Written by Chris Carrier, RWC Senior Marketing Director The shortage of plumbers our industry is dealing with has become so serious, it’s making headlines in the business world. An article in Bloomberg Businessweek’s March 2024 issue puts the problem in a national context: “America’s Plumber Deficit Isn’t Good for the Economy.” The article elaborates with a slew of Read more

Featured Articles

Written by Chris Carrier, RWC Senior Marketing Director

The shortage of plumbers our industry is dealing with has become so serious, it’s making headlines in the business world. An article in Bloomberg Businessweek’s March 2024 issue puts the problem in a national context: “America’s Plumber Deficit Isn’t Good for the Economy.” The article elaborates with a slew of stats that back up this subheading: “Young people are shunning an occupation that’s physically demanding and sometimes dirty, though well paid.

While the labor shortage isn’t new to those who have been in the industry long, it’s worth exploring the main cause of it and ways to get more people into the trade right now.

Understanding the plumbing recruitment crisis: The age factor

Age plays two roles in the plumber shortage. A large portion of the current plumbing workforce is nearing retirement age, and recruiting young people into plumbing is proving difficult. Although the recruitment pipeline is leaking at both ends, the jobs are there for the taking, with plenty of new opportunities opening. The latest data from the U.S. Bureau of Labor Statistics (BLS) projects there will be nearly 43,000 job openings for plumbers, pipefitters and steamfitters each year through 2032. These jobs mostly result from the need to replace workers who retire, change occupations or leave the workforce.

Knowing plumbing is one of the steadiest industries, how can plumbing business owners stay staffed with good plumbers? The truth is that it’s going to take some convincing.

Images courtesy of SharkBite Plumbing Solutions.

Repairing the leaky recruitment pipeline through education

If you run a plumbing company, the most concerning consequence of the labor shortage is the challenge of keeping enough good plumbers on your team. In the skilled trades, recruiting hinges on educating recruits. Raising awareness of opportunities is foundational. Many young Americans are simply unaware of the specialty options, job security and earning potential in plumbing. As an industry, we must invest more resources in promoting the plumbing profession. Just ask Mark Brown, a Philadelphia high school plumbing program instructor.

“There are so many people in our country who struggle with finding a suitable career path for them, and I believe it’s due to lack of exposure to career choices such as plumbing,” Brown said. After telling young people an opportunity exists, we need to convince them to explore it. To be persuasive, explain why plumbing is an excellent career option. Then dispel the myths and be open and truthful about the hard parts. Any recruiting efforts—whether joint or solo, online, printed or spoken—should start by selling the benefits, including:

Clint McCannon owns Cannon Plumbing in Braselton, Georgia.

Job security and stability

When you need a plumber, it’s rarely optional. Plumbing is an essential service with consistent demand, providing long-term job security and protection against economic downturns. For example, when the COVID pandemic put millions out of work, plumbers stayed on the job with a steady income.

“I was really nervous when COVID hit,” said Clint McCannon, owner of Cannon Plumbing in Braselton, Georgia. “I didn’t know what was going to happen. Our numbers were up over 35%, and it didn’t slow down. It sped up. Even when the economy is going down, if it’s something they can’t handle on their own, they’re going to call you.”

Given the plumber shortage, it’s highly unlikely that this career benefit will change anytime soon. Even as technological advances disrupt other trades, in plumbing, new technology tends to make the work easier rather than displacing the workers.

High earning potential

Plumbers enjoy competitive wages, and many have opportunities for overtime and bonuses. Their extent varies depending on the employer and specific job role. Even without pursuing overtime or bonuses, plumbers can enjoy a financially rewarding career free from the burden of student debt.

A high school diploma or equivalent is the standard education requirement for starting paid training or trade school. The BLS lists the 2023 median pay at $61,550 per year ($29.59 per hour), up from $60,090 in 2022 ($28.89 per hour), with plumbers at the high end of the spectrum earning a six-figure salary.

Geography greatly influences earnings, with average wages varying by state, based partly on the cost of living. According to Consumer Affairs, Illinois ranks highest with an annual average wage of $88,000, while Arkansas is at the bottom with plumbers earning $47,000 on average. Nationally, the top 10% of wage earners made more than $101,000 annually, and industry wages have been climbing steadily since at least 2012.

Paid training as an apprentice plumber

You don’t need any prior experience to start training to become a plumber, and once you apply for and secure an apprenticeship, it’s paid training on the job. Vocational-technical schools and unpaid pre-apprenticeships are the most common routes people take before getting on-the-job experience.

Choosing a paid plumbing apprenticeship over attending college with an unpaid internship can be a game-changer. With an apprenticeship, you’re earning money from day one while learning a valuable trade, rather than racking up student debt. You earn hands-on experience, real-world problem-solving skills and a direct path to a rewarding career in a high-demand field.

Apprenticeships also provide a structured learning environment where mentors are invested in your success, ensuring you gain both practical knowledge and industry credentials. For anyone looking to build a stable and prosperous future without the financial burden of college, a paid apprenticeship offers a practical and lucrative track.

Leslie McGlenen owns Pipe Wench Plumbing & Heating.

Career advancement opportunities

The plumbing profession also offers clear pathways for advancement, including opportunities to become a well-paid master plumber, start your own business or move into management roles. After finishing a plumbing apprenticeship, career advancement in the U.S. plumbing industry typically follows a structured path.

First, you become a journeyman plumber, gaining more responsibilities and independence. With experience and further certification, you can advance to a master plumber, which opens doors to higher-paying jobs and leadership roles. Any apprentice can become a master in this trade if they’re dedicated, and it pays to work your way up. An HR technology company called PayScale reports that in 2023, the median pay of a master plumber went up to $82,700—a jump of 21% from 2022.

Some plumbers eventually become contractors or specialize in areas like pipefitting, leading to even more career opportunities. Some of the most profitable plumbing businesses are owned or managed by plumbers who started as apprentices. Lesley McGlenen owns and operates Pipe Wench Plumbing & Heating in British Columbia, Canada.

“I got a lot of experience as a young apprentice,” she said. “Most of the time, I was the only apprentice at this company, so I got to work under three skilled journeymen who did different parts of the job. Depending on who I was working under, I learned different techniques.”

Successful franchise owners like Lesley can expand their businesses, creating a comfortable income and good jobs.

Kim Yeagley owns Gold Canyon Plumbing in Gold Canyon, Arizona.

Job satisfaction and community impact

Plumbers play a vital role in maintaining public health and safety. Being an essential part of your community’s workforce provides a sense of pride and fulfillment for those who appreciate making a tangible difference in people’s lives, homes and workplaces.

“When you leave, you’ve fixed their problem, you’ve made their day. That’s a good feeling inside,” said Kim Yeagley, owner of Gold Canyon Plumbing in Gold Canyon, Arizona. Despite the occasional dirty conditions, the satisfaction of solving problems and providing essential services to your community is genuinely rewarding. And like other skilled trades, plumbers take pride in their craftsmanship and enjoy building something from scratch. As a plumber, you can also choose to prioritize family and personal time.

“I don’t live to work. I work to live,” said Russel Sweeney, owner of Sweeney Remodeling and Plumbing in Jacksonville, Florida. “Through the years, I’ve learned that there is a necessity for work-life balance.”

Flushing fears and reconfiguring perceptions of plumbing

While there are many benefits in plumbing, there are still a lot of misconceptions and valid concerns that must be addressed in recruitment, including:

Physical demands

Don’t sugarcoat it. Plumbing is physically strenuous, often involving heavy lifting, strong tool work, awkward positions and repetitive movements. But desk jobs aren’t for everyone either. Plumbing can be a great career fit for people who love working with their hands. Former plumbing apprentice Anna Pearson said an office job just wouldn’t suit her.

“Forty hours out of my life every single week, being stuck in a cubicle, it’s just my actual nightmare,” she said.

Modern equipment helps with the physically challenging aspects. Advancements in technology and tools have made most tasks easier and more efficient than in decades past. For example, push fittings like SharkBite Max make it easy for new plumbers to start repairing and reconfiguring pipes with minimal instruction, performing smaller jobs in just minutes. They also help plumbers get in and out of tight or uncomfortable spaces more quickly so they can put minimal strain on their bodies.

Russel Sweeney owns Sweeney Remodeling and Plumbing in Jacksonville, Florida.

Safety and working conditions

The job sometimes involves working in dirty and confined environments, which can be unappealing or seen as hazardous. Fortunately, plumbers of all types get paid to earn comprehensive safety training through their certifications that prepare them to handle potentially dangerous job site situations safely. Plus, safe working conditions are required by law. The Occupational Safety and Health Administration (OSHA) enforces federally mandated safety standards that plumbing employers must comply with, which apply to both service and commercial plumbers. Employers provide all the necessary protective gear and equipment to ensure safety and comfort on tough jobs, including water-proof gloves, knee pads, safety glasses, hard hats and respirators.

Serious injuries are very rare for plumbers, pipefitters and steamfitters. Nonfatal injuries are also exceptionally rare for both residential plumbers and commercial plumbers who work on new builds, even though working in people’s homes is generally considered safer than plumbing on a construction site. In 2022, BLS data shows that out of 865 reported fall injuries, including slips and trips, only 27 involved plumbers (3%). The BLS lumped plumbers in with HVAC contractors. This group had no reported injuries that year from exposures to harmful substances or environments, and no injuries caused by contact with objects or equipment.

Social stigma and perception

The reality is that many college graduates have student debt and still earn less than the plumber they call to fix their toilet, but there’s a strong societal push toward college degrees in high school, leading many young people to overlook the trades as they’re considering a career path. In the absence of hard facts, students often view trades like plumbing as a less prestigious career compared to white-collar jobs.

However, plumbers earn competitive salaries with excellent job security because they’re essential to our homes, businesses and critical infrastructure. Remind recruits that this trade offers opportunities for entrepreneurship and a stable, upward career path, with the added satisfaction of helping people every day. Another perk is that you can live almost anywhere and still have excellent job prospects.

Job security concerns

Some mistakenly perceive plumbing as less stable compared to careers in rapidly growing tech and service sectors where layoffs are actually far more common. Layoffs are very rare in plumbing, even during recessions, and the labor shortage shows that’s unlikely to shift.

“It’s a very recession-proof job,” Sweeney said. Research firm IBISWorld reports that “constant demand keeps direct competition low.” Industry analysts expect a steady demand for plumbing services in new construction, and IBISWorld states that “refurbishment and maintenance of aging plumbing systems have remained steady streams of income for independent plumbers and companies alike. This will not change in the near future.”

If you encounter stability concerns as you do outreach, set the record straight and back it up with facts. The U.S. Department of Labor provides a helpful resource with its Occupational Outlook Handbook for Plumbers, Pipefitters and Steamfitters. This periodically updated handbook answers every question a plumbing recruit is likely to ask.

Training requirements

Extensive apprenticeships and on-the-job training can deter those looking to enter the workforce quickly. Plumbing apprenticeships can indeed last up to 5 years, but they allow you to earn a living while gaining hands-on experience in the field, providing valuable training without the high costs of a traditional degree.

Another option is vocational-technical programs that fast-track your plumbing career, offering practical skills, recognized certifications and employment immediately after graduating.

Mark Brown, a Philadelphia high school plumbing program instructor.

Take advantage of the facts

Whether it’s educational social media videos, partnering with trade schools or hosting open- house demonstrations in your community—whichever format, strategy or platform you choose for your recruiting efforts—take a fact-based approach. Reality is your ally in persuasion. With excellent job prospects and rising pay, it’s a great time to join the plumbing profession, and having the facts on your side can make recruiting a little easier. Take it from Pearson.

“I researched it for a few days, I saw nothing but good things,” the former plumbing apprentice said. “And so, I decided to go ahead and take the plunge.”

With 53 men on the Jacksonville Jaguars roster, practicing 5 to 6 days per week for 10 to 12 hours a day, the demand for hot water must be enormous. As the choice for the team’s practice facility’s hot water storage and water heating capabilities, here are the details. How about 1,880 gallons storage capacity Read more

With 53 men on the Jacksonville Jaguars roster, practicing 5 to 6 days per week for 10 to 12 hours a day, the demand for hot water must be enormous. As the choice for the team’s practice facility’s hot water storage and water heating capabilities, here are the details. How about 1,880 gallons storage capacity and 2,400,000 btu/hr heating the water?

The Miller Electric Center is a new state-of-the-art practice facility in downtown Jacksonville that serves as the Jaguars’ football operations headquarters. The $120 million dollar facility is 125,000 square foot and includes locker rooms, training and medical facilities, office space and a draft room. It also features two full-size grass practice fields and one indoor field, along with shaded public viewing stands, concession areas and a team store.

Big men need big spaces

Luckily, Lochinvar’s Armor Condensing water heaters are up for the job. The Armor’s stainless steel heat exchanger delivers hot water at 98% thermal efficiency and modulates at a 10:1 turndown ratio. That means the units can fire as low as 10% of their total capability and modulate up to 100% when the demand is greatest. The Jag’s facility has 3 of the AWH0800NPM units installed providing the ability to cascade which ensures the units operate with equal runtime and extends the life of the heaters. The Armor’s SMART TOUCH operating control makes adjusting parameters and troubleshooting a breeze— which is nice in Florida.

With a proven storage vessel like the Lock-Temp Round Jacketed Storage Tank,

making sure the stored hot water is ready for delivery is a given. These tanks

have the exclusive Lock-Temp baffle that keeps water evenly stratified and the

80% draw factor allows almost the entire capacity to be used at the designated

temperature.

With the help of local manufacturers’ rep firm, Harry Warren, the installing contractor, Touchton Plumbing out of Jacksonville reported that the whole experience went off without a hitch. “The installation went extremely well, and the units have been working without fail through the first year of the facility being in use,” said Parker Touchton, project manager. The equipment was installed and commissioned according to schedule and is said to be performing as promised—and at the end of a 12-hour practice, there’s no room for disappointment.

- Plumbing Contractor – Touchton Plumbing Jacksonville

- Manufacturers’ Rep – Harry Warren, Inc.

- Engineer – Henderson Engineering

- Architect – Rossetti

- GC – Haskell

- Jaguars Facility Manager – Geoff Deluca

To see more about the future at Lochinvar, click here.

With jobsite productivity and safety at the forefront of the construction industry, it’s important to know the innovations that are enabling faster, easier installs for contractors while providing end users with more efficient, sustainable systems. Check out a few of these solutions that can help make jobs easier and buildings more efficient. A first in Read more

With jobsite productivity and safety at the forefront of the construction industry, it’s important to know the innovations that are enabling faster, easier installs for contractors while providing end users with more efficient, sustainable systems.

Check out a few of these solutions that can help make jobs easier and buildings more efficient.

Heat-Interface Units

A first in the North American market, these prefabricated, self-contained, heat-interface units (HIUs) convert a building’s hydronic heating supply to on-demand domestic hot water (DHW).

Ideal in multifamily structures, hospitality buildings, dormitories, assisted-living centers, and healthcare patient towers, these HIUs (sold under the brand name AquaPort™) feature a proportional control valve (PCV) and double-wall heat exchanger to create the DHW from the hydronic heating supply.

This solution removes the centralized DHW and recirculation piping to provide numerous benefits, including energy and water savings, improved water quality, installation efficiencies, reduced maintenance, and reduced risk. The PCV does not require any utility connections and eliminates the DHW heat source, supply piping, recirculation network, pumps, and storage tanks. It also optimizes efficiencies of the hydronic heating supply.

For energy efficiency, it returns the lowest water temperature possible, enabling boiler systems to reach their maximum-rated efficiency. It also provides a more centralized location in an individual unit of a building, which leads to faster hot-water delivery times and reduced water waste, helping to reduce the whole-life carbon for the building.

Compared to traditional pipe-routing methods, incorporating this solution can reduce hot-water energy use by up to 35%, eliminate up to 40% of unnecessary piping, mitigate microbial growth in the DHW system, and remove more than 50% of the total DHW volume in a building for greater sustainability and hygiene.

The compact, in-wall design is only 25.6″ tall by 14.5″ wide and 5.4″ deep to maximize overall square footage, and it is extremely lightweight at 47 lbs. for the 100K BTU/hr. version and 57 lbs. for the 180K BTU/hr. version, which makes it easy for one person to maneuver and install.

Prefabricated Radiant Mats: Cleveland Health Education Clinic, Ohio | Radiant floor heating install with Radiant Rollout Mats

Introduced into the market about a decade ago, prefabricated radiant mats have become extremely popular in commercial radiant heating and cooling projects, helping to save up to 85% in installation time compared to traditional methods.

Ideal for radiant heating and cooling systems in large commercial spaces as well as turf conditioning, snow and ice melting, and permafrost prevention (cold storage) applications, these mats are customized, prefabricated, and pre-pressurized solutions that are designed and delivered to jobsites to speed commercial installs and maximize radiant system performance.

The mats feature oxygen-barrier PEX pipe, which is a flexible, durable material that protects ferrous components in a radiant heating and cooling system. Some manufacturers also include engineered polymer (EP) connections, which are approved for burial in a slab, that are included in a reverse-return header option. This design can help reduce required manifold ports by up to 80%, helping to save time and install costs.

Since the mats are customized to meet each individual project, the pipe sizes, loop lengths, and on-center spacing varies depending on the design. Once the mats arrive on the jobsite, installers simply move the mats into place, cut the zip ties, unroll the mats into place, and fasten.

The mats also can reduce fastening hardware by up to 40%, further increasing installation efficiencies and jobsite safety. Best of all, pre-pressurized piping and self-balancing circuits provide dependable commissioning and system startup for a seamless transition from installation to end use.

Flexible Underground Pre-Insulated Piping Systems

When it comes to underground piping distribution for radiant heating and cooling, snow and ice melting, turf conditioning, or permafrost prevention (cold storage) applications, the industry is discovering the benefits of flexible, PEX-based, pre-insulated piping systems, and the solution is beginning to dominate over traditional copper or steel.

With pre-insulated PEX systems, there are typically one or two service pipes surrounded by insulation and covered by a jacket or casing. This type of system offers numerous advantages over rigid systems, such as lighter weights, fewer connections, and significant installation efficiencies.

The lighter weight allows contractors to maneuver the piping around a jobsite much easier, faster, and more effectively with less impact on the body. The piping is also available in long, continuous coils (rather than straight, segmented pieces of rigid pipe), which eliminates the need to dig a straight or level trench (since the coils can curve around existing structures and obstacles). Additionally, longer coils mean fewer (or sometimes no) underground connections for faster installations.

Plus, because the insulation is already added to the pipe, it eliminates the two-step process of installing the pipe and then insulating after installation. All of these benefits add up to significant labor savings and maximum jobsite productivity.

It is important to note that there are two types of PEX-based pre-insulated piping systems: bonded and slip. In a slip system, the PEX service pipe is covered by multilayer polyethylene-foam or PEX-foam insulation and covered by a corrugated HDPE jacket. This design is more flexible because the different layers can move independently. Additionally, if an installer needs to access the PEX service pipe, it’s a much simpler process of cutting away the foam insulation rather than scraping off the glue that adheres the insulation to the service pipe in a bonded design.

When deciding to install a PEX-based pre-insulated system, it is important to understand the thermal performance differences between a single-pipe system and a twin-pipe system. Some code jurisdictions do not allow twin-pipe configurations due to the reduction in insulation thicknesses, which can result in greater heat loss in heating applications. However, because twin-pipe configurations significantly reduce the amount of surface area exposed to the ground, it can have a positive effect on heat loss.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Pfister® Faucets continues its celebrated docuseries, hosted by country music star and Army Reserve soldier Craig Morgan, spotlighting real-life stories of plumbers’ successes and the individual approaches that enabled them to achieve their dreams through a career in plumbing. Pfister® Faucets, a trailblazer in the plumbing industry, proudly announces the launch of the fifth season Read more

Pfister® Faucets continues its celebrated docuseries, hosted by country music star and Army Reserve soldier Craig Morgan, spotlighting real-life stories of plumbers’ successes and the individual approaches that enabled them to achieve their dreams through a career in plumbing.

Pfister® Faucets, a trailblazer in the plumbing industry, proudly announces the launch of the fifth season of their docuseries, American Plumber Stories. Over the past four seasons, this series has captivated audiences nationwide, showcasing the inspiring stories of plumbers who have overcome challenges to pursue their dreams in the plumbing trade.

Season 5 will present perspectives from plumbing experts in Australia, Alaska, Canada, Hawaii, and California, shedding light on the common challenges faced by plumbers worldwide. For the first time, the show has ventured outside the United States, creating great excitement about reaching an international audience—especially the next generation of plumbers.

Craig Morgan Returns for Season 5

Country music star and Army Reserve soldier Craig Morgan will return as the show’s charismatic host. Craig’s authentic passion and profound connection to the stories of tradespeople make him the ideal guide on this journey of discovery and inspiration.

“This year, Pfister’s American Plumber Stories is heading to my second home state of Alaska and beyond, and five seasons in, it remains an honor to share these stories of inspiring men and women on the frontline of the worldwide plumbing trade,” Craig Morgan shared.

Strong Alliance Partners and New Partnerships

Three new partners joined forces with American Plumber Stories for Season 5. The International Code Council, NIBCO and AprilAire will help expand the reach of the series to their sizable audiences in the US and around the world. They are joining the ranks of industry leaders RIDGID, Cintas, Oatey, and the PHCC in this important mission.

“NIBCO partnering with American Plumber Stories was a natural fit, as we are committed to supporting and elevating the plumbing industry,” said Ashley Martin, president and COO, NIBCO. “The U.S. is in critical need of the next generation of plumbers. This show is helping to engage young men and women in an authentic way to help change the perception and inspire successful and fulfilling careers in the plumbing trades.”

Beyond the Boundaries

Season 5 tracks down some interesting plumbers around the world.

- Maui–Arecently retired plumber lost his house and everything he owned in the Lahaina fire disaster. The set-back motivates his son Raymond to recruit the next generation of plumbers to help build Lahaina back.

- Australia– Martin is the “Crocodile Dundee” of the plumbing industry in Tasmania. He specializes in servicing remote locations that he reaches by helicopter and small “bush” planes.

- Alaska– In this episode we explore the beauty of Alaska and what it’s like for Bill to work as a plumber in an extreme climate.

- Vancouver Island, B.C.– This episode tells the inspirational story of Mary Anne who employs an all-female team of plumbers. Her 100K+ social media followers know her as @the_ladyplumber. Discover why she is a role model to tradeswomen.

- Salinas, CA– Plumber Instructor Jorge helps rehabilitate inmates by teaching them the plumbing trade in the Soledad State Prison. We have an open discussion with the warden on why this approach works so well.

- Victorville, CA– Meet the Motherflushers. They are young and passionate about plumbing and have changed the perception via social media– well beyond the borders of the United States.

For more information and to watch the new episodes of American Plumber Stories, please visit www.americanplumberstories.com.

Interested plumbers who would like to share their own story can do so here: www.americanplumberstories.com/pages/i-am-an-american-plumber.

Stay Connected

YouTube.com/c/AmericanPlumberStories

Instagram.com/AmericanPlumberStories

Facebook.com/AmericanPlumberStories

Linkedin.com/showcase/American-Plumber-Stories

TikTok.com/@AmericanPlumberStories

Subscribe to Email and Text Message Alerts www.americanplumberstories.com/pages/subscribe

North Andover, Mass.—Watts Water Technologies celebrated its 150-year anniversary in style this past week as nearly 300 past and current employees, trade press and local dignitaries gathered to celebrate the long-continued success of the company. Keynotes from Chris Jameison, Senior Vice President and General Manager, and Bob Pagano, CEO, and a special presentation from Tim Read more

Bob Pagano, CEO, Watts

North Andover, Mass.—Watts Water Technologies celebrated its 150-year anniversary in style this past week as nearly 300 past and current employees, trade press and local dignitaries gathered to celebrate the long-continued success of the company. Keynotes from Chris Jameison, Senior Vice President and General Manager, and Bob Pagano, CEO, and a special presentation from Tim Horne, Director Emeritus, Watts Water Technologies kicked off the event.

The goal for Watts moving forward—to paraphrase Jameison— is to “improve comfort, safety and quality of life” for its customers. Pagano echoed that sentiment emphasizing safety, water conservation and energy efficiency as key tenets for the company.

Tim Horne

Horne regaled the audience of stories of his great grandfather breaking ground, mock home explosions and company growth. What started as a $15,000 investment with the purchase of the company from Joseph E. Watts, a machinist who emigrated to Lawrence, Mass., by Burchard Everett “B.E.” Horne, the company grew exponentially over the years due to expansion through acquisitions, and innovations such as the introduction of the T&P relief valve and entering the backflow market among others, for example. The company stayed in the Horne family for three generations where it is now in good hands, run capably by current CEO Pagano. The company is now worth more than $2+ Billion. Yes, that’s with a B. “Anniversaries are actually more about the future than the past,” says Horne.

The trade media experienced cutting-edge technologies with access to six stations manned by Watts/Bradley experts in what was called the 2024 New Innovations Tour.

Phil Jagelski, Senior Technical Instructor and Instructional Designer, Bradley/Watts gives a tour of the Bradvan, while showing Bradley’s Eyewash Station, wash basin, and an impenetrable storage locker, for example.

Oh, before all of that, media members were granted an exclusive tour of one of the “Bradvans,” one of six of Bradley Corp.’s mobile units that traverses the United States. Backstory, Watts acquired Bradley—a veteran manufacturer of commercial washroom and emergency safety solutions, serving the commercial and industrial end markets for more than 100 years—in 2023.

Three vans feature Bradley commercial, more architectural products, while the other three vans feature Bradley’s Safety Industrial Solutions such as the Halo Swing Activated Faucet Eyewash.

Stop 1 saw the future for Watts technology in its Nexa intelligent water management system. Coming very soon, this sensing technology empowers building owners and operators with unmatched insight and control, improving system efficiency, mitigating the risk of water damage, and conserving water and energy to provide the best occupant experience possible.

Stop 2 on the Innovation Tour featured Watts’ Smart Strainer, which prevents suspended particles and debris from damaging downstream equipment. Integrated differential pressure monitoring proactively alerts users to pressure drops, helping to prevent system damage, avoid downtime, and ensure consistent flow.

Nate Kogler talk about Bradley’s Commercial Washroom and Emergency Safety and Industrial Solutions.

Stop 3 was the inclusion of Bradley products, which featured The Elvari™ Collection of washroom accessories seamlessly blends style and substance for a modern, commercial washroom experience. The Halo™ Swing Activated Faucet Eyewash space-saving design combines best-in-class critical safety equipment for swift emergency response. Elegance meets efficiency with the Verge® with WashBar® WB2 1-Station, providing a touchless, all-in-one solution for washing, rinsing, and drying hands.

The Verge with touchless WashBar WB2 1-Station is so slick, and it just makes sense—clean, rinse and dry your hands all in one place.

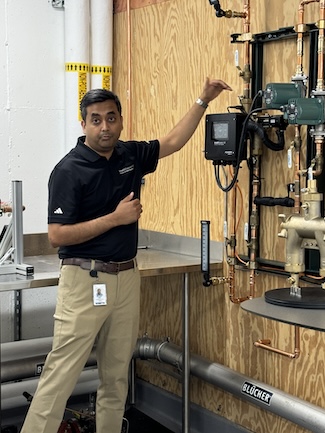

Shashwat Nath demos the Intellidation 2.

Stop 4 featured the The IntelliStation® 2 loT-enabled Digital Mixing Valve, which offers significantly improved performance over traditional thermostatic mixing valves, ensuring consistent water temperatures in low and high-demand situations. IntelliStation 2 seamlessly integrates with Nexa for enhanced system insight and control and comes available in pre-piped

configurations for unique installations.

Stop 5 a highly unique investment of Ultra High-Purity Piping (UHP), which offers clean room piping for ROID, manufacturing, and cooling processes. Molded from highly-durable Kynar® PVDF resin, all piping is made-to-order in North America, ensuring short lead times for faster system build-outs.

Stop 6, the last stop on the Innovation Tour, featured Leak Defense’s BuildAlert™ product, which provides 24/7 job site leak protection, providing protection against flooding even when you’re offsite. With remote monitoring and control, you can prevent costly water damage claims and avoid project delays.