By Norman Hall A competitor recently asked how we can afford to spend so much time and money training our employees and our customers. My response is, “How can you afford not to train your people?” I would argue that education should be a prominent expense item for all contractors, wholesalers, and representatives in the Read more

Uncategorized

By Norman Hall

A competitor recently asked how we can afford to spend so much time and money training our employees and our customers. My response is, “How can you afford not to train your people?” I would argue that education should be a prominent expense item for all contractors, wholesalers, and representatives in the HVAC and plumbing world. In this industry, where product and technical information can feel like a tsunami, customers rely on us to act as trusted advisors guiding them to the best solution. Our staff cannot simply exist as a walking, talking brochure. Arming our people with the knowledge and empowerment to think critically and to act with integrity has resulted in a thriving business and a dedicated customer base here at R.L. Deppmann.

“OK, Show Me the Boiler and I’ll Help you out.”

A few months ago, I was at lunch with a commercial mechanical contractor. By the way, it was a real lunch, not a Zoom meeting. The contractor started asking about the importance of the R. L. Deppmann seminar series for the winter season. He told me the story. Last fall he purchased some equipment for a project from a competitor. The equipment was installed and ran fine for a short time. In the spring he received a call from the owner. There were complaints of sporadic shutdowns of the boiler. The younger salesperson who took the original order was called out to the jobsite to assist in troubleshooting.

The rep stood in the mechanical room and asked the contractor to take him to the equipment with the trouble. The response was, “it’s right behind you.” Imagine the look on the contractor’s face. The young salesperson was embarrassed and the customer lost confidence. No one wants this to be a story in their company.

Starting in the Industry

Employees are valuable assets of any successful company. Today, it appears there are more positions available than people to fill them. The result is a younger work force that is changing jobs and careers. The person you are hiring may have little knowledge of the industry and certainly little knowledge of your company.

Exposing this new employee to knowledge about the company, the job, and the growth opportunities is paramount. The new employee will leave you or you may leave them if they are not successful in a short time. There is a roadmap to training if you are willing to invest in it.

The New Employee Education Road Map

Image Credit: Carbuyer

Our company, R. L. Deppmann, is a successful manufacturer’s representative of hydronic, steam, and plumbing products in Michigan and Ohio. Our customers call us to help them solve problems because we have, and teach, the knowledge they need. How does this happen? Our hiring pool on the sales and engineering end is no different than other companies, but the training program is.

- Start with core values and what the company is all about. Our new employees are purposely exposed to the company business and culture three times in the first few weeks of their career. The HR department presents, the managing supervisor presents, and a senior manager describes the business and culture.

- Know the team that supports you. Our customers are contractors, wholesalers, and owners. It is important for the new inside or outside salesperson to understand the various departments of support.

- The new sales rep spends a short time in the warehouse, learning, seeing, and touching the products. They also begin to learn the ERP and CRM systems.

- Next, they move into the startup and warranty (service) department. Here they begin to see installed products and how they are commissioned. With the Service Tech as their mentor, the employee will gather knowledge of the terms used in the industry, proper installation, and troubleshooting. There is also a chance to interface with customers.

- Customer service/inside sales is the next stop. Here they begin the process of satisfying customer requests. They learn product, parts, and our business systems. They work in a team with open conversation about the hundreds of different product types and customer issues. The employee learns to help the customer make a better decision about what they are asking for.

- We have a strong new construction business. The salesperson will learn the plans, specifications, proper selection and sizing, proper detailing to avoid issues, and pricing. Here there is the baseline process of speaking with contractors, wholesalers, engineers, and coordinating with other employees.

- By this time, the employee is well into their training period. They now go out on calls with a senior sales rep. They are prepared with some understanding of product, installation, troubleshooting, selection, and quoting. Daily discussions with the senior rep will fill in the features, benefit, and competitive landscape for company and individual success.

- Now the employee is prepared to be a resource for their customer. They understand who knows what and the resources available to satisfy the customer’s needs. The new employee feels like they are part of a team. They may have developed a friendship with other employees. They feel like they belong.

Getting Started: How to Create a Training Program

This program may seem difficult to start. We developed this over many years. The departments a new employee is exposed to changes with their job. An accounting employee will go through the core ideology training. They may not experience the customer service department but warehouse experience in return goods or the purchasing process knowledge may help them do their job better.

Start with that core ideology process. Make sure the employee understands who you are, where you fit in the industry, and what to think about when making decisions. Next, just pick one support department for the job and list what they need to know about it. Communicate with all the department employees what the goal is and just try it out for a couple weeks. You will develop your own program.

Next quarter I’ll share the continuing training program we use once the employee is in the job full time.

Norman Hall is an engineer and leader at the R. L. Deppmann Company, a manufacturer’s representative, in Michigan and Ohio. Norm has assisted in the design and troubleshooting of hydronic and steam systems for 45 years.

Norman Hall is an engineer and leader at the R. L. Deppmann Company, a manufacturer’s representative, in Michigan and Ohio. Norm has assisted in the design and troubleshooting of hydronic and steam systems for 45 years.

RIDGID, part of Emerson’s professional tools portfolio, is committed to supporting trade education RIDGID, a part of Emerson’s professional tools portfolio, will award scholarships to four plumbing and HVACR apprentices as part of its partnership with the Plumbing-Heating-Cooling Contractors (PHCC) Educational Foundation and its apprentice contest. Each winner will receive a $1,000 education scholarship, plus Read more

RIDGID, part of Emerson’s professional tools portfolio, is committed to supporting trade education

RIDGID, a part of Emerson’s professional tools portfolio, will award scholarships to four plumbing and HVACR apprentices as part of its partnership with the Plumbing-Heating-Cooling Contractors (PHCC) Educational Foundation and its apprentice contest.

Each winner will receive a $1,000 education scholarship, plus $1,500 of tools from RIDGID and a special recognition at PHCC CONNECT 2021, Oct. 20-22, in Kansas City, Mo. Scholarship winners are selected by the PHCC Educational Foundation Scholarship Committee’s contractor members.

“RIDGID has had a long-standing commitment of supporting trade education and has been a proud sponsor of the PHCC Apprentice Contest for over a decade,” said Denis Hanna, director of sales and vocational training programs, RIDGID for Emerson. “The contest is a great opportunity for apprentices to showcase their skills and learn from others. We’re excited to see the impact each of this year’s RIDGID scholarship winners has on the industry in the coming years.”

2021 scholarship recipients include:

- Christopher Friendly of Anchorage, Alaska, is studying plumbing installation, service and repair at Alaska Vocational Technical Center.

- Paul Kwiecinski of Chicago, Ill., is studying HVACR installation, service and repair at HVAC Technical Institute Chicago.

Paul Kwiecinski

- Martin Gorman of Belmont, Mass., is studying plumbing installation, service and repair at New England Institute of Technology.

Martin Gorman

- Tyler Earle of Forestdale, Mass, is studying plumbing installation, service and repair at Upper Cape Tech Adult & Continuing Education.

Tyler Earle

To learn more about RIDGID, visit RIDGID.com.

Conversations about the skilled labor shortage have become commonplace. And though high profile champions, like Mike Rowe, have given new visibility and importance to the looming challenge that threatens all trade professions nationwide, articles typically bemoan the lack of young people entering the trades while offering few solutions. The need for qualified technicians isn’t the Read more

Conversations about the skilled labor shortage have become commonplace. And though high profile champions, like Mike Rowe, have given new visibility and importance to the looming challenge that threatens all trade professions nationwide, articles typically bemoan the lack of young people entering the trades while offering few solutions.

The need for qualified technicians isn’t the only concern facing the trades, though. Others issues – such as quality of work and the time in which it’s completed – are as much a symptom of the first problem as they are challenges in their own right.

Many proactive, growing companies have squared off with the workforce shortage out of necessity, dealing it blows where they can. This often comes in the form of a bolstered recruiting game, or a train-your-own technician approach.

Local advocacy in high schools helps, too, though positive results come gradually as part of a longer-term effort. And, some companies implement systems and QC measures that help, to a degree at least.

If Baker Group, in Des Moines, IA, wasn’t already a mechanical force to be reckoned with over the past half century, this changed dramatically in early 2017.

Managers within the 650-person design-build firm, already intimately familiar with the advantages of prefabricating plumbing and mechanical systems offsite, made a bold move to expand their manufacturing space by nearly 150 percent. This, they say, has helped to solve several high-level concerns.

Baker Group is a 650-person, design-build mechanical firm in Des Moines, IA.

Manpower, quality, timeline

The decision to expand was made in order to produce higher quality products, in less time, without creating an unrealistic need for additional skilled manpower.

The firm’s new, 144,000 square-foot facility contains offices as well as manufacturing space, and is called Baker Group Advanced Manufacturing. As many as 75 craftsman can work during a single shift.

“We’ve done prefabrication work since the 1960s,” said Rob Cross, operations manager at Baker Group. “We added a large shop in 1998, and since then, we’ve steadily gained momentum. Our growth necessitated this new expansion last year.”

“The dynamic of the entire construction industry today is built on quality and speed,” says Tom Wengert, VP of Baker Group’s sheet metal business unit. “With this facility, we can prefab systems in a controlled environment, which improves quality while reducing labor costs.

“Additional benefits include increased safety, less congestion on construction sites, less jobsite trash and better scrap material recycling,” added Wengert.

While speed and quality are two major advantages to having a large manufacturing space at your disposal, the efficiency of off-site manufacturing means that fewer employees are needed to accomplish the same task.

Much of the in-shop sequencing implemented by Baker Group at the new facility was adapted from the automotive industry. For example, the flow of materials comes in west side of the shop and leave on the east side.

In 2017, Baker Group expanded their manufacturing space by 150 percent, or 144,000 square feet.

More than sheet metal

Completed in March of 2017, Baker Group Advanced Manufacturing includes 80,000 square-feet of fabrication space with almost 9,000 of that dedicated to multi-trade prefabrication alone.

The multi-trade space is located centrally among the sheet metal, piping and electrical shops. Here, trades work collaboratively in a weather-controlled environment to build to specifications and then ship to the job site.

The space features a 10-ton crane, allowing workers to construct large assemblies. By reducing on-jobsite time, this moves the entire construction timeline forward. The approach increases value to clients, and more than doubles Baker Group’s production capacity.

It’s in this centrally-located, multi-trade space that the various trades come together to assemble systems, sometimes even full mechanical penthouses. Welders work on framing and dunnage while pipefitters connect boilers, chillers, pumps and other equipment. Electricians wire the components and control technicians prepare everything to plug into a BAS.

“A good example of how we build to exact specifications in the shop can be seen in fabrication of gang restroom assemblies,” said Cross. “We can complete an eight-stall bathroom assembly in a little over a day, where it would take nearly a week onsite.”

Welders create an angle-iron framework, perfectly centering all the Watts closet carriers. Once assembled, the system is piped and hydro-tested. Waste water is also tested before the assembly is broken into several pieces for deliver to the job.

A Baker Group mechanic prefabricates large gang restroom assemblies at the new Advanced Manufacturing facility.

Baker Group has used the Watts back-to-back wall mounted, floor mounted and single closet carrier configurations for a wide variety of projects.

“We’ve standardized on the Watts carriers because the fab crews prefer them and they can be rapidly assembled,” said Cross. The Watts “industry standard closet carriers” come out of the box pre-assembled. The carriers feature a patented compression sealed nipple, which provides fast installation without the need for additional sealants. Adjustment is much easier than when threaded nipples are used.

“We never have any trouble with the closet carriers once they’re in the field, and the support we get from Jeff Howe, at Mack McClain & Associates – our manufacturer’s rep agency – is fantastic,” he continued

Cross has been with Baker Group for 23 years, and the relationship with rep firm Mack McClain goes back as long as he can remember. The firm supplies most of Baker Group’s plumbing components, including toilets, eyewash stations, backflow assemblies, drains and water heaters.

Baker Group has standardized on Watts closet carriers because the fab crews prefer them and they come out of the box pre-assembled.

Still adding capabilities

Toilet carriers aren’t the only plumbing systems that Baker Group prefabricates though. Like their ability to assemble boiler and chiller systems offsite, mechanics also build water service entrances, backflow assemblies, pump skids, pressure reducing stations and water purification systems. Once assembled, these items are broken down only as far as needed to be palletized, and the kits shipped to the jobsite.

“Every year we add something new to what we fabricate here on site,” Cross says, adding that Baker Group’s mechanical capabilities now include fabrication of ASME-rated vessels and components. “We’re equipped with the skills, knowledge, equipment and space to do this intricate and very strict code welding work.”

“Give us your biggest problem; the answer lies within the body of knowledge our people possess. We’ll find the solution,” he continued.

A premanufactured restroom assembly installed onsite.

Filling the new shop

While Baker Group Advanced Manufacturing allows the company to provide more capacity with reduced manpower, the need for new hires to fill the shop still requires ongoing effort.

“We’re a big local advocate for the trades,” said Cross. “We visit high schools and technical schools, invite people to take tours or do job shadowing programs. But we still can’t hire fast enough to fill the need.”

Baker Group is one of the largest, most capable design-build contractors in the Midwest, and they take that title seriously.

The content available on their website and YouTube channel speaks not only to potential clients, but also potential employees.

If the company’s dedication to recruiting parallels their insistence on delivering the best solution on time and on budget, staffing the new shop won’t be an unsurmountable task.

Adds Four Hydronic Solutions, Reintroduces Braukmann Product Name to Global Product Offering Resideo Technologies Inc. (NYSE: REZI), a leading global provider of home comfort and security solutions, today announced new hydronic heating components that complement its full water solutions portfolio. Resideo’s world-class hydronic portfolio offers the ultimate in performance, comfort and consistency, and works together seamlessly Read more

Adds Four Hydronic Solutions, Reintroduces Braukmann Product Name to Global Product Offering

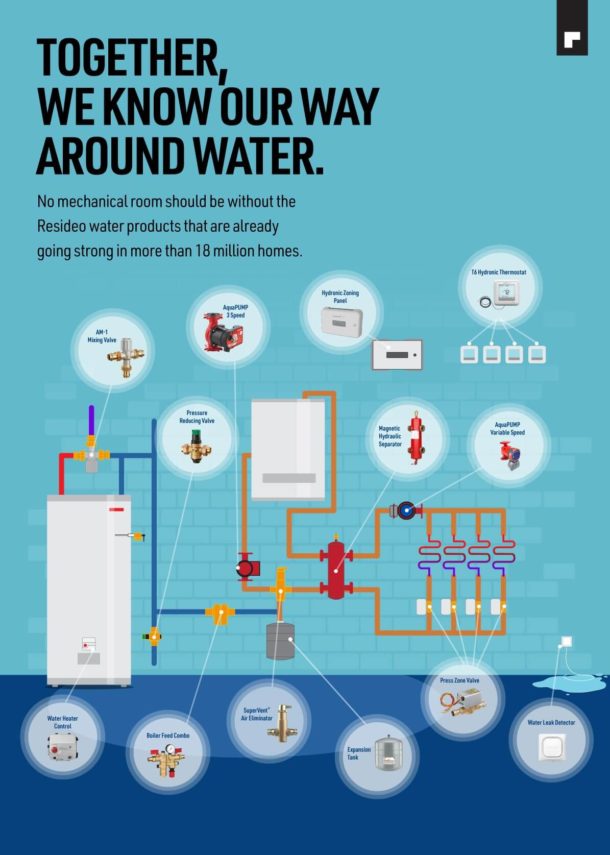

Resideo Technologies Inc. (NYSE: REZI), a leading global provider of home comfort and security solutions, today announced new hydronic heating components that complement its full water solutions portfolio. Resideo’s world-class hydronic portfolio offers the ultimate in performance, comfort and consistency, and works together seamlessly to offer an end-to-end hydronic control system.

“Our professional contractors’ time and energy are precious, so we’re looking forward to offering them a complete, easy-to-install hydronics system from Resideo that is engineered for accuracy, safety and reliability,” said Matthew Robbins, vice president global product management, Comfort & Care. “Our new hydronics solutions are our first Resideo-branded offerings and serve as a true example of what our professionals can expect from Resideo’s behind-the-wall solutions: quality solutions that help save our professionals time, money, labor, and parts.”

Resideo Hydraulic Separator

Resideo’s new hydronic solutions include:

- AquaPUMP Variable Speed Circulating Pumps are offered in both cast iron and stainless-steel models for closed- and open-looped applications. Available in five different modes of operation, the pumps provide versatility to cover the performance of fixed- and variable-speed circulators and utilize pressure responsive control. These quiet and energy-efficient pumps are backed by a five-year warranty.

- Magnetic Hydraulic Separators regulate pressure, reduce flow velocity, minimize audible noises with air elimination and protect the boiler system from ferrous sediment with a standardized magnet. Magnetic Hydraulic Separators are ideal for greater boiler efficiency and protection in various applications from residential homes to multi-family housing. Hydraulic Separator bodies are offered with union connections from one-to two-inch for sweat, threaded, or press fitting. Flanged bodies are available with connections from two to six inches.

- Press PV SuperVent® Air Eliminators easily vent out the air in hydronic systems with the most secure connection offered in the industry. SuperVent® Air Eliminators have debris baffles to control dirt fouling and to prevent failing. The adjustable collar ring allows for easy installation and application flexibility.

- Press Boiler Trim Kits offer a high-quality Press PV SuperVent® Air Eliminator, Press NK300 boiler feed combination and expansion tank with service check valve all in one box. Best-in-class fittings make for a simple, seamless and high-quality installation.

The newly expanded hydronic portfolio is now available in the U.S. and Canada through Resideo’s distribution network.

Resideo Braukmann

Resideo is reintroducing the Braukmann product name to its global potable water products, such as pressure reducing valves and mixing valves. The changes reflect the company’s ongoing opportunity to build and strengthen the Resideo brand and product portfolio.

“Our European and North American customers have known and trusted the Braukmann name for more than 40 years, and we’re honored to bring back the well-known potable water product family,” said Lisa Goldson Armstrong, vice president of global marketing at Resideo. “Reintroducing the Braukmann name acknowledges our proud heritage and gives us an opportunity to take another step in our Resideo brand journey.”

The company acquired Braukmann in 1980 from its founder, and with more than 75 years of experience in the European residential water control market it’s become well-known for demonstrating proven reliability. The water products can be found in more than 18 million households and are trusted by more than 100,000 installers.

Resideo Braukmann solutions are available globally through Resideo’s distribution network.

World of Concrete 2021 concluded its 46th edition with a very strong event for the concrete & masonry industries. This signature annual event drew tens of thousands of industry professionals, featuring more than 650 exhibiting companies across just under 300,000 net square feet of exhibit space. This postponed edition of WOC from January, was the Read more

World of Concrete 2021 concluded its 46th edition with a very strong event for the concrete & masonry industries. This signature annual event drew tens of thousands of industry professionals, featuring more than 650 exhibiting companies across just under 300,000 net square feet of exhibit space. This postponed edition of WOC from January, was the first large-scale event to take place in Las Vegas and reignite the tradeshow industry in what promises to be a booming Summer and Fall live event season. World of Concrete’s arrival comes on the heels of Las Vegas’ full reopening to 100 percent capacity on June 1.

The Las Vegas Convention and Visitors Authority (LVCVA) debuted the Las Vegas Convention Center’s (LVCC) $1 billion, 1.4 million square foot West Hall expansion with a ribbon cutting ceremony, followed by doors opening to Informa Market’s World of Concrete, the first major convention to return to Las Vegas and to the U.S. post-pandemic.

The arrival of World of Concrete signals the return of meetings and conventions to Las Vegas, named the number one trade show destination in North America for 26 consecutive years by the Trade Show News Network (TSNN.) The addition of the West Hall brings the total square feet of meeting space in the destination to 14 million and makes the LVCC the 2nd largest facility in the country. During a normal year, the meeting and convention industry represents $11.4 billion in economic impact to the area.

“We are thrilled to be returning to the live event format, especially in the home of the exhibitions industry in the U.S., Las Vegas,” said Nan Walsh, President, North America at Informa Markets. “There is an unparalleled magic about in-person connection—from sharing laughs with old friends, creating new ones, learning from industry experts, and seeing and feeling the latest products and innovations. We are so happy to be the first large-scale trade show to return to the show floor in the U.S., and the first to use the Las Vegas Convention Center’s incredible new West Hall, and through that partnership I believe we are signaling a return to business and connection that is needed now more than ever.”

“World of Concrete is grateful for the support of all the participating exhibitors and attendees who braved the heat of a June event and paved the way for an even larger and stronger return in January 2022,” said Jackie James, Group Director, World of Concrete. “We would like to thank them along with our cosponsoring associations and media partners who supported this endeavor throughout a very challenging 15 months leading up to this important industry event.”

The Concrete Industry Management (CIM) program held its 16th annual unreserved silent and live auctions at World of Concrete 2021 and simultaneously online as a hybrid auction event. The silent and live auctions raised just over $1.175 million, with a total of over $13 million to the CIM program in the past 16 years. The CIM program is a business program that has been developed specifically for the concrete industry to provide students with a four-year Bachelor of Science degree in Concrete Industry Management. The program gives students entering the concrete work force industry experience early in their careers.

At the SPEX MIX BRICKLAYER 500®, Mason David Chavez and mason tender Guadalupe Hernandez with Ranch Masonry in Houston, TX teamed up to earn the title, “World’s Best Bricklayer.” This is the second time Chavez has earned the World Champion title, winning it all in 2018. The recognition comes after winning the most exciting contest in masonry, the SPEC MIX BRICKLAYER 500.

20 of the best masons and tenders in the world came together at World of Concrete at the Las Vegas Convention Center to test their skill, speed and stamina by battling to determine who can build the largest and best 26-foot-long brick wall, with the least amount of errors, in one hour. The event headlined the first convention of its size to be held in Las Vegas since efforts to combat the pandemic caused a national shutdown.

It was an action-packed competition featuring some of the most decorated craftsmen in North America. Not even temperatures in the 90’s could slow down Chavez, as he earned the keys to a new Ford F250 4×4 Super Duty Truck, $5,000 in cash, a Multiquip Essick Pro12 Mortar Mixer and other great prizes.

With over $125,000 in cash and prizes to be earned, masons from across North America were invited to Las Vegas to compete in the SPEC MIX BRICKLAYER 500 after winning a regional series qualifying event.

16 regional series competitions were held in 2020, shy of the typical 24, due to local restrictions during the Covid-19 pandemic. Along with two returning automatic qualifiers (World Champion and SPEC MIX TOP CRAFTSMAN) and four Wild Card qualifiers, 20 total masons lined the arena in Las Vegas for one of the most exciting and anticipated events in the World of Masonry.

With workforce development being the primary battle cry for the skilled trades, the SPEC MIX BRICKLAYER 500 is a tool designed to create interest from a new generation of masons in the rewards and opportunity possible in masonry and construction.

World of Concrete 2022 will be held January 18-20; Education 17-20, back at the Las Vegas Convention Center.