Provides Guidance on Selecting and Installing The Plastics Pipe Institute’s Building & Construction Division has published a major revision of PPI TN-55 “Plastic Piping Materials for Ground Source Geothermal Heating and Cooling Applications”. Originally issued in 2018, the latest edition of TN-55 was published in August 2024 with the input of industry experts including PPI Read more

PEX

Provides Guidance on Selecting and Installing

The Plastics Pipe Institute’s Building & Construction Division has published a major revision of PPI TN-55 “Plastic Piping Materials for Ground Source Geothermal Heating and Cooling Applications”. Originally issued in 2018, the latest edition of TN-55 was published in August 2024 with the input of industry experts including PPI members and the International Ground Source Heat Pump Association (IGSHPA).

According to Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division, “Because the piping material is critical to the overall success of the ground heat exchanger (GHX) in a geoexchange system, PPI TN-55 focuses on piping, fittings, and manifold materials. TN-55 lists the technical requirements for systems using HDPE, PEX, and PE-RT piping, plus requirements for PP pipes used as indoor piping, headers, and manifolds.”

A coil of PE4710 HDPE ground loop piping configured as a premanufactured U-bend assembly. Photo courtesy of Centennial Plastics.

The new technical note describes eight types of installation techniques, such as vertical boreholes, inclined or angled configurations, horizontal directional drilling (HDD), and energy piles, and discusses design topics, such as the effects of borehole depth on static water column pressure. It also addresses why oxygen diffusion barrier layers are typically not required for ground heat exchanger piping.

MacNevin continued, “The new TN-55 is intended to be a valuable resource on piping information, but this is just one of the latest tools available to specifiers and designers of geothermal heating and cooling systems. Details about pipe installation and pressure testing are found in PPI Model Specification MS-7, which published in 2023, and industry codes such as CSA/ANSI/IGSHPA C448 and the Uniform Mechanical Code.”

PPI is the non-profit North American trade association representing the plastic pipe industry, including several manufacturers of geothermal pipes, fittings, manifolds, and vaults. PPI formed its Geothermal Steering Committee in 2018 to develop industry publications, collaborate on codes, and create educational information about these systems.

A HDPE vault for connections of ground loop piping. Photo courtesy of PPI.

The revised PPI TN-55 is available directly from PPI at: www.plasticpipe.org/common/Uploaded files/Technical/TN-55.pdf

Additional information and data about ground source geothermal systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Viega is the first U.S. manufacturer to make a transition coupling with press technology to join dissimilar materials Viega continues to find innovative solutions for piping systems with a new line of MegaPress® Transition Couplings that can be used to transition between galvanized or carbon steel pipe and copper, PEX, or stainless steel in seconds Read more

Viega is the first U.S. manufacturer to make a transition coupling with press technology to join dissimilar materials

Viega continues to find innovative solutions for piping systems with a new line of MegaPress® Transition Couplings that can be used to transition between galvanized or carbon steel pipe and copper, PEX, or stainless steel in seconds. Viega is the first press fitting manufacturer to offer a press coupling of this kind that can be used in commercial, residential, and

industrial applications.

The company will be offering three products available in ½” to 2” sizes:

- Viega MegaPress ZL Bronze IPS to CTS Transition Coupling (Model: 4813.4ZL) – This transition coupling includes a factory-installed EPDM sealing element and is ideal for transitioning between IPS and CTS piping systems, including PEX.

- Viega MegaPress ZL Bronze IPS Transition Coupling (Model(s): 4815ZL and 5915ZL) – These couplings include an option for factory-installed EPDM or FKM sealing elements and are ideal for joining carbon steel to stainless steel or galvanized steel to stainless steel.

All of the Viega MegaPress Transition couplings are made of zero-lead (ZL) bronze that can be used to connect dissimilar metals while reducing the risk of galvanic corrosion. The MegaPress Transition Couplings also feature Smart Connect® technology to quickly detect and resolve unpressed connections.

The couplings with EPDM sealing elements carry an NSF-61 rating for potable water.

”Customers have been asking us for this type of product that uses press technology,” said Will Schneider, Product Manager at Viega. “Up until now, transitioning from one type of pipe to another has been challenging and time-consuming with the use of cumbersome traditional joining methods. Now, our

customers have a quick and secure option to connect dissimilar materials.”

Schneider continued, “These transition couplings allow our residential customers to easily retrofit homes with old galvanized potable water lines. They can now use our IPS x CTS transition coupling on the galvanized pipe and add a ProPress® fitting to the street end, to transition to copper, or a ProPress by

PureFlow® adapter to transition to PEX. They are also available in IPS x IPS models with EPDM or FKM seals, allowing commercial or industrial customers to transition from Carbon or Galvanized Steel to Stainless Steel with ease for a variety of applications.”

Product will be available to order starting in late fall 2024. To learn more about Viega’s transition couplings, visit viega.us/press-transition.

TotalFit™ is the professional-grade, engineered polymer (EP), push-to-connect fitting solution that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings. Ideal for residential repair, maintenance, or remodels for potable hot-water and cold-water distribution piping systems in single-family homes, townhomes, apartments, and condominiums, TotalFit is designed for use with Read more

TotalFit™ is the professional-grade, engineered polymer (EP), push-to-connect fitting solution that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings.

Ideal for residential repair, maintenance, or remodels for potable hot-water and cold-water distribution piping systems in single-family homes, townhomes, apartments, and condominiums, TotalFit is designed for use with PEX, PE-RT, CPVC, and copper piping systems.

The innovation features patent-pending technology to provide a strong, lasting connection professionals can depend on, and TotalFit is one of the only full-featured, EP, push-to-connect fittings on the market.

Available in sizes from ½” to 1″, the TotalFit solution offers about a 30% savings over brass push-to-connect fittings, and it meets or exceeds all performance requirements of the PEX system performance standard, ASTM F877, as well as the push-fitting performance standard, ASSE 1061.

The complete offering is approved by the Uniform Plumbing Code (UPC) and International Plumbing Code (IPC) for direct burial in soil or concrete (with 4 to 6 mil poly wrap) as well as behind walls without access panels. Additionally, the offering is solidly backed by a 25-year product warranty for added peace of mind.

Get more with Uponor TotalFit for residential plumbing repairs, maintenance, and remodels.

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Read more

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Rauterkus will join GF’s Executive Committee and will lead the new division together with his Uponor leadership team.

After all conditions of the tender offer have been fulfilled, GF closes the transaction as of 13 November 2023.

To accelerate the implementation of GF Piping Systems’ Strategy 2025 and to further benefit from global megatrends, GF will start an ambitious value creation program to unleash the full potential of this acquisition. GF Piping Systems will focus on the industrial and utility business, providing its customers with sustainable leak-free piping solutions for numerous end markets such as microelectronics, water treatment, energy, chemical processing, marine, data centers or water & gas utilities. Uponor’s infrastructure business will become part of GF Piping Systems and will further strengthen the division’s portfolio to provide customers with combined solutions.

In the new division, GF Uponor, the building technology businesses will be combined to offer a complementary portfolio for safe and clean water, as well as energy efficient heating and cooling. The consolidation of complementary businesses provides an ideal platform to develop markets with high potential for both divisions. As the brand Uponor stands for high quality and innovation, it will drive growth in intelligent Building Flow Solutions.

These organizational changes will be implemented during the course of 2024 while GF will ensure operational excellence and business continuity to customers.

“We will continue to implement our strategy, and leverage powerful global trends, such as the need for safe and clean water, or more efficient energy use,” GF CEO Andreas Müller said. “On behalf of all my colleagues, I am happy to welcome Uponor employees and start this new chapter together.”

New Technical Document and Details Proper Steps for Use A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA). Prepared by Read more

New Technical Document and Details Proper Steps for Use

A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA).

Prepared by PPI’s Building & Construction Division, PPI TN-69 Recommendations when Applying Spray Polyurethane Foam Insulation on and around Plastic Pressure Pipes & Fittings discusses the proper application of spray polyurethane foam insulation to avoid damage due to heat generated by the foam. Pipe and fitting materials include CPVC, PEX, PEX/AL/PEX, PE-RT, PP-R, PP-RCT, PSU, PPS, PPSU, and PVDF.

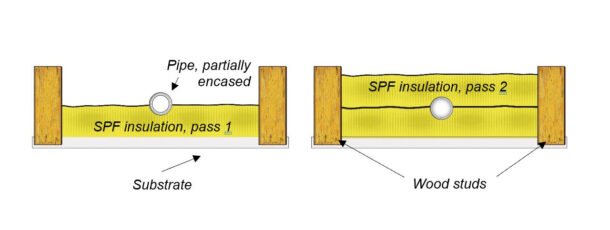

Figure 1: The first layer of SPF insulation is stopped when it reaches the pipe (left), just barely touching or encasing it. After sufficient cooling time, the second layer of SFP insulation is sprayed over the pipe to the required thickness (right).

PPI and SPFA recommend that when there are plastic pipes and fittings in a wall, ceiling, or floor cavity, the SPF installer should apply one layer of foam until it touches the pipe but does not encase the pipe. SPF installers should let the first layer of foam cure for a sufficient amount of time while heat is released from the foam and the pipe remains partially exposed before installing the second layer of foam. These procedures are described in detail within PPI TN-69.

Plastic pressure pipes and fittings are commonly used in applications such as hot- and cold-water plumbing, fire protection, and hydronic heating and cooling systems, including radiant distribution systems. In certain instances, pipes and fittings are installed inside areas that must be insulated, such as within a ceiling or wall cavity. In other installations, the pipes and fittings themselves must be insulated to reduce the transfer of heat through the pipe wall.

According to the SPFA, Spray Polyurethane Foam, or SPF, is a high-performance insulation material commonly used in homes and buildings of all types, and has been used as insulation for decades.

“The spray polyurethane foam curing reaction is exothermic,” explained Richard Duncan, Ph.D., P.E., executive director of SPFA, “which means that heat is generated during the foam reaction. The heat of reaction is highly dependent on the SPF formulation and is also based upon the overall intended application or lift (i.e., layer) thickness installed. Peak temperature within the layer of foam typically occurs within 5 to 15 minutes of application, followed by gradual cooling.”

According to SPFA documents, the chemical reaction that takes place during the application and curing of SPF will generate exothermic temperatures above the 120°F – 130°F setpoint temperatures of the proportioner and hoses. Peak temperatures at the mid-thickness of a pass can exceed 200°F for several minutes and reach peak temperatures 250°F – 275°F for a minute or two, especially for closed-cell SPF, when applied at the maximum pass thickness.

“Plastic pipes and fittings in both residential and commercial plumbing, residential fire protection, and most hydronic applications are typically required to have pressure ratings at 180°F (82°C) operating temperature,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division.

MacNevin continued, “The plastic pipes and fittings referenced in PPI TN-69 will withstand short-term exposure to temperatures above 180°F. However, exposure to temperatures above the rated operating temperature of each material, which may occur if pipes are encased in a thick pass of closed-cell SPF, are likely to have negative effects on these materials, potentially leading to premature failure. It is important that SPF insulation is installed correctly to prevent overheating of pipes and fittings.”

Access the full content of PPI TN-69 at https://plasticpipe.org/common/Uploaded%20files/Technical/TN-69/PPI%20TN-69.pdf or by scanning:

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction