Offerings now include new MegaPress®G valves for gas applications Viega LLC, the leader in pressing technology and systems, is now the single solution for press valves. Viega is introducing an entirely new line of MegaPress®G valves in sizes 1⁄2″ to 2″. These valves, like MegaPressG press fittings, are approved for use in gas and fuel Read more

Product Spotlight

Offerings now include new MegaPress®G valves for gas applications

Viega LLC, the leader in pressing technology and systems, is now the single solution for press valves.

Viega is introducing an entirely new line of MegaPress®G valves in sizes 1⁄2″ to 2″. These valves, like MegaPressG press fittings, are approved for use in gas and fuel oil applications. The valves are suitable for use with ASTM Schedule 5 to Schedule 40 carbon steel pipe.

Viega also is launching larger sizes of its MegaPress 3-piece ball valves, the first press ball valve of its kind in the 21⁄2″ to 4″ range.

In addition, ProPress® valves are now available in sizes 21⁄2″ to 4″ for use with copper and stainless CTS pipes.

The new valves are approved for more commercial, industrial and residential applications than any other system. All Viega valves are equipped with Smart Connect technology, which makes it easier to find unpressed connections.

Regardless of the application or product line, using Viega valves and fittings means no open flames, faster connections and greater labor savings, resulting in safer and more efficient projects that come in on time and on budget.

“The addition of our new valves means customers will no longer have to pair Viega fittings with valves from other manufacturers. Instead, they can install a complete Viega system with the confidence that valves and fittings are designed and engineered for each other and will deliver the highest quality in the industry,” said Luke Paulo, manager of product portfolio development.

To learn more about Viega valves, click here.

New convenient and efficient electric water heater delivers high performance and reliability along with continuous on-demand hot water Bradford White Water Heaters, an industry-leading manufacturer of residential and commercial water heating and storage products, introduces the KwickShot®, a reliable and easily installed tankless electric water heater available in thermostatic and non-thermostatic models to meet a range Read more

New convenient and efficient electric water heater delivers high performance and reliability along with continuous on-demand hot water

Bradford White Water Heaters, an industry-leading manufacturer of residential and commercial water heating and storage products, introduces the KwickShot®, a reliable and easily installed tankless electric water heater available in thermostatic and non-thermostatic models to meet a range of water temperature needs in a variety of everyday applications.

With on-demand hot water and continuous water flow, KwickShot® ensures hot water is instantly available for kitchens, bathrooms, utility sinks, wet bars and other household needs. KwickShot® offers speed and reliability combined with premier high performance.

With on-demand hot water and continuous water flow, KwickShot® ensures hot water is instantly available for kitchens, bathrooms, utility sinks, wet bars and other household needs. KwickShot® offers speed and reliability combined with premier high performance.

“The KwickShot® is a great option for anyone looking for a tankless electric water heater,” said Louise Prader, senior director-product management for Bradford White. “From installation to upkeep, the KwickShot® offers reliable hot water with the ease of a compact unit. Customers can also rest easy knowing Bradford White is available to answer any questions they may have.”

The KwickShot® provides silent operation and its compact size delivers easy installation, flexibility and convenient access for maintenance. Intelligent controls provide active protection and self-diagnostics. Dry-fire protection prevents potential equipment damage, and the heater’s high temperature limit ensures safe operation in a variety of conditions.

The Kwickshot® tankless electric water heater also includes:

- A safe control system that activates the heater only on demand.

- An LED indicator communicates system status and heater operation feedback.

- A five-year limited warranty on leaks and one-year warranty on parts.

To learn more about Bradford White Water Heaters, please visit https://www.bradfordwhite.com or call (215) 641-9400.

About Bradford White Water Heaters

Bradford White Water Heaters is a full-line manufacturer of residential, commercial and industrial water heating, space heating, combination heating and storage products. The company maintains headquarters in Ambler, Pennsylvania, and has manufacturing facilities in Middleville, Michigan; Niles, Michigan; and Rochester, New Hampshire; and distribution and training centers in Halton Hills, Ontario, Canada. For more information, visit www.bradfordwhite.com.

New convenient and efficient electric water heater delivers high performance and reliability along with continuous on-demand hot water

Bradford White Water Heaters, an industry-leading manufacturer of residential and commercial water heating and storage products, introduces the KwickShot®, a reliable and easily installed tankless electric water heater available in thermostatic and non-thermostatic models to meet a range of water temperature needs in a variety of everyday applications.

With on-demand hot water and continuous water flow, KwickShot® ensures hot water is instantly available for kitchens, bathrooms, utility sinks, wet bars and other household needs. KwickShot® offers speed and reliability combined with premier high performance.

“The KwickShot® is a great option for anyone looking for a tankless electric water heater,” said Louise Prader, senior director-product management for Bradford White. “From installation to upkeep, the KwickShot® offers reliable hot water with the ease of a compact unit. Customers can also rest easy knowing Bradford White is available to answer any questions they may have.”

The KwickShot® provides silent operation and its compact size delivers easy installation, flexibility and convenient access for maintenance. Intelligent controls provide active protection and self-diagnostics. Dry-fire protection prevents potential equipment damage, and the heater’s high temperature limit ensures safe operation in a variety of conditions.

The Kwickshot® tankless electric water heater also includes:

- A safe control system that activates the heater only on demand.

- An LED indicator communicates system status and heater operation feedback.

- A five-year limited warranty on leaks and one-year warranty on parts.

To learn more about Bradford White Water Heaters, please visit https://www.bradfordwhite.com or call (215) 641-9400.

About Bradford White Water Heaters

Bradford White Water Heaters is a full-line manufacturer of residential, commercial and industrial water heating, space heating, combination heating and storage products. The company maintains headquarters in Ambler, Pennsylvania, and has manufacturing facilities in Middleville, Michigan; Niles, Michigan; and Rochester, New Hampshire; and distribution and training centers in Halton Hills, Ontario, Canada. For more information, visit www.bradfordwhite.com.

App Designed to Support Performance, Productivity and Profitability of Contractor Businesses A new app to support Weil-McLain® will help turn technicians into hydronics experts by putting a variety of Weil-McLain boiler product information at their fingertips. The Weil-McLain ProTools™App, available for iOS and Android devices, allows contractors and other heating professionals to conveniently access information on Weil-McLain Read more

App Designed to Support Performance, Productivity and Profitability of Contractor Businesses

A new app to support Weil-McLain® will help turn technicians into hydronics experts by putting a variety of Weil-McLain boiler product information at their fingertips. The Weil-McLain ProTools™App, available for iOS and Android devices, allows contractors and other heating professionals to conveniently access information on Weil-McLain boiler setup, maintenance and troubleshooting.

“Contractors trust Weil-McLain to support the performance, productivity and profitability of their businesses and this new app is designed to do just that,” said David DeVries, Director of Product Management with Weil-McLain.

The Weil-McLain ProTools App, developed based on extensive contractor research, helps spotlight the contractor’s hydronic expertise and will streamline technician’s customer visits to provide clients with a premium and differentiated experience.

“We talked to contractors to determine the issues they wanted to solve and the help they needed to make their jobs easier, and we focused on that feedback to develop this app,” said DeVries. “The result is a one-stop resource for what contractors need today – whether it’s contacting the right person for customer support, checking a warranty, finding troubleshooting information or getting to the right page of the boiler manual quickly.”

The new app puts users in control of the boiler maintenance and monitoring experience through several key features:

- Troubleshoot – Review fault codes for troubleshooting that go straight to the proper manual page for next steps.

- Find Parts – Find parts quickly and easily by model with illustrations.

- Review Technical Manuals – Quickly view product manuals, schematics, wire diagrams, maintenance, annual start-up and product brochures.

- Get Tech Support – Connect to technical support by phone, email, chat or video call.

- Retrieve Warranties – Register a product or review a warranty statement by scanning a convenient CP# on the boiler.

- Watch How-To Videos – Look up videos by boiler model for detailed instructions.

Future upgrades to the app in early 2022 will include Bluetooth connectivity to Weil-McLain boilers like the ECO Tec® line that will allow contractors and technicians to conduct additional functions.

“Our goal is to continuously build on this platform by adding additional features that will make our technicians’ and contractors’ jobs easier moving forward,” added DeVries.

Weil-McLain will showcase the new ProTools App at the Weil-McLain booth #C1516 at the AHR Expo, Jan. 31 – Feb. 2 at the Las Vegas Convention Center. For more information on the new Weil-McLain ProTools App, visit www.weil-mclain.com or download the app via the App Store.

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter. https://youtu.be/pmZaip09_kA The drain makes it simple Read more

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter.

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter.

The drain makes it simple to remove accumulation, with a strapped cap that can be used to actuate the drain valve and a large filter body that increases time between service. A service tool is also included to help install and maintain the filter with ease. G-threads make it simple to swap out your choice of press, MIP, FIP, or sweat G-union end connections in sizes 1¼” or 1½”. The MBF XL can withstand 250°F and 145 PSI CWP.

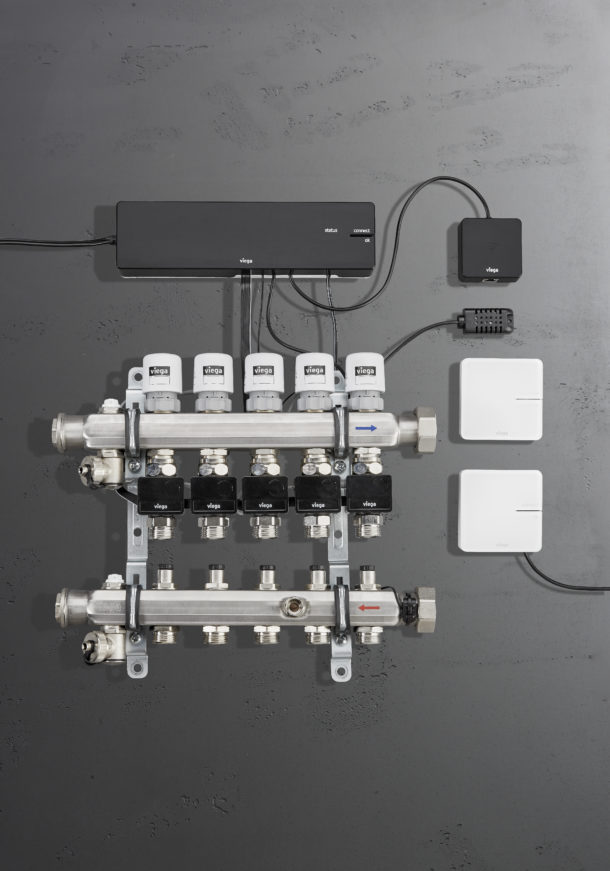

First technology to allow monitoring of every return circuit in a radiant system Viega LLC’s new Radiant Auto-Balancing System (RABS) delivers an unprecedented level of control and consistency in radiant heating systems. RABS gives users for the first time the ability to independently control each zone in a radiant heating system. Balancing valves are not Read more

First technology to allow monitoring of every return circuit in a radiant system

Viega LLC’s new Radiant Auto-Balancing System (RABS) delivers an unprecedented level of control and consistency in radiant heating systems.

RABS gives users for the first time the ability to independently control each zone in a radiant heating system. Balancing valves are not required and installers can commission as many as eight thermostats and 12 circuits per control unit. RABS achieves the desired temperature in each zone by analyzing the supply water temperature, each circuit’s return temperature and zone air temperatures where a wireless thermostat is used. The system offers four operation methods that complement each other.

“Achieving and maintaining consistent temperatures through multiple zones has been a challenge for radiant heating systems. RABS automates and digitizes the process, which helps installers and users alike,” said Adam Botts, Portfolio Manager.

RABS compensates for system inconsistencies and imperfections like:

- Different circuit lengths or tube sizes

- Varying installation clearances or tube depths/spacing

- Change of floor coverings

- Fluctuating supply temperatures, outdoor temperatures or external heat sources

In addition, a web-based app-enabled control lets users to manage the system from anywhere in the world. It allows remote control of power levels, thermostats and operation software. A local device can access the web app or it can be accessed remotely via the internet.

For more information about RABS, click here.