https://vimeo.com/1032700697 We hope everyone has a wonderful Thanksgiving and you are able to take some time to share it with family, friends and loved ones. This update is dedicated to some examples of those giving back. We’ll also tell you what’s cooking with our weekly podcasts as well Read more

piping

We hope everyone has a wonderful Thanksgiving and you are able to take some time to share it with family, friends and loved ones. This update is dedicated to some examples of those giving back. We’ll also tell you what’s cooking with our weekly podcasts as well.

Elkhart, Indiana-based NIBCO Inc. celebrated in style this week as esteemed guests were invited to dinner, drinks and dancing in what was a wedding reception-like ceremony that included a multi-piece band. The following day, invitees were treated the ribbon cutting of the new Rex Martin NIBCO Interactive Museum, and took the tour. The museum offers Read more

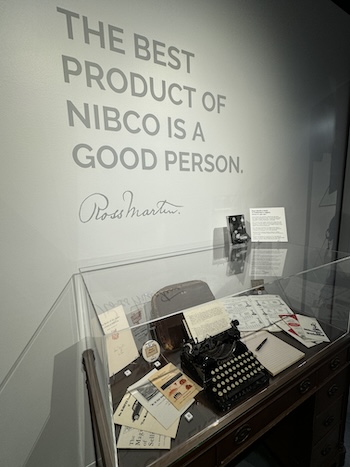

Elkhart, Indiana-based NIBCO Inc. celebrated in style this week as esteemed guests were invited to dinner, drinks and dancing in what was a wedding reception-like ceremony that included a multi-piece band. The following day, invitees were treated the ribbon cutting of the new Rex Martin NIBCO Interactive Museum, and took the tour.

The museum offers a unique and enriching experience from a historical perspective, interactive learning, inspiration, community impact, and career opportunities. Not just a place to learn about the past, it’s a place to get excited about the future of plumbing and the opportunities it holds.

“Our decision to build the NIBCO Interactive Museum and name it after my father is a tribute to his remarkable contributions to the plumbing industry and a continuation of a legacy that began with my great-great-grandfather in 1904,” said NIBCO’s President and CEO Ashley Martin. “This ambitious project was something I wanted to complete and dedicate on NIBCO’s 120th anniversary to make it extra special. The museum is not just about preserving our history; it’s about showcasing the profound impact we’ve had on the evolution of plumbing and our philanthropic efforts within the community.”

“Our decision to build the NIBCO Interactive Museum and name it after my father is a tribute to his remarkable contributions to the plumbing industry and a continuation of a legacy that began with my great-great-grandfather in 1904,” said NIBCO’s President and CEO Ashley Martin. “This ambitious project was something I wanted to complete and dedicate on NIBCO’s 120th anniversary to make it extra special. The museum is not just about preserving our history; it’s about showcasing the profound impact we’ve had on the evolution of plumbing and our philanthropic efforts within the community.”

Martin continued, “I want our NIBCO associated, our customers, local school kids to be able to come here and use this so it needed to be interactive. We also highlighted plumbing: where our products go, how they bring water to you, take waste away, but it also highlights our four manufacturing processes—plastics, copper, bronze and iron.”

Martin continued, “I want our NIBCO associated, our customers, local school kids to be able to come here and use this so it needed to be interactive. We also highlighted plumbing: where our products go, how they bring water to you, take waste away, but it also highlights our four manufacturing processes—plastics, copper, bronze and iron.”

The museum offers a unique and enriching experience from a historical perspective, interactive learning, inspiration, community impact, and career opportunities. Not just a place to learn about the past, it’s a place to get excited about the future of plumbing and the opportunities it holds.

Artifacts, representing various aspects of the history of plumbing, as well as the history of NIBCO, are exhibited throughout the museum, including:

- Early foundry tools

- Original crown jewels of NIBCO

- Original early fittings including the first fitting from 1927 and early valves

- Original product blueprints from the 1930s

- Items from Lee Martin’s collection

- Original printings of Ross Martin’s collection of booklets

- Philanthropic contributions

- Collectibles and promotions

The 8,845-square-foot building was completely renovated beginning in 2023. The museum portion of the space is 3,254 square feet, and additional space in the building will be used as a training area for customers, distributors, and NIBCO associates.

Aalberts integrated piping systems (IPS), a global leader in advanced integrated piping systems for the distribution and control of liquids and gasses, is excited to announce its participation in the upcoming ASPE Convention & Expo, taking place from October 18-23, 2024 in Columbus, OH. Aalberts IPS will be exhibiting at booth #1815, where attendees can Read more

Aalberts integrated piping systems (IPS), a global leader in advanced integrated piping systems for the distribution and control of liquids and gasses, is excited to announce its participation in the upcoming ASPE Convention & Expo, taking place from October 18-23, 2024 in Columbus, OH. Aalberts IPS will be exhibiting at booth #1815, where attendees can explore the company’s latest innovations, services, and product lines, designed to deliver complete, tailored piping solutions across industries.

Aalberts IPS is renowned for its mission-critical products surrounding valve and connection technology, with a legacy spanning 96 years under its “Apollo”® Valves brand. The company offers a wide range of products, including: ball valves, butterfly valves, safety relief valves, control valves, mixing valves, backflow preventers, and more. These products are engineered domestically to meet the needs of key verticals from commercial to industrial and utility markets globally.

Aalberts IPS is renowned for its mission-critical products surrounding valve and connection technology, with a legacy spanning 96 years under its “Apollo”® Valves brand. The company offers a wide range of products, including: ball valves, butterfly valves, safety relief valves, control valves, mixing valves, backflow preventers, and more. These products are engineered domestically to meet the needs of key verticals from commercial to industrial and utility markets globally.

At the ASPE Convention & Expo, Aalberts IPS’ booth will feature key information about the company’s design and field services, as well as products like the Revit plug-in among the Shurjoint and “Apollo”® product lines. Aalberts IPS provides expert advice and support for piping applications, from the initial planning stages to the final implementation of piping systems. Their unique design service ensures that every project is optimized for efficiency and effectiveness. Additionally, Aalberts IPS offers a comprehensive range of field services to ensure that piping systems are installed correctly and operate efficiently. Their experienced team provides on-site support, from installation to maintenance, ensuring long-term system reliability with minimal downtime.

Booth visitors will be able to witness the Aalberts IPS Revit plug-in, a powerful tool designed to streamline the design process, allowing engineers and architects to easily integrate Aalberts IPS products into their projects. This plug-in enhances project accuracy and efficiency, ensuring things are done right the first time and minimizing costly extended lead times. The Shurjoint range of mechanical piping solutions, which will also be highlighted at the event, is known for its versatility and ease of installation. This product line is designed to offer reliable and extremely durable pipe connections for a variety of piping systems whereas the “Apollo” SmartPress® line of press fittings and valves offer quick and secure connections, reducing installation time and costs while ensuring long-term reliability.

Allen Stanley has been promoted to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing. Elkhart, Ind. — NIBCO INC. has announced the promotion of Allen Stanley to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing. Both Stanley and Smith will report to Ashley Read more

Allen Stanley has been promoted to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing.

Elkhart, Ind. — NIBCO INC. has announced the promotion of Allen Stanley to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing.

Both Stanley and Smith will report to Ashley Martin, president and COO, NIBCO.

Allen Stanley

“Allen and Rudy have long careers with NIBCO and the knowledge and expertise that they both bring to these roles will be valuable for the success of our organization,” said Martin. “Join me in congratulating them on their well-deserved promotions.”

In this new role, Stanley has responsibility for the Stuarts Draft, Virginia manufacturing operations and the Demand Planning department, along with his current responsibilities for the U.S. distribution centers, world headquarters logistics, and all plastic manufacturing facilities.

Stanley began his career in 1997 at NIBCO as administrative manager at the Atlanta Distribution Center. He held a variety of roles of increasing responsibility including operations manager at the Elkhart Distribution Center, manager, distribution and transportation, and most recently, director, plastic fittings manufacturing and distribution.

Stanley holds a bachelor’s degree in marketing from the University of West Georgia in Carrollton, Georgia. He also earned his master’s degree in marketing from Georgia State University in Atlanta, Georgia.

Rudy Smith

In his new role, Smith will have responsibility for NIBCO’s Blytheville, Arkansas, facility, along with the company’s Nacogdoches, Texas, McAllen, Texas, and Reynosa, Mexico facilities.

Smith began his career at NIBCO in 1996 in logistics at NIBCO’s world headquarters. Two years later, he was promoted and transferred as operations manager of NIBCO’s Nacogdoches facility. He held various roles from production superintendent, plant superintendent, plant manager, and most recently, senior plant manager at Reynosa, prior to his new role.

Rudy holds a bachelor’s degree in management from Rice University, in Houston, Texas.

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Read more

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Rauterkus will join GF’s Executive Committee and will lead the new division together with his Uponor leadership team.

After all conditions of the tender offer have been fulfilled, GF closes the transaction as of 13 November 2023.

To accelerate the implementation of GF Piping Systems’ Strategy 2025 and to further benefit from global megatrends, GF will start an ambitious value creation program to unleash the full potential of this acquisition. GF Piping Systems will focus on the industrial and utility business, providing its customers with sustainable leak-free piping solutions for numerous end markets such as microelectronics, water treatment, energy, chemical processing, marine, data centers or water & gas utilities. Uponor’s infrastructure business will become part of GF Piping Systems and will further strengthen the division’s portfolio to provide customers with combined solutions.

In the new division, GF Uponor, the building technology businesses will be combined to offer a complementary portfolio for safe and clean water, as well as energy efficient heating and cooling. The consolidation of complementary businesses provides an ideal platform to develop markets with high potential for both divisions. As the brand Uponor stands for high quality and innovation, it will drive growth in intelligent Building Flow Solutions.

These organizational changes will be implemented during the course of 2024 while GF will ensure operational excellence and business continuity to customers.

“We will continue to implement our strategy, and leverage powerful global trends, such as the need for safe and clean water, or more efficient energy use,” GF CEO Andreas Müller said. “On behalf of all my colleagues, I am happy to welcome Uponor employees and start this new chapter together.”