As soon as Viega LLC introduced its MegaPressG fitting system for joining gas and fuel oil pipes, contractors began asking for it in larger sizes. The original lineup included fittings for carbon steel pipes from ½” to 2″. They were the first fittings approved for use in gas and fuel oil applications and they quickly Read more

Product Spotlight

As soon as Viega LLC introduced its MegaPressG fitting system for joining gas and fuel oil pipes, contractors began asking for it in larger sizes.

The original lineup included fittings for carbon steel pipes from ½” to 2″. They were the first fittings approved for use in gas and fuel oil applications and they quickly proved popular among contractors for their speed, reliability and ease of use. However, the 2″ limit restricted the number of applications in which they could be used.

In February, Viega introduced MegaPressG fittings for 2½”, 3″ and 4″ pipe, creating a comprehensive lineup of fittings approved for use in gas and fuel oil applications. And it’s the only system on the market that allows secure press connections on gas lines 2½” to 4″ in 16 seconds or less.

Constructed of carbon steel with a corrosion-resistant zinc nickel coating and first-of-its-kind graphite separator ring in larger sizes, MegaPressG is suitable for use with ASTM Schedule 5 to Schedule 40 carbon steel pipe

Using MegaPressG means no open flames, faster connections and labor savings, resulting in safer and more efficient projects that come in on time and on budget. It can reduce labor costs by as much as 60% to 90% over traditional methods.

Configurations include elbows, couplings, no-stop couplings, reducers, tees, reducing tees, adapters, reducing adapters, caps and flanges.

Combining productivity with peace of mind, MegaPressG fittings are equipped with Viega Smart Connect® technology, which allows installers to easily identify unpressed connections during pressure testing.

MegaPressG fittings offer the same proven quality and durability as all Viega products, bringing complete confidence to every job.

For more information on the new line of MegaPressG fittings, click here.

Taco Comfort Solutions’ Near-Boiler Trim Kit provides a quick and convenient way to purchase all the accessories needed for near-boiler piping. The Near-Boiler Trim Kit comes in premium, advanced and select configurations, and is available in 1” and 1-1/4” sizes so installers can select the kit that fits their needs. All versions of the kit Read more

Taco Comfort Solutions’ Near-Boiler Trim Kit provides a quick and convenient way to purchase all the accessories needed for near-boiler piping.

Taco Comfort Solutions’ Near-Boiler Trim Kit provides a quick and convenient way to purchase all the accessories needed for near-boiler piping.

The Near-Boiler Trim Kit comes in premium, advanced and select configurations, and is available in 1” and 1-1/4” sizes so installers can select the kit that fits their needs. All versions of the kit include air separators, boiler feed and backflow preventer, 4.5-gallon expansion tanks, and all fittings and connections.

The trim kits are designed for easy installation and are ASSE listed.

For more information, visit www.TacoComfort.com

Navien introduced three new innovative products in booth 1573 during AHR 2020 in Orlando, FL. The new NPN series non-condensing tankless water heaters, NPE-2 series condensing tankless water heaters and NCB-H series condensing combi-boilers were all displayed at the front of the Navien booth inside the Orange County Convention Center for attendees to get a Read more

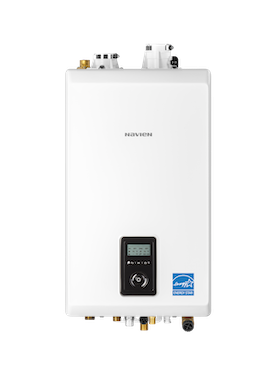

NPN-Universal

Navien introduced three new innovative products in booth 1573 during AHR 2020 in Orlando, FL. The new NPN series non-condensing tankless water heaters, NPE-2 series condensing tankless water heaters and NCB-H series condensing combi-boilers were all displayed at the front of the Navien booth inside the Orange County Convention Center for attendees to get a first look at the technological advancements within each series.

Available in the NPN-Universal series (indoor or outdoor with vent cap) and NPN-Exterior series (outdoor only), Navien utilizes the technology and innovation that helped make the NPE series the number one condensing tankless water heater in North America in their new non-condensing NPN series, with some new additional features. The NPN series is the first and only non-condensing tankless series to offer NaviTech™ technology that includes a stainless-steel heat exchanger and an advanced stainless-steel burner with the same very low NOx level as the NPE. Both the NPN-U and NPN-E have built-in recirculation control, air pressure sensor, water adjustment valve and mixing valve, and are designed with a pin-to-pin matching configuration for easy retrofit installations.

NPE-2

The NPE-2 series brings the biggest update to condensing tankless water heaters since the NPE series changed the landscape of the industry in 2012. The new features found in the NPE-A2 and NPE-S2 series include a turndown ratio up to 15:1, an upgraded advanced multi-line control panel in plain English for easy set up, and increased 2” PVC venting length. The NPE-2 will continue to offer the high-efficiency features that made the NPE the number one selling condensing tankless water heater, such as dual stainless steel heat exchangers, half-inch gas pipe capability up to 24 feet, cascade and common vent capability, industry leading efficiency up to 0.97 UEF, and the patented ComfortFlow™ recirculation system with built-in pump and buffer tank on the NPE-A2.

NCB-H

NCB-H (high output) series condensing combi-boilers are packed with industry leading upgrades to the popular NCB-E series, including industry leading BTU output on DHW, 15:1 turndown ratio, a more dynamic BTU lineup with added models, greater DHW performance, a new DHW module with flow control, enhanced controls with multi-line text display, increased 2” PVC venting length, easy serviceability with upfront 3-way valve and built-in controls for up to 3 zones.

All three innovations are on display inside Navien booth 1573 at AHR in Orlando, FL until February 5, 2020. To learn more, visit NavienInc.com.

The new OmniTherm series of near condensing boilers and volume water heaters includes industry leading electronic air-to-fuel ratio control, long-life stainless steel heat exchangers, and the Laars Linc® icon-driven control system. OmniTherm units can easily be installed in Category I, II, III or IV vent systems for new or replacement applications. Laars Linc intuitive control Read more

The new OmniTherm series of near condensing boilers and volume water heaters includes industry leading electronic air-to-fuel ratio control, long-life stainless steel heat exchangers, and the Laars Linc® icon-driven control system. OmniTherm units can easily be installed in Category I, II, III or IV vent systems for new or replacement applications.

The new OmniTherm series of near condensing boilers and volume water heaters includes industry leading electronic air-to-fuel ratio control, long-life stainless steel heat exchangers, and the Laars Linc® icon-driven control system. OmniTherm units can easily be installed in Category I, II, III or IV vent systems for new or replacement applications.

Laars Linc intuitive control system with color touchscreen has an easy to navigate control structure that displays key performance measures, a quick start option, and a USB input for parameter upload. It easily connects to building automation systems via BACnet, and has many other features including the ability to cascade up to 8 units.

Available in six sizes from 1250 to 3000 MBH, Laars OmniTherm units offer up to 7:1 turndown, thermal efficiencies as high as 87%, and can be installed in low return water temperature applications.

Learn more at www.laars.com

Viega MegaPressG with an HNBR sealing element is the first press fitting system for carbon steel pipe approved for use in gas and fuel oil applications. Viega MegaPressG is ideal for industrial, commercial and residential applications and performs well in both new installations and retrofit projects. Tested to the strictest standards in North America, Viega MegaPressG joins carbon Read more

Viega MegaPressG with an HNBR sealing element is the first press fitting system for carbon steel pipe approved for use in gas and fuel oil applications. Viega MegaPressG is ideal for industrial, commercial and residential applications and performs well in both new installations and retrofit projects.

Tested to the strictest standards in North America, Viega MegaPressG joins carbon steel pipe reliably through the engineered design of the fittings and a battery-powered press tool. Not approved for use with potable water.

• Suitable for use with ASTM Schedule 5 to Schedule 40 carbon steel pipe as allowed by local code.

• With an HBR sealing element, MegaPressG is the first press fitting approved for carbon steel pipe approved for use in gas and fuel oil applications.

• The Viega Pressgun 6 with an actuator and ring makes press connections up to 2″. Connections 2 1/2″ up to 4″ can be made with the use of the Z3 actuator or booster with the appropriate tools.

FEATURES AND BENEFITS

- Engineered with a 420 stainless steel grip ring plus a 304 stainless steel separator ring for sizes ½” to 2″ and a graphite separator ring for sizes 2½” to 4″

- Approved for more applications than any other carbon steel

pipe press fitting system - Suitable for use with ASTM Schedule 5 to Schedule 40 carbon steel pipe in accordance with AHJ requirements

- Corrosion-resistant zinc nickel coating

- More than 200 engineered fitting configurations from ½” to 4″

- Approved for underground applications in accordance with

code and local AHJ - The same hanger and support requirements as threaded systems

- Patented Smart Connect technology helps installers easily identify unpressed connections, providing increased confidence in the integrity of connections