https://vimeo.com/1012594655 In today’s edition, we’ll talk mandates on circulator efficiency as we welcome back Taco’s John Barba. We’ll scratch the surface with heat pump water heaters, and Eric Aune talks about our weekly podcasts, and a cool incentive from Navien Read more

Featured Articles

In today’s edition, we’ll talk mandates on circulator efficiency as we welcome back Taco’s John Barba. We’ll scratch the surface with heat pump water heaters, and Eric Aune talks about our weekly podcasts, and a cool incentive from Navien.

The BitRip® App, Desktop Pro, and scannable BR Code™ labels from Duck Pro® by Shurtape® are delivering tremendous value in safety inspection documentation The MEP contracting industry has adopted digital technology over the last 15 years or so with a pace that sometimes seems as fast as a Lucid Air Sapphire’s zero-to-sixty time. We could Read more

The BitRip® App, Desktop Pro, and scannable BR Code™ labels from Duck Pro® by Shurtape® are delivering tremendous value in safety inspection documentation

The MEP contracting industry has adopted digital technology over the last 15 years or so with a pace that sometimes seems as fast as a Lucid Air Sapphire’s zero-to-sixty time. We could debate the degree to which the industry has adopted digital technology willingly versus opportunistically, but at the end of the day digital technology is saving lives, time, and money.

Technologies including mobile communications, building information modeling, virtual reality, drones, the internet of things, and 3-D printing have drastically changed the construction industry, but the degree to which different general contractors and contractors use these technologies varies widely. Across the construction industry, however, the drive to improve worker safety is constant. According to the U.S. Bureau of Labor Statistics (BLS), nearly one in five deaths among U.S. workers is in the construction industry, and 1,056 construction workers died on the job in 2022.

Each scan of a BR Code™ label reveals the code’s GPS location, unlocking field visibility and helping managers locate assets in the field.

Also, according to the BLS, each year, about 1% of construction workers suffer a fatal injury, which is the highest rate in any industry. So, it’s safe to say that nearly everyone involved in the mechanical, electrical, and plumbing (MEP) industry aspires to improve worker safety, and if properly adopted and used, digital technology can make a dramatic difference.

A Military Origin

While safety wasn’t the initial impetus for the products he imagined and helped to create, Nick Dimitruk wanted to find a better way for people to keep track of materials, equipment, and more. He was stationed in Afghanistan in 2011, serving as a Marine logistics officer, and he needed a simple way of keeping track of aviation materials, equipment, people, and aircraft.

“Clipboards and spreadsheets weren’t cutting it. When I looked at possible asset tracking solutions, they were too expensive, complicated, and bloated. I wanted something simple,” he recalled. He needed a solution that was straightforward, that provided a GPS location, and was updatable.

“I needed something I could train my Marines to do in minutes and not weeks, and nothing was out there,” he said. Ten years later, he and Catherine Chapman co-founded Nastro Technologies, BitRip’s parent company.

Designed for the field and built for managers, the BitRip® App, Desktop Pro and scannable BR Code™ labels from Duck Pro® by Shurtape® seamlessly track any type of physical asset using heavy duty labels, and each code allows users to store massive amounts of data and track every scanned location, unlocking field-level visibility.

Ladders are supposed to be inspected daily, but a 2018 U.S. workplace safety survey found that over $17 billion is spent on falls resulting from working at height. BitRip® and BR Code™ labels can help track ladder inspection compliance.

This three-pronged solution provides a huge array of applications including asset, maintenance, and shipment tracking, but the construction safety arena has evolved into one of the biggest applications for BitRip and BR Code labels. Chapman said the app company and Shurtape Technologies developed a simple solution that allows users to quickly and easily “do the right thing” when it comes to safety inspection management, with specific forms for fire extinguishers, personal protective equipment (PPE), and ladders/lifts.

According to Occupational Health & Safety magazine, there were 5,370 construction industry ladder injuries in 2020. The publication also reported that a 2018 U.S. workplace safety survey found that over $17 billion is spent on falls resulting from working at height. According to the Occupational Health & Safety Administration (OSHA), ladders are supposed to be inspected daily, but it seems unlikely that happens on every jobsite every day.

Helping Them Go Home Everyday

“It doesn’t have to be hard. We’re trying to make it super simple to just do your inspection, look at it, and make sure you’re safe before you or anyone else gets up on the ladder. Ladder-related falls are one of the main culprits preventing workers from going home to their families at the end of the day, and BitRip and Shurtape are excited to provide a solution,” she said. From a dollars-and-cents standpoint, when a company can show documentation that proper ladder inspections were performed prior to a ladder accident, that proof can also provide legal protection and help prevent potentially huge legal liabilities.

Graham Construction, a leading Midwestern general contractor based in Des Moines, IA, has over 100 field employees working on an average of 25 active projects on any given day throughout Iowa and Nebraska. One of the most essential tenets of the company’s success is a total commitment to safety.

Graham’s Superintendent, Joe Thomas, and his team strive to ensure all PPE is regularly maintained and inspected and to know the proper working condition and whereabouts of valuable and essential tools and equipment. They had been tracking safety equipment inspections using forms generated by a popular construction management software program and stored on a shared network drive, and they used a common tool and materials software management solution for tracking tools and equipment.

Affixing BR Code™ scannable labels under the inspection tags of safety harnesses allows the safety devices to be digitally “connected” to a Bit, or unique file in the cloud. The rugged, inexpensive labels provide flexibility in organizing, sharing, and storing data, and are making an enormous difference in safety, equipment, and maintenance inspections, and tracking.

However, those programs didn’t provide the kind of visibility and ease of use that Thomas and his team believed was possible. One of Graham’s yard managers told Thomas about BitRip and BR Code labels and soon he, and Eastern Nebraska Field Resource Leader Joe Lercara, and their teams were off and running with this solution.

“It only took about a minute to train them,” Thomas recalled. “I watched a few videos on it, ordered the BR Code Labels, and my yard assistant and I did a few test Bits. Then we got started,” he said. A Bit is a unique cloud-based file with data attached to one single BR Code label. They piloted the solution in their Omaha, NE, location and then started putting the labels on the company’s fall protection equipment.

Thomas explained that he sees BitRip as especially valuable in monitoring fire extinguisher and ladder inspections since the app features check-listed inspection forms. “The labor foremen usually do the inspections so they will have it on their phones, they’ll be able to scan it in and do a weekly fire extinguisher checklist quickly and simply,” Thomas said, adding that the same applies to ladder inspections.

“So, you can’t just sit in a trailer and ‘pencil whip’ the things. So, we can see that they have gone out and scanned the ladder, scanned the fire extinguisher, and see that they actually looked at it,” he added.

On-the-go Records and Certifications

Donna Thompson has worked as a site-safety manager on projects all over the western U.S. over the last two dozen years. She’s currently the Senior Safety Manager for the Austin, TX, and Houston offices of San Antonio-based Big State Electric, Ltd. One aspect of her job includes managing and maintaining the safety training and certifications for scissor lifts, forklifts, and heavy equipment for more than 250 employees.

Throughout much of her career, keeping certification and inspection records current and present has always presented a major and time-consuming challenge. “At the time of training I had to create a card saying they’ve been trained, and those cards would get lost a lot or damaged and would need to be redone because you’re not allowed to use the equipment without proof of training,” she said. When she first learned about BitRip and BR Code labels, her thoughts immediately jumped to safety and training documents.

Companies like Graham Construction are realizing multiple benefits using BitRip® and BR Code™ labels to quickly and easily track and manage safety inspections with forms for fire extinguishers, personal protective equipment (PPE), and ladders/lifts.

At Big State, the process of creating a training card takes 10-15 minutes per card, multiplied by over 250 employees (between 40-63 hours) . Plus, with all the different types of trainings/certifications (ranging between 8-40 depending on the employee), the time involved in replacing lost/damaged cards and doing updates really adds up. Thompson added that having a user/operator unable to do his job because he doesn’t have proof of certification is a huge waste of time and can negatively impact schedules.

Every quarter, she and her team do inspections on fall protection, ladders, and the company’s bigger tools. Prior to finding BitRip and BR Code labels, the inspections were all recorded on paper. “So, I could see, yes, this inspection on this ladder number was done, but I would have to go through probably 400 pieces of paper to find that inspection on that ladder,” Thompson said. “And if something happened, God forbid, you know, someone got seriously injured, I would have to prove inspections and that was hard to do in a timely manner.”

Now Thompson records all ladder and fire protection equipment inspections on a Bit. She has also benefited immensely from BitRip’s inspection forms, which simplify the process and help with compliance. “And all I have to do is pull up that equipment number and it shows me all the inspections, so it’s very simple to prove that we’ve been doing our inspections the way we should, and it saves a ton of time.”

Thompson said that the field employees have fully embraced BitRip and BR Code labels. “So, they’re happy because it takes a lot less time in the field. And that’s always one of those, you know, you’re taking guys away from their normal job in the field and so it costs money to do all of that. And it’s a lot less time to do it that way instead of having to deal with pieces of paper,” Thompson added.

Staying On It

Graham Construction’s Thomas said BitRip Desktop Pro allows him to easily create projects and view each Bit, as well as calculate billing for the barrier system on each job. Graham uses orange PSL (Permanent Scannable Labels) BR labels and yellow PXL (Permanent Heavy-Duty Scannable Labels) BR labels.

Shurtape also offers other BR Code labels for a variety of applications, including:

- FL 227 BR scannable paper tape codes – for indoor use, can be torn at any length and will conform to a range of surfaces and substrates while offering easy removal.

- PC 627 BR scannable duct tape codes – for durable adhesion to multiple surfaces, and constructed with a waterproof backing, allowing for indoor or outdoor use.

Thomas said that there have been “zero issues” with the BR Code labels and they have stayed affixed on every item they’ve been used on, including under the inspection tags on safety harnesses. By connecting the physical world with rugged, inexpensive labels then providing a huge degree of flexibility in organizing, sharing, and storing digital Bits, BitRip and BR Code labels are making an enormous difference in safety, equipment, and maintenance inspections and tracking.

According to satisfied customers like Big State Electric and Graham Construction, the solution’s ease of use combined with a very affordable price point (the mobile app is free, Desktop Pro is $90/mo., and the labels are roughly $1-$2 apiece), make it a “no brainer.”

Try BitRip for free by downloading it via the App Store or Google Play, access a free 30-day trial of BitRip Desktop Pro here, and purchase BR Code labels by clicking here.

https://vimeo.com/1008155465?share=copy On this week’s update we address the fear of Friday the 13th, chat with AHR Expo director of marketing Nicole Bush about the AHR Expo 2025 in Orlando in February, and highlight Taco After Dark with Joha Barba, Taco Comfort Solutions’ director of training. We finish up with sharing the latest Make Trades Great Read more

On this week’s update we address the fear of Friday the 13th, chat with AHR Expo director of marketing Nicole Bush about the AHR Expo 2025 in Orlando in February, and highlight Taco After Dark with Joha Barba, Taco Comfort Solutions’ director of training. We finish up with sharing the latest Make Trades Great Again and Appetite For Construction podcasts and how to connect with Mechanical Hub Media on ideas and topics that resonate in the industry. Make it a lucky Friday the 13th!

In 1971, Chicago native James Guercio, a musician and producer, purchased a 2,000-acre ranch in Nederland, CO, with plans to turn the property into a recording studio and rural escape for the biggest names in the music business. He modified the property’s old barn into a recording studio. In ‘72, Joe Walsh recorded “Rocky Mountain Read more

In 1971, Chicago native James Guercio, a musician and producer, purchased a 2,000-acre ranch in Nederland, CO, with plans to turn the property into a recording studio and rural escape for the biggest names in the music business.

He modified the property’s old barn into a recording studio. In ‘72, Joe Walsh recorded “Rocky Mountain Way” while the barn still had a dirt floor. This was the first of many hits that would be produced at Caribou Ranch, as Guercio called the estate. Other stars followed, including Elton John, Stevie Wonder, Chicago, John Lennon, Michael Jackson and hundreds more.

The 3,300 square foot home was a guest residence for musicians recording at the Caribou Ranch Studio.

On a parcel adjacent to the ranch sits a 3,300 square foot home built in 1973, where many of the travelling artists took up residence while writing and recording music. Fast forward to 2022: the home – and the piece of music history it represents – was sold.

The new owner found one of the old boilers leaking and called Peak to Peak Plumbing & Heating.

“We’re one of only a few shops that regularly travel up the Peak to Peak Highway to serve rural customers,” said Joe Ryan, 33 years old and owner of the company.

Ryan found that neither the old cast iron boiler nor the electric boiler was leaking. Instead, the water came from a foundation leak. To address that issue, Ryan called a general contractor he works with on a regular basis, Tom Akins, who owns AP Construction.

After some deliberation, the owner decided to renovate the entire home.

Joe Ryan, owner of Peak to Peak Plumbing.

Ground-source or air-source

Plans were drawn to update the house as well as the dual-fuel hydronic system installed years earlier. The owner’s two requirements were that heat pumps be used and radiant heating be installed throughout.

“Our first conversation about the heating retrofit took place two years ago,” said Ryan. “Both the homeowner and I were torn between installing geothermal units or an air-to-water heat pump system. Whenever I have questions like that, I reach out to Tommy Carroll at Boulder Winnelson.”

“Tommy’s about my age, casual and humble, which can be misleading, because he’s an hydronic mastermind,” he continued. “He’s an engineer by training and he designs hydronic systems in his sleep.”

Nearby Boulder is one of the greenest towns in the country, so it’s no surprise that local supply houses might have someone on staff to design high-efficiency, high-comfort hydronic systems.

“We compared air-to-water heat pumps with a geothermal system,” said Carroll. “In the end, it wasn’t a hard decision.”

Using an outdoor design temperature of -2°F, the home required 81,000 BTU/H. Given the ground temperature at 8,700 feet above sea level, a geothermal system would have required five, 500-foot boreholes. That expense alone made air-to-water heat pumps more attractive.

(left to right) Tommy Carroll and Joe Ryan connect thermostat wires.

BTU Wrangler

“Air-to-water systems have come far enough along that they’re somewhat comparable in capacity and COP to geothermal heat pumps,” said Carroll. “In the long run, air-to-water just made more sense. Air-to-water adds some cost to the plumbing side of the project, but the overall cost is significantly less.”

Customers go to Boulder Winnelson with tricky hydronic projects. Carroll’s business card reads “BTU Wrangler” for good reason.

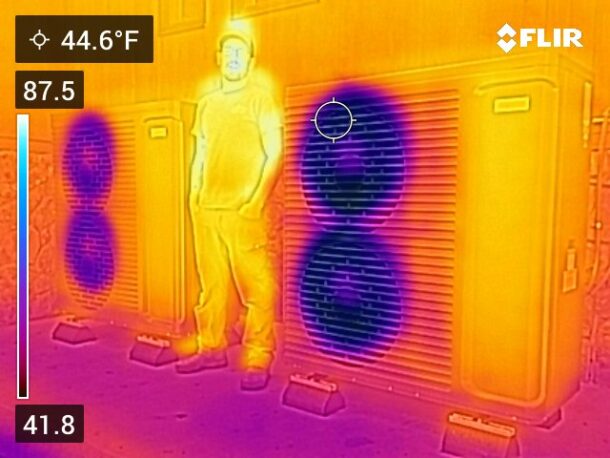

Installer Joe Ryan stands between the Ambient Heat Pumps.

Carroll conducted the heat-loss analysis based on the improvements that AP Construction was making to the building envelope, designed the heat pump system and put together a plan for the controls, allowing Ryan to install two air-to-water heat pumps with a condensing boiler for backup.

“Joe and I have worked together on a few projects in the past,” said Carroll. “He counts on us for experience and expertise, but he’s so competent that he doesn’t need help often.”

Quick pivot

Typical of old, custom homes, the renovation work proceeded slowly, thanks to surprises that kept coming up during construction. Ryan and Carroll had their system design finished in 2023 but were waiting until they could fully implement it. Not much changed until early 2024, when U.S. Boiler Company’s Dave Hansen called on Boulder Winnelson.

“Dave showed me their new Ambient air-to-water heat pump, and the specs on it matched what we needed perfectly,” said Carroll. “So, we changed the design. We’ve had a relationship with U.S. Boiler Company for decades. We knew we could count on them if we needed help.”

Almost a year before the release of the Ambient heat pump, Peak to Peak Plumbing & Heating had already piped many of the indoor components, including a 155 MBH condensing boiler, 70-gallon buffer tank, circulators, sidearm tank, HBX heat pump controller, and more. For this reason, Ryan didn’t need the complete Ambient heat pump package. He just needed the outdoor units.

Two, five-ton Ambient air-to-water heat pumps are used to heat the 3,300 square foot home, which was built in 1973.

“There was an old electric boiler here before I arrived, so the heat pumps didn’t require an electrical service upgrade,” said Ryan. “We just poured a slab outside and core-drilled through the wall to run water lines to the mechanical room.”

Akins, the builder, was mildly concerned that noise or vibration from the heat pumps would transfer through the slab and into the home, but only time would tell.

On the inside

The entire system is freeze-protected by a 35 percent Enviro-Frost glycol mixture. Supply and return lines run from the outdoor units to the large buffer in the mechanical room. This tank has an electrical element but plans to hook it up were discarded when the Ambient heat pumps were selected.

“The Ambient heat pumps are five tons in capacity each,” said Ryan. “They’re capable of supplying up to 140°F water and continue operating down to an outdoor temperature of -13°F. We designed the radiant system to require only 121°F supply water on a design day, and there’s a gas boiler piped to the buffer tank in the unlikely event the home needs supplementary heat.”

When operating at full capacity, 15.3 GPM is pumped through each Ambient heat pump and into the 70-gallon AltSource buffer tank, which also contains a reverse-indirect coil for DHW.

The mechanical room, designed by Ryan and Carroll, uses hot water from the heat pumps for the radiant system and to pre-heat domestic hot water.

“The buffer tank won’t cover the DHW load, simply because it sits at about 120°F on design day,” explained Carroll. “That’s great for radiant floors, but too cool to heat the DHW to final temp. Instead, the coil in the buffer tank just pre-heats the water on its way to the sidearm tank. We went with the reverse indirect coil because it is an easy way – requiring no pumps or moving parts – to use the heat pumps to cover some of the DHW load by preheating the incoming cold water on its way to the sidearm tank. The boiler will always have to raise the DHW to final temp.”

On the space heating load side of the buffer tank is a single Grundfos Alpha circulator distributing water to six zones, which are controlled by a bank of Taco zone panels and Zone Sentry valves.

The entire floorplan is heated with half-inch Uponor PEX, held in place by Legend Valve’s VersaTherm floating floor panel system.

The new mechanical room, wrapped in grey diamond plate aluminum and tongue-and-groove pine, occupies what had previously been a large closet. The 200-square foot room that used to contain the messy old mechanical system is now storage space.

“One of our big draws for making this a dual fuel system with a propane back-up boiler was that the gas boiler can be run off a battery back-up or small, cheap generator in the event of a prolonged power outage,” explained Carroll. “This makes the system more resilient than an all-electric system, which is important up in the mountains where the weather is unpredictable, and the power grid is less robust.

(left to right) – Chris Altenderfer, Tommy Carroll and Joe Ryan.

Evolution

Chris Altenderfer, manager of electric heating development at Burnham Holdings Engineering Company, joined Hansen, Ryan, Carroll and Akins onsite for system start-up. Watching through a Flir infrared device, they waited only a minute to see the heat pumps’ discharge fans turn purple, and the inch-and-a-quarter supply water lines turn red.

“I saw immediately that my concern about noise was unfounded,” said Akins.

“Even running at full speed, the Ambient units are quieter than any mini-split I’ve seen,” he added. “But this was completely new to me. This is the future of hydronics, and most of the homes we build have radiant systems. Peak to Peak Plumbing & Heating is on the cutting edge of the heating industry. Boulder is slowly forcing residents away from fossil-fuel appliances, so I’m excited that Joe is on the front end of the electric hydronic evolution.”

The homeowner is excited, too.

“As we undertook a big renovation, we knew that we wanted to plan for the future,” said the homeowner. “We went with this system for a combination of energy efficiency and the comfort of radiant heat. It helped that we have a great team, led by Joe Ryan and Tom Akins, who are both excited about the system. We couldn’t be happier.”

https://vimeo.com/1006933600 Welcome to our exclusive weekly update where every Friday we bring you the lates industry news, products and what’s trending on social media Read more

Welcome to our exclusive weekly update where every Friday we bring you the lates industry news, products and what’s trending on social media.