Keeping occupants of a building or facility warm and comfortable is a year-round priority. Whether the leaves are turning, snow is falling or spring is blooming, maintaining the right temperature is key to ensuring occupants are happy and productive. Some buildings – such as yoga studios, swimming pools, hospitals and laboratories – require spaces to Read more

Industry Blogs

Keeping occupants of a building or facility warm and comfortable is a year-round priority. Whether the leaves are turning, snow is falling or spring is blooming, maintaining the right temperature is key to ensuring occupants are happy and productive.

Some buildings – such as yoga studios, swimming pools, hospitals and laboratories – require spaces to be kept at specific temperatures to ensure optimal performance for specialized activities. Yogis and swimmers perform better when they are warm, patients heal faster when they are comfortable, and researchers gather more accurate results when temperatures are constant.

For these and other types of retail and office facilities with unique heating demands, radiant ceiling panels are an optimal choice for providing consistent warmth without disrupting activities. The right radiant ceiling panels ensure a high level of comfort, and can be incorporated into the interior’s seamless warmth.

For these and other types of retail and office facilities with unique heating demands, radiant ceiling panels are an optimal choice for providing consistent warmth without disrupting activities. The right radiant ceiling panels ensure a high level of comfort, and can be incorporated into the interior’s seamless warmth.

Hidden Advantage

In a yoga studio or hospital, for example, the right interior furnishings and design are vital to creating a positive experience for occupants. Yoga studios are often simplistic in design to help calm those who are practicing, allowing them to focus on their poses and their breath. Similarly, studies have shown that the way a hospital is laid out and decorated has a significant impact on patient care and well-being.

Therefore, the addition of radiant ceiling panels should not alter these well-crafted designs, but rather blend the units into the existing surroundings as effortlessly as possible. Consider radiant ceiling panels specifically designed to act as invisible sources of warmth, able to match the color scheme of a room perfectly with paint or silkscreens so occupants don’t even realize they are present.

But hidden warmth refers to more than just visual customization. Areas such as yoga studios, locker rooms, office conference rooms, hospital ICUs and laboratories also want to keep their rooms quiet and without unnecessary drafts. A heating unit that produces strong air flow can spread dust particles and debris, while loud fans are disruptive to office productivity, quiet meditation and healing.

Radiant ceiling panels with no moving parts – such as fans – create no air movement or excess background noise, and therefore require no additional maintenance. Customizable options from QMark or Berko can be sized and colored to meet specific dimensions and themes, for a quick and silent addition.

Personalized Warmth

A customizable heating unit should not only match the look of a facility, but its specific temperature requirements as well. One of the many benefits of radiant ceiling panels is their ability to provide primary or supplemental comfort. This means a building’s primary source of heat may be enhanced in specific spaces throughout where higher temperatures are required without overheating the rest of the facility.

In a yoga studio, some rooms may need to surpass 100 degrees Fahrenheit, while others can remain at a more standard room temperature. In lobbies, bathrooms and hallways as well, specific rooms may call for higher temperatures to enhance comfortability.

Radiant ceiling panels are able to offset perimeter heat loss from doors, windows or other sources of drafts. Likewise, they can provide primary heat to an entire space such as a yoga room without altering adjacent spaces’ temperatures. This ensures each space throughout the facility can have the temperature customized for the occupants’ needs.

Materials Matter

To ensure radiant ceiling panels produce silent, invisible heat while keeping occupants safe, they must be made with the right materials. Galvanized or aluminized steel housing provides a stable base to hold the panels. Encapsulated casted element assures the units deliver uniform temperature across the surface, while increasing the panels’ longevity. Stability T-bar grip clips that can guarantee the panels stay intact during heavy storms or earthquakes are also important, as well as the use of fire retardant materials so there is no added risk in an emergency.

Some facilities may require specialized materials such as a stainless steel construction for chlorine storage areas that seal tightly with connectors and silicone. Exterior moisture and condensation do not affect heating panel performance, but water inside the unit can cause it to fail. Panels in locker rooms or swimming pools should be totally sealed with silicone at the factory before shipment to prevent moisture penetration. High-moisture facilities may also opt for seal-tight connectors and conduit, rather than greenfield flexible conduit and straight connectors.

Conclusion

When reviewing radiant ceiling panels for facilities with specific heating demands, consider all the options available as well as features to personalize. Berko and QMark offer customized radiant ceiling panels for a wide array of facilities looking to heat rooms with unique needs and uses. What may work for a laboratory setting may not be ideal for a yoga studio or swimming pool. Be sure to address all the different details of the space to ensure the needs are met and occupants can enjoy hidden, uninterrupted comfort every day.

Guest Blogger: Jim Herring is the supervisor of Total Custom Solutions & Technical Services at Marley Engineered Products®, a leading North American designer and manufacturer of reliable comfort heating and ventilation solutions for residential, commercial and institutional buildings. Recognized by contractors, architects, engineers and HVAC professionals for providing a wide range of high-performance, reliable heating and ventilation solutions, Marley Engineered Products’ brands include QMark®, Berko®, Fahrenheat® and Leading Edge®. Marley Engineered Products’ manufacturing operations are based in Bennettsville, S.C., with regional sales representatives located throughout the U.S. and an administrative office in Burr Ridge, Ill.

The cost of consumables can seem minor when calculating a job. Compared to the costs of labor, tools, material and transportation, the expenditure for consumables can seem unavoidable and of relatively minor importance. But when using traditional methods of joining pipe, such as welding, soldering and threading, consumables are a constant cost and one that Read more

The cost of consumables can seem minor when calculating a job.

Compared to the costs of labor, tools, material and transportation, the expenditure for consumables can seem unavoidable and of relatively minor importance.

But when using traditional methods of joining pipe, such as welding, soldering and threading, consumables are a constant cost and one that can easily cut into profit margins.

This sample bill of materials explains it well:

This sample bill of materials explains it well:

Say a job requires a contractor to make 1,500 x ½” pipe connections and, based on material and application, he chooses to use threading to join the pipe.

Consumables for the job are a cutting die, cutting oil, Teflon tape and pipe thread compound. Let’s look at the quantities involved:

- The ½” cutting die has a 1,500-cut life span.

- For those 1,500 cuts, two gallons of cutting oil are used.

- Three wraps of Teflon pipe are used on each pipe joint.

- One pint of pipe thread compound lasts five times as long as the Teflon rolls.

At face value, here are the price points associated with each of these consumables:

- Die: $123.48

- Cutting oil: $33.27

- Teflon tape: $15.78

- Pipe thread compound: $10.32

When you spread these numbers across 1,500 connections, you end up with a total cost of $0.318 per joint.

If you think about this from a long-term perspective, it’s easy to see where the dent in your budget forms. Perform the same job above 50 times over and the consumable bill reaches nearly $24,000.

Now, consider a scenario where you need a 2″ pipe joint to perform the above job. In this case, you have a total cost of $0.749 per joint. Perform this same job 50 times and your consumable bill stretches to more than $56,000.

(While on the topic of costs, it’s also worth mentioning that a threading machine alone will run you about $7,000.)

While the above example uses threading, other traditional pipe-joining techniques like soldering and welding introduce the same concerns over consumable costs. Whether you need spools of solder, flux and fuel or welding sticks, grinding discs and a galvanizing spray, you’ll have payments that never cease and are bound to add up.

The best way to eliminate consumable costs is to use press tool technology. While the greatest efficiencies with press technology comes with reduced labor costs, the savings on consumables will add up, job after job, year after year.

In addition, there’s no need for open flame and you’ll have the ability to install in any weather conditions, so you’ll avoid the cost of fire watches and hot work permits, as well as potential costly delays in project schedules due to environmental conditions.

Will Dutcher, Associate Product Manager – Industrial, has been with Viega LLC for three years, beginning as a product engineer. He holds a bachelor’s degree in mechanical engineering from The State University of New York at Buffalo (UB) and has engineering experience in a variety of industries, including pharmaceutical, high-end jewelry and consumer plastics.

Will Dutcher, Associate Product Manager – Industrial, has been with Viega LLC for three years, beginning as a product engineer. He holds a bachelor’s degree in mechanical engineering from The State University of New York at Buffalo (UB) and has engineering experience in a variety of industries, including pharmaceutical, high-end jewelry and consumer plastics.

According to a Kabbage survey of construction firms, 28 percent cited cash flow as the biggest challenge during their first year in business, outweighing finding new customers. As your business grows, the struggle to manage a positive cash flow may continue. Towards the end of a project subcontractor fees, invoices, inspection fees and finish materials Read more

According to a Kabbage survey of construction firms, 28 percent cited cash flow as the biggest challenge during their first year in business, outweighing finding new customers. As your business grows, the struggle to manage a positive cash flow may continue.

Towards the end of a project subcontractor fees, invoices, inspection fees and finish materials are due all at once. If you front-load payments or don’t track outstanding bills, you may find yourself undercapitalized.

The good news is that there are practical steps you can take to structure your cash flow and stay ahead.

Align project cash flow with company cash flow.

Plan to pay your company’s quarterly taxes, marketing costs, insurance premiums and other predictable expenses when big bills for your project are not due. Additionally, if you invested in capital equipment, you may be able to claim depreciation and other write-offs to minimize quarterly tax payments and free up cash.

You can also work with your accountant or use tools to analyze your finances and make small adjustments to smooth out the peaks and valleys in your cash flow.

Break up your invoices.

Customers appreciate prompt, smaller bills because it helps them manage their own cash flow. John Montijo took several years of trial and error after starting his construction business in Staten Island, New York to figure out the best way to ease the burden on his business and his customers.

John realized that he didn’t have to follow the industry standard of billing in three or four large installments over the course of a job. Instead, he broke his invoices up further, billing after each stage of a job: for demolition, sheetrocking, windows, insulation, plumbing, electrical work and so on.

Instead of writing a check for $25,000 on a $100,000 job, John’s customers can pay $10,000 at a time, a cash flow win-win for both sides.

Have a cushion.

Dennis Moloney of Best Restorations in Delray, Florida, doesn’t like when his company’s cash flow gets tight.

This forces him to devise new budgeting strategies to stay ahead. Dennis takes advantage of early-payment discounts from his vendors to save money and utilizes lines of credit to bridge cash-flow gaps.

“In 14 years, I’ve never bounced a check or been overdrawn, and I want to keep it that way,” says Dennis. “I borrow to make sure I’m always looking good. “

Aditya Narula is the head of customer success at Kabbage, a FinTech company helping small businesses get access to working capital.

Aditya Narula is the head of customer success at Kabbage, a FinTech company helping small businesses get access to working capital.

As the HVAC industry evolves further in response to new market opportunities, sustainability initiatives and changing consumer demands it’s easy to be left at a loss of how to cut through the marketing speak and deliver benefit-driven information to your customers. Putting in the extra work to fully understand how to translate product features into Read more

As the HVAC industry evolves further in response to new market opportunities, sustainability initiatives and changing consumer demands it’s easy to be left at a loss of how to cut through the marketing speak and deliver benefit-driven information to your customers. Putting in the extra work to fully understand how to translate product features into real-world customer benefits will give you an edge in the market. Below is a discussion on how to navigate an industry of new and old considerations across customer demographics. Follow along to understand how you can shift your strategies to build customer relationships through simple communication training of your sales staff.

Define your competitive edge through no-nonsense delivery

Is it just me, or does every HVAC product on the market have the same features?

Tell me if you’ve heard this one before: “Our new, highly-efficient product provides homeowners with a simple, flexible, and cost-competitive solution.”

Does this sound like a product line you offer? Truth be told, this description could apply to any number of products. For example, a system that offers “zoning” could be anything from a sophisticated ductless system to a simple air conditioner with manual air dampers.

Here’s the problem: today’s customers are the most educated customer base we’ve ever experienced. With access to information at our literal fingertips in our smartphones, customers can fact-check a sales pitch in an instant. HVAC repair and replacement is an expensive investment for most customers to begin with, so it’s understood that they want to know exactly what they’re paying for.

If you state that a product is efficient, customers want to know: How efficient and what are the benefits? Compared to what? Does it cost more, if so, what’s the price difference? Do I really need it?

If you’re not being clear with your customers, you can trust that they are getting their information elsewhere — perhaps even pulling purchase decision information from your competition.

There are simple improvements to your sales information delivery that can help to move past the jargon and build meaningful conversations with your customers that leave them feeling well-informed and satisfied in their decision. In short, you can build credibility – and become the authority – by being honest and transparent.

As mentioned, using vague terms to describe a product as efficient, variable, or flexible tells the customer very little. The way to fix this is to always speak in terms of comparison. By speaking in comparisons, you will educate the customer on all of the options available to them – not just the one you’d like to sell. This is a critical step in achieving value in customer satisfaction.

If you’re not comfortable speaking in comparison, here are three ways to help get you started:

- Stop talking features & benefits and start talking sell points and personas

If you’re speaking to a customer about a solution they are just one step away in the sales funnel from making a purchase. It’s important at this stage that you carefully consider what you say and how you say it.

Consider this: most brochures you’ll hand a customer have a long list of features & benefits… those features are often phrased in comparison to an older version of that same product or directly to a competitor’s product – “Even quieter!” or “More flexible than ever!”

But the homeowner doesn’t care if it’s “even quieter” than a previous generation of a product that isn’t in the consideration set they are making for their home. Focus on the information your homeowner actually wants and needs: what options do you recommend; what specifically makes you recommend these based on my needs; how much does it cost?

Hone in on information by defining the sell points for all the products in your portfolio. An easy way to do this is to determine the five whys for each of your products:

- Who would most want or need to purchase this product?

- What type of situation is this product most suitable for?

- Why would they need this product?

- When can we promise to deliver this product to the customer?

- Where are most of the customers geographically located who need this product?

Notice the emphasis on the extremes in these questions. The goal is not to answer in general – “who could use or purchase this product” – but rather “who MOST wants or needs this product and why.” This is critical to defining the true selling points of a product.

By taking this approach, your team will be able clearly to describe the important reasons behind a recommendation because they have clear guidance as to why to recommend it in the first place. You might even consider building a questionnaire that will help both you and your customer come to a decision on the right choice for them.

- Group your product offerings using tiers

Instead of confusing customers with an onslaught of product brochures covered in brand names, shiny logos, and pretty pictures, consider packaging your products into tiers. Most homeowners are able to easily pick up the concept of Good, Better, and Best – or Bronze, Silver, and Gold.

By grouping your offering into rungs on a ladder, you’re giving the customer a baseline to compare products against one another. The key to this approach is to ensure your groupings offer key differences. Perhaps package A is best for the cost-conservative homeowner, package B is best for the energy-conscious customer, while package C is most suitable to the customer seeking a quick turnaround.

With this system, customers can easily determine the difference between your products and make informed decisions on which products best fit their needs.

-

Give three options whenever possible

When ordering drinks at your local coffee shop, why is it so many of us opt for the medium size? A small seems too small, and a large seems, well…too large. When we are given three options, often we are seeking the Goldilocks “just right” feeling.

No one wants to miss out on an upsell, but the goal should not be to dupe your customer into buying the highest-margin product by failing to tell them about a more cost-effective option that likely checks off the needs on their list. Provide customers with three options: something that doesn’t quite meet their needs, something that over-delivers, and a solution that falls in the middle. Because you have tuned in to exactly what the customer needs, selling the middle option in comparison to the other two should be simple.

If you are the service provider for all three options, this strategy gives you an added bonus. If the customer chooses the more elaborate option, you’ve earned more. If they choose the less desirable option, they will know up front what they’re getting and perhaps sacrificing – and you’ve earned their trust in the process.

What does this sound like?

The common – although tired – sales pitch I shared at the beginning turns into a richer conversation once you’ve added comparisons. In this example, I’ve uncovered that the customer is most concerned with the ability to stay comfortable in their home, with affordability being their second concern.

“The package I’d like to offer you today is our Premier package. Your upstairs and downstairs will have individual thermostats, which I know is what you were looking for. I’d like to share with you some other options for your consideration. Our Platinum package would give you even more comfort options: every room could have its own set point. The higher price could be offset with some rebates, but it is more expensive than the Premier package. Another option is our Economy package. This is the most affordable of the three, but it doesn’t come with the zoning you asked for. Given what we have discussed so far, I think the Premier package most meets your needs.”

By defining the sell points for your products, grouping them into tiers, and offering at least three options you can successfully provide the customer with a well-thought-out and easily understandable reasoning for your recommendation.

Resolve to make comparison-speak a habit in your organization and your customers will see you as a more trustworthy source of information for their buying decision process.

Pam Duffy, P.E. is the Owner of Spark One Solutions, LLC based in Dallas, TX – a marketing and business solutions consulting company based serving HVAC businesses.

She serves as a member of the AHR Expo Expert Council – a collaboration of HVACR experts and thought leaders launched by the AHR Expo in 2019 to educate and stimulate discussion concerning the biggest issues impacting the industry.

She has a mechanical engineering degree from the University of Central Florida and is a licensed PE. She has 10 years of experience in the HVAC industry and is most well-known for bringing new HVAC products to life.

Pam will be speaking more in-depth on this topic at AHR Expo 2020, and it will be a free session with attendee registration. Register HERE.

Residential plumbing and HVAC installers take note: you can pipe an entire home with the durability, flexibility and cost-effectiveness of PEX — for plumbing, fire sprinkler systems and radiant floor heating. Here’s how… PEX plumbing With more new homes plumbed with PEX than copper and CPVC combined, you’re probably already aware of the benefits of Read more

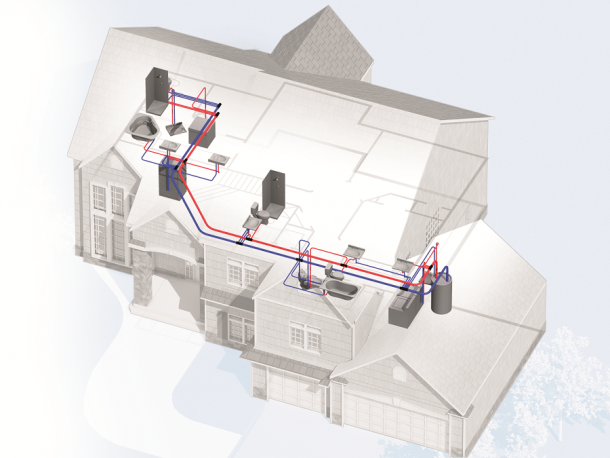

Residential plumbing and HVAC installers take note: you can pipe an entire home with the durability, flexibility and cost-effectiveness of PEX — for plumbing, fire sprinkler systems and radiant floor heating.

Here’s how…

PEX plumbing

With more new homes plumbed with PEX than copper and CPVC combined, you’re probably already aware of the benefits of plumbing with PEX. However, you may not know about a newer, smarter way to install a PEX plumbing system that goes in faster, uses less materials, requires fewer connections and minimizes your liability.

With more new homes plumbed with PEX than copper and CPVC combined, you’re probably already aware of the benefits of plumbing with PEX. However, you may not know about a newer, smarter way to install a PEX plumbing system that goes in faster, uses less materials, requires fewer connections and minimizes your liability.

This innovative design is called Logic plumbing.

The Logic approach uses the flexibility of PEX pipe to minimize connections and reduce potential leak points while also incorporating multiport tees located near fixture groupings to limit the amount of pipe and connections needed.

What’s a multiport tee, you ask? It’s essentially a bunch of tees all molded together to create one long tee with multiple outlets. This design greatly reduces the number of fittings and connections needed to plumb a home (think: reduced materials cost and labor time).

Here’s an example of how a multiport tee saves installation time and materials: a flow-through multiport tee with six outlets has eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Six regular tees, on the other hand, have a whopping 18 connections. That’s an increase of more than double the connections — and double the installation time.

Here’s an example of how a multiport tee saves installation time and materials: a flow-through multiport tee with six outlets has eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Six regular tees, on the other hand, have a whopping 18 connections. That’s an increase of more than double the connections — and double the installation time.

Best of all, multiport tees are not considered manifolds, so they can be installed behind walls without the need for an access panel. Double win, there!

For a Logic layout, a main line connects to a multiport tee with distribution lines going out from the multiport to provide water to all fixtures in a single or adjacent grouping. This design uses significantly less pipe than a home-run layout, with just a few more connections. Plus, it requires considerably fewer connections compared to a trunk-and-branch installation.

For example, a 2,300-square-foot, two-story home using a Logic design requires only 637 feet of pipe while a home-run system uses 1,515 feet of pipe. And, while it’s true a Logic installation uses slightly more connections than a home-run layout (59 vs. 48 in the 2,300-square-foot, two-story home example), the amount of pipe savings is significantly more beneficial with the labor and material savings you get with less pipe to install.

A Logic layout also installs much faster compared to a trunk-and-branch system due to the vast reduction in connections. With the two-story home example, a Logic layout uses a mere 16 fittings and 59 connections compared to a whopping 96 fittings and 165 connections for trunk and branch.

PEX multipurpose fire sprinkler systems

If you’re a licensed plumber who wants to add an additional service to your offering, check out PEX multipurpose fire sprinkler systems. These systems combine the fire sprinklers with a home’s cold-water plumbing. It’s genius!

If you’re a licensed plumber who wants to add an additional service to your offering, check out PEX multipurpose fire sprinkler systems. These systems combine the fire sprinklers with a home’s cold-water plumbing. It’s genius!

Installation is remarkably easy — the sprinkler is essentially just another fixture to tie into the plumbing line. For most contractors who already install PEX plumbing systems and have the tools, knowledge and, most importantly, the relationships with the home builders, this is a slam dunk.

Depending on the jurisdiction, multipurpose systems typically don’t need check valves or backflow preventers, and because they combine with the potable plumbing, they don’t use antifreeze, so all those added costs are eliminated.

To get started in most jurisdictions, licensed plumbers just need the appropriate training and a quality design that meets the NFPA 13D standard requirements for home fire sprinkler systems.

If you’re interested in learning more, email me at kim.bliss@uponor.com, and I can get you all the information you need to add this profitable new service to your business.

PEX hydronic radiant floor heating

There’s nothing like the comfort of radiant floor heating — ask anyone who has experienced it. And, homeowners will pay nicely for a quality radiant floor heating system, so there is definitely income potential if you can learn to do it right.

That said, with radiant floor heating, there’s a little more to learn. But, like fire sprinkler systems, starting with a proper design is key. If your design is wrong in the beginning, there’s not much you can do to fix the system once it’s installed.

That said, with radiant floor heating, there’s a little more to learn. But, like fire sprinkler systems, starting with a proper design is key. If your design is wrong in the beginning, there’s not much you can do to fix the system once it’s installed.

Take advantage of the radiant design services many PEX manufacturers offer to guide you through the process. There are several design factors to know, including floor R-values, heat-loss calculations, pipe sizing, loop lengths, pump sizing, manifold types and more.

Once you learn the basics of radiant design and get a few small jobs under your belt, you have the potential to take your expertise to the next level with bigger, more profitable projects. But again, be sure to get the proper design and training before you tackle a radiant project. It will be well worth it in the long run.

To get a jumpstart on all things radiant, visit the following industry websites at radiantprofessionalsalliance.org, healthyheating.com or heatinghelp.com.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.