Who wouldn’t want to save nearly 500 man-hours on a project? That’s what CSM Mechanical did on a job for the City of Dearborn in Michigan – thanks to Viega’s MegaPressG fittings. By reworking plans to make the natural gas piping distribution system 4” or smaller on the police and courts buildings, and by choosing Read more

Viega

Who wouldn’t want to save nearly 500 man-hours on a project?

That’s what CSM Mechanical did on a job for the City of Dearborn in Michigan – thanks to Viega’s MegaPressG fittings. By reworking plans to make the natural gas piping distribution system 4” or smaller on the police and courts buildings, and by choosing to press instead of weld, the CSM Mechanical crew calculated a savings of 491 man-hours.

“The job just went in absolutely phenomenally,” said Craig Mortz, owner of CSM Mechanical. “We saved so much. We took an estimated 30-day project and finished it in 12 days!”

CSM Mechanical has been working for the past four years on an upgrade and update of the mechanical systems campus-wide for the City of Dearborn’s five municipal buildings. Originally constructed in the 1950s, the buildings all had one central powerhouse with heated and chilled water. The renovation plans included disconnecting the heating plant from the central source, upgrading the central chiller plant and giving each building its own individual boiler plant for improved efficiency and energy savings.

None of the buildings were plumbed for gas, and original plans for the police department building included a 6” gas main that was to be welded. Mortz and his team took a look at the project and knew they could improve on the design.

“In working with the owners and with Viega, we got concessions from the natural gas provider to increase the supply pressure so that we were able to get the system down to a 4” line,” he said. “We told the customer we could then also press it instead of welding, which would be faster, safer and save money.”

CSM Mechanical put in almost 1,000 feet of 4” gas pipe, using MegaPressG fittings. CSM Mechanical’s team was the first in Michigan to have the jaws and tool for the larger-diameter MegaPressG fittings, and they were excited to put them to work.

A four-man crew (instead of the six that would have been needed for welding), led by Field Operations Manager Tyler Pryzwara, completed the job. The workers put eight air handlers and four gas-fired boilers in the police and courts buildings, connecting everything with MegaPressG.

Specifications and assistance from Viega were vital in getting MegaPress – and the smaller-diameter pipe – approved for the project, Mortz said.

We showed the owners all the pressure test ratings and standards that MegaPressG is capable of,” Mortz explained. “When we increased the supply pressure and decreased the plumbing size to 4, we were well within any operational and conditional limits for this installation.

“Just the logistics of welding 6” carbon steel pipe and manually distributing it across the various building roofs is where our biggest time savings came from,” Mortz said. “As opposed to 4” pipe that is lighter and can be cut and prefabricated – that saved a lot of time.”

The safety aspect on this project was also a huge benefit. Because the police building is occupied and active 24 hours a day, welding posed significant safety and fire hazards since there were no “off hours” to do the work in. Plus, the buildings have a tar/pitch roofing system.

“We didn’t have to weld on the roof, so we didn’t have sparks and flames and fire blankets and all of the associated PPE,” Mortz said. “Safety was a huge win for us on that building and on the project overall.”

Once installed, CSM Mechanical pneumatically pressure tested the system, which included 1,811 mechanical joints, to 150 psi with no issues or leaks. As winter temperatures set in, the buildings were heated via the new boilers and natural gas line without a problem, providing the City of Dearborn with substantial energy savings and improved efficiencies.

Pressgun 6 and Pressgun 6 Picco offer an affordable entry to pressing technology Broomfield, Colo. — Viega LLC, the company which introduced pressing to North America, now has its own branded pressing tools for use with its fittings. The Viega Pressgun 6 and Pressgun 6 Picco are now available in distributors and through Viega. The Read more

Pressgun 6 and Pressgun 6 Picco offer an affordable entry to pressing technology

Broomfield, Colo. — Viega LLC, the company which introduced pressing to North America, now has its own branded pressing tools for use with its fittings.

The Viega Pressgun 6 and Pressgun 6 Picco are now available in distributors and through Viega. The tools, which are the first in North America to carry the Viega name, cost less than similar press tools from other manufacturers and are an affordable way for contractors to adopt pressing.

“We know the cost of tools has been a barrier for some contractors who want to adopt pressing,” said Dominic Küng, Senior Manager, Product Portfolio. “The lower price of the Pressgun 6 and Pressgun 6 Picco will make it easier for those customers to buy a tool and begin realizing the enormous benefits of pressing.”

Tools aren’t a new offering for Viega. It has sold branded tools in Europe for years in collaboration with RIDGID, whichmanufactures the Pressgun 6 and Pressgun 6 Picco for Viega.

The Pressgun 6 is a no-frills, cost-efficient workhorse that can press up to 4″ ProPress copper and stainless and 2″ MegaPress with the V2 actuator and rings, as well as 2″ PureFlow PEX. Its features include:

- Eight-second press cycle

- LED display indicating number of presses left on a charge

- Steel cylinder head and jaw intake

- 270° rotating cylinder head

- Forward and backward compatibility with RIDGID batteries

The less expensive and less powerful Pressgun 6 Picco can press up to 11⁄4″ ProPress with the C1 actuator and rings, 11⁄2″ PureFlow and 3⁄4″ MegaPress.

Neither tool can be used with the MegaPress XL PressBooster or MegaPress Z3 Actuator.

Both tools come with an 18-volt lithium-ion battery and charger. The 2.5/5.0 Ah battery offers 25% more presses per charge than the previous battery. It includes a battery life indicator. The charger comes with a standard 100-240V charging cord and a 12V DC charging cord so it can be charged off a vehicle lighter. The battery also features forward and backward compatibility with RIDGID batteries, chargers and tools.

“We’re excited to make it possible for additional contractors to become more efficient and productive through pressing,”Küng said. “They’ll find that the Pressgun 6 and Pressgun 6 Picco will revolutionize their businesses and quickly pay for themselves.”

To learn more about the tool, visit here.

When premium wholesale plumbing supplier, Winston Water Cooler, decided to build a large training and distribution center in Phoenix, not only did they choose to stock Viega products, but they chose to show them off in their own plumbing and piping as well. The 35,000-square-foot building was recently completed for use with customer training. “The Read more

When premium wholesale plumbing supplier, Winston Water Cooler, decided to build a large training and distribution center in Phoenix, not only did they choose to stock Viega products, but they chose to show them off in their own plumbing and piping as well.

The 35,000-square-foot building was recently completed for use with customer training. “The Workbench” gives tradespeople the opportunity to do hands-on product demos and learn about the situations they might find on the job, as well as learn about products they can use.

“This is all live fire,” explained Phillip Clark, Partner of Winston Water Cooler in Phoenix. “There is water pumping through the heaters, gas running to the heaters, that sort of thing. We can simulate certain problems by putting different parts in and having people troubleshoot to find the issues. It’s all hands-on, which makes it valuable in our industry for these guys. We want them to be comfortable with the products, and it gives them a comfort level so they can come up here and screw up something instead of potentially screwing up their customer’s stuff!”

Clark said the training center includes products seen in multifamily buildings, plus parts of a mechanical room setup, including boilers, booster pumps and mixing valves. The building contains equipment supplied by a variety of manufacturers. Originally a data center, Winston remodeled the space into a training center.

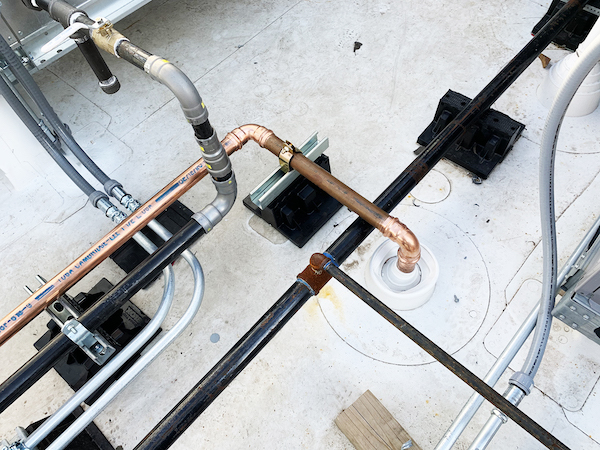

All the water in the building is piped with ProPress, and gas lines are run with MegaPressG. About 200 feet of 2½” and 3” copper lines connect to storage tanks, where water can be circulated through heating and pressure-boosting segments. The gas lines have 1½” MegaPressG fittings.

“We wanted to become a stocking distributor for Viega for years, and in 2019 we jumped at the opportunity when it came,” Clark said. “We phased out Apollo as we brought in Viega. We realize the value in the product and know it’s good – and that a lot of customers only trust Viega.

“The product line with Viega is more diverse with the larger-diameter fittings, and Viega has some fittings in configurations and tighter tolerances. It’s just a good market presence that speaks for itself. We’ve had issues with other [brands], where we’re responsible for going back and taking care of the customer after hours. But Viega’s track record for quality and consistency is far superior to the competitors’ and it makes our customers happy.”

Clark said it’s a great advantage to hold training classes and show products at work that they also have in stock on their shelves. Attendees can see how Viega fittings work and that they’re a clean installation. All the piping in the facility is exposed on the walls and anchored so it can be used for show-and-tell.

Viega LLC’s ProPress Automatic Recirculation Balancing Valve ensures a balanced domestic water recirculation system by dynamically changing with varying conditions. The valve can help prevent the growth of legionella bacteria by keeping hot water out of the growth zone temperature of 95°F to 115°F (35°C to 46°C), while still preventing scalding and conserving energy. The Read more

Viega LLC’s ProPress Automatic Recirculation Balancing Valve ensures a balanced domestic water recirculation system by dynamically changing with varying conditions.

The valve can help prevent the growth of legionella bacteria by keeping hot water out of the growth zone temperature of 95°F to 115°F (35°C to 46°C), while still preventing scalding and conserving energy.

The Automatic Recirculation Balancing Valve is a modification of a Viega product that has been used successfully in Europe for years. It helps keep water temperatures more uniform by adjusting flow with changes in temperature. The results are faster hot water delivery, minimized waste energy and water and less stagnation and chance of contamination. Among the valve’s features:

The Automatic Recirculation Balancing Valve is a modification of a Viega product that has been used successfully in Europe for years. It helps keep water temperatures more uniform by adjusting flow with changes in temperature. The results are faster hot water delivery, minimized waste energy and water and less stagnation and chance of contamination. Among the valve’s features:

- Unlike with manual valves, temperature can be set once and be maintained automatically. Settings can be changed easily, if needed.

- Can be installed on risers or branches

- Remote monitoring with temperature sensor

- Optional thermometer provides visual indication of valve setting

- Threaded ends allow it to be used with Viega ProPress or Viega PureFlow fittings systems for easy integration with copper or PEX

- Includes bypass for thermal disinfection

Additional accessories that can be used with the valve include a thermometer, drain valve and optional insulation sleeve.

“Viega is committed to providing hot water quickly and efficiently while improving water quality and the new Automatic Recirculation Balancing Valve is a significant step toward that goal,” said Paige Riddle, Senior Manager, Market Manager. “This valve offers more features than any other on the market while requiring minimum work on the part of designers, engineers, installers and building maintenance personnel.”

For more information on the ProPress Automatic Recirculation Balancing Valve, click here.

When you take an old space and make it new, there are inherent challenges to it. And that’s exactly what happened with a restoration project in downtown Buda, Texas. Tight spaces to work in meant Viega products were a perfect partner. In the downtown space, old and unused factories have slowly been getting facelifts. Developers Read more

When you take an old space and make it new, there are inherent challenges to it. And that’s exactly what happened with a restoration project in downtown Buda, Texas. Tight spaces to work in meant Viega products were a perfect partner.

In the downtown space, old and unused factories have slowly been getting facelifts. Developers are turning them into retail and restaurant spaces. It’s what Hill Country Plumbing was brought in to do with the old Buda Mill and Grain Company, changing it into Los Olivos Market, a wine shop and bistro.

“The big challenge was that there was another restaurant backing up to it, a common space with a delineating wall,” explained Colie Curry, owner of Hill Country Plumbing. “And there were two different architecture firms that got their measurements inconsistent, so we had to sacrifice space. The roof space we had for grease vents and mechanicals was very tight.”

“The big challenge was that there was another restaurant backing up to it, a common space with a delineating wall,” explained Colie Curry, owner of Hill Country Plumbing. “And there were two different architecture firms that got their measurements inconsistent, so we had to sacrifice space. The roof space we had for grease vents and mechanicals was very tight.”

Existing utilities had been run through the ceilings and were undersized for the new needs, so everything had to be retrofit. The 2½” gas line ended up going up the exterior of the building, down a soffit and then jumping up onto a flat roof to bypass a walkway access—in other words, it would have been nearly impossible to thread pipe together where it needed to be hung.

“I’ve been a fan of Viega for years and we use PureFlow on a daily basis—plus I’ve used smaller MegaPressG fittings,” Curry said. “I heard that the larger diameter was coming out in January, and we did this project in March, so the timing was perfect!”

With the help of Viega reps, Curry acquired a MegaPress PressBooster and rings so he could get the project done on time. There were about 20 fittings in the 2½” size, and then the pipe necked down to 2” for the equipment manifold and again to ¾”.

“We could have tried to thread, but hanging a 50-foot-long piece of threaded pipe that is 2½” and weighs 300 pounds would have taken six guys – that’s not good. Plus, we would have had to work our way from it after hanging it,” Curry said. “With Viega, we were able to work in multiple directions. We did a lot of the interior piping before the roof penetration, and we could cut in wherever we needed.

“In about four and a half hours we did what would have probably taken two days—it was a ton of labor savings! And if there had been a leak we would have had to start over after cutting that part out. Using the Viega fittings worked out really, really well.”

“In about four and a half hours we did what would have probably taken two days—it was a ton of labor savings! And if there had been a leak we would have had to start over after cutting that part out. Using the Viega fittings worked out really, really well.”

Curry and his crew also used PureFlow PEX, in sizes 1¼” and smaller, for waterlines to the bathrooms and commercial kitchen.