The great experiment with with my radiant driveway is continuing. First some background: At Reisssmann Plumbing, we have done many driveways and walkways over the years, all the way up to a 5-zone, 6,000-sq.-ft. driveway whose owner calls every year after a snowfall to tell me how appreciative he/she is for having it installed.

The problems I had with my 8,500-sq.-ft. parking lot and driveway are numerous. Plowing is a pain, as I have to move all of the trucks so I have somewhere to push the snow. If we get rain, it freezes at night when the temps drop. When the sun comes up—being so low at that time of the year—the trees shade parts of the driveway, leaving it slippery—salt is the only option.

The short part of the driveway that slopes down to the entrance to the office is particularly dangerous when everyone comes to work so, again, it’s the salt option that has to start at about 5 a.m. to do any good.

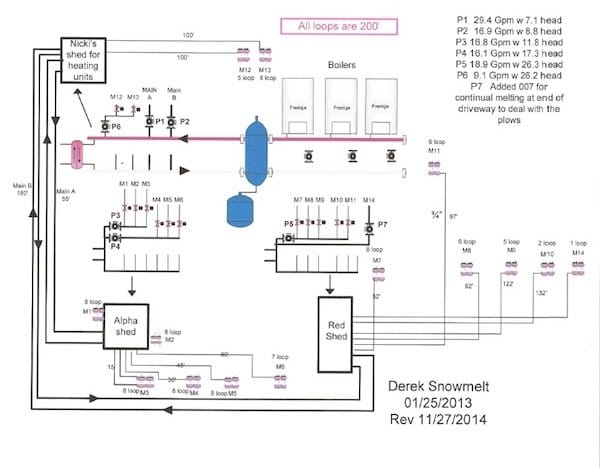

We decided to solve the problem with 14 zones. We had 13 initially but added a single loop at the end of the driveway—at the end of the road—to deal with snowplows. This gave us the opportunity to apply heat where it is needed without turning entire driveway on. The average cost—with the snowfall we had last year—was about $100 per snow. This is without controls, as I am still working on them, so I expect this number to come down.

Last year we had two snowfalls per week so I was able to do a lot of testing. For example, I tried waiting until there was 1″ of snow before turning on the system. It took one hour from a cold start to see where the tubing was and three hours to all black, which is totally acceptable.

One of the problems with heavy tubing—5/8″ and up—is that is does not bend well or fasten down easily. we used 1/2″ tubing—yes you read it correctly: 1/2″—with loops no longer than 200 feet. The system operates from three sheds outside. The main one has three Triangle Tube Prestige 399 boilers integrated in the cascade format. All air elimination an expansion happens there. The 2″ PEX lines go to each of the other sheds with a feed and return loop using primary/secondary supplying heat to each of the secondary – primary/secondary loops, one in each of the other sheds. They then send heat to each of the manifolds, which are located in sprinkler boxes along the side of the parking lot and driveway. There are no pumps outside; all are located in the sheds. All of the pumps and zone valves are Taco and all of the tubing is Uponor.

Reliability is key with snowmelt. It’s not a quick service call to fix a heat zone. When someone has paid a lot of money to put a snowmelt system in, there is no option for failure. I have use Taco and Uponor for many years without a problem. (Jeff Weidemann, the multi-talented genius from Uponor and John Barba from Taco were both a great help to me.

This was my first venture into Triangle Tube (TT) boilers. I reached out to friends in the business and got a “thumbs-up” on TT, especially from Bob Bona, who had put in a lot of them.

I was looking for something that would have no problem with a 50/50 propylene glycol mix, and be extremely reliable. Roger, my chief tech and right arm, and I visited the TT factory in South Jersey. I was impressed with what I saw. No corners were cut on using the best materials available. I bought the system with their solid manifold set up for the boilers, and I could not be more pleased. It assembled well and it is very sturdy. Once it was attached to the system, I got a crash course at setting it up, as we were due for snow that same night. I reached one of TT’s tech support people after 5 p.m. and he walked me through getting them going. After the initial information was entered, they literally set themselves up. Very nice.

Last summer, I added a pool kit from Energy Kinetics, who by the way, make a great boiler, too. This heat exchanger and controls allow me to take the heat from my driveway in the summer and use it to heat my pool. The driveway takes precedence for the heating, and if more heating is needed, the pool heater kicks in. I have an override if I have to heat the pool quickly for a party, and found that I could even kick in the TT boilers as an assist, reaching an amazing heat-up speed for the pool of multiple degrees per hour, and bringing the pool heat by 10 degrees in a very short time. Not bad for 50,000 gallons.

The controls are what I am working on now. The pool uses a Hayward Aquaconnect computer to give me iPhone access for control. I use salt water and it keeps the pool perfect at all times without chemicals. It paid for itself in a few years. I like the Web access and plan controls that I can control myself from anywhere.

As you know, it is difficult to do ANYTHING for yourself when you have a business; your clients take precedence. I only get to do this to try it out before I sell it.

We already put Internet access in all three sheds while we were laying the driveway. I am currently looking at ControlWeb.com, which has a nice array of controls. I will pass on my findings and get back to you with another report once I have it complete.

Join the conversation: