Lochinvar is hosting a free webinar to introduce the new CON·X·US™ remote connect capability. Presently available as an option on the FTXL Fire Tube Boiler, CON·X·US will become available on even more high-efficiency Lochinvar products in 2015. CON·X·US technology lets you use any smart device to link up with SMART SYSTEM™ boiler controls from around Read more

Lochinvar

Lochinvar is hosting a free webinar to introduce the new CON·X·US™ remote connect capability. Presently available as an option on the FTXL Fire Tube Boiler, CON·X·US will become available on even more high-efficiency Lochinvar products in 2015. CON·X·US technology lets you use any smart device to link up with SMART SYSTEM™ boiler controls from around the corner or halfway around the world!

Join Lochinvar for the webinar on May 20, 2015 at 10:00 AM CDT, or June 3, 2015 at 10:00 AM CDT.

Click here to register or visit www.Lochinvar.com for more information.

LEBANON, TN – March 12, 2015 – Lochinvar has named the latest winners of the VIP Installation Showcase and the VIP Drawing for the 2014-2015 heating season. Nathan White of White’s Plumbing & Heating in Kenai, Alaska was named the February winner of the VIP Installation Showcase, and Joseph DiPietro of DiPietro Heating & Cooling Read more

LEBANON, TN – March 12, 2015 – Lochinvar has named the latest winners of the VIP Installation Showcase and the VIP Drawing for the 2014-2015 heating season. Nathan White of White’s Plumbing & Heating in Kenai, Alaska was named the February winner of the VIP Installation Showcase, and Joseph DiPietro of DiPietro Heating & Cooling in Bradford, Massachusetts was selected in the season’s fifth monthly VIP drawing. Both contractors will each receive an all-expenses-paid trip for two to Lochinvar’s Nashville Experience this June. The prize also includes tickets to the world’s largest country music festival.

An Impressive Installation

White’s entry in the VIP Installation Showcase, which is housed on Lochinvar’s Facebook page as well as on www.knightheatingboiler.com, featured two 155,000 Btu/Hr. KNIGHT® Wall-Mount Heating Boilers and one 80-gallon Squire Stainless Steel Indirect Water Heater being used to convert a 7,900 square feet, 14-zone home in Homer, Alaska to natural gas from fuel oil. After receiving numerous votes, White’s entry was selected by a panel of Lochinvar judges as the February winner.

“We chose to install two Lochinvar KNIGHT boilers for their state-of-the-art fire tube heat exchangers and their space-saving wall-mounted design,” said White. “We’re excited to see the installations improve the home’s efficiency, and it’s an honor to be recognized by Lochinvar with the VIP Installation Showcase award.”

Through April 2015, approved contractors can upload a photo and brief description of any eligible boiler installation to the contest interface. Qualified products include the high-efficiency KNIGHT® (55,000 – 399,000 Btu/hr models), Solution™ and Cadet® Boilers, as well as the Squire® Indirect Water Heater.

Once an entry has been submitted, it is featured in a gallery where Facebook users can vote for their favorite installations. Each month of the Showcase, the top three entries with the most votes are selected as finalists, and a panel of Lochinvar judges chooses the winner.

If an Installation Showcase entry is not named a winner in the month it was registered, there’s still a chance it may win in a later month. While VIP Contractors can only win the Nashville Experience once per year, submissions continue to be eligible to win even after the first month they are entered.

Rewards for Registrations

In addition to White, DiPietro was also named a winner in the VIP Contractor Program for February. DiPietro was randomly selected in the monthly drawing for approved VIP Contractors. Every approved VIP Contractor is entered into a monthly drawing to win the Nashville Experience. For every qualified boiler registration, VIPs receive a Visa® Reward Card pre-loaded with $25 value. Each registration of the Squire Indirect Water Heater earns a card pre-loaded with $10 value.

“It is awesome that I won Lochinvar’s Nashville Experience,” said DiPietro. “I am a firm believer in Lochinvar’s reliability that is delivered through their high efficiency products, and I cannot wait to spend a few days in a great city, touring Lochinvar’s headquarters and visiting some old college friends.”

During the all-expenses-paid trip for two, winners and their guests will stay at Nashville’s Omni Hotel, a short walk from the ultimate experience for any country music fan. As part of the Nashville Experience, the winning VIP Contractors will also tour Lochinvar’s world headquarters and take part in a round-table discussion where they can share insights and information with Lochinvar executives.

For more information about the VIP Contractor Program, visit knightheatingboiler.com.

This is what we know from last month’s AHR Show: according to the numbers, attendance was shattered — more than 61,000 total attendees, including 42,400 visitors, participated in the Expo. What was trending at this year’s show? Themes from the show included continued product efficiency and systems that now have intuitive communications—which were once considered Read more

This is what we know from last month’s AHR Show: according to the numbers, attendance was shattered — more than 61,000 total attendees, including 42,400 visitors, participated in the Expo. What was trending at this year’s show?

Themes from the show included continued product efficiency and systems that now have intuitive communications—which were once considered disparate components in the mechanical room—are now becoming more integrated, holistic platforms with intuitive communications which can interact from one unit to another, and communicate with a tech or homeowner.

It’s interesting to note: I covered the corporate security world about 12 years ago and the integration of security systems with building automation, the ability to notify the building owner of a problem and the ability to access a building’s security remotely via a secure web connection was the talk at every trade show.

What we’re hearing

The plumbing/HVAC industry, while some say is a very mature industry, has adopted similar practices when it comes to integration and communication among components through the Internet and Wi-Fi-enabled devices.

It’s a matter of getting used to. We hear it more and more and we’ll be hearing more of it in the years to come. Leveraging the advancements and growth in machine-to-machine communications, for instance, Daikin Applied is launching Intelligent Equipment. This new technology platform harnesses the Internet of Things (IoT) for the first time in commercial HVAC equipment, making it possible for HVAC systems to talk to operators and proactively take action, in order to improve efficiencies and exponentially increase cost savings.

“The Internet of Things is impacting all levels of how we interact with, control and maintain HVAC equipment,” said Paul Rauker, vice president of systems and controls at Daikin Applied. “We’re able to unlock data and use that information in ways never possible before now. We’re able to receive actionable, real-time data and see proactive shifts in behavior instantly, without expending additional effort.”

With the technology, HVAC systems can be monitored and controlled remotely using any mobile device. It moves users from a reactive to a proactive model, in order to quickly adjust ineffective systems and help facility managers maintain equipment before it loses efficiency or impacts occupant comfort.

Selling & Profitability

There are two schools of thought on this when it comes to the residential contractor level, however. One is that any technology is a positive, especially when it comes to servicing a boiler, water heater or AC unit. The other, however, is how this affects the bottom line with the consumer. When the heat or AC goes, the first call that goes out is, “how quickly can you be here to replace it and how much is going to cost me.” Difficulty in finding the right price points for consumers and serviceability is just as important as the equipment itself. Yet, information is paramount, and can’t be undervalued.

“The ability to troubleshoot remotely and to be armed with the information and parts in hand before I show up increases my profitability and efficiency on the job,” says the Hub’s Eric Aune, who works on the job everyday with his business, Aune Plumbing, LLC.

I suppose these new systems need to be sold and marketed to customers, as contractors and media alike need to get up to speed on these new systems.

During the AHR Show, Lochinvar, LLC announced that it has expanded its line of CREST® Condensing Boilers to include three new models with 750,000, 1.0 million and 1.25 million Btu/hr inputs. Featuring Lochinvar’s patented Wave™ fire-tube design and advanced combustion technology, the new CREST Boiler models deliver 96.2 percent thermal efficiency and up to 20:1 modulation turndown. With the addition of the new models, the CREST line now includes 10 condensing commercial boilers with inputs ranging from 750,000 Btu/hr up to 5.0 million Btu/Hr.

In addition, Lochinvar’s FTXL™ Fire Tube Boiler is among the products recognized in the 2015 AHR Expo Innovation Awards Competition. The new FTXL Fire Tube Boiler represents a new generation of fire-tube technology, delivering up to 10:1 turndown and models ranging from 97 to 98 percent Thermal Efficiency – higher than any other boiler in its class. With five models ranging from 399,999 to 850,000 Btu/hr, the FTXL Boiler is well suited for light commercial applications.

Enabled for CON-X-US™ remote connect capability as part of the advanced SMART SYSTEM™ operating system, the FTXL Boiler offers complete control from across town or across the country. This remote connectivity option redefines monitoring by simplifying data acquisition and providing remote diagnostics.

Make Lahti, vice president sales & marketing at Lochinvar, kicks off the Lochinvar press conference at AHR.

With the Con-X-Us remote connectivity, status alerts can be sent to a smart device, and the user can monitor and re-program control parameters from almost anywhere.

Rheem continues to delve into this side of the market with its EcoNet system—as seen at the KBIS/IBS Show last month—which is a smart technology that will efficiently manage 65% of a home’s energy consumption. EcoNet is the first system to connect a home’s heating, cooling, and water heating systems through a central hub, making it easy for homeowners to conveniently manage energy usage and monitor diagnostics and maintenance schedules.

The system uses a home’s existing WiFi connection to locate and link all compatible Rheem air and water products. Homeowners can then securely control these products through the free EcoNet mobile app on smartphones or tablets (both iOS and Android platforms), or a control center mounted in their home.

The first installment of the Hydronics CSI was won by Nathan White, Whites Plumbing & Heating, Kenai, AK. His well-thought, concise answer earned him a Lochinvar Jacket. Congratulations to Nathan. Please stay tuned for more Hydronics CSI opportunities. The Flaw: Nathan White’s response: First let’s use a Knight Mod con boiler for this application where Read more

The first installment of the Hydronics CSI was won by Nathan White, Whites Plumbing & Heating, Kenai, AK. His well-thought, concise answer earned him a Lochinvar Jacket. Congratulations to Nathan. Please stay tuned for more Hydronics CSI opportunities.

The Flaw:

Nathan White’s response:

First let’s use a Knight Mod con boiler for this application where we can take advantage of the low return water temp, modulation , outdoor rest features for a high efficiency package. But since it is a solution boiler here’s what needs changed. 1) need closely spaced tees (the ones in the picture are incorrect as you need min 10 pipe dia of straight pipe from each branch and a maximum of 4 pipe dia between the branches) or use my personal favorite a Caleffi Sep4 hydro separator to hydraulically decouple the two circulators, eliminate air, dirt and magnetic particles. 2)The solution boiler with its copper fin construction needs a Low temperature bypass valve in constant low temperature application. This valve would be placed before the suction side of the boiler pump which need to have a(3) integral check or a check valve on the discharge side of it. (4) if not using the Caleffi Sep4 then you will need a Y strainer as well on the return side of the boiler to protect the heat exchanger. (5) The air separator could be removed from the system if a Caleffi Sep4 was used. (6) A system sensor also needs to be hooked up when the solution is ran in a low temp application with the LBV. (7) lets put some valve in this design Paul for the poor guy that has to service it in the future doesn’t have to drain the world to replace a pump. So iso valves on both sides of each pump and ball valves with purge drains on the other lines as a bare minimum to make for easy filling and purging of the system. (8) The boiler pressure relief valve needs to be turned down toward the floor.

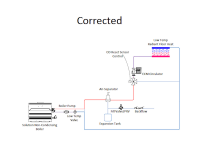

The Correction:

The Answer:

1) The closely spaced tee’s separating the boiler loop from the secondary loop do not isolate the differential pressure from the boiler pump. In short, the boiler pump was in series with the zone pump.

2) The boiler is a non-condensing boiler and the (typical) low-return water temperatures from the radiant floor heat would cause the boiler to condense. Sustained flue gas condensation would over-time cause the heat-exchanger in the boiler to fail and the vent could degrade and allow CO to fill the structure. The LTV (Low Temp Valve) will ensure the water temperature entering the boiler will be 140°F or higher.

3) The boiler will produce temperatures above that of low temperature radiant floor heat requirements. The use of a 3rd party mixing valve to provide outdoor reset will allow the proper mixing. (One of several methods of OD reset mixing)

1) The closely spaced tee’s separating the boiler loop from the secondary loop do not isolate the differential pressure from the boiler pump. In short, the boiler pump was in series with the zone pump. 2) The boiler is a non-condensing boiler and the (typical) low-return water temperatures from the radiant floor heat would cause Read more

1) The closely spaced tee’s separating the boiler loop from the secondary loop do not isolate the differential pressure from the boiler pump. In short, the boiler pump was in series with the zone pump.

2) The boiler is a non-condensing boiler and the (typical) low-return water temperatures from the radiant floor heat would cause the boiler to condense. Sustained flue gas condensation would over-time cause the heat-exchanger in the boiler to fail and the vent could degrade and allow CO to fill the structure. The LTV (Low Temp Valve) will ensure the water temperature entering the boiler will be 140°F or higher.

3) The boiler will produce temperatures above that of low temperature radiant floor heat requirements. The use of a 3rd party mixing valve to provide outdoor reset will allow the proper mixing. (One of several methods of OD reset mixing)