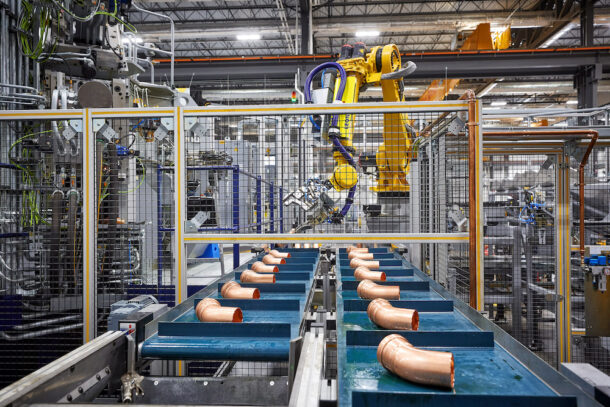

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025. Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Read more

press technology

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025.

Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Markus Brettschneider made the announcement.

“This is an exciting time at Viega, as our growth continues to prompt the expansion of our North American footprint,” said Markus Brettschneider, CEO and President of Viega LLC. “This new facility in Ohio, along with recent investments in our existing Kansas facility, further supports our growing demand and is part of Viega’s plan to increase North American production. We look forward to expanding our presence in this part of the country to further support our customers.”

The 80-acre parcel in Shalersville and the construction of the new plant represent an investment of approximately $200 million in Ohio. Viega’s business continues to grow in the U.S., and the additional plant will help support the increased demand for Viega products. It also aligns with the company’s sustainability goals, which include reducing the carbon emissions associated with importing products by manufacturing more items in the U.S. The new facility will be completely carbon neutral from the start, supporting the company’s long-term goal of achieving net-zero carbon emissions for all their plants by 2035.

“The expansion of our operations into Ohio shows our commitment to creating highly skilled jobs in the U.S.,” said Marki Huston, Head of Manufacturing for Viega LLC. “Our goal is to build more sustainable manufacturing processes and continue developing tomorrow’s workforce. With production scheduled to begin in early 2025, we expect to start hiring for positions as soon as January 2024, bringing more than 68 new jobs to the area over the next few years.”

Viega recently announced investments in new equipment for its McPherson, Kansas, manufacturing and distribution facility. In addition, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with more North American expansion planned for 2024 and 2025.

Viega worked with local, regional, and state organizations, including Team NEO, JobsOhio, Portage Development Board and the Shalersville-Streetsboro Joint Economic Development District on tax credit assistance and to select the 80-acre site. “We have a great manufacturing legacy, dedicated talent pool, and future-oriented industry resources to support Viega’s new operations,” said Team NEO Chief Executive Bill Koehler. “Along with JobsOhio and our local partners, we welcome Viega to the Northeast Ohio Region. We are confident they will thrive here.”

Viega adds MegaPress® 316 Spring Check Valves in 1⁄2” to 2” sizes, MegaPress® Ball Valves in 1⁄2”-4” sizes and ProPress ECO Tubing 316 and Manual Balancing Valves for Potable Water Broomfield, Colo. — Viega announces the availability of new products in its MegaPress® and ProPress® product lines. The expanded line of ball valves completes the Read more

Viega adds MegaPress® 316 Spring Check Valves in 1⁄2” to 2” sizes, MegaPress® Ball Valves in 1⁄2”-4” sizes and ProPress ECO Tubing 316 and Manual Balancing Valves for Potable Water

Broomfield, Colo. — Viega announces the availability of new products in its MegaPress® and ProPress® product lines. The expanded line of ball valves completes the MegaPress system and is ideal for commercial and industrial applications, including gas applications. All the valves have Viega’s SmartConnect® technology, which helps installers easily identify unpressed connections during a pressure test. The new products being added to the line of MegaPress ball valves are:

- – MegaPress Ball Valve 1⁄2” to 2” (EPDM Sealing Element) – a full port valve featuring a carbon steel body, double-stem seal, stainless steel ball, and a lockable handle.

- – MegaPress FKM Ball Valve 1⁄2” to 2” (FKM Sealing Element) – this valve has the same carbon steel body, double-stem seal, stainless steel ball, and lockable handle, yet features an FKM sealing element which is designed for use in higher-temperature applications. The 2-1⁄2” to 4” valves feature a carbon steel body, chrome-plated ball and an SST lockable handle.

- – MegaPress 304 FKM Ball Valve 1⁄2” to 4” (FKM Sealing Element) – this valve features a 304 stainless steel body, double-stem seal, stainless steel ball, and lockable handle. The combination of the FKM sealing element and the 304 stainless steel makes this option ideal for harsh environments that require higher operating temperatures.

- – MegaPress 316 Ball Valve 1⁄2” to 4” (EPDM Sealing Element) – this valve works in a variety of harsh environments, including cleaning agents, acid, and potable water. It is made of a 316 stainless steel body featuring a double-stem seal, a stainless steel ball, and lockable handle.

- – MegaPressG Ball Valve 2 1⁄2” to 4” (HNBR Sealing Element) – now available in large diameters, the valves feature an HNBR sealing element at the press-ends which is compatible with fuel and gas applications.

- – MegaPress 316 Check Valve (EPDM Sealing Element) – the check valve helps create directional flow of fluid in one direction while preventing fluid from flowing back. It is ideal for industrial applications, including potable water, rainwater, chilled and hydronic water.

“After 10 years of success, it’s exciting to have the MegaPress portfolio grow with maintenance-free MegaPress ball valves that enable fast, safe and efficient installation from 1⁄2” to 4″. MegaPress 316 spring check valves are a useful addition to the MegaPress 316 portfolio and carry an NSF®-61-372 listing,” said Christian Becker, Product Manager, Valves, of Viega LLC.

Viega also released two new products for the ProPress system – the ProPress Manual Balancing Valve and ProPress 316 ECO Tubing. The ProPress 316 ECO Tubing is a stainless-steel alternative to copper. It’s engineered for commercial potable systems where the piping may come into contact with corrosive cleaning liquids. It is compatible with ProPress 316 fittings and is a great option for potable water, air, acidic and cleaning solution applications.

Viega also released two new products for the ProPress system – the ProPress Manual Balancing Valve and ProPress 316 ECO Tubing. The ProPress 316 ECO Tubing is a stainless-steel alternative to copper. It’s engineered for commercial potable systems where the piping may come into contact with corrosive cleaning liquids. It is compatible with ProPress 316 fittings and is a great option for potable water, air, acidic and cleaning solution applications.The Viega ProPress Manual Balancing Valve features an adjustable handle with an integral scale visible on the side used to increase or decrease the flow rate. The two pressure-test ports are used to measure the differential pressure across the seat of the valve, which can be used to calculate the flow rate. The ProPress Manual Balancing Valve is suitable for commercial applications, including potable and hydronic systems.

“Our customers now have more options to use press technology for a larger number of applications,” said Luke Paulo, Manager, Product Portfolio Development of Viega LLC. “The new ProPress 316 ECO tubing is a natural extension to our existing ProPress 316 line. It carries an NSF®-61-372 listing, which means our ProPress 316 system can be used in potable water systems.”

Broomfield, Colo. — Viega is celebrating a milestone with the tenth anniversary of the introduction of MegaPress. Press technology has been in the U.S. since 1999, and Viega has continued to release new fittings and valves to make Viega press technology an industry standard in commercial, residential and industrial applications. Viega MegaPress systems have hundreds Read more

Broomfield, Colo. — Viega is celebrating a milestone with the tenth anniversary of the introduction of MegaPress. Press technology has been in the U.S. since 1999, and Viega has continued to release new fittings and valves to make Viega press technology an industry standard in commercial, residential and industrial applications. Viega MegaPress systems have hundreds of configurations, thousands of approvals, and more than 22 million fittings sold. Over the past ten years, Viega MegaPress systems have saved contractors millions of dollars in installation costs.

Viega MegaPress and MegaPressG were the first press systems in the U.S. market engineered explicitly for gas and hydronic applications. Since the launch, MegaPress systems have expanded to include more than 200 configurations from 1⁄2” to 4” and are approved for more applications than any other carbon steel fitting system.

The value of a MegaPress system is in its unique engineering. The Grip Ring uses bi-directional teeth to provide mechanical strength and securely lock the fitting to the pipe. The sealing element provides elastomeric insurance behind the metal-to-metal contact to compensate for small irregularities of the pipe surface; this ring stays outside the flow path. The Viega MegaPress system has a long lifespan and is tested to withstand a broad range of pressures, temperatures and applications. All Viega fittings come equipped with Smart ConnectTM technology that identifies unpressed connections during pressure testing, allowing for easy identification to ensure the fittings are installed right the first time.

“In the past 10 years, labor costs have been rising while labor availability has been dwindling. It’s a perfect storm. Our MegaPress systems solve both of those challenges and help contractors across the country get more done with less. It’s a proven and trusted technology that isn’t just faster, but it’s reliable, mitigates jobsite risk because of the flameless installation, and eliminates the need for fire watch,” said Will Schneider, Product Portfolio Manager of Viega LLC.

Following the initial success of MegaPress, Viega launched MegaPressG with an HNBR sealing element approved for use in gas and fuel oil applications. Initially available 1⁄2” – 2”, MegaPressG also became the first fitting approved for connecting gas pipe up to 4”.

MegaPress FKM was added to the lineup for higher-temperature applications. With more than 180 configurations 1⁄2” to 4”, MegaPress FKM is now a staple in residential and low-pressure steam, compressed air, fire protection and fuel/oil applications.

With the rapid rise of press fitting adoption, Viega engineered a system for connecting large diameter 304 and 316 IPS stainless steel pipe. MegaPress Stainless comes with a choice of EPDM or FKM sealing elements and makes secure connections in less than 16 seconds.

In recent years, MegaPress systems expanded to meet contractor demand for a complementary valve offering. This included Viega MegaPressG Valves which come with HNBR sealing elements and are available in sizes 1⁄2” to 2”. And Viega MegaPress 3-piece ball valves are available 1⁄2” to 4” and work on potable water, hydronic water and a wide range of other system applications.

“I’ve had the opportunity to train thousands of plumbers and contractors on MegaPress systems and it’s been exciting to see the industry truly embrace this revolutionary technology,” said Troy Locke, Manager, Customer Engagement, Viega LLC. “We’re about pushing the industry forward. We’re going to continue to add more sizes, more applications and secure more approvals. In a decade, I believe we’ve only started to scratch the surface of what is possible with these types of pipe fittings and valves.”

RIDGID, part of Emerson’s professional tools portfolio, introduces the smallest and lightest press tool on the market, the RP 115 Mini Press Tool. Designed for residential and lightweight commercial plumbing use, it completes the majority of press connections installed in the market with ease, while getting professionals to their next job faster. Engineered with the Read more

RIDGID, part of Emerson’s professional tools portfolio, introduces the smallest and lightest press tool on the market, the RP 115 Mini Press Tool. Designed for residential and lightweight commercial plumbing use, it completes the majority of press connections installed in the market with ease, while getting professionals to their next job faster.

RIDGID, part of Emerson’s professional tools portfolio, introduces the smallest and lightest press tool on the market, the RP 115 Mini Press Tool. Designed for residential and lightweight commercial plumbing use, it completes the majority of press connections installed in the market with ease, while getting professionals to their next job faster.

Engineered with the quality and technology that have kept RIDGID first in pressing for decades, the RP 115 can press 1/2-inch to 3/4-inch copper and stainless steel fittings. It is 14.6 inches long, 2.5 inches wide and weighs only 5.5 pounds with battery and jaws. The RP 115 has a SlimGrip handle and optimized trigger for balance and control; one-handed jaw opening and operation for reach and ease of use; and 210-degree head swivel for access to tight spaces.

Visit RIDGID.com for more info.

Viega will sponsor pit crew in select races and have presence on the No. 47 Camaro ZL1 throughout the NASCAR Cup Series season. JTG Daugherty Racing has united with Viega, which is a a worldwide leader in pipe fitting installation technology for industrial, commercial, and residential projects. Viega is sponsoring the newly formed JTG Daugherty Read more

Viega will sponsor pit crew in select races and have presence on the

No. 47 Camaro ZL1 throughout the NASCAR Cup Series season.

JTG Daugherty Racing has united with Viega, which is a a worldwide leader in pipe fitting installation technology for industrial, commercial, and residential projects. Viega is sponsoring the newly formed JTG Daugherty Racing pit crew, and will have placement on Ricky Stenhouse Jr.‘s No. 47 Camaro ZL1 C-Post throughout the entire NASCAR Cup Series season.

“Viega supports professionals that make things happen, and we’re aligned to promote the high quality of their products,” Stenhouse Jr. said. “Pit crews are professionals with a special skill set, and they must have the right tools to do their job to work fast, efficiently and effectively just like the trades people working with Viega products. We have a fitting pit crew that Viega has partnered with this season. We’re looking forward to being successful on and off the track together, and communicating that Viega’s press technology is a safer secure alternative for connecting pipe.”

Viega’s saying is “Fast, Safe and Secure.” That key messaging will be showcased on the yellow and black Viega pit crew uniforms specially featured during 11 NASCAR Cup Series races this year when they service Stenhouse’s race car.

“Races are won and lost in the pits – it’s all about maximum efficiency and knowing the wheels are safely secured,” said Jared Mackrory, Viega Marketing

Director. “It’s the same challenge the professionals in our industry face as they install pipe fittings and hustle to get critical lines back up and running. We love that shared connection and are proud to support the professionals on the JTG Daugherty Racing pit crew.”

Viega’s pit crew uniform branding will include Las Vegas Motor Speedway (both races 3/6 & 10/16), Circuit of The Americas (3/27), Talladega Superspeedway (4/24), Dover Motor Speedway (5/1), Kansas Speedway (5/15), World Wide Technology Raceway (6/5), New Hampshire Motor Speedway (7/17), Pocono Raceway (7/24), Michigan Speedway (8/7), Watkins Glen International (8/21).

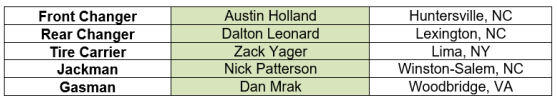

Viega is also pleased to announce the pit crew lineup for those races as follows:

For More information visit http://www.viega.us/ or contact the company at communications@viega.us.