunity to learn new methods for troubleshooting, maintenance and boiler setup,” added DeVries. “As we prepare for what could be another colder than normal winter, we want to ensure service technicians have all the digital tools and knowledge they need to help expedite customer visits while providing homeowners a best-in-class service experience.”

The Weil-McLain ProTools App helps enhance service technicians’ hydronic expertise by putting a variety of Weil-McLain boiler product information at their fingertips. From reviewing fault codes for troubleshooting and accessing how-to videos to viewing product manuals and schematics and quickly finding parts, the app has become a one-stop resource for boiler installation and maintenance.

For more information on the upgraded Weil-McLain ProTools App, visit www.weil-mclain.com or download the app via the App Store or Google Play.

Watts will unveil solutions for a Safer, More Sustainable World at the American Society of Plumbing Engineers’ (ASPE) Convention & Expo, September 16-21, in Indianapolis, IN. Watts representatives will be on hand in Booth #1133 to discuss solutions supporting sustainability in the areas of heating and hot water, drainage, backflow & mixing, data centers, and Read more

Watts will unveil solutions for a Safer, More Sustainable World at the American Society of Plumbing Engineers’ (ASPE) Convention & Expo, September 16-21, in Indianapolis, IN.

Watts representatives will be on hand in Booth #1133 to discuss solutions supporting sustainability in the areas of heating and hot water, drainage, backflow & mixing, data centers, and water management. They will represent such brands as AERCO, BLÜCHER, Lync, ORION, POWERS, PVI, The Detection Group, and Watts.

Watts experts will also be featured speakers at two technical sessions:

- David Desjardins, Business Development Manager-Mixing, Wholesale East, will present Smarter, Safer, Hot Water (Track: Codes and Standards/Water Quality) on September 20 from 8:30–9:45 am.

- Laurie Conner, President, The Detection Group, will present Wireless Water Leak Detection Systems for Commercial Applications (Track: System Design) on September 21 from 10:00–11:15 am.

For more information and to register for the ASPE Convention & Expo, go to: 2022 ASPE Convention & Expo – September 16-21, 2022 .

Grundfos, a global leader in water technology, has released the Grundfos UP 10-16 Digital Timer. The hot water recirculation pump, made for homes with a dedicated return line, includes an integrated digital timer that allows the pump to be programmed to only run when hot water is needed, resulting in more efficient water usage. “We’re Read more

Grundfos, a global leader in water technology, has released the Grundfos UP 10-16 Digital Timer. The hot water recirculation pump, made for homes with a dedicated return line, includes an integrated digital timer that allows the pump to be programmed to only run when hot water is needed, resulting in more efficient water usage.

“We’re pleased to launch another cost-effective, sustainable addition to the UP 10-16 range,” said Kirk Vigil, Grundfos vice president of sales for domestic buildings in the USA. “Now, with the new digital timer, you can run hot water on your own time. And like the other UP 10-16 models, it’s easy to install, runs quiet and can save up to 12,000 gallons of water per year by giving the homeowner instant hot water.”

The Grundfos UP 10-16 range sets a new standard for energy-efficient hot water recirculation in residential homes. The pump’s low-noise permanent magnet motor reduces energy consumption to as little as 5 to 8.5 watts. UP 10-16 pumps are easy to install and deliver reliable operation for buildings with a footprint of up to 2,000 square feet. The lead-free bronze housing complies with the latest U.S. safe drinking water standards. Three control modes — Basic, Temperature and Auto — make it easy for installers to select a pump that matches the needs of the homeowner.

The Grundfos UP 10-16 Digital Timer is now available for purchase through local Grundfos distributors in the USA. Find where to buy: http://bit.ly/2KWrEiT

Learn more about Grundfos’ instant hot water circulator pumps by visiting https://bit.ly/3gzywfQ.

When Pine Valley Ranch, a Spencerville, Ohio-based egg-breaking facility was looking for an energy efficient way to wash 600 cases of eggs an hour they turned to Consolidated Hunter, a local heating contractor, and Pickrel Brothers, a leading provider of industrial heating supplies to help present options. Their recommendation? Install six Weil-McLain SlimFit 750 commercial Read more

When Pine Valley Ranch, a Spencerville, Ohio-based egg-breaking facility was looking for an energy efficient way to wash 600 cases of eggs an hour they turned to Consolidated Hunter, a local heating contractor, and Pickrel Brothers, a leading provider of industrial heating supplies to help present options. Their recommendation? Install six Weil-McLain SlimFit 750 commercial high-efficiency hot water boilers.

“We’re an egg-breaking plant,” explains Evan Fleck, an owner of Pine Valley Ranch. “Our eggs come straight from the barn and are immediately washed. Then they are broken, separated and chilled. Once this is done, they are loaded into liquid tankers and shipped to be pasteurized. Every step of the process is important, especially the washing of the eggs. We need plenty of hot water for that, as well as for other daily operations.”

The 4.5 million BTU/hour Pine Valley heating system supports seven individual heating zones. The first three zones are dedicated to the egg washing machines and supported with 750 BTU/hour boilers. The fourth and fifth zones support the clean-in-place equipment (990,000 BTU/hour heat exchangers) while the two remaining zones are for the indirect fired water heater and the on-site plant mixing station.

“Every zone is critical to ensuring a high-quality, efficient production process,” says Fleck. “We have more than 900,000 chickens at this facility and they produce a lot of eggs. The Weil-McLain boiler systems provides a consistent source of hot water to accommodate this large number.”

SlimFit boilers have been serving the heating industry since 2009 with rugged, cast horizontal heat exchanger sections that provide thermal efficiencies up to 95.8% (SlimFit 1000 & 1500 models). The boilers feature a low pressure drop design, with large water passageways to accommodate a wide range of commercial installations, including retrofit and replacement applications with older water systems.

The larger SlimFit 1000-2000 models feature a narrow “door-fit” profile and integrated roller casters for improved installation maneuverability in confined spaces and weight restricted areas, saving contractors time and money. Other standard features include a composite condensate tray for heat exchanger longevity, customizable control mounting location (front or side) and leveling legs, which mitigate the need for a concrete service pad.

Control features include a setup wizard that guides the installer through the start-up process and 10 preset typical heating operation conditions. The SlimFit also features zone stacking up to 24 programmable zones without the need for additional external panels and 0-10 VDC analog output signal for easy integration with a lag boiler in a hybrid system.

“We really appreciate how the Weil-McLain boiler-system enhances our operation,” says Fleck. “The equipment was installed when the facility was built so they’ve been part of our production process from the beginning. Running a plant of this size always presents challenges, but our hot water needs are not one of them.”

Taco Comfort Solutions’ Near-Boiler Trim Kit provides a quick and convenient way to purchase all the accessories needed for near-boiler piping. The Near-Boiler Trim Kit comes in premium, advanced and select configurations, and is available in 1” and 1-1/4” sizes so installers can select the kit that fits their needs. All versions of the kit Read more

Taco Comfort Solutions’ Near-Boiler Trim Kit provides a quick and convenient way to purchase all the accessories needed for near-boiler piping.

Taco Comfort Solutions’ Near-Boiler Trim Kit provides a quick and convenient way to purchase all the accessories needed for near-boiler piping.

The Near-Boiler Trim Kit comes in premium, advanced and select configurations, and is available in 1” and 1-1/4” sizes so installers can select the kit that fits their needs. All versions of the kit include air separators, boiler feed and backflow preventer, 4.5-gallon expansion tanks, and all fittings and connections.

The trim kits are designed for easy installation and are ASSE listed.

For more information, visit www.TacoComfort.com