The Pennsylvania Petroleum Association (PPA) has become a leading source of knowledge and training expertise for HVAC professionals throughout the Northeast and Mid-Atlantic regions. One of their most popular courses, Advanced Hydronics, is offered as a one-day course at PPATEC—the association’s Technical Education Center in Middletown, Pa.—one to three times yearly, and as a half-day Read more

PPATEC

The Pennsylvania Petroleum Association (PPA) has become a leading source of knowledge and training expertise for HVAC professionals throughout the Northeast and Mid-Atlantic regions.

One of their most popular courses, Advanced Hydronics, is offered as a one-day course at PPATEC—the association’s Technical Education Center in Middletown, Pa.—one to three times yearly, and as a half-day session 4 to 6 times yearly by instructor/trainer Dave Holdorf. In October ’23, he returned to PPATEC (his 5th visit in ’23) to lead their advanced hydronics course. Holdorf not only wrote the book used for the multi-day course, but also designed the laboratory they’re used for hands-on training.

Dave Holdorf giving his in-person Adnvaced Hydronics course at PPATEC.

Holdorf’s become a cult phenomenon and is now regarded as one of the nation’s best trainers of hydronic trade professionals.

His book, Advanced Hydronics, published by NORA (National Oilheat Research Alliance), is a favorite resource among hydronic system technicians.

An outgoing and amusing educator, Holdorf is also a Taco Comfort Solutions’ Product and Applications Instructor—East, a role that routinely puts him in the “bullpen” with two other equally-engaging and amusing hydronic experts, John Barba and Rick Mayo. Their “Taco After Dark” (see sidebar) webinar was hosted by PPATEC on October 4, with Holdorf as the emcee.

Holdorf has been in the hydronic industry for 25 years, specifically in the radiant heating side of the business for the better part of his career. Holdorf was presented with the “Dan Holohan Instructor of the Year” award in 2020.

“I love what I do—and the best of it happens when I’m among an group of trade professionals. We laugh, swap stories and learn. What could be better?” asked Holdorf.

‘Mecca’ for Hydronics Training

During his trips to PPATEC’s growing facility, Holdorf enjoys the training spotlight typically focused on PPA’s other HVAC instructors, including their very own Lead Technical Trainer, Alan Mercurio—one of the most popular trainers in the Northeast region.

Alan Mercurio (c), doing what he loves to do — teach.

Trade pros flock to the facility near Harrisburg as something of a “Mecca” for HVAC technicians eager to deepen their understanding of installation and service techniques and theory. Visiting trainers at the PPATEC facility, many of whom make multiple trips each year to the facility, include Brian Kiernan of Energy Kinetics, Bruce Graham of Carlin/Hydrolevel, Curtis Martin or R. W. Beckett, Joe Sacco of Riello, and Ron Beck, Training Manager emeritus, U.S. Boiler.

Advanced Hydronics

In October, Holdorf spent several days teaching advanced hydronics, much of it from his book, to jam-packed trade pro audiences at PPATEC. There wasn’t a spare seat in the classroom.

“We love it when Dave comes to teach. He’s one of our most popular trainers,” said Mercurio. “He has a special way of keeping a classroom full of technicians engaged and eager to learn.”

Contractors arrive at PPATEC for in-person training.

According to Holdorf, anyone can put together a bunch of parts and call it a hydronic heating system. But are those parts and pieces selected properly and being used as they were intended? That was the focus of the advanced hydronics course, intended to take attendees through the decision process, prior to system design. The goal: to guide deliberate, informed system development, startup and commissioning.

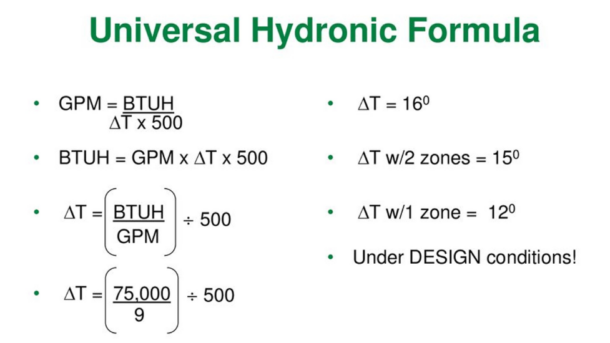

Of course—you’ve heard it many times before from these savvy hydronic-ians: every good system begins with a heat load calculation. “The math isn’t difficult, but it’s necessary,” assured Holdorf. Whether in class, or speaking to a Taco After Dark audience, Holdorf and Barba steer participants toward the Universal Hydronic Formula.

In essence:

• GPM (gallons per minute, or required flow) = BTUH ÷ ∆T and multiplied by 500

• ∆T is the temp drop across the piping circuits (difference between supply + return)

• Why the 500?

“Well, it’s a math shortcut,” he explains. The number stems from the weight of one gallon of water (8.33 lbs.) x the number of minutes in an hour x 1, or . . .

8.33 x 60×1 = 499.8 . . . and 500 is close enough.

To provide comfort within a home, a well-designed and installed hydronic system provides proper thermal energy transfer (or the ability “to carry the BTUs”) to all points of distribution. For residential systems, Holdorf recommends at 20°∆T.

From there, Holdorf and Barba led the live and online audience through several explanations that tie to this formula:

• Glycol is thicker and doesn’t carry as much energy (and its pH should be checked routinely)

• Proper flow rate for a load calculated at 82,401 BTUs (a decent-sized home):

GPM = BTUH ÷ (∆T x 500), so . . .

GPM = 82,401 BTUs ÷ (20 x 500)

GPM = 8.2

From there, Holdorf leads his audience through the basics of transporting that heat outward for distribution, and back to the boiler to be reheated:

• ¾” copper will move 2-4 GPM

• 1” pipe will move 4-9 GPM – the right size for the 8.2 GPM calculation above; typically, this is all that residential systems require. Large pipe is required for “starter castle” homes and commercial purposes.

• 1-1/4” pipe allows movement of 8-14 GPM

• 1-1/2” permits 14-22 GPM

Too much flow creates velocity noise. Insufficient flow makes it difficult to purge entrained air from the water. The challenge of air within the hydronic solution—whether water, or glycol—became the segue to air elimination. And, with Holdorf and Barba guiding the conversation, it becomes a fascinating topic: one you can easily find on the Taco After Dark website: https://www.tacocomfort.com/training/online-training/taco-after-dark/ (take your cursor to the Oct. 4 broadcast).

Heat Emitters; and Pipe Sizing, Air Control and Pumping Away

Once you know the BTUH heating load, you can now get down to the business of adequately sizing heat emitters. Typically, the choices are: fin-tube baseboard, cast-iron and panel-type radiators, radiant floor heating +/or hydro-air.

From there, Holdorf and Barba discussed the use of cast iron and mod-con boilers, and air-to-water heat pumps. They also illustrated how to interpret output and design charts so installers can match heat emitters to the water temperatures produced by the heat plant

Holdorf and Barba also spoke about how to properly size a boiler header and distribution piping based on the BTUH load.

A few other points stirred lively conversation among participants:

- Hydronic system components, what goes where and why

- Boiler size

- Pipe size

- Near boiler piping—best practices and options

- Finally: controls

“I’ve now learned from Dave [Holdorf] on a couple of occasions at PPATEC,” said Eric Love, a technician with HB Home Services, a division of H. B. McClure Company, based in Harrisburg. “He’s a terrific instructor, and very entertaining. He’s one of many reasons I now look forward to more training there.”

Free Online Training for Boiler Heating Systems

Taco After Dark – LIVE from PPATEC, 10-4-23, on Mechanical-Hub

Weekly, Wednesday evening Taco After Dark webinars have risen to the top as the nation’s most popular online source of live (and YouTube-archived) hydronics knowledge and expertise.

The focus of Taco After Dark—practical, real-world solutions to the challenges hydronics professionals face every day.

Mechanical-Hub

The, um, “Magical Mystery Tour” of Taco After Dark began early in the Covid pandemic. Holdorf and fellow Taco trainers John Barba and Rick Mayo made a call to Mechanical-Hub’s managing partners – hoping to offer an exciting online training platform. Long story short: Taco and th’ Hub worked together to engaged both of their trade pro audiences. These days, all of the Taco After Dark broadcasts are recorded onto Mechanical-Hub’s YouTube page.

As th’ Hub’s Editor, John Mesenbrink, so succinctly said, “Online learning brings us together.” And that’s exactly what happened when Holdorf went live with the “Taco After Dark” broadcast from 7-9 pm on October 4 from PPATEC’s newest hydronic lab.

As th’ Hub’s Editor, John Mesenbrink, so succinctly said, “Online learning brings us together.” And that’s exactly what happened when Holdorf went live with the “Taco After Dark” broadcast from 7-9 pm on October 4 from PPATEC’s newest hydronic lab.

Before the online audience joined in to learn, and to contribute, Holdorf enjoyed connecting with show co-host John Barba—Taco’s lead residential instructor —and special guest Dave Yates who was the owner (now retired) of York, PA-based F. W. Behler, Inc., a full-service mechanical contracting firm. Talk about a forum for fun! These guys could make you laugh through the last, post-apocalyptic hour of mankind.

In the lab’s studio, Holdorf was joined by several of PPA’s staff and a gaggle of students—advanced installers and service pros among them—for the fun, fast-paced training session. The evening’s broadcast topic: hydronic piping and circulation.

If you haven’t yet experienced the style of humor and education—the clash of laughter and learning that’s unique to Taco After Dark—you owe it to yourself to check it out. Don’t take my word for it—all of their sessions are archived; the stored broadcasts are almost as much fun as the live productions.

If you haven’t yet experienced the style of humor and education—the clash of laughter and learning that’s unique to Taco After Dark—you owe it to yourself to check it out. Don’t take my word for it—all of their sessions are archived; the stored broadcasts are almost as much fun as the live productions.

Holdorf, true to form for the broadcast, took just a slice of the full-day residential hydronics training class, served with a healthy measure of merriment. He and Barba—often in concert with Taco’s other trainers, Rick Mayo, Rich Medairos and Brett Zerba (Medairos + Zerba focus their efforts on commercial hydronic systems)—deftly held the attention of live and online trade pros.

Enraptured audience

It would be quite a challenge to educate and entertain a large, mixed group of hydronic techs, but not for Holdorf and Barba with just the right mix of antics, humor and trade secrets.

One young technician in the live audience for the PPATEC Taco After Dark broadcast was Owen Kunder, a mid-20s service and installation tech with Stevens, Pa.-based Vertex Mechanical. Kunder drove more than 30 miles to attend the live event.

“I haven’t had much training for boiler work yet, so being there for the broadcast was really exciting,” he said. “I learned a lot. One thing that stuck out was hearing Dave talk about system design, and the differing PSI levels that vary with building height. It was fascinating.

“I’ve been installing Taco components since I was 16, but wasn’t aware that they offered air eliminators,” he added. “I really enjoyed myself and will be sure to catch more Taco After Dark broadcasts.”

Kunder was soon joined by fellow Vertex installer, Jared Fox. After greeting each other, they spotted the boxes of pizza and then settled in for the “show.” Meanwhile, the live audience was admiring the immaculately-installed hydronic system that, two years earlier, Fox installed.

“This was a first experience for me with Taco After Dark,” said Fox. “I wasn’t sure what to expect, but when Dave got rolling, I was very impressed.

“[Holdorf] offered insights into why things are done certain ways when designing and installing hydronic systems,” continued Fox. “I learned a lot in a short period of time; he gave me a deeper understanding of concepts and practices that I thought I knew a lot about. I was also learning from his answers to my questions—and especially the questions of others. There’s always new stuff to learn, and this experience was super valuable.”

“Holdorf leaves you with a good, lasting impression,” said Eric Love, a technician with HB Home Services. “I’ll always recall that a circulator doesn’t move water—it creates a pressure differential between the inlet and the outlet.” Oh, the things that define the uniqueness of hydronics!

Remaining LIVE/on-location presentations of Taco After Dark

October 25: Flow, Heat and the Finer Points of Circulator Selection

The next step in building a great hydronic system is understanding the interrelationship between BUTH, flow, pressure loss (known as head loss) and pipe sizing. All of those ingredients go into proper circulator selection.

In this class, you’ll learn why there’s no such thing as one circulator for all applications, and how our industry actually has a chronic circulator oversizing problem. And we’ll also start the discussion on variable speed ECM circulators and why there’s no such thing as a circulator that sizes itself.

ON-SITE & ONLINE

New England Institute of Technology

1 New England Tech Blvd

East Greenwich, RI 02818

Wednesday, Oct. 25

7:00 pm EDT

November 1: ECM Circulator Essentials

ECM stands for Electronically Commuted Motor. And those three little letters are transforming residential hydronics. But do we really know what we need to know about how these remarkable little devices work?

Variable speed technology can do wonders for the modern residential hydronic system, but they’re not magic. They don’t size themselves and they don’t take the thinking out of circulator selection, no matter how many times you press that AUTO button. In this session, we’ll dispel the many myths and common falsehoods about ECM circulators. And we’ll show you the real value of these things will help you create the most efficient system possible for your customers.

7:00 pm EDT

Circulators or Zone Valves

If you were King of Hydronics and you could dictate to the industry how to zone a system, would you insist on one circulator per zone, or would you rule in favor of one circulator and zone valves?

It’s an age-old question, and in this session of Taco After Dark we’ll examine the pros, cons, realities, and myths of both options. And by the time the hour is up, we’ll provide you with the ultimate and definitive answer as to which one is better and why.

Wednesday, Nov. 8

7:00 pm EDT

November 15: Air-To-Water Heat Pumps and Low Temperature Hydronics

With the movement to “beneficial electrification” well underway, air-to-water heat pumps are becoming a factor in modern residential hydronics.

In this program, we’ll discuss how these things work, what they can (and can’t) do, and how to get into this rapidly growing business. You’ll also learn about the new Taco System M air-to-water heat pump and its unique capabilities.

ON-SITE & ONLINE

Johnson College

3427 North Main Ave.

Scranton, PA 18508

7:00 pm EDT

Register

Attendees may register for each session individually, and each program will be recorded and archived for later viewing. Each session qualifies installers for one PDH credit. (YOU MUST ATTEND ONE OF THE LIVE WEBINAR SESSIONS (NOT THE RECORDED SESSION IN ORDER TO RECEIVE THE PDH CERTIFICATE.) The link to the PDH certificate, along with a link to the recorded webinar session, will be emailed to you approximately 24 hours after the end of each webinar session.

David Holdorf

Residential Trainer, Eastern Region, Taco Comfort Solutions

Holdorf has been in the hydronic industry for 25 years, specifically in the radiant heating side of the business for the better part of his career. Starting out in the technical support/design role and then took over as Engineering Manager overseeing the Technical Support and Design Department. Later he took a position as a Field Technician; supporting training, designing, installing and troubleshooting.

John Barba

Director of Training, Taco Comfort Solutions

John Barba has been in the plumbing heating industry most of his life, growing up in his family’s plumbing and heating business in Harvard, MA. John’s practical experience includes everything from ditch digging and drain cleaning to boiler piping and PEX slinging, as well as business management and contractor sales. Since 1995, John has trained over 30,000 contractors on the fine art and subtle science of hydronic heating design and installation through highly interactive, entertaining and informative seminars.

He is the 2012-2014 recipient of the Carlson-Holohan Industry Award of Excellence, and was recently named the industry’s Best Trainer for 2015 by AHRI News Magazine.

Rick Mayo

Western Product and Application Instructor, Taco Comfort Solutions

Rick started his career in the hydronic heating industry as a plumber in 1977. In 1981, he transitioned into a wholesale role. Over the next 21 years, he worked his way up to a regional heating manager and left to pursue a training/technical support position with Uponor-Wirsbo. Seven years later, Rick took a western regional sales manager/corporate trainer role with Triangle Tube/ACV. Since joining Taco in 2015, Rick has made an impact as the Western Product and Application Instructor through his training that stretches from Alaska to San Diego, as well as four provinces in western Canada.

Richard Medairos

Director of Engineered Products and Systems Training

Medairos is a Senior Systems Engineer and Director of Commercial Training at Taco Comfort Solutions. He has over forty years of experience with demonstrated expertise in engineering, project management and planning. Throughout his career, he has worked on projects with major clients such as NASA’s Kennedy Space Center, Disney World, Universal Studios Florida, Boston University, Rhode Island School of Design, First Data Corporation, and Taco’s Innovation & Development Center.

Brett Zerba

Applications Engineer, Taco Comfort Solutions

Zerba is an Application Engineer at Taco Comfort Solutions with over twenty years of experience at the company. He graduated with his Bachelor of Science in Mechanical Engineering from the University of New Hampshire in 1981, and in 2003 he earned his Master of Business Administration from Johnson & Wales. Mr. Zerba has demonstrated his skill and expertise in the field of hydronic systems as an ASHRAE and Hydraulic Institute member.

The Northeast U.S. has been the hydronics stronghold in America since boilers were first put to use as a source of heat. To serve the interests of trade professionals, especially those just entering the field (though by no means limited to introductory training), the Pennsylvania Petroleum Association (PPA) technical education center (PPATEC) has substantially expanded Read more

The Northeast U.S. has been the hydronics stronghold in America since boilers were first put to use as a source of heat. To serve the interests of trade professionals, especially those just entering the field (though by no means limited to introductory training), the Pennsylvania Petroleum Association (PPA) technical education center (PPATEC) has substantially expanded its facility in the Harrisburg, Pa. area.

For over 35 years, PPA has offered oil-fired hydronics and forced-air equipment training at the facility, serving thousands of trade professionals who came to hone their skills while under the skilled guidance of expert instructors. The equipment in PPATEC’s oil-fired training room is connected to a large, primary hydronics loop, enabling all of the heating systems to operate under real-world conditions. PPA won accolades as having one of the best facilities of its kind, and with quality of training second to none. Currently, classes range from one-half day to two weeks in length.

Though PPA is recognized for excellence in oil-fired training, association managers recognized the need to evolve their programs to train for all types of energy sources. This included a greater focus on gas-fired equipment, air conditioning, and electrical components, and to accommodate larger classes. By late 2019, preparations for the new facility had begun.

Though, soon after the association initiated an expansion to accommodate the need for gas-fired training, COVID-19 swept in with hard repercussions worldwide. “Among the many concerns we had, we had to consider the negative impact on the new facility’s mission, and had we chosen exactly the wrong time to expand?” asked PPA’s Executive Vice President Ted Harris. He and Trainer Alan Mercurio certainly had their hands full since the expansion project began in early 2020.

As it turned out, the forced pause in association activity allowed its managers to turn their full attention to making sure the new facility, including a modern classroom and a working lab, would exceed the needs of trade professionals “when they returned; not if,” insisted Mercurio.

Through last year, as the economy’s pace slowed to a crawl—sure enough, and just as predicted—a silver lining emerged. Addition of the association’s new gas-fired hydronic facility was not only completed, but attracted the attention of manufacturers, reps, wholesalers and installers who wanted to help. And now the expanded facility is teeming with students.

The new facility – with Ed Howell as the key “gas-side/HVAC” instructor – offers plenty of room for students and additional instructors and serves as the ideal training venue for a wide range of classes. Students receive training on all facets of gas-fired equipment and mini-split system operation, service work and troubleshooting.

As many veterans to the mechanical trades will affirm: it’s easy to install new equipment; it’s another thing entirely to know how to diagnose and treat ailing systems. Students who attend classes at PPATEC’s now-enhanced training facility get the best equipment service training available anywhere.

Classes resumed early this year, with lots of interest in troubleshooting and service work, allowing “students” to hone skills in a lab setting that allows instructors to replicate a wide variety of especially challenging conditions. “The repeatability of any technical challenge is one of the greatest assets of our facility,” said Mercurio. Not only do students get to work through a problem until it’s fully solved, giving them the best hands-on experience with it, but instructors can also add new challenges to reproduce a real-world encounter.

Trade Pros Give PPATEC Two Thumbs-Up

One trade professional who recently completed training at PPATEC’s workshop—on the “oil side”—is Damon Allen, an 18-year air-side veteran of the HVAC trades based in Randallstown, MD. Allen, an HVAC service technician with H. B. McClure Company said, “I was glad that H. B. McClure saw the advantage of sending me to PPATEC training because it allowed me to expand confidently into hydronics work. The three-day service course, focusing mainly on service and maintenance of oil-fired equipment, was extremely valuable.”

Another veteran of the trades—and also a military vet who served four years in the U. S. Marines—is Shane Lang, a service technician with Philipsburg, PA-based J J Powell Inc. Last fall, Lang attended PPATEC’s two-week training, affectionately referred to by attendees as “burner school.” Lang said that, “A number of trainers, each coming from different manufacturers, provided detailed instruction in trouble-shooting, maintaining and servicing equipment—from boilers and furnaces, to burners. The course taught me a lot about burner technology, and how to keep the systems running at their best.

“The quality of training [at PPATEC] was excellent,” added Lang. “I’d recommend it to anyone ion the HVAC trades. I’ll hope to return for more instruction there.”

Yet another military vet, and rather new to the HVAC trade, is Jeremy Perez, an ex-Marine and NATE-certified HVAC tech with Towanda, PA-based Energy Distribution Partners. “The training at PPATEC goes deeper than NATE schooling, so I appreciate that. The hands-on experience is valuable, and the simulator training—which allows us to run through various conditions with live voltage—is very helpful.”

Cody Watts, also an HVAC technician with Energy Distribution Partners, was attending a two-week PPA course with Perez. After serving for a decade on shale gas drilling rigs where he worked routinely with industrial pumps and three-phase equipment, Watts chose to enter the HVAC trade and quickly found that PPATEC’s training played a valuable role in helping him make the transition. “Most beneficial for me has been the hands-on experience I got at PPATEC, the simulators for real-world troubleshooting, and the binder that’s full of material—tied to each aspect of the training.”

“Throughout the training – whether it’s a few days or a few weeks in length – we provide all students with plenty of review and instructional material,” assured Mercurio. “It’s one of our hallmarks. We hear routinely [from students] that it’s greatly beneficial.”

Veteran benefits/”Gateway” program

Mercurio says that they’ve trained a substantial number of military veterans at the PPA facility. “Aware of that, one of Ted Harris’ visions for training here is to develop a 10-week workforce development program specifically for vets. The plan [now underway] is to meet conditions for GI Bill veterans benefits so that ex-military students can use funds available to them for extensive training, even to include travel and hotel expenses.”

PPATEC received approval and recognition from the PA Dept of Education in February 2021 as a private licensed school. This allows PPA to admit students to a 10-week, entry-level trade course, one not paid by a current employer. PPA is set to introduce the course in 2022. “This segment of the market [individuals not currently employed in the HVAC industry] is one we very much want to cover, ideally allowing graduates to be hired by one of our members,” added Harris.

Industry support is crucial

Harris explained that industry support from manufacturers, wholesalers and contracting firms plays an important role in making PPA’s mission viable. “Our purpose here is to offer valuable, maybe even life-changing instruction, but without the help of our industry partners, we simply couldn’t do it.”

Key supporters of the association include Taco Comfort Solutions, NTI, APR Supply, Fujitsu, Sid Harvey, Rheem, Crown, Rhoads Energy, Tevis Energy, Ferguson, Navien, Friedrich, Burnham, Honeywell, Energy Kinetics, Ray Murray Inc., R. W. Beckett, Field Controls, Mitsubishi Electric, and F.W. Webb Company.

“Overall, the support we receive from manufacturers and other industry stakeholders is terrific,” added Harris.

Taco Gear + Dave Holdorf Expertise

Shortly after learning of PPA’s desire to install a new hydronic training lab with gas-fired (and ductless HVAC) technology, Johnny White, Jr., CEO of Taco Comfort Solutions, asked for a list of needed components.

Taco residential systems trainer Dave Holdorf also got wind of the project. He and White soon offered not only to provide many of the essential hydronic system components—including many of their newest, most advances ECM circulators—but that Holdorf would also make trips from Long Island to deliver the materials and to serve as a consultant to the installation firm (Stevens, PA-based Vertex Mechanical) chosen to assemble all of the new, hydronic lab equipment. “Johnny’s words to me were, ‘Give them anything they need, and all the support they can use,’ said Holdorf.

“I designed the facility to represent realistic conditions as closely as possible, with an emphasis on real-world variations and practicality,” said Holdorf. “For instance, I designed-in system circulation with zone valves for one of the cast iron boilers, and zone valves for the other. And, for the NTI boiler, the addition of a hydroseparator—just because it’s a possibility that a service tech will encounter scenarios like these in the field.”

Vince Youndt, owner of Vertex, explained that they wanted to do the installation work; he chose HVAC/hydronic systems installer Jared Fox as the lead technician. Holdorf used Taco’s FloPro Design software to develop a spreadsheet with all of the needed components and to design the systems, with many integrated boilers, as well.

Steve Wieland, MidAtlantic sales manager for NTI Boilers, Inc. was also one of those who, after learning of the association’s needs, quickly expressed interest in providing support. Not long after that, the very first, newest FTVN-110 boilers were rolling off the line. He received two of them, and soon delivered one of the company’s newest, most advanced mod-con boilers—an up to 11:1 turndown system with sizes of 85-200 MBH (purely) for heat, and 110-200 MBH for combi (heat with domestic water). “We’re delighted to support them, and I must say that after seeing the installation work there, the new lab is extraordinary. It’ll serve them well,” said Wieland.

The new hydronics lab now includes a variety of mod-con gas boilers (including the latest from NTI) and two that are atmospheric. And, according to Mercurio, software in equipment sends diagnostic signals to the cloud for instant access to operational conditions, quickly availing information to any portable device.

Simulators, too

PPATEC has also added three HVAC simulator units from iConnect Training. According to Harris, the new simulators allow students to better understand the theory and operational techniques for electrical components, gas furnace systems and heat pumps. The simulator workstations feature a variety of live-fire conditions for heating and cooling systems:

- 9240 HVAC Electrical Control Trainer This simulator—with A/C, heat pump, basic electricity, commercial electricity and supermarket refrigeration modules, among many others—allows a trade pro to “build” a complete HVAC system by connecting the wires to the appropriate modules. Once complete, instructors can demonstrate how everything is working properly, or if there are failures, what can be done to solve the problem.

- 9250 Gas Furnace Controls Training Systems Specifically built to replicate a high efficiency gas furnace with air conditioning, this simulator allows an instructor to walk students through wiring from one module to the next until a system is fully operational. The sim has an actual gas burner to replicate close-to-real conditions. Students then learn about adjusting gas pressure and combustion air, and how to properly use a multi-meter to check flame rectification and a variety of faults, among other things.

- 701 Table Top Heat Pump Trainer Instructor use this simulator to demonstrate the proper way to use refrigeration gauges. Super-heat sub-cooling is also taught. Students can see refrigerant going through glass tubes to help them understand at which point the refrigerant flashes off from a liquid to a vapor and back to a liquid. A reversing valve gives an instructor the ability to explain its purpose, and troubleshooting techniques.

PPA and PPATEC members

Currently, PPA has about 400 members, most of which are fuel delivery firms who offer HVAC services. Though, there’s a wide range of wholesaler and manufacturer members. “Statewide, there are about 5,000 HVAC service and installation companies; we invite them all,” said Harris. Through membership, all member firms benefit through their alliance with PPA through the availability of training for techs, and through a greatly-improved, higher-skilled workforce.

“Fortunately, we now have over 40 HVAC contractor firms that don’t offer fuel delivery who’ve joined the association as PPATEC members. This new membership category, introduced in 2019, now provides installing contractors the opportunity to receive various PPA benefits such as discounts for technical training,” added Harris. “We hope to continue to expand [membership] regionally—say, within a four-hour radius of Harrisburg.”

Equipment and components

Generous donations of HAVC and hydronic equipment, and components, came in from many manufacturers. “We were thrilled that, shortly after announcing our plan to expand the training facility, offers began to stream in,” said Harris.

Key contributors included Taco, which supplied a wide range of ECM circulators, zone valves, zone controls, hydraulic/dirt and air separators, boiler feed valves and other hydronic components. APR Supply chipped in with ductless mini split systems, one each from Fujitsu, and Friedrich. James Miracle and Mike Woods from Mitsubishi Electric contributed a two-head multi-zone system. John Monaghan, with Crown boilers, informed them that they had two atmospheric boilers and one condensing boiler to provide. Condensing boilers were also given by Energy Kinetics. Steve “Wheels” Wieland called from NTI to say that one of their newest boilers would soon be on its way (its only other twin, just off the line, would serve as a demo unit for Wieland’s own training efforts); he made the delivery personally.

Doug Oest called from Lancaster, PA-based Burnham Corporation to say that they would provide a very substantial nine-section, cast iron light commercial V9 gas boiler. Matthew Nowicki and Kurtis Mumma called from Ferguson HVAC to say that they would provide (in partnership with Navien) a tankless gas water heater. In partnership, Rheem and Sid Harvey supplied a tank-type gas water heater.

Residential and commercial gas burners were donated by R. W. Beckett. A power vent was donated by Field Controls; RegO and Fischer regulator products were donated by Ray Murray Inc. and F.W. Webb Company. A variety of Honeywell thermostats were given by Venco Sales Inc., and Viega ProPress fittings were discounted by RF Fager Company. A Monessen vent-free log set was donated by Ray Murray Inc. A Premier propane cooking range was donated by Martin Appliance.

John Vastyan owns Common Ground, a plumbing and mechanical, hydronic, HVAC and geothermal trade communications firm based in Manheim, Pa. He can be reached at JohnV@SeekCG.com.