Cutting-edge greenfield plant produces STERLING brand bathing and showering products to meet growing demand and enhance customer experience Kohler Co., a global leader in kitchen and bath products headquartered in Kohler, Wisconsin, officially opened the doors to its new manufacturing facility in Casa Grande, Arizona, with a ceremonial ribbon-cutting event hosted by company leadership. Among Read more

Industry News

Cutting-edge greenfield plant produces STERLING brand bathing and showering products to meet growing demand and enhance customer experience

Kohler Co., a global leader in kitchen and bath products headquartered in Kohler, Wisconsin, officially opened the doors to its new manufacturing facility in Casa Grande, Arizona, with a ceremonial ribbon-cutting event hosted by company leadership. Among those in attendance were Arizona Governor Katie Hobbs, some of the new Kohler associates filling more than 400 full-time administrative and production positions, state and local officials, and Kohler customers.

The facility produces STERLING brand bath and shower fixtures and is approximately one million square feet on 216 acres with room for future expansion. The multi-million dollar capital investment features an innovative manufacturing facility, ancillary warehouse, distribution center, office space, and cafeterias. The site also includes a best-in-class showroom for customers and visitors to view leading-edge products.

“Arizona is a recognized hub of excellence for manufacturing, innovation, and sustainability, all of which are enhanced by the addition of Kohler’s new state-of-the-art facility,” said Arizona Governor Katie Hobbs. “As one of the world’s most recognized brands known for its commitment to sustainability and innovation, Kohler strengthens Arizona’s rapidly growing manufacturing industry.”

The ceremony was attended by Arizona Governor Katie Hobbs, Kohler Chair and CEO David Kohler, company leaders and associates, state and local officials, and Kohler customers. Participating in the ribbon cutting were: (left to right) Tracy Jaeger, VP & GM of Bathing & Showering – Kohler Co.; John Bishopp, Plant Manager – Kohler Co.; Casa Grande Mayor Craig McFarland; Governor Katie Hobbs; David Kohler, Chair & CEO of Kohler Co.; Laura Kohler, Chief Sustainable Living Officer – Kohler Co.; Norb Schmidt, President of Kitchen & Bath North America – Kohler Co.; Sandra Watson, President and CEO of the Arizona Commerce Authority; Heath Holtz, Chief Operations & Supply Chain Officer – Kohler Co.; and David Mortenson, Chairman – Mortensen.

“We welcome our new associates to Kohler Co. and look forward to being an active participant in the greater Casa Grande community, contributing to its growing economy and quality of life, providing good-paying jobs and benefits, and offering opportunities for career development and advancement,” said Norbert Schmidt, President-Kitchen & Bath North America for Kohler. “The new plant provides the capacity to support our strong growth projections for STERLING to better serve our customers with the highest level of quality and delivery. We thank our loyal customers and partners who have been crucial in helping to build our STERLING business to what it is today.”

The plant incorporates smart factory elements and production technology that create durable and stylish baths, shower receptors, and bath/shower walls. The company will also track key sustainability measures to minimize greenhouse gas emissions, water use, solid waste, as well as energy efficiency.

In March, Kohler was selected by the U.S. Department of Energy (DOE) Office of Clean Energy Demonstrations to begin award negotiations for up to $51.2 million, matched by company investment, to demonstrate a commercial scale decarbonization solution at the Casa Grande plant.

Kohler is pursuing an electric boiler and microgrid system and expects the upgrades to prevent at least 7,865 MT CO2e from being released annually. This represents a reduction of at least 90% of the pressing process emissions by eliminating CO2e emissions from natural gas boilers. Kohler will incorporate electric boilers, install a 21MW solar array microgrid, utilize long-duration energy storage (LDES) batteries with 68MWh of storage, and install 12MW of HVO-capable KOHLER industrial backup generators. The LDES batteries coupled with advanced microgrid controls eliminate all possible solar curtailment scenarios and enable the facility to run the boilers on renewable energy while performing solar smoothing, thereby reducing carbon emissions.

Additionally in 2023, Kohler supported a multi-year project led by Bonneville Environmental Foundation, Arizona State University, and Bridgestone to convert high water use crops to low water use crops to alleviate water stress on the local aquifers.

“The City of Casa Grande welcomes Kohler Company with open arms and is pleased that the organization has invested in us for the long-term. A global force in kitchen and bath, Kohler has established itself as a highly successful forward-thinking organization that cares for and contributes to its local communities,” said Craig McFarland, Mayor of Casa Grande. “We are proud to have Kohler as an integral member of our community.”

“Kohler’s new facility is a significant win for Casa Grande and Arizona,” said Sandra Watson, President and CEO of the Arizona Commerce Authority. “Kohler’s sustainable manufacturing facility showcases Arizona’s attractiveness as a premier global destination for advanced manufacturing. We’re grateful an iconic company like Kohler is investing in our state while creating hundreds of skilled jobs in rural Arizona.”

“In opening this massive factory in Casa Grande, Kohler is capitalizing on the advantages Greater Phoenix offers in serving its customer base in the western U.S.,” said Chris Camacho, Greater Phoenix Economic Council President & CEO. “This globally recognized brand has found a home for manufacturing, warehousing and office space, and we’re thrilled to officially welcome them into the market.”

Malco Tools, one of the nation’s leading solution developers and manufacturers of a variety of high-quality tools for the HVAC and building construction trades, has been named a 2024 Minnesota Manufacturing Award winner from the Minneapolis/St. Paul Business Journal. For the second time since 2018, Malco has been named Manufacturer of the Year in the medium-sized Read more

Malco Tools, one of the nation’s leading solution developers and manufacturers of a variety of high-quality tools for the HVAC and building construction trades, has been named a 2024 Minnesota Manufacturing Award winner from the Minneapolis/St. Paul Business Journal.

For the second time since 2018, Malco has been named Manufacturer of the Year in the medium-sized business category. The awards celebrate the successes and contributions of leading manufacturers to the region’s economy.

Malco, which employs 150+ associates at its plant in Annandale, is a 100% employee-owned employee stock ownership plan (ESOP) company. Malco aims to be a destination company in central Minnesota and has made many significant positive changes to the business to achieve this goal, including setting new company core values and an internal “Look Good, Feel Good, Do Good” campaign to renovate workspaces, promote employee collaboration and wellbeing, and give back to the community.

Since its last Manufacturer of the Year award win, Malco has welcomed a new leadership team and strategic board members focused on driving measured and strategic growth, and strengthening the brand as it expands its product lines.

“Earning this recognition is such an honor, and an amazing way to celebrate the entire team’s work over the years to strengthen our internal culture, improve processes and bring in strategic experts to help guide our growth, all while maintaining our commitment to developing and manufacturing the highest quality tools for skilled trade pros,” said Rich Benninghoff, president and CEO at Malco. “We are immensely proud to once again be recognized among the leading manufacturers in the state of Minnesota who are doing fantastic work and promoting our local manufacturing industry.”

Malco is also a strong advocate for trade careers, donating significant quantities of in-kind products and apparel annually to national skilled trade education programs, competitions and events. Malco has also reached 85,000+ vocational students through its national “Head of the Class” Student Recognition Program, partnering with educators to recognize high-potential students and entire graduating classes in the trades.

Malco celebrates a safety-first culture, continuously maintaining its OSHA Safety and Health Achievement Recognition Program (MNSHARP) recognition since 2004, and earning the Minnesota Safety Council’s Governor’s Safety Award 13 times in the last 20 years.

Additionally, Malco is transitioning to environmentally-friendly recyclable packaging materials with significantly less plastic, reducing waste, conserving resources, and lessening its environmental impact.

Malco will be profiled in the July 19 issue of the Minneapolis/St. Paul Business Journal, and more information about the award can be found here.

For more information about Malco Tools, visit www.malcotools.com.

“More Time, More Money and More Peace of Mind” was the theme of the Plumbing-Heating-Cooling Contractors—National Association (PHCC) Educational Foundation’s popular Creating Super Foremen class held last week. A packed classroom of twenty-seven attendees engaged in a highly interactive and intense two-day workshop conducted May 3-4. The event was held at the Viega Training Facility in Nashua, New Read more

“More Time, More Money and More Peace of Mind” was the theme of the Plumbing-Heating-Cooling Contractors—National Association (PHCC) Educational Foundation’s popular Creating Super Foremen class held last week. A packed classroom of twenty-seven attendees engaged in a highly interactive and intense two-day workshop conducted May 3-4. The event was held at the Viega Training Facility in Nashua, New Hampshire, with lead instruction from Purdue University Professor Emeritus Kirk Alter.

Effective time management is a direct strategy for success and Alter gave attendees an insightful introduction to some of technology’s newest offerings that can save time. By showing the class how they could harness artificial intelligence (AI) tools in their day-to-day work, he opened their eyes to the possibilities. Attendees experimented with prompts to use in ChatGPT when starting a budget analysis and saw how the chatbot can save time when gathering project information, writing emails, and even creating a 5-year career plan.

The second part of the theme was captured by a key question asked by Alter: “How do you make money?” His answer: “By solving other people’s problems.” For foremen, that means becoming effective front-line managers. “As the subcontractor business owner, I am handing my wallet to you, my foreman, every single day,” Alter explained. “If you are asking good questions, managing with numbers and making the best decisions you can with the information you have, it will absolutely show in the results for your jobs. What do think that will do to your career path at my company?”

Finally, Alter illustrated how foremen can face fewer surprises and have more peace of mind. This breakthrough came when Alter introduced attendees to the importance of using spreadsheets to analyze the status of a construction project. Groups worked independently one evening on analyzing the numbers. The next day Alter led the class through an activity where they experienced firsthand how to extract details about labor productivity, management decisions, and where things went wrong.

“You get frustrated on your jobs because of surprises, but if you know how to read the numbers, the whole story is there,” he said. “Being able to spot productivity issues or other problems early will help you to solve those issues when you still have time to recover. That is going to make your jobs and your life so much easier.”

Foremen are problem-solvers who can impact a company’s success. After two days of ‘aha’ moments, the PHCC Super Foremen class left equipped with new strategies to achieve three things that drive success: more time, more money and more peace of mind.

Viega sponsored and hosted the foremen class at their New Hampshire Training Facility, providing the training room, A/V, meals for the attendees and more. “We are very grateful for Viega’s support for this class. As in past years, the attendees expressed how great of an experience this class is and how seamless Viega makes it to learn in their classroom space,” said John Zink, Vice President of Development and Communications, PHCC Educational Foundation.

Project managers and foremen who wish to register for future class offerings of the Foundation can add their names to the notification lists at https://phccfoundation.org/essentials.

Bradford White was once again a proud sponsor of the For Pete’s Sake Cancer Respite Foundation Walk on Sunday, April 28th. This annual fundraiser takes place at Citizens Bank Park and home of the Philadelphia Phillies. Several Bradford White employees and their families participated in this meaningful event to support For Pete’s Sake which provides much needed respite Read more

Bradford White was once again a proud sponsor of the For Pete’s Sake Cancer Respite Foundation Walk on Sunday, April 28th.

This annual fundraiser takes place at Citizens Bank Park and home of the Philadelphia Phillies. Several Bradford White employees and their families participated in this meaningful event to support For Pete’s Sake which provides much needed respite experiences for families during their cancer journey.

For more information visit: https://takeabreakfromcancer.org/

For more information about Bradford White, visit: https://www.bradfordwhite.com/.

US Military Veterans Are Offered Special Hours to Help with Job Search To coincide with Military Appreciation month in May 2024, PumpMan, a leading provider of onsite maintenance, repair, and replacement of equipment used in water and wastewater systems, proudly announces that it will establish a special recruitment call center for US Military Veterans who Read more

US Military Veterans Are Offered Special Hours to Help with Job Search

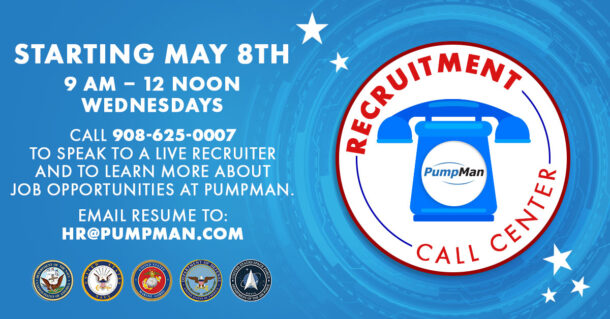

To coincide with Military Appreciation month in May 2024, PumpMan, a leading provider of onsite maintenance, repair, and replacement of equipment used in water and wastewater systems, proudly announces that it will establish a special recruitment call center for US Military Veterans who are seeking employment. Veterans are encouraged to call in order to learn about the opportunities available throughout the PumpMan organization and to have a personal conversation with a PumpMan associate who can answer any questions they may have.

“At PumpMan, we value our veterans, and we greatly appreciate their service to our country,” said Donald C. Devine, chief executive officer, PumpMan, and a West Point graduate. “We have veterans working at all levels of leadership, as well as in our field operations, and we want to extend our heartfelt invitation to explore the possibilities of joining us! At PumpMan, we pride ourselves at creating a work environment that fosters and supports rewarding and successful careers for our employees. If there are veterans who are looking for employment, we urge them to take advantage of this unique opportunity during the month of May. We look forward to speaking with you and to welcoming you into the PumpMan community.”

The Call Center will be open on Wednesdays, from 9am – 12noon, EST during the month of May 2024 starting May 8th. Interested veterans should call (908) 625-0007. Additionally, US Military veterans can email their resume and questions to HR@pumpman.com.