The first time I’d ever heard of a disruptive technology, it didn’t sound like good news to me. As it turns out, the term refers to a technology that changes the way we do things— usually for good. Perhaps you’ve heard the story of buggy whips? Not much need for them after motor vehicles came Read more

Industry Blogs

The first time I’d ever heard of a disruptive technology, it didn’t sound like good news to me. As it turns out, the term refers to a technology that changes the way we do things— usually for good. Perhaps you’ve heard the story of buggy whips? Not much need for them after motor vehicles came along.

My own personal experience involved tube style TVs. I needed to buy a replacement TV to fit my entertainment center, because my 35” color TV finally quit. Having had no reason to shop for a television in years, I was shocked to find that tube style TVs were no longer sold.

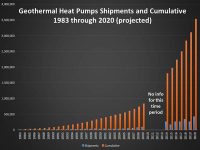

I’ve been involved with GHPs for 26 years, since starting EggGeothermal in 1989. I was pleased to find that the Energy Information Administration (EIA), a division of the DOE, was reporting sales and had produced a graph in 2009. At that point, the Federal Stimulus Package of 2009 was signed into law, and things began to heat up for renewable technologies with a nice 30% federal tax credit.

But the Fed stopped reporting GHP shipments, and nobody, of which I’m aware, had any real ideas of how things were going.

On larger projects, owners sometimes need a level of comfort that may not be quite there yet. Even when geothermal exchange has been proven as effective and efficient at a local level, some require a feasibility report be completed for further assurances. That information is available and can be applied to specific projects effectively. Just contact the geothermal industry organizations; they are there to help you succeed.

Like many before you, the first couple of geothermal projects undertaken will and should be carefully executed. Once you’ve reached a level of reasonable confidence, you’ll want to attend geothermal exchange training to provide certification for your efforts going forward. Then you can be listed on the geothermal industry websites as a geothermal professional/contracting entity, providing the same help to clients and fellow professionals according to your own wishes.

The International Ground Source Heat Pump Association (IGSHPA) and the Geothermal Exchange Organization (GEO) are your resources for all of these efforts.

Recently though, a friend to the geothermal industry, Tom Konrad, wrote a piece in Forbes in which he posted a graph gleaned from a Navigant study.

I fed some information from the Navigant graph to John Fontano, an old friend and former employee who is pretty handy with Excel, and he came up with this graph, over which I superimposed an illustration of a disruptive technology trend.

It seems obvious that geothermal is a disruptive technology. If you’re wondering if that’s a good thing- it is.

If you’ve been dragging your feet, it’s not too late. Here what you need to do to get involved:

Geothermal HVAC is the way the industry is going, and right now is the perfect time to get in. Here are some pointers that will help you to get involved and claim your piece of a phenomenal growth market.

With geothermal, you get to take advantage of your current customer base and skill-set, because geothermal exchange systems are typically similar to standard mechanical system inside the building. The geothermal exchanger is new piece to most, so you’ll want to identify a good partner with which to work on the first projects you contract. Depending on the project(s), you will need one or more other local geothermal drillers or designers to assist you on the first few. A good geothermal contractor will help you to complete a competent ground loop or well system to complement what you’re probably already doing for the building inside. He will probably even have knowledge of the geological conditions and be able to help you get right down to business.

Many manufacturers have a line of geothermal/water sourced equipment. You’ll want to select a brand that can support your efforts in a wide variety of markets.

In larger projects, owners sometimes need a level of comfort that may not be quite there yet. Even when geothermal exchange has been proven as effective and efficient at a local level, some require a feasibility report be completed for further assurances. That information is available and can be applied to specific projects effectively. Just contact the geothermal industry organizations; they are there to help you succeed.

Like many before you, the first couple of geothermal projects undertaken will and should be carefully executed. Once you’ve reached a level of reasonable confidence, you’ll want to attend geothermal exchange training to provide certification for your efforts going forward. Then you can be listed on the geothermal industry websites as a geothermal professional/contracting entity, providing the same help to clients and fellow professionals according to your own wishes.

The International Ground Source Heat Pump Association (IGSHPA) and the Geothermal Exchange Organization (GEO) are your resources for all of these efforts.

Don’t forget to get your name and support onto the National Geothermal Day website. These are the groups to which you and others can and should go to get information, training and list your company as a geothermal heating and cooling entity.

I’m not saying that standard AC’s, heat pumps and furnaces are “buggy-whips” or “tube-TV’s”. Let’s just say I’m not inclined to wait around and see what happens.

Jay Egg is a geothermal consultant, writer, and the owner of EggGeothermal. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jayegg.geo@gmail.com.

Jay Egg is a geothermal consultant, writer, and the owner of EggGeothermal. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jayegg.geo@gmail.com.

The Department of Energy (DOE) formally proposed the first-ever standards for commercial and industrial pumps, which are projected to produce up to $1.1 billion in net energy bill savings from pumps sold in the next 30 years and are supported by both industry and efficiency advocates. The proposed standards, which were published in today’s Federal Read more

The Department of Energy (DOE) formally proposed the first-ever standards for commercial and industrial pumps, which are projected to produce up to $1.1 billion in net energy bill savings from pumps sold in the next 30 years and are supported by both industry and efficiency advocates.

The proposed standards, which were published in today’s Federal Register, will cover clean water pumps ranging from 1 to 200 horsepower in size, that are generally used in commercial, industrial, agricultural, and municipal applications. Examples include pumps used in agricultural irrigation, building heating and cooling systems, and water treatment plants.

Commercial and industrial pumps and pump systems are responsible for about 0.6 percent of U.S. annual energy use – while this number may sound small, it is significant for a single product category and therefore, improvements in pump efficiency offer potentially large energy savings. The proposed standard is a good step forward in capturing the energy savings opportunity from this important product and is the result of a DOE-led negotiated rulemaking that was comprised of representatives from the pump and motor industries, utilities, and efficiency advocates, including NRDC.

The Savings

Overall, the proposed standards will save about 30 billion kilowatt-hours from pumps sold over the next 30 years, equivalent to the annual electricity use of 2.8 million U.S. households, and result in 16 million metric tons of carbon pollution emissions reductions. For most pump types, life cycle cost savings range from $92 to $173 per pump, with simple paybacks under three years.

These standards are also an important step toward meeting President Obama’s goal of achieving 3 billion metric tons of carbon pollution emissions reductions by 2030. Over 2 billion metric tons are already on the books from standards finalized since 2009. The pump standards would add another 2.5 million metric tons of reductions through 2030, equivalent to the annual emissions from the electricity used by 360,000 homes in one year.

Pumps would be required to meet the new standards four years after the final rule is published, which is expected by the end of 2015.

Required Pump Efficiency

For most pump types, the proposed standards would raise the efficiency floor to remove the worst 25 percent of pumps on the market. The efficiency levels were determined using a similar approach to the EU which involves taking an inventory of the efficiency levels of all the pumps on the market and using this information to create a floor that can be moved up and down to achieve the desired level of efficiency, balancing energy savings, consumer benefits, and manufacturer impacts. The levels agreed on in the negotiations represent a balance of all these factors.

In order to meet the standards, manufacturers can either improve their pump models through hydraulic redesign, polishing, or other design improvements — or choose to drop inefficient pumps from their product line (a manufacturer might make this decision if they have another more efficient model in their line that can meet the same pressure and flow requirements).

The metric for pump standards is called the “Pump Efficiency Index or PEI.” The PEI compares the power consumption of the pump to a reference pump that just meets the standard: a pump that just meets the standard would have a PEI of 1, a pump that is 10% better than the standard would have a PEI of 0.9. The standards would apply to pumps however they are sold: either as a bare pump (just the hydraulic component) or the pump plus motors and controls if present. For pumps sold with motors and controls, the PEI gives credit to motor and control systems (such as variable speed drives, or VSDs) that can reduce the power consumed by the pump when the pump is not operating at full speed. This will help reduce energy even further: currently many pumps systems are controlled using throttling valves on pipes, rather than controlling the speed and flow of the pump. This is analogous to controlling the speed of your car with the brake alone, while keeping your foot fully on the gas. Variable speed drives have the potential to offer significant energy savings in many applications by reducing the pump’s speed and therefore electricity use!

As part of the negotiated agreement, committee members recommended that DOE also initiate rulemakings for circulator pumps (pumps used to circulate water in buildings) and pool pumps, which were not covered in this rulemaking and represent additional opportunities for energy savings. DOE should move forward on these rulemaking to capture these additional energy savings opportunities.

It’s great to see DOE move forward on another efficiency standard that will add to the long history of the DOE standards program delivering benefits to consumers and the environment!

This post originally appeared on NRDC’s Switchboard

Meg Waltner is Manager, Building Energy Policy, San Francisco, Calif. As an energy efficiency advocate at NRDC, Waltner focuses on ways to promote energy efficiency in buildings and appliances in California, at the Federal level,and internationally. Waltner primarily works to advance efficiency through grant programs, tax incentives, buildings energy codes and appliance efficiency standards. She joined NRDC’s DC office in August 2009, after graduating from Stanford with an MS and BS in Civil Engineering, with a focus on efficiency in buildings and renewable energy technologies, and moved to NRDC’s SF office in 2013.

Meg Waltner is Manager, Building Energy Policy, San Francisco, Calif. As an energy efficiency advocate at NRDC, Waltner focuses on ways to promote energy efficiency in buildings and appliances in California, at the Federal level,and internationally. Waltner primarily works to advance efficiency through grant programs, tax incentives, buildings energy codes and appliance efficiency standards. She joined NRDC’s DC office in August 2009, after graduating from Stanford with an MS and BS in Civil Engineering, with a focus on efficiency in buildings and renewable energy technologies, and moved to NRDC’s SF office in 2013.

As a native Californian, Waltner grew up hiking in the parks around the Bay Area and in the Sierras and have always loved spending time outdoors. When she’s not in the office, she like to spend my time hiking and camping, going on long runs, cooking new things and being with friends and family.

You can read more blogs from Meg here.

Brian Fenske offers his thoughts to an article we posted: How are you venting? PVC Flues Are They Safe? More often than not the 140 degree Fahrenheit limit for Sch 40 DWV in misinterpreted and misused. The 140 degree limit is in fluid piping situations with pressure. The charts, if I recall, are 20 PSI Read more

Brian Fenske offers his thoughts to an article we posted:

How are you venting? PVC Flues Are They Safe?

More often than not the 140 degree Fahrenheit limit for Sch 40 DWV in misinterp reted and misused. The 140 degree limit is in fluid piping situations with pressure. The charts, if I recall, are 20 PSI for the 140 degree temperature limit. Last time I checked, flues don’t see a fluid pressure, and the vent pressures are well under 1 PSI. Schedule 40 PVC has a upper temp limit of 149 degrees Fahrenheit, with degradation beginning to occur at 158 degrees Fahrenheit. This would be the reason for the Canadian ULC-S636 standard of 149 degrees F/65 C. They know and understand the true material temperature limit. I agree that the PVC manufacturers don’t list the application or temperature limits of PVC pipe for venting, but why should they? Where’s the listing for 26 gauge stove pipe to be found?

reted and misused. The 140 degree limit is in fluid piping situations with pressure. The charts, if I recall, are 20 PSI for the 140 degree temperature limit. Last time I checked, flues don’t see a fluid pressure, and the vent pressures are well under 1 PSI. Schedule 40 PVC has a upper temp limit of 149 degrees Fahrenheit, with degradation beginning to occur at 158 degrees Fahrenheit. This would be the reason for the Canadian ULC-S636 standard of 149 degrees F/65 C. They know and understand the true material temperature limit. I agree that the PVC manufacturers don’t list the application or temperature limits of PVC pipe for venting, but why should they? Where’s the listing for 26 gauge stove pipe to be found?

Way more people have died from rotted, rusted, sagging, inappropriately installed single wall sheet metal chimneys and appliance connectors than any other vent material, where is that call to action to ban?

Since UL (Underwriters Laboratory) doesn’t test or list products for venting, it would be wrong to say PVC pipe should be listed by UL.

“UL certified gas-fired appliances and venting systems for these products are intended for installation in accordance with the following installation codes:

• ANSI Z223.1/NFPA 54 National Fuel Gas Code

• International Fuel Gas Code

• International Residential Code

• Uniform Mechanical Code.

These codes include requirements intended to minimize the hazards associated with high temperatures and combustion gases. In general, factory built vents and chimneys are required to be listed (certified), except for instances where limited use of metal chimneys and vents are specifically allowed. In general, US codes permit Category IV gas-fired appliances to be vented using unlisted plastic vents where such vents are tested and covered under the specific appliance listing. These vents are intended to be installed in accordance with the appliance manufacturer’s installation instructions.”

PVC venting and all required or approved vent material are however tested and approved by CSA. CSA exceeds the UL standards with specialization with gas fired equipment (UL does not)

ANSI Standards, does address PVC venting also meets their requirements under exact conditions –

How Appliances are Certified:

Gas fired boilers and water heaters are required to be safety certified by a third party testing agency according to the American National Standards/CSA Standards. Boilers are design certified to ANSI Z21.13/CSA 4.9 and commercial water heaters are design certified to ANSI Z21.10.3/CSA 4.3. As a part of this certification, the appliance must undergo tests to assure the specified venting system is appropriate for use with the appliance. Each standard includes specific test procedures for Non-metallic venting like PVC/CPVC. The appliance is placed in a closet and the water temperatures are raised to the highest permissible level. This generates the highest flue gas temperatures. Under these conditions, data is collected to verify the vent material’s temperature limitations are not exceeded. The vent tests measure the actual pipe material temperature, not the flue gas temperature to determine the effect of hot flue gases on the vent material. ANSI test procedures are under constant review by the ANSI standards committees to assure the test conditions are appropriate and up to date.

CSA also knows and understands the true upper safe temperature limit of all plastic vent materials and test the appliances under the different operating conditions to these plastic temperature limits.

I am not saying PVC pipe is OK for all applications, but if we can, as an industry, follow the installation instructions, installing the correct material for the application, in a proper manner, we wouldn’t need to use a few instances that were wrong to build a case against a product that makes sense to use.

Brian Fenske is specialty channel sales manager and national training manager for Navien America, Inc.