The REHAU EVERLOC+® compression-sleeve fitting system has 26 additional configurations making transitions between pipe sizes more convenient in plumbing and hydronic piping. The system comprises RAUPEX® PEXa pipe in 3/8 to 2-in. diameters, polymer and lead-free brass fittings and power tools for reliable, safe and cost-competitive connections. Designed for no-leak security, the two-step fitting expansion Read more

Product Spotlight

The REHAU EVERLOC+® compression-sleeve fitting system has 26 additional configurations making transitions between pipe sizes more convenient in plumbing and hydronic piping. The system comprises RAUPEX® PEXa pipe in 3/8 to 2-in. diameters, polymer and lead-free brass fittings and power tools for reliable, safe and cost-competitive connections. Designed for no-leak security, the two-step fitting expansion and compression process is performed quickly in any weather, making installation faster than copper and other PEXa cold-expansion fittings. The NSF/ANSI 14&61-certified system delivers safe drinking water with no mineral build-up and is backed by a 25-year limited warranty.

The REHAU EVERLOC+® compression-sleeve fitting system has 26 additional configurations making transitions between pipe sizes more convenient in plumbing and hydronic piping. The system comprises RAUPEX® PEXa pipe in 3/8 to 2-in. diameters, polymer and lead-free brass fittings and power tools for reliable, safe and cost-competitive connections. Designed for no-leak security, the two-step fitting expansion and compression process is performed quickly in any weather, making installation faster than copper and other PEXa cold-expansion fittings. The NSF/ANSI 14&61-certified system delivers safe drinking water with no mineral build-up and is backed by a 25-year limited warranty.

Navien introduces the new NFC series stainless steel fire tube combi-boilers. This innovative product is available in two sizes, NFC-175 (175,000 BTU/H) and NFC-200 (199,900 BTU/H), with enough heating input for larger homes and continuous domestic hot water supply for up to three bathrooms. Best applications include retrofits and new installations in single-family homes, multi-family Read more

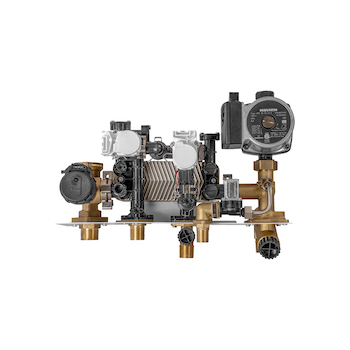

Navien introduces the new NFC series stainless steel fire tube combi-boilers. This innovative product is available in two sizes, NFC-175 (175,000 BTU/H) and NFC-200 (199,900 BTU/H), with enough heating input for larger homes and continuous domestic hot water supply for up to three bathrooms. Best applications include retrofits and new installations in single-family homes, multi-family houses, and light commercial buildings.

Navien introduces the new NFC series stainless steel fire tube combi-boilers. This innovative product is available in two sizes, NFC-175 (175,000 BTU/H) and NFC-200 (199,900 BTU/H), with enough heating input for larger homes and continuous domestic hot water supply for up to three bathrooms. Best applications include retrofits and new installations in single-family homes, multi-family houses, and light commercial buildings.

The new Navien NFC combi-boiler package comes with a patented in-house designed and manufactured heat exchanger, Low Profile Burner for ease of service, advanced controls offering intuitive user navigation, an advanced built-in DHW module (pump, flat plate heat exchanger, 3-way valve, mixing valve, water adjustment valve and auto water fill valve), common venting capability up to 8 units (1 NFC and 7 NPEs), cascading capability up to 16 units (1 NFC and 15 NPEs), and built-in hardware to connect up to 3 zone pumps without a need for additional external controllers. Plus, each unit ships with 16 accessories including a NaviClean™ magnetic filter, an isolation valve kit and an NFC primary loop manifold for easier installation.

Other NFC combi-boiler features include:

Other NFC combi-boiler features include:

- 5 modes of external domestic recirculation control built-in (Always on, Intelligent, Scheduling, HotButton, Aquastat)

- 95% AFUE for energy savings — Energy Star Most Efficient 2019

- 11:1 turndown ratio delivering wide operating range without cycling

- Low NOx < 20 ppm SCAQMD certification

- PVC, CPVC, polypropylene and stainless-steel venting materials up to 150 ft.

- Easy field convertibility from natural gas (NG) to propane (LP), conversion kit included

- High altitude approval for up to 10,100 ft.

- Modern space-saving design

- Easy access to all serviceable components

- Industry leading residential and commercial warranties

To learn more about the Navien NFC series fire tube boilers, visit NavienInc.com.

The redesigned Sanibest Pro from SFA Saniflo u.s.a. is the industry’s first and only 1-horsepower, upflush grinder system – with 25 percent more power than the previous generation. This enables home and business owners to confidently add a complete modern bathroom wherever it is impossible or cost-prohibitive to do so with conventional plumbing. Operating at Read more

The redesigned Sanibest Pro from SFA Saniflo u.s.a. is the industry’s first and only 1-horsepower, upflush grinder system – with 25 percent more power than the previous generation. This enables home and business owners to confidently add a complete modern bathroom wherever it is impossible or cost-prohibitive to do so with conventional plumbing.

The redesigned Sanibest Pro from SFA Saniflo u.s.a. is the industry’s first and only 1-horsepower, upflush grinder system – with 25 percent more power than the previous generation. This enables home and business owners to confidently add a complete modern bathroom wherever it is impossible or cost-prohibitive to do so with conventional plumbing.

Operating at 3,600 RPM (revolutions per minute) for rapid elimination of heavy-duty waste, the Sanibest Pro is designed for homes, as well as public restrooms in offices, schools, factories, restaurants, and any other situation where flushing sanitary items might be a concern. It pumps effluent higher and farther than other systems: up to 25 feet vertically when it is installed below the sewer line; or nearly 150 feet horizontally to the sewer stack. The stainless-steel grinder blade rotates against a stationary, perforated base plate, so that waste is quickly and easily dispersed through the base plate’s holes before being pumped into the 3/4-inch discharge line.

Using the two-inch inlets on either side of the unit, the Sanibest Pro can discharge waste water not only from a toilet, but also from two other fixtures, such as a sink, a bathtub, a shower or even a clothes washer (but always indirectly through a laundry tub). An integral check valve on the 3/4-inch discharge pipe conveniently rotates 360-degrees without any special tools to accommodate different installations. The top of the Sanibest Pro also features a service panel, allowing for easy access without removing current plumbing connections or disconnecting the entire unit from a toilet.

For more information, click here: www.saniflo.com

Viega, the leader in press fitting technology, is introducing MegaPress® Stainless XL® fittings for 2½”, 3″ and 4″ pipe. The new fittings join the current MegaPress Stainless offerings of ½”, ¾”, 1″, 1½” and 2″ sizes to create a comprehensive lineup for a broad variety of applications, including maintenance and repair. Designed for Iron Pipe Read more

Viega, the leader in press fitting technology, is introducing MegaPress® Stainless XL® fittings for 2½”, 3″ and 4″ pipe. The new fittings join the current MegaPress Stainless offerings of ½”, ¾”, 1″, 1½” and 2″ sizes to create a comprehensive lineup for a broad variety of applications, including maintenance and repair.

Designed for Iron Pipe Size (IPS) stainless steel, the new line of MegaPress Stainless XL fittings makes secure connections in seconds, which helps keep a project on time or ahead of schedule. MegaPress fittings reduce installation time by up to 90 percent compared to traditional pipe joining methods.

Designed for Iron Pipe Size (IPS) stainless steel, the new line of MegaPress Stainless XL fittings makes secure connections in seconds, which helps keep a project on time or ahead of schedule. MegaPress fittings reduce installation time by up to 90 percent compared to traditional pipe joining methods.

Combining productivity with peace of mind, MegaPress Stainless XL fittings are equipped with patented Viega Smart Connect® technology, which allows installers to easily identify unpressed connections during pressure testing. And MegaPress Stainless XL fittings offer the same proven quality and durability as all Viega products, bringing complete confidence to every job.

“Since Viega introduced MegaPress Stainless fittings in 2017, customers have been asking for them in larger sizes,” said Dominic Küng, Viega Product Manager for Metals. “The new XL fittings will allow customers to experience the same time savings and quality they expect from MegaPress fittings on an even greater number and variety of jobs.”

MegaPress Stainless XL fittings are available in 304 and 316 stainless steel and are approved for use with Schedule 10 to Schedule 40 pipe.

MegaPress Stainless XL fittings are available in 304 and 316 stainless steel and are approved for use with Schedule 10 to Schedule 40 pipe.

In addition to its stainless steel lineup, Viega also offers MegaPress fittings for carbon steel pipe up to 4″ and copper nickel alloy pipe up to 2″.

For more information on the new line of MegaPress Stainless XL fittings, visit www.viega.us/mpstainless.

NIBCO INC. announced that it has filled out its line of hydronic heating press-connect fittings, including two types of elbows and a fin tube stiffener. The additions include forged bronze vent elbows, a wrot copper extended elbow and a wrot copper fin tube stiffener. All of the products are lead-free. The PC-705-D forged bronze Press Read more

NIBCO INC. announced that it has filled out its line of hydronic heating press-connect fittings, including two types of elbows and a fin tube stiffener. The additions include forged bronze vent elbows, a wrot copper extended elbow and a wrot copper fin tube stiffener. All of the products are lead-free.

NIBCO INC. announced that it has filled out its line of hydronic heating press-connect fittings, including two types of elbows and a fin tube stiffener. The additions include forged bronze vent elbows, a wrot copper extended elbow and a wrot copper fin tube stiffener. All of the products are lead-free.

The PC-705-D forged bronze Press x Press 90° vent elbows are available in ½-inch and ¾-inch sizes. The vent elbows have been specifically designed for use in hydronic heat applications. They comply with the performance standards of ASME B16.51 and are third-party certified to UPC and PS-117. The elbows have an operating pressure 200 PSI and a temperature range -20°F to 250°F.

The PC607E-2 wrot copper 6-inch extended elbow comes in a ¾-inch Fitting x Press connection on a 90° elbow. The extended elbow has been specifically designed for use in heating applications to provide a clean transition through the floor or wall. The elbows have an operating pressure 200 PSI and a temperature range -20°F to 250°F.

The extended elbow is third-party certified to ASME B16.51, UPC and PS-117.

The wrot copper ¾-inch fin tube stiffener ensures secure connections with the extended elbow.

The NIBCO leak detection system identifies uncrimped connections during system testing. When properly crimped a unique “N” witness mark is clearly visible. The NIBCO® Press System® includes a complete line of fittings, valves, accessories and pressing tools.

Our copper press fittings, including our new extended elbow and fin tube stiffener, are manufactured in our Stuarts Draft, Virginia, facility from 100% North American pure copper. NIBCO has been manufacturing metal plumbing fittings in the United States since 1927.