In recent years, PP-R pipe has become an increasingly popular choice in plumbing and hydronic heating systems. Introduced over 30 years ago, this copolymer made from Polypropylene-Random has been a top choice among plastic piping options. Suitable for both hot and cold pipe, it’s known as a naturally insulating option that allows the installer to Read more

PP-R pipe

In recent years, PP-R pipe has become an increasingly popular choice in plumbing and hydronic heating systems. Introduced over 30 years ago, this copolymer made from Polypropylene-Random has been a top choice among plastic piping options. Suitable for both hot and cold pipe, it’s known as a naturally insulating option that allows the installer to make fast connections that are both permanent and leak-free. Using heat fusion technology, the installer can do more than just join two PP-R ends together – they can create a joint that has the same strength as that of the pipe wall. In contrast to other pipe-joining methods, common long-term concerns like corrosion and fatigue damage are eliminated with heat fusion. In fact, fusion connections are touted to be so robust that they will outlast their own piping system.

In the mid 2000’s, a new generation of PP-R pipe was introduced to the market – Polypropylene-Random Crystallinity Temperature – or PP-RCT. Its crystallinity allows the copolymer to resist greater levels of pressure at higher temperatures. The advancement of copolymers in recent years has begun to shift opinions on plastic pipe, leaving behind outdated misconceptions about its dependability.

But the ways of the past are not all gone. Installers may be embracing plastic pipes and fittings, but they have been slower to accept plastic bodied valves. The proven field reliability of brass-bodied construction remains favorable in a time when strong, reliable plastics are still a relatively new concept. As such, manufacturers who work with PP-R and PP-RCT have been trying to figure out how to bridge the gap between the time tested technology and recent innovations.

In order to incorporate brass valves into a PP-R/PP-RCT piping system, installers have historically had few choices. Options for brass valves with fully integrated connections have been somewhat limited. Some piping manufacturers have elected to offer valves that are compatible only with their specific line of piping, so finding a valve that is compatible with all PP-R and PP-RCT piping systems proved increasingly difficult. In absence of a universal solution, installers made use of transitional fittings to connect their brass ends to PP-R/PP-RCT pipe, at the expense of additional leak paths and labor.

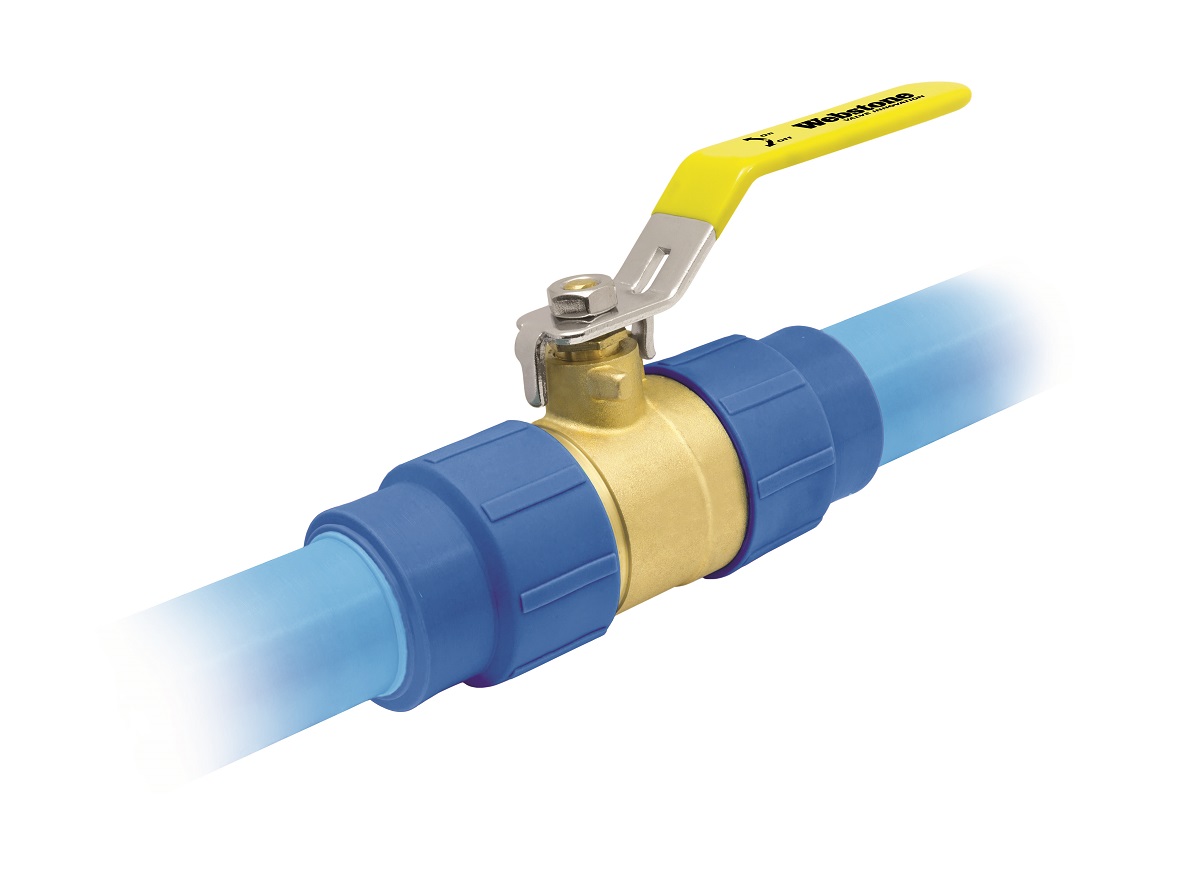

That’s where Webstone comes in. Known for their quality brass valves, Webstone has introduced fully integrated PP-R or PP-RCT ends to their most popular engineered products. The Pro-Connect PP-R Pro line now includes the Isolator with Rotating Flange (a uni-flange ball valve with 360 degrees of motion and optional multi-function hose drain), the Pro-Pal Ball Drain, and ball valves (including PP-R/PP-RCT x FIP ends to transition to or from metal piping).

These products all feature socket style connections, which makes the heat fusion process as quick and simple as possible. Valves come in a variety of sizes and are certified lead free for both residential and commercial use. Additionally, all Webstone products carry a lifetime guarantee against manufacturer’s defects – ensuring peace of mind that no other valve manufacturer in the industry can match. To learn more, visit WebstoneValves.com/PP-R-Pro

Irving, Texas—The Plastics Pipe Institute, Inc. (PPI) has announced the creation of the Polypropylene Pressure Pipe Steering Committee within its Building and Construction Division (BCD). This new group will focus entirely on polypropylene pressure pipe, and is a significant development for PPI in supporting this industry. PPI is the major North American trade association representing Read more

Irving, Texas—The Plastics Pipe Institute, Inc. (PPI) has announced the creation of the Polypropylene Pressure Pipe Steering Committee within its Building and Construction Division (BCD). This new group will focus entirely on polypropylene pressure pipe, and is a significant development for PPI in supporting this industry. PPI is the major North American trade association representing all segments of the plastic pipe industry.

The Steering Committee focuses on two types of polypropylene pressure pipes: PP-R, polypropylene random copolymer, and PP-RCT, polypropylene random copolymer with modified crystallinity and temperature resistance. Both types of pipes are approved for potable hot and cold water plumbing systems, hydronic heating and cooling systems, as well as other applications.

PP-R and PP-RCT pipes are available in metric sizes ranging from 16 to 355 mm and IPS schedule 80 sizes ranging from 1/2 to 6 inches. The minimum hydrostatic pressure ratings are 160 psi at 73ºF (1105 kPa at 23ºC) and 100 psi at 180ºF (690 kPa at 82ºC) for plumbing applications, but pipes with different dimension ratios (DRs) can have higher or lower pressure ratings, as needed by the customer.

The recent formation of the Polypropylene Pressure Pipe Steering Committee (P4 SC) reflects the rapid growth and continuing acceptance of polypropylene pressure pipe in the North American market.

According to PPI President Tony Radoszewski, CAE, “PPI has been a strong advocate and technical resource for many types of plastic pipe systems since its formation in 1950, including new materials as they develop. While not new in Europe, polypropylene pressure pipes are relatively new in North America, and PPI can serve members by helping to grow this market in a technically correct and responsible manner. Pipe producers see the value in this industry collaboration. In fact, the number of polypropylene producer members at PPI has tripled since this Steering Committee was initiated in late 2017.”

The P4 SC fits well with the BCD focus on plastic pressure pipe and tubing systems used within buildings and on building premises for applications such as plumbing, water service, fire protection, hydronic heating and cooling, snow and ice melting and ground source geothermal piping systems.

The mission of PPI’s Building & Construction Division is to promote the expanded acceptance and use of high-reliability plastic pressure pipe and tubing systems in building and construction environments by providing research, education, and code and standard development with a focus on delivering sustainable and safe plastic system solutions that enrich people’s lives.

According to PPI’s BCD Director of Engineering Lance MacNevin, P.Eng. “Our first activity was to publish a new PPI webpage dedicated to PP-R and PP-RCT piping systems. This webpage – https://plasticpipe.org/building-construction/bcd-pp.html – contains technical information, lists of advantages and applications, plus links to PPI member firms that produce PP-R and PP-RCT systems.”

In addition to coordinating industry research programs, developing technical publications, and creating educational information about these systems, the PPI technical staff participates within the standards development organizations (SDOs) ASTM, CSA, and NSF, code bodies IAPMO and ICC, as well as other organizations such as ASPE, CACP, PMAC and RPA.

MacNevin continued, “The new committee will engage in a wide range of activities. For instance, supporting industry efforts to update and harmonize product standards ASTM F2389 and CSA B137.11; coordinating and publishing research on proper uses of PP systems for plumbing and hydronic applications; developing online calculators for design of PP piping systems; and creating educational content about PP materials.”

New Technical Document Now Available

The first publication related to polypropylene (PP-R) pressure pipe is PPI TN-57 Proper Integration of Copper Tubing and Components with PP-R Piping Materials for Plumbing Applications, which was published in June 2018. The purpose of this technical document is to provide information regarding proper integration of copper tubing and components with random copolymerized polypropylene (PP-R) piping materials for plumbing applications. “This document is a great example of the kind of educational content the P4 SC and PPI can generate to help the industry as a whole,” MacNevin commented. The direct link to this document is https://plasticpipe.org/pdf/tn-57.pdf

Additional information can be found on the Plastics Pipe Institute’s website: www.plasticpipe.org.