In 1971, Chicago native James Guercio, a musician and producer, purchased a 2,000-acre ranch in Nederland, CO, with plans to turn the property into a recording studio and rural escape for the biggest names in the music business. He modified the property’s old barn into a recording studio. In ‘72, Joe Walsh recorded “Rocky Mountain Read more

Uponor PEX

In 1971, Chicago native James Guercio, a musician and producer, purchased a 2,000-acre ranch in Nederland, CO, with plans to turn the property into a recording studio and rural escape for the biggest names in the music business.

He modified the property’s old barn into a recording studio. In ‘72, Joe Walsh recorded “Rocky Mountain Way” while the barn still had a dirt floor. This was the first of many hits that would be produced at Caribou Ranch, as Guercio called the estate. Other stars followed, including Elton John, Stevie Wonder, Chicago, John Lennon, Michael Jackson and hundreds more.

The 3,300 square foot home was a guest residence for musicians recording at the Caribou Ranch Studio.

On a parcel adjacent to the ranch sits a 3,300 square foot home built in 1973, where many of the travelling artists took up residence while writing and recording music. Fast forward to 2022: the home – and the piece of music history it represents – was sold.

The new owner found one of the old boilers leaking and called Peak to Peak Plumbing & Heating.

“We’re one of only a few shops that regularly travel up the Peak to Peak Highway to serve rural customers,” said Joe Ryan, 33 years old and owner of the company.

Ryan found that neither the old cast iron boiler nor the electric boiler was leaking. Instead, the water came from a foundation leak. To address that issue, Ryan called a general contractor he works with on a regular basis, Tom Akins, who owns AP Construction.

After some deliberation, the owner decided to renovate the entire home.

Joe Ryan, owner of Peak to Peak Plumbing.

Ground-source or air-source

Plans were drawn to update the house as well as the dual-fuel hydronic system installed years earlier. The owner’s two requirements were that heat pumps be used and radiant heating be installed throughout.

“Our first conversation about the heating retrofit took place two years ago,” said Ryan. “Both the homeowner and I were torn between installing geothermal units or an air-to-water heat pump system. Whenever I have questions like that, I reach out to Tommy Carroll at Boulder Winnelson.”

“Tommy’s about my age, casual and humble, which can be misleading, because he’s an hydronic mastermind,” he continued. “He’s an engineer by training and he designs hydronic systems in his sleep.”

Nearby Boulder is one of the greenest towns in the country, so it’s no surprise that local supply houses might have someone on staff to design high-efficiency, high-comfort hydronic systems.

“We compared air-to-water heat pumps with a geothermal system,” said Carroll. “In the end, it wasn’t a hard decision.”

Using an outdoor design temperature of -2°F, the home required 81,000 BTU/H. Given the ground temperature at 8,700 feet above sea level, a geothermal system would have required five, 500-foot boreholes. That expense alone made air-to-water heat pumps more attractive.

(left to right) Tommy Carroll and Joe Ryan connect thermostat wires.

BTU Wrangler

“Air-to-water systems have come far enough along that they’re somewhat comparable in capacity and COP to geothermal heat pumps,” said Carroll. “In the long run, air-to-water just made more sense. Air-to-water adds some cost to the plumbing side of the project, but the overall cost is significantly less.”

Customers go to Boulder Winnelson with tricky hydronic projects. Carroll’s business card reads “BTU Wrangler” for good reason.

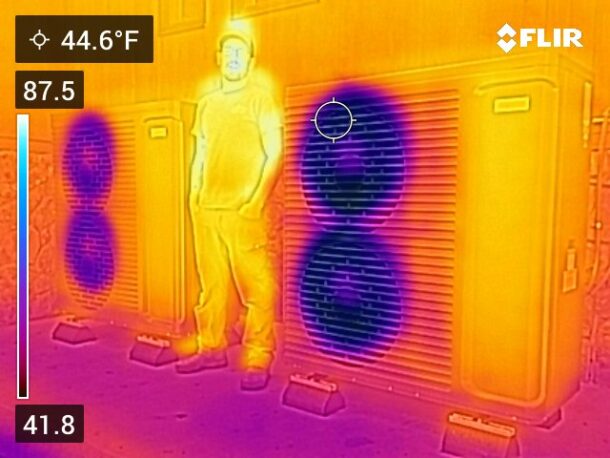

Installer Joe Ryan stands between the Ambient Heat Pumps.

Carroll conducted the heat-loss analysis based on the improvements that AP Construction was making to the building envelope, designed the heat pump system and put together a plan for the controls, allowing Ryan to install two air-to-water heat pumps with a condensing boiler for backup.

“Joe and I have worked together on a few projects in the past,” said Carroll. “He counts on us for experience and expertise, but he’s so competent that he doesn’t need help often.”

Quick pivot

Typical of old, custom homes, the renovation work proceeded slowly, thanks to surprises that kept coming up during construction. Ryan and Carroll had their system design finished in 2023 but were waiting until they could fully implement it. Not much changed until early 2024, when U.S. Boiler Company’s Dave Hansen called on Boulder Winnelson.

“Dave showed me their new Ambient air-to-water heat pump, and the specs on it matched what we needed perfectly,” said Carroll. “So, we changed the design. We’ve had a relationship with U.S. Boiler Company for decades. We knew we could count on them if we needed help.”

Almost a year before the release of the Ambient heat pump, Peak to Peak Plumbing & Heating had already piped many of the indoor components, including a 155 MBH condensing boiler, 70-gallon buffer tank, circulators, sidearm tank, HBX heat pump controller, and more. For this reason, Ryan didn’t need the complete Ambient heat pump package. He just needed the outdoor units.

Two, five-ton Ambient air-to-water heat pumps are used to heat the 3,300 square foot home, which was built in 1973.

“There was an old electric boiler here before I arrived, so the heat pumps didn’t require an electrical service upgrade,” said Ryan. “We just poured a slab outside and core-drilled through the wall to run water lines to the mechanical room.”

Akins, the builder, was mildly concerned that noise or vibration from the heat pumps would transfer through the slab and into the home, but only time would tell.

On the inside

The entire system is freeze-protected by a 35 percent Enviro-Frost glycol mixture. Supply and return lines run from the outdoor units to the large buffer in the mechanical room. This tank has an electrical element but plans to hook it up were discarded when the Ambient heat pumps were selected.

“The Ambient heat pumps are five tons in capacity each,” said Ryan. “They’re capable of supplying up to 140°F water and continue operating down to an outdoor temperature of -13°F. We designed the radiant system to require only 121°F supply water on a design day, and there’s a gas boiler piped to the buffer tank in the unlikely event the home needs supplementary heat.”

When operating at full capacity, 15.3 GPM is pumped through each Ambient heat pump and into the 70-gallon AltSource buffer tank, which also contains a reverse-indirect coil for DHW.

The mechanical room, designed by Ryan and Carroll, uses hot water from the heat pumps for the radiant system and to pre-heat domestic hot water.

“The buffer tank won’t cover the DHW load, simply because it sits at about 120°F on design day,” explained Carroll. “That’s great for radiant floors, but too cool to heat the DHW to final temp. Instead, the coil in the buffer tank just pre-heats the water on its way to the sidearm tank. We went with the reverse indirect coil because it is an easy way – requiring no pumps or moving parts – to use the heat pumps to cover some of the DHW load by preheating the incoming cold water on its way to the sidearm tank. The boiler will always have to raise the DHW to final temp.”

On the space heating load side of the buffer tank is a single Grundfos Alpha circulator distributing water to six zones, which are controlled by a bank of Taco zone panels and Zone Sentry valves.

The entire floorplan is heated with half-inch Uponor PEX, held in place by Legend Valve’s VersaTherm floating floor panel system.

The new mechanical room, wrapped in grey diamond plate aluminum and tongue-and-groove pine, occupies what had previously been a large closet. The 200-square foot room that used to contain the messy old mechanical system is now storage space.

“One of our big draws for making this a dual fuel system with a propane back-up boiler was that the gas boiler can be run off a battery back-up or small, cheap generator in the event of a prolonged power outage,” explained Carroll. “This makes the system more resilient than an all-electric system, which is important up in the mountains where the weather is unpredictable, and the power grid is less robust.

(left to right) – Chris Altenderfer, Tommy Carroll and Joe Ryan.

Evolution

Chris Altenderfer, manager of electric heating development at Burnham Holdings Engineering Company, joined Hansen, Ryan, Carroll and Akins onsite for system start-up. Watching through a Flir infrared device, they waited only a minute to see the heat pumps’ discharge fans turn purple, and the inch-and-a-quarter supply water lines turn red.

“I saw immediately that my concern about noise was unfounded,” said Akins.

“Even running at full speed, the Ambient units are quieter than any mini-split I’ve seen,” he added. “But this was completely new to me. This is the future of hydronics, and most of the homes we build have radiant systems. Peak to Peak Plumbing & Heating is on the cutting edge of the heating industry. Boulder is slowly forcing residents away from fossil-fuel appliances, so I’m excited that Joe is on the front end of the electric hydronic evolution.”

The homeowner is excited, too.

“As we undertook a big renovation, we knew that we wanted to plan for the future,” said the homeowner. “We went with this system for a combination of energy efficiency and the comfort of radiant heat. It helped that we have a great team, led by Joe Ryan and Tom Akins, who are both excited about the system. We couldn’t be happier.”

By Aaron Stotko When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high. That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion Read more

By Aaron Stotko

When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high.

That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion connections to be the ideal system, due to its durability and ease of installation in addition to the job-site productivity, safety and, best of all, profitability potential it provided.

And City Wide Mechanical isn’t alone in their findings. Many mechanical contractors are discovering the benefits of PEX-a pipe and F1960 connections as the preferred alternative to copper, iron, and steel, which have dominated the mechanical piping industry for decades.

Benefits of PEX-a

PEX is an acronym for crosslinked polyethylene. It has been used in North America since the mid-1980s, starting with radiant floor heating systems, then moving into plumbing and, eventually, to hydronic hot-water heating and chilled-water applications.

PEX can be manufactured via three different processes, which create products with varying crosslinking percentages that allow for different characteristics. PEX-a is the most durable, flexible, and resilient with crosslinking around 85%. PEX-b is a stiffer piping product with crosslinking around 65% to 70%, and PEX-c features crosslinking around 70% to 75%.

ASHRAE Headquarters Grand Opening Fall 2021, photos by Devin Abellon

One major benefit of the higher crosslinking in PEX-a is its extreme flexibility along with its thermal and shape memory. The flexibility of PEX-a eliminates most connections in smaller-diameter piping, saving time and money with up to half the connections required in rigid metal piping systems. To make a change in direction, the installer simply bends the pipe instead of having to stop and make a fitting. There are also bend supports available that help hold a bend securely in place.

The thermal memory of PEX-a provides kink repairability with a simple shot of heat from a heat gun. This eliminates the need to add in a coupling if a kink ever occurs in the pipe. (It is important to note that kink repairability is not possible with PEX-b or PEX-c pipe.)

The shape memory of PEX-a allows the pipe to expand and contract back down to its original shape. This makes it extremely resilient in freezing conditions and also provides for the fastest, easiest, most reliable PEX-a fitting system — F1960 expansions.

Expansion fittings require one simple tool to expand the pipe and an expansion ring before inserting a fitting. As the pipe and expansion ring naturally shrink back to their original shape, it creates a strong, durable connection that holds tight and can never be dry-fit. (Note: It is not recommended to expand PEX-b or PEX-c pipe due to microcracking that can occur.)

The innovative expansion fitting method eliminates torches, glues, and solder from a job site for greater worker safety. Plus, the system is extremely easy for installers to learn, helping get new crews up to speed quickly.

Speaking of job-site safety, PEX is also much lighter in weight compared with metal systems. For example, a 300-foot coil of 1/2-inch PEX weighs about 18 pounds, whereas the same amount of copper pipe weighs around 85 pounds. The lighter weight of PEX makes it safer and easier for installers to move around a job site and also eliminates the need for heavy-lifting equipment.

PEX-a also has a long-term advantage over copper when it comes to performance longevity. It is a static system, meaning its internal surfaces — which are three times smoother than copper — will not pit, scale, or corrode. That means its performance will remain the same from day one through decades of use.

Finally, because it is not a traded commodity, PEX-a holds a relatively stable material cost. This makes bidding a project much more consistent and reliable.

Application Details and Installation Tips

PEX-a is regulated by the ASTM F876 standard, which denotes temperature and pressure ratings of 200°F at 80 psi (pounds per square inch), 180°F at 100 psi, and 73.4°F at 160 psi. These values are well within the range of operation for most hydronic systems, including chilled beams, fan coil units, baseboards, radiators, hydronic VAV (variable-air volume) reheat coils, and radiant manifolds.

Because PEX is oxygen-permeable, it is important to use a pipe with an oxygen barrier that limits oxygen diffusion to levels below DIN 4726. This will protect the metallic components in the mechanical piping system, such as valves, strainers, and pump volutes, from corrosion.

The pipe is manufactured in sizes from 5/16 inch up to 4 inches and features a copper tube size (CTS) outside diameter. This means all the off-the-shelf components used in a copper hydronic piping system — hangers, supports, and insulation — can be the same.

For horizontal piping, the industry offers PEX-a Pipe Support — a galvanized-steel channel that is 9 feet in length and available in PEX pipe sizes from ½ inch to 3½ inches. This solution enables hanger spacing similar to copper pipe and helps control the natural expansion and contraction of the pipe as it heats and cools.

Because PEX-a expands at 1.1 inches per 100 feet per 10°F Delta T (which is 10 times that of copper), installing anchors every 65 feet and using PEX-a Pipe Supports allows PEX-a to function much like a copper system. In fact, different installation methods have a different effect on the overall net expansion rate.

With a strut-and-clamp system, using PEX-a Pipe Supports and anchoring with fixed points reduces the expansion rate of PEX-a to 0.08 inches per 100 feet per 10°F Delta T (a rate less than copper). And a loop-and-clevis system can reduce the rate to 0.12 inches per 100 feet per 10°F Delta T.

If you’d like to learn more about PEX-a piping systems, visit the Plastics Pipe Institute at plasticpipe.org or the Plastic Pipe and Fittings Association at ppfahome.org.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.