It’s been quite the start to 2022 for Ryan Bickerton, owner/operator of Bickerton Plumbing and Heating LLC, Boston. Recently recovered from COVID, his phone hasn’t stopped ringing. He’s been busy, and that’s a good thing. Mostly specializing in high-end renovations, old houses in the historic areas of Boston and high-efficiency boilers, Bickerton has run his Read more

Radiant heating

It’s been quite the start to 2022 for Ryan Bickerton, owner/operator of Bickerton Plumbing and Heating LLC, Boston. Recently recovered from COVID, his phone hasn’t stopped ringing. He’s been busy, and that’s a good thing.

Mostly specializing in high-end renovations, old houses in the historic areas of Boston and high-efficiency boilers, Bickerton has run his own company since 2014. At the age of 18, Bickerton started into plumbing, working for a larger residential company doing large multi-unit buildings where he worked for 2 1/2 years before moving to a smaller company doing mainly commercial work.

The itch started for Bickerton when he started in construction over the summers during high school, working for a roofing company and a general contractor, basically doing whatever was needed on a job site. “I tried helping whoever needed to be helped on the site—plumbers, electricians, carpenters—cleaning up, making coffee runs, etc. I remember those summers working for the GC and I enjoyed helping the plumbers more than anything else. I realized I was falling in love with the industry, and the rest is history,” says Bickerton.

Nevertheless, Bickerton was encouraged to make an attempt at college even though he didn’t really want to; he gave it a shot anyway. He lasted less than a year and decided that was it. “For me, it was a waste of time and money,” says Bickerton. “My parents were okay with me leaving after giving it a valiant effort, but my father said ‘pick a trade because you’re not going to be sitting around here all day.’”

Nevertheless, Bickerton was encouraged to make an attempt at college even though he didn’t really want to; he gave it a shot anyway. He lasted less than a year and decided that was it. “For me, it was a waste of time and money,” says Bickerton. “My parents were okay with me leaving after giving it a valiant effort, but my father said ‘pick a trade because you’re not going to be sitting around here all day.’”

Bickerton recalls speaking to his father, and a few other people he knew who worked in the trades, and was pushed in the direction of electrical or plumbing mainly because, “you’ll never be looking for work.”

After obtaining his Journeyman Plumbing and Gas Fitting License in 2008, Bickerton completely shifted gears and joined the United States Marine Corps where he was deployed to Afghanistan. It was a difficult decision but joining the military was something Ryan had always wanted to do. In 2008, it was the right time. After six years of service with the Marines, Bickerton returned to plumbing and got his Master Plumbing and Gas Fitting License. “I started doing more and more side work until I landed a few bigger jobs that motivated me to leap into owning my own company. I haven’t look back since,” says Bickerton.

Part of that drive came from his biggest role model, his father, who worked most of his life in a power plant in South Boston as a general mechanic—he could pretty much fix anything and everything that needed fixing. “My father is the hardest working person I know. I remember as a young kid not seeing him for days at a time because he was getting home late and leaving early before we were awake. I knew he was out working hard taking overtime to provide for us. He could and would fix most things around the house. I remember one year our water heater went out on Thanksgiving and he took care of it by himself. I thought that was pretty cool, and still do,” says Bickerton.

As for Ryan, he never considered himself a role model, but he tries to conduct himself that way. Any chance he gets, he’ll speak highly of the trades. “If any young kids ask me about the trades, I do my best to steer them in the right direction and let them know it’s a very viable option. It’s a rewarding career choice, and college and white-collar work doesn’t have to be for everyone,” says Bickerton.

Bickerton does rough-ins to beautiful renovations.

Bickerton’s trade role model was his first foreman, Mike Sheehan, a plumber for 30+ years, his body broken from years of moving massive boilers and extra heavy cast-iron pipe. “But he still loved the trade. He taught me a lot of my early skills, and he would say that this trade has all the potential to do anything you want with it, which has really stuck with me to this day,” says Bickerton.

Bickerton’s go-to tool has been the ProPress/MegaPress. “Don’t get me wrong, I loved to solder and took great pride in having clean joints, and still think it’s a necessary skill to have, but the press system is a complete game changer.”

While respecting these two men’s work ethic, Bickerton knows that balancing work and family life is important. It’s probably his most difficult task, says Bickerton. “I’m usually out the door by 5 am and home around 5 pm, and the kids go to bed between 7:30-8 pm and then most nights I have to do estimates or invoices when they’re in bed so I don’t have as much ‘leisure time’ as I’d like. I try to make every second I’m home count.”

And the weekends are for family. Bickerton used to work every Saturday and even some Sundays. Lately, however, Ryan doesn’t work Sunday unless it’s a catastrophic emergency, and on Saturdays he tries to be done by 12 or sometimes not at all. “Like I said before, I love plumbing and working but I don’t think I’ll ever regret not working more and spending less time with my family so I try to best divide my time in the fairest manner possible.”

It’s clear that family time is most important. “In my spare time, more than anything, I enjoy hanging out with my wife and our children. My wife Micayla and I have been married for six years and our three kids are growing up fast. If I’m not working, I’m with them. They are starting to get into different activities, hockey, baseball, football, swimming, horseback riding, and I just enjoy every second of that. Even if it’s just hanging out and watching a movie, it’s never wasted time for me,” says Bickerton.

It’s clear that family time is most important. “In my spare time, more than anything, I enjoy hanging out with my wife and our children. My wife Micayla and I have been married for six years and our three kids are growing up fast. If I’m not working, I’m with them. They are starting to get into different activities, hockey, baseball, football, swimming, horseback riding, and I just enjoy every second of that. Even if it’s just hanging out and watching a movie, it’s never wasted time for me,” says Bickerton.

Perhaps family means a bit more to Bickerton because his daughter, Mallory, was diagnosed with a rare genetic disorder called Rubenstein Taybi Syndrome (RTS). In 2017, Ryan and Micayla, along with some close friends, started a non-profit organization called Mals Pals Foundation. “We have been very fortunate with Mallory. We live in the epicenter for healthcare; she has had an inclusive educational opportunity here in Boston and it helps that we are able to pay for anything and everything she has needed in order to thrive,” says Bickerton.

Mal’s Pals Foundation aims to ease the burden of other families who maybe are not as fortunate. The Bickertons raise awareness for rare diseases like RTS, and they help educate newly diagnosed families. “We are trying to make difference in other people’s lives even if it’s just a small one. You can check us out at malspalsfoundation.org.”

Mal’s Pals Foundation aims to ease the burden of other families who maybe are not as fortunate. The Bickertons raise awareness for rare diseases like RTS, and they help educate newly diagnosed families. “We are trying to make difference in other people’s lives even if it’s just a small one. You can check us out at malspalsfoundation.org.”

Mallory is now seven-years-old and doing well. “Initially, there were concerns, but honestly, I wouldn’t have it any other way,” says Bickerton.

Bickerton looks forward to going to work every day. “But the most rewarding to me is being able to sit back at the end of the day or at the end of a job and look at what I’ve done,” says Bickerton. “I like having something tangible, that I can look at and touch and say I did that, or I fixed that or I created that. Whether it’s fixing a leaking faucet, creating a bathroom where there wasn’t one before, plumbing a 5-unit building completely from scratch or providing someone with heat and hot water for the next 20-30 years. That’s pretty cool.”

In the end, Ryan really loves plumbing, even if he’s stressed out and jobs are behind, or he’s behind on paperwork, or he’s made a mistake and or redo something. “I still consider myself lucky to be doing what I love every day. And on those harder work days, I still get to come home to three beautiful children and a wife who loves me. Every time I walk in the door and they scream ‘DAD!’ all that stress lifts off instantly, and it’s all worth it.”

In the end, Ryan really loves plumbing, even if he’s stressed out and jobs are behind, or he’s behind on paperwork, or he’s made a mistake and or redo something. “I still consider myself lucky to be doing what I love every day. And on those harder work days, I still get to come home to three beautiful children and a wife who loves me. Every time I walk in the door and they scream ‘DAD!’ all that stress lifts off instantly, and it’s all worth it.”

Congratulations to Duane Huisken SVP marketing for IAPMO as he receives the Les Nelson Achievement Award for his contributions to the HIA-C mission and his efforts in furthering the hydronics and radiant industries. Nelson was instrumental in incorporating additional hydronics code language and the new sections of geothermal into the Uniform Solar Energy Code, making Read more

Congratulations to Duane Huisken SVP marketing for IAPMO as he receives the Les Nelson Achievement Award for his contributions to the HIA-C mission and his efforts in furthering the hydronics and radiant industries.

Congratulations to Duane Huisken SVP marketing for IAPMO as he receives the Les Nelson Achievement Award for his contributions to the HIA-C mission and his efforts in furthering the hydronics and radiant industries.

Nelson was instrumental in incorporating additional hydronics code language and the new sections of geothermal into the Uniform Solar Energy Code, making it the Uniform Solar, Hydronics and Geothermal Codeit is today. He was working on projects related to the increased electrification of hydronic systems.

As the executive director of the Radiant Professionals Alliance and staff liaison to the Hydronics Industry Alliance – Commercial (HIA-C), Nelson was able to gain increased cooperation within the industry. He was skilled at keeping the teams focused in order to maintain and grow these industry segments.

The latest version of HydroSketch – a simple, intuitive cloud-based software for making piping and electrical schematics is now available at www.hydrosketch.com. Version 2.0 includes several enhancements including: • A much larger drawing canvas to reduce the need for scrolling. • Vector-based graphics that allows component symbols to be scaled over wide ranges while maintaining Read more

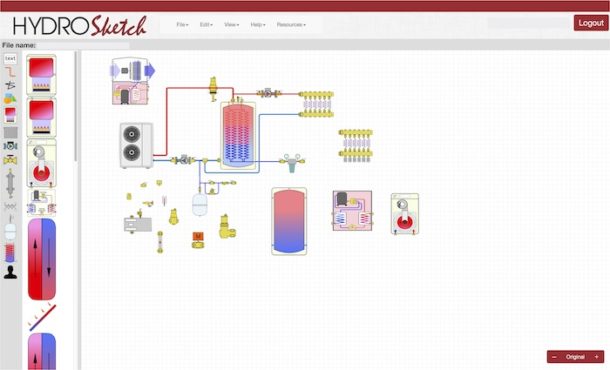

The latest version of HydroSketch – a simple, intuitive cloud-based software for making piping and electrical schematics is now available at www.hydrosketch.com.

Version 2.0 includes several enhancements including:

• A much larger drawing canvas to reduce the need for scrolling.

• Vector-based graphics that allows component symbols to be scaled over wide ranges while maintaining “crisp” appearance.

• New component symbols.

• Additional resources such as YouTube tutorials.

A free 30-day trial version of HydroSketch 2.0 is available at www.hydrosketch.com A single user license, valid for 3 years from the date of purchase remains at $US 99.

Existing users will automatically work with version 2.0 when logging in. The original version of HydroSketch will remain supported through the end of 2021.

Against the odds, Dan Foley rises above, displaying courage, strength and exemplary work through steadfast leadership. We are honored to name Dan Foley Mechanical Hub’s Person of the Year. When the calendar flipped to 2020, the new year was looking like one of the best years for Dan Foley, owner, Foley Mechanical, Inc. (FMI), Lorton Read more

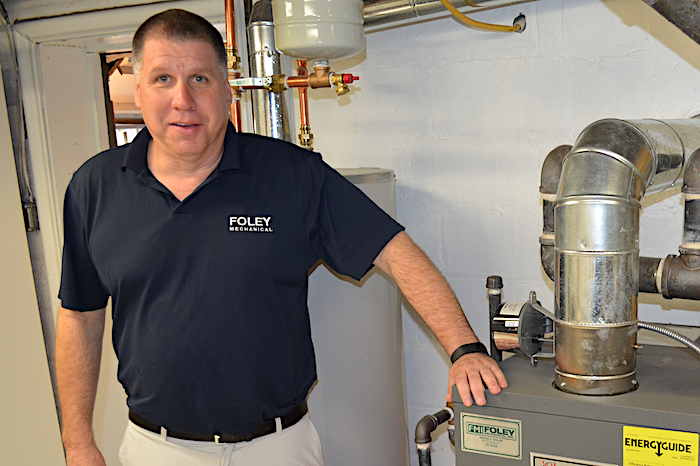

Against the odds, Dan Foley rises above, displaying courage, strength and exemplary work through steadfast leadership. We are honored to name Dan Foley Mechanical Hub’s Person of the Year.

When the calendar flipped to 2020, the new year was looking like one of the best years for Dan Foley, owner, Foley Mechanical, Inc. (FMI), Lorton, Va. Until the nasty pandemic hit back in March, that is. “It was the worst medical experience in my life. I got it the first week of April. I have no idea how I contracted the virus. I am at job sites, supply houses and architect meetings every day. Over the course of a week, I am in contact with dozens of people. Obviously, I picked it up somewhere along the way,” says Foley.

Foley knew something wasn’t right with his body. “At first I felt a little funny but I did not feel sick. Then, extreme fatigue set in. I could not function. I would sleep 20 hours a day and was more tired when I woke up. I did not have a cough or high fever so I did not think I had Coronavirus, maybe just a bug or the flu. But think of it like this, I went 12 rounds with Mike Tyson and then got hit by a bus,” continues Foley.

A fairly rare acquaintance—Foley and the doctor visit—“I did a virtual appointment with my doctor and was instructed to go immediately to the emergency room where I tested positive for COVID-19, as well as pneumonia. Once admitted, my fever spiked twice to 103°F and I was in the hospital for seven days. When I was released, I was in bed for two weeks at home. I lost 30 lbs. over those three weeks, as I could not eat. At times, I felt like I was in a fog. Although it affected me mentally and physically, I slowly regained my strength,” says Foley.

Throughout this potentially perilous time, Foley’s employee Ron ran the ship. “He shut down for two weeks in April while he sorted everything out. Luckily, no one else in my company got sick,” recalls Foley.

Over time, Foley’s condition improved, and today he is back 100%. Back to record-breaking business months of June, and July is not far behind. It’s halfway through the year, and throughout all of it, Foley Mechanical is up for the year. “We were down in April and May, as clients understandably didn’t want anyone in their homes. June was a record month and July is shaping up to be the same. I believe it is a combination of pent-up demand, with more people staying at home and hot weather. When it is 65°F outside, there is no need for our service. When it is 95°F and humid, we worked out ways to service, repair and replace HVAC system while maintaining employee and customer safety,” says Foley.

And by customer safety, Foley stresses that they are following standard protocols—distancing, PPE (gloves, masks and shoe covers). Many of Foley’s service customers leave a basement door open for service techs. Customers can communicate by phone or Facetime so there is no direct interaction, and all billing is done through the office for the time being.

And by customer safety, Foley stresses that they are following standard protocols—distancing, PPE (gloves, masks and shoe covers). Many of Foley’s service customers leave a basement door open for service techs. Customers can communicate by phone or Facetime so there is no direct interaction, and all billing is done through the office for the time being.

For Foley, he’s rested, ready to get back to work, Corona-free, with antibodies. Herd immunity, right? Not so fast, my friend. Pump the brakes, says Foley. “I thought the same—I’m home free now that I have antibodies. My doctor warned me that very little is known about the Coronavirus. It can evolve and mutate. He warned me to behave as if I never had it. I am following his direction. Respect the virus,” says Foley.

Getting Started in the Trades

Foley started out as summer help at Arlington Heating while he was in college. After he graduated in 1988 from Virginia Tech with a degree in Business Management, he went to work full time while he figured what he wanted to do. “Thirty-two years later, I’m still in the trade,” says Foley.

After spending fifteen years at Arlington Heating and A/C, Inc., rising to the position of Vice President, Foley left the company in April 2002 to start his own company – Foley Mechanical, Inc., an HVAC company specializing in steam/radiant/snowmelt/renewable/solar systems.

Foley currently serves on the executive board of ACCA national, and his local ACCP, the local chapter of ACCA, and has been a past board member of his local PHCC chapter. He is also a past President of the Radiant Panel Association. He is the current chairman of the ACCA Radiant & Hydronics Council. He holds Master HVAC and Master plumbing/gas fitting licenses in Virginia, Washington, D.C. and Maryland.

Foley’s perseverance, work ethic, and never-give-up attitude stems from his father, a retired Marine Corps colonel. “He taught me the values of hard work and persistence. Never quit, never give up,” says Foley.

Foley, while still learning the business and trade, attributes much to Woolye Croker, founder of Arlington Heating Co., and his bosses Tom and Linda Croker, who still have an influence on him to this day.

Other influences include Dan Holohan, who indoctrinated Foley on hydronics back in the early ’90s when he was strictly a forced-air guy. “He gave me the knowledge, encouragement and confidence to jump into the radiant and hydronics world.”

John Siegenthaler was very generous with his knowledge early on. Foley still uses design graphics and ideas he learned from him more than 25 years ago.

Mitchell Cropp, owner of Cropp-Metcalfe AC, and past chairman of ACCA, was very helpful sharing his business experience.

Skipper Joyce, founder of The Joyce Agency helped Foley open accounts with suppliers when he first started my company. “No one knew who I was but everyone knew Skipper. I was able to secure open accounts with several key suppliers on Skipper’s word alone.”

Skipper Joyce, founder of The Joyce Agency helped Foley open accounts with suppliers when he first started my company. “No one knew who I was but everyone knew Skipper. I was able to secure open accounts with several key suppliers on Skipper’s word alone.”

Last, and certainly not of least importance, Jeff Riley, owner of Coredron, and formerly with Thos. Somerville Co., has been a friend and supporter since the first day FMI opened for business, April 2002.

Foley truly loves his career in the trades. “I like the challenge of landing big projects and designing new mechanical systems. I like watching my crew bring my creation to life. And, I like working with the architect, GCs and owners to find creative solutions to problems. It is something new and different every day,” says Foley.

Foley is so dedicated to his craft and his business that finding balance between work and time spent away from the job can be challenging. “That is the hard part. There really is no balance, but I enjoy what I do. When I no longer enjoy it, I know it will be time for a change,” says Foley.

Yet, when asked the last time he had a great day? “Every morning! In all seriousness, I love what I do,” says Foley. “Aside from work, I last said that as I teed off for a round of golf with my father at Ford’s Colony Golf Club, Williamsburg, Va.”

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service. Features of the new design include full opening integral union ends, bi-directional condensate flow, ¾” Female NPT inlet/outlet tappings and ¾” Read more

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service.

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service.

Features of the new design include full opening integral union ends, bi-directional condensate flow, ¾” Female NPT inlet/outlet tappings and ¾” male NPT x socket fittings. The unit also comes with snap-in mounting brackets included.

The redesigned CN4B-600C, CN4B-850C, CN4B-1200C, CN4B-2000C four-inch neutralizers are designed to facilitate the use of Neutra-Safe’s proprietary media sacks for simple recharging of the unit. This Neutra-pH media blend is a blend of blend of 99 percent pure calcite and magnesium oxide, provides the most efficient neutralization possible. It eliminates clumps that can clog traditional neutralizers. The sack can be opened to release the media for use in Neutra-Safe’s older four-inch tube models.

The best features of the original four-inch neutralizer remain, including a clear tube for easy visual inspection and patented integral union ends with O-ring seals for a leak-proof connection.

Neutra-Safe’s tube style condensate neutralizer line includes seven models, serving high-efficiency, gas-fired appliances up to 2 million BTUH input capacity.

For more info, www.NeutraSafe.com.