Professional cannabis growers are well aware that environmental conditions play a critical role in plant quality and overall yield. Most can recite the ideal temperature and humidity for their crops without missing a beat. But ask most growers which type of pipe is best and they’ll likely to refer you to the closest head shop. The fact is professional growers (of cannabis or otherwise) are generally unaware of the piping options they have or the extent to which these options impact structural costs, energy efficiency and overall sustainability. When these matters are given proper consideration, polypropylene emerges as a great choice for this burgeoning industry.

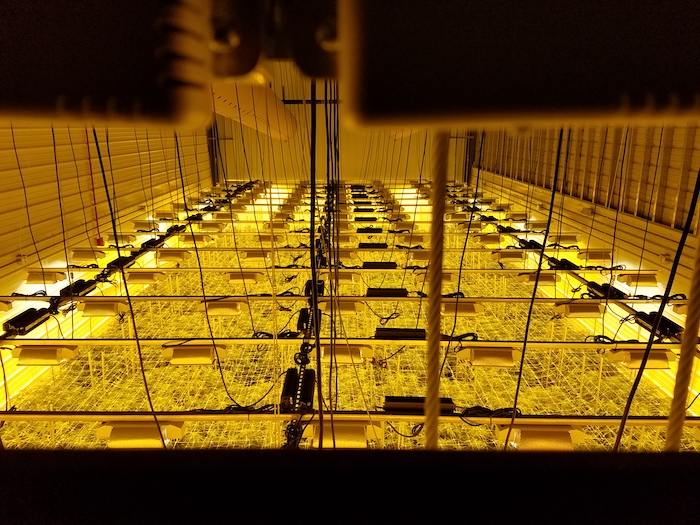

Cannabis growing facilities use a lot of energy and generate a lot of heat, making a reli- able cooling system essential.

Polypropylene pipe has been widely used for plumbing and hydronic heating in Europe since the 1970s. However, it was not introduced to North America until 2005. Since then, it has become increasingly popular for a wide range of applications, from radiant heating of sports fields to process applications in craft breweries. It is a lightweight yet highly durable thermoplastic pipe with pressure and temperature tolerances that make it suitable for hydronic heating and cooling, potable water, and industrial and food-grade applications.

Depending on size and wall thickness, polypropylene pipe can weigh up to 70% less than carbon steel pipe.

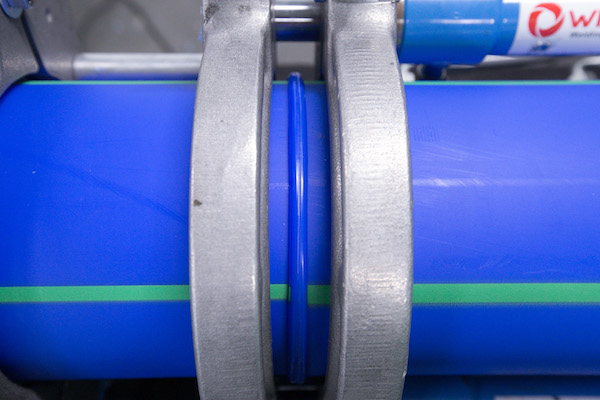

Unlike metal pipe, the installation of polypropylene pipe does not involve traditional torch welding. Instead it relies on a flameless heat-fusion method that’s easy to learn and highly reliable at creating virtually leak-free connections. When contractors become adept at heat fusion, they can typically install polypropylene piping much faster than welding copper, carbon steel and stainless-steel pipe.

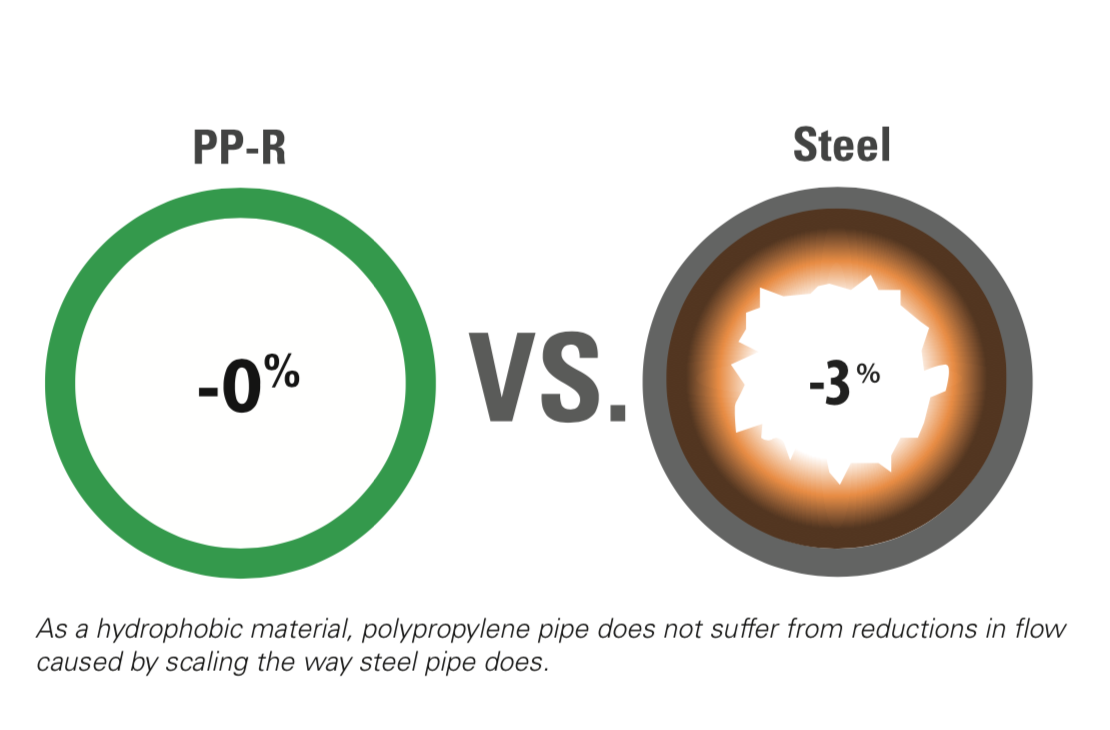

An appealing characteristic of polypropylene is its chemical purity and inertness. It does not rust, scale or leach any impurities into to the fluids it transports, nor does it react with most chemicals. This not only improves its longevity over other piping materials, it also makes it suitable for a wide range of applications. Furthermore, unlike PVC or CPVC piping, polypropylene pipe does not become brittle or susceptible to cracking when exposed to cold temperatures. A full list of the physical/performance characteristics of polypropylene and associated benefits is shown in Table 1.

Where does polypropylene fit into the day-to-day operation of a grow facility? The answer is pretty much any application that requires the transport of fluids. But to truly understand the potential roles that polypropylene can play in the growing cannabis industry, one must first look at the special needs, challenges and values of the industry.

An Energy Intensive Industry

The electrical demand of cannabis grow facilities is staggering. According to the 2018 Cannabis Energy Report, legal cannabis cultivation in the U.S. consumes an estimated 1.1 terawatt-hours of electricity a year, enough to power all of Newark, New Jersey or Anaheim, California.[1] In indoor grow facilities — very often repurposed warehouses or other types of vacant buildings —this massive energy consumption is caused by the artificial light required to grow cannabis. Heat from these lights imposes another energy burden: cooling. Year-round cooling loads are unavoidable in indoor facilities since carefully controlled space temperatures are essential for growers to achieve maximum yields. Greenhouse facilities may avoid most of the need for artificial light, but still need heating, cooling and dehumidification. In either case, large facilities benefit from the long-term efficiency of centralized hydronic heating and/or cooling systems, which are typically about 15 percent to 20 percent more efficient than other HVAC options.[2] These systems utilize piping to transport the heating water to and from a central boiler system and to transport cooling water to and from a chiller and/or evaporative cooling equipment.

Polypropylene piping is ideal for these applications for reasons that directly impact the efficiency and longevity of a grow facility. First, the inner walls of polypropylene pipe are uniquely smooth, resulting in reduced friction losses, reducing pump energy consumption. The friction losses of polypropylene start out low and remain low for the life of the system because the pipe is not susceptible to rust or scale. Steel, copper and other metals do rust and corrode over time, increasing friction losses and the pump energy required to overcome those losses.

Socket fusion (shown here) is one method of heat-fusing polypropylene pipe and fittings.

Polypropylene pipe also can be used in conjunction with geothermal heat pump systems which are frequently applied in agriculture. Geothermal systems rely on the earth or a body of water as a heatsink and/or heat source for highly efficient transfer of heat to and from the growing spaces for space conditioning and agricultural processes. In these applications, polypropylene pipe transports the heating and/or cooling fluid from the central energy source to forced-air equipment or a radiant distribution loop. The pipe can be buried in the ground and/or concrete floors without the need for any protective sleeves or wrap.

Another strategy that grow facilities often use to reduce their energy consumption is heat reclaim. In these applications, polypropylene pipe can be used to transfer energy to or from process water, wastewater, or any other source that can be used to pre-heat or pre-cool water for other heating, cooling or process needs. This gives growers the opportunity to fully optimize whatever resources are available to them – whether it be the sun, a nearby lake, or even a nearby wastewater treatment plant. It’s all been done with polypropylene.

Specialized Growing Strategies

Not all commercial cannabis is grown in soil. Some is grown hydroponically with plant roots submerged in a nutrient-rich solution of water and fertilizers while others are grown aeroponically with roots suspended in air, drawing nutrients from a sprayed mist. These grow strategies very often rely on high purity water (typically reverse osmosis or deionized water) when existing water sources are determined unsuitable.

Versatile fusion tools allow polypropylene pipe to be heat- fused in spaces in which welding metal pipe would be difficult or impossible.

High purity water automatically limits piping options. Copper should never be used with deionized water because if the fluid’s pH levels fall below 6.5, corrosion may occur and copper molecules can leach into the supply. Although stainless steel piping is an option for these applications, it is often cost-prohibitive and it, too, will leach over time if the water should become too acidic or too alkaline. Polypropylene is ideal for these applications because it does not leach, and its installation never requires the use of any potential contaminants such as solder, flux or glue. It can even be used for potable water and food processing since it is available in formulations that meet both NSF 51 and NSF 61.

Facilitating Construction and Expansion

Growers and owners are typically under a lot of pressure to quickly get grow facilities operational so they can begin the journey from seed to profit as soon as possible. Construction schedules are always a challenge, particularly when it comes to mechanical components like piping. Installing metal pipe requires licensed welders (expensive and increasingly scarce) as well as special permitting for the use of open flames on a jobsite. In addition, maneuvering heavy sections of metal pipe into existing structures and then supporting it so it can be welded into place is both logistically and physically challenging. Under these circumstances, a seemingly trivial error like a miscalculation in metal pipe length can put a project several days (if not weeks) behind schedule.

Polypropylene pipe is hydrophobic and will never scale and corrode the way metal pipe does.

Opting for polypropylene pipe keeps these jobsite nightmares at bay for the following reasons:

- Polypropylene is lightweight – especially helpful in greenhouses where structural support is limited

- Polypropylene fittings can be prefabricated offsite in controlled areas so that jobsite fabrications are minimized – some manufacturers even offer fabrication services

- Improper lengths can usually be amended at the jobsite with little disruption to work schedules

- The pipe’s maneuverability compared to metal means it can be better negotiated in tight spaces

If an owner has hopes to expand the facility in the future (as many do), polypropylene piping systems are much easier to build out than metal pipe. Strategically located shut-off valves make it easy to isolate flow and cut into existing pipe to create new connections with minimal disruption to current operations. Fusion outlets allow for easy and relatively inexpensive expansions and one manufacturer offers a hot tap solution. Again, no flames or permits are required.

Beer There, Done That

If cannabis entrepreneurs need relevant examples of all that polypropylene can do, they need only look as far as the craft brewing industry. Craft brewers, an intensely collaborative group, have solidly embraced polypropylene for all that it has to offer, most notably its purity, sustainability, and fast and flexible installation – interests that closely parallel those of the cannabis industry.

“The word of mouth in the craft brewing industry is amazing, so we’ve had tremendous growth from breweries using it, not just for the glycol lines but in their heating and cooling applications, their geothermal applications, their domestic water supply, CO2, compressed air applications and beyond,” said Barry Campbell, VP of Marketing at Aquatherm, a leading manufacturer of polypropylene pressure piping systems.

A properly executed heat-fusion on polypropylene pipe creates a single piece with no leak paths.

According to Campbell, the fact that polypropylene is among the most environmentally friendly piping systems available has helped Aquatherm gain favor among craft brewers. One polypropylene pipe manufacturer has also done the certification work to allow the product to contribute to LEED v4 credits in the U.S. Green Building Council’s (USGBC) program.

An interest in sustainability is just one of the many commonalities that exist between the cannabis and brewing industries. Like so many newly incorporated cannabis growers, many craft brewers begin their entrepreneurial journey in the shell of a vacated building where existing infrastructure can challenge piping installations. The building or parking lot next door is “Phase II” of their venture. Finally, owners are often the same people brewing the beer or growing the cannabis, so they tend to be more hands-on in the selection of mechanical equipment. They do their own research and tend to look outside the box for ways to conserve energy.

Robert Millspaugh, operations supervisor at Flathead Lake Brewing Company in Bigfork, Montana, did extensive research on what piping to use for the process side of the brewery before ultimately choosing polypropylene. Flathead Lake, born from the ruins of an old bowling alley, installed several thousand feet of polypropylene to transport both heating water and glycol for heating, cooling, and process applications. Part of the system even uses clean effluent from a nearby water treatment plant to indirectly pre-temper process water for better efficiency.

“We were looking for products that would help us achieve a LEED certification and [polypropylene] had a lot to offer. I also came across an article on Epic [Brewing Company in Salt Lake City] and how they used [polypropylene] in a renovation and discussed the product with the brewer there,” said Millspaugh.

Polypropylene also has been used successfully in brewing applications that require piping for food-grade and potable water.

Avondale Brewing Co., in Birmingham, AL was the first North American brewery to use Aquatherm’s food-grade (NSF-51) polypropylene pipe to transport beer from vessels in the main brewery to its packaging building where it is kegged, canned and bottled. The piping, which also is NSF-listed for potable water, is cleaned and sanitized between uses. Of course, like all of the manufacturer’s polypropylene systems, the piping is guaranteed to be free of heavy metals and toxic chemicals.

Cleanliness is a high priority in breweries and is one of the main reasons Founders Brewing Co. in Grand Rapids, MI, decided to use polypropylene in a heat reclaim process that taps heat from the brewing process to pre-heat outdoor air before it enters the building’s HVAC system. The piping is wash-down rated, so the brewer can keep the brew facility sparkling clean.

Examples like these demonstrate the potential for polypropylene piping in the cannabis industry.

“The craft brewing industry and everything it has been able to do with our pipe has created an unexpected blueprint for cannabis growers and how they can use polypropylene to facilitate construction, save energy and be more sustainable,” said Campbell.

[1] New Frontier Data, 2018 Cannabis Energy Report. Scale Microgrid Solutions and Resource Innovation Institute, co-authors. https://newfrontierdata.com/product/2018-cannabis-energy-report/

[2] Surna, Sustainability for Your Indoor Garden (blog) https://surna.com/sustainability-for-your-indoor-garden/

Join the conversation: