For a boiler to operate properly, the liquid it contains must maintain the correct pH levels. If the pH level is not regularly tested and properly maintained, minerals can build up on the inside of the components. Or the water can turn acidic and attack the boiler’s metallic components and piping from the inside out, causing rust to form.

Scale or rust buildup reduces system performance over time. Enough buildup can essentially stop the operation of the system altogether.

Understanding pH levels in hydronic heating systems

Historically denoting “potential of hydrogen,” pH is the measure of how acidic or basic the water inside a hydronic heating system is. According to usgs.gov, the universal reading for pH goes from 0-14, with 7 being neutral. Less than 7 indicates acidity; greater than 7 indicates a base.

- Examples of items that have a pH of less than 7 are black coffee (pH=5), grapefruit juice, soda, or tomato juice (2.5-3.5), and lemon juice or vinegar (2).

- Examples of items that have a pH of greater than 7 would be seawater (8), baking soda (9.5), ammonia solution (10.5-11.5), and liquid drain cleaner (14).

pH is an important indicator of water that is changing chemically. Boiler systems need to have the perfect pH level balance. If the pH goes too high or too low, it can drastically impact a system.

The correct pH level will depend on the metallic composition of the heat exchanger. Some recommended pH levels range from 8 to 8.5. We recommend checking the boiler installation and operation manual to determine the acceptable pH range. Systems with a cast iron, stainless steel or copper exchanger are resilient and usually have a wide range of acceptable levels. Aluminum is more prone to corrosion and may require a specific pH.

Performing pH testing

Do a visual reading by opening the drain valve and bleeding off some liquid. If it appears clear, proceed with a pH test. As mentioned above, the correct pH level depends on the composition of the heat exchanger.

-

How to test pH levels

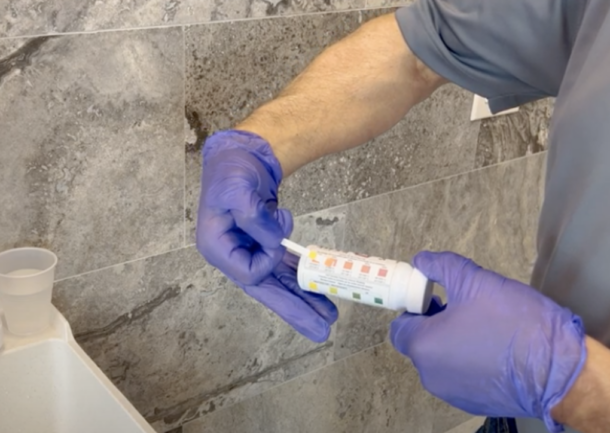

You can buy test strips that provide a color-coded readout. If you need a more precise reading for an aluminum system, use a digital pH meter.

Hercules Cryo-Tek Test Strips, available in packs of 6 to 10 color-coded and disposable test strips, can simultaneously check both the level of freeze protection (propylene glycol) and the level of corrosion protection in a system.

To conduct the test, drain some water from the boiler and then dip one of the pH test strips into the sample. Once a bit of color starts to pop up, compare the strip to the color chart to determine the pH level.

-

How often should you test pH levels?

These are closed systems, so there are usually no external signs of corrosion, making it difficult to spot an equipment leak — unless, of course, water is visibly running onto the floor. (If so, corrosive water inside the boiler is a likely cause.)

This general lack of immediate visibility is why it’s important to test hydronic systems annually. If your locale has hard water or there are conditions causing the water to be more acidic, testing should be done twice a year.

The lack of visibility is also why sampling the water for a test, as described above, is a must: It is the best way to tell if anything is wrong. If rust or sludge appears in your sample, you should test and replace the water.

-

What happens if a boiler’s pH is too high or too low?

If you find the pH levels too high, you’ll start to notice scale or limescale buildup in the boilers. Too much mineral buildup will restrict the system’s water flow. Essentially, the effectiveness of the boiler is lessened.

If the pH levels are too low, the water has turned acidic. This leads to rust and corrosion — a serious problem since boilers are typically made of copper, cast iron, and aluminum. As mentioned earlier, enough corrosion can stop system operation altogether.

-

How to balance out the pH

Maintenance managers or contractors can use a corrosion inhibitor to balance out the pH — a seamless fix. However, if the buildup or corrosion has been going on for several years, the system will probably not recover with this treatment. Instead, you’ll have to use a cleaner to flush the system to maximize boiler efficiency.

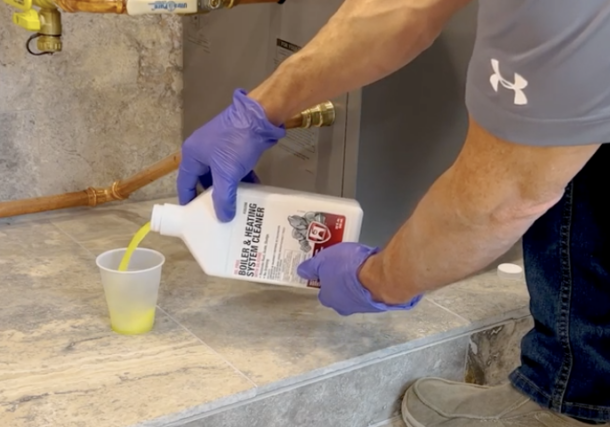

The Hercules® Boiler and Heating System Cleaner is formulated to clean and condition both steam and hot-water hydronic systems by removing rust, scale, and sludge. The cleaner can also free and lubricate zone valves and help stop priming and foaming with a special anti-foam agent. Ultimately, it is a liquid cleaner and corrosion-prevention treatment.

The Hercules® Sludgehammer System Restorer & Noise Reducer is another option for maintaining a boiler system. More aggressive than the system cleaner, it also cleans and reduces kettling (bubbling and banging), while restoring system efficiency. Maintenance managers or contractors can pair this product with a corrosion inhibitor for annual heating system-maintenance checks.

If the pH level is off:

- Drain about a gallon of liquid from the boiler and dispose of it.

- Fill a container with a quart of corrosion inhibitor, such as Hercules® Sludgehammer™ Universal Corrosion Inhibitor, and 3 quarts of fresh water. Pump it back into the system and allow it to circulate for about a half-an-hour.

- Test again. Usually, a single dose of inhibitor does the job, but if the reading is still too low, repeat the process

Watch the video below to learn how to remove sludge and corrosion in hydronic heating systems with Sludgehammer.

In conclusion, you must test the pH of boiler systems to maximize their efficiency, using products that can make monitoring pH levels simple and easy. If this testing uncovers damage to the system, there are also ways to alleviate and fix that damage.

But regardless of your boiler’s condition, Oatey products can offer a solution. For more information, go to Oatey.com for their heating chemicals and antifreeze products/resources.

Author’s biography: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Author’s biography: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Join the conversation: