Original dates of January 25-27, 2021 have been officially postponed; March 15-17, 2021 continues to be considered with a final decision expected by October 15, 2020 AHR Expo Show Management today announced the postponement of the original planned Show dates of January 25-27 for the 2021 AHR Expo in Chicago. Both McCormick Place and Choose Read more

HVACR

Original dates of January 25-27, 2021 have been officially postponed; March 15-17, 2021 continues to be considered with a final decision expected by October 15, 2020

AHR Expo Show Management today announced the postponement of the original planned Show dates of January 25-27 for the 2021 AHR Expo in Chicago. Both McCormick Place and Choose Chicago , an organization dedicated to bringing visitors to Chicago, recognize how vital the Show is to the city and have offered Show Management the dates of March 15-17, 2021 to host the HVACR industry. In a survey conducted by AHR Expo, the proposed move to March is preferred by nearly 80% of exhibitors and attendees. The decision to postpone the original planned January dates was difficult, however, the AHR Expo, ASHRAE and AHRI are encouraged about hosting a live event in March and continue to explore feasibility. A final decision will be announced no later than October 15, 2020.

“We continue to exhaust all possibilities that will allow us to host a safe and successful event for all industry stakeholders,” said Mark Stevens, Show Manager. “But we have to take into account that there are barriers for allowances within the state of Illinois and the city of Chicago that we cannot control. We remain cautiously optimistic that we can meet together in Chicago in March.”

In consideration of the significant planning and preparation required to participate in the Show, AHR Expo Show Management, along with co-sponsors ASHRAE and AHRI, will make the final determination and announcement on or before October 15th. While six months remain between now and March, a decision to make a final call well in advance will allow both exhibitors and attendees to more easily plan.

Throughout the spring and summer, countless meetings have been held to explore all possible avenues in order to produce a safe and successful Show in Chicago. In partnership with Show co-sponsors and the advisory committee, Show Management has been in close contact with McCormick Place, the city of Chicago, Show vendors, and other officials to provide the best guidance to host the event. These meetings will continue throughout the month as all options are considered.

“All of us in the industry understand the vital role HVACR plays in the world. We at AHR Expo know the importance of the Show in providing a unique environment where members of the HVACR community can congregate to learn, share, and grow as professionals while experiencing all that’s new in the industry,” continued Stevens. “I think we all understand the challenges this year has presented thus far, and while HVACR has emerged as a primary player in how we can hope to combat COVID-19 and other pandemic threats of the future, there are safety, governmental, and practical considerations that have to be taken into account.”

Show Management will continue to follow updates within the state of Illinois, the Governor’s office, as well as the CDC and other advisory councils.

Finding and installing Heating, Ventilation, Air Conditioning & Refrigeration (HVAC&R) applications for high-pressure systems has become more difficult as international regulations have eliminated some common refrigerants. R22, for example, is set to become illegal on January 1, 2020, due to its high global warming potential (GWP). With this in mind, the industry has begun developing Read more

Finding and installing Heating, Ventilation, Air Conditioning & Refrigeration (HVAC&R) applications for high-pressure systems has become more difficult as international regulations have eliminated some common refrigerants. R22, for example, is set to become illegal on January 1, 2020, due to its high global warming potential (GWP). With this in mind, the industry has begun developing sustainable, durable tubing materials.

Some copper tubing designated for HVAC&R applications does not provide the wall thicknesses necessary to handle the temperatures and pressures of carbon dioxide systems. However, copper-iron (C19400) material offers high strength, good thermal conductivity, and great workability, making it an exceptional, sustainable tubing option for HVAC&R applications. The C19400 alloy is rated for pressures in the range of 90 bar (1,305 psi) to 130 Bar (1,885 psi) and above at operating temperatures up to 300°F, compatible with the operating ranges of CO2 refrigeration systems.

Installation Details:

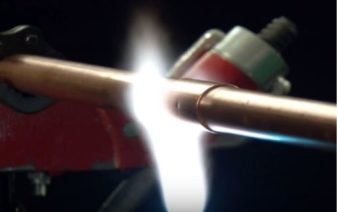

Brazing techniques for copper-iron alloy are the same as those for brazed joints in standard copper and copper alloy systems for plumbing, HVACR, medical gas and other systems that require strong, leak-free, fatigue-resistant joints.

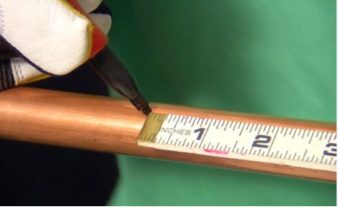

- First, measure the copper iron alloy tube accurately and precisely, so it will completely fill the socket when inserted into the fitting.

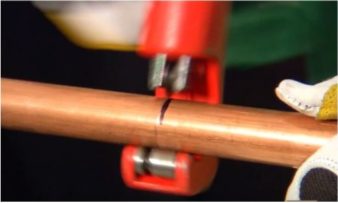

- Cut the tube square to the desired length.

- Deburr the inside edge of the tube and chamfer the outside edge.

- Clean the outside of the tube and inside of the fitting cup(s) to ensure the surfaces to be brazed are free from dirt, oxides or other contaminants that can impede the flow of filler metal into the joint.

When joining copper-iron tubing/fittings to each other, brazing flux is not required and brazing filler metals containing at least 2% silver of AWS B-cup series are recommended. When joining copper iron tube to materials that do not contain phosphorus (which acts as a fluxing agent itself), like black steel, brazing flux is required. Additionally, you must use brazing alloys meeting AWS BAg series of 45-56% silver.

- Assemble the joint by inserting the tube into the socket hard against the stop. The assembly should be firmly supported so that it will remain in alignment during the brazing operation.

- To conduct heat into the joint space, first preheat the tube. For a horizontal joint, begin preheating the bottom 2/3 of tube for a distance approximately equal to the depth of the fitting cup. When the tube begins to darken, begin heating both the tube and the fitting cup, focusing on the bottom 2/3 of the joint.

- Heat until the fitting cup reaches the proper brazing temperature; temperatures vary by tube size and type and can be found in section 14.4a of the Copper Tube Handbook.

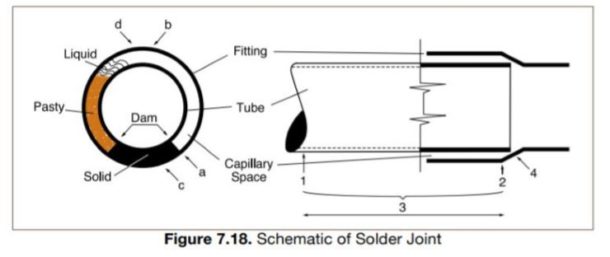

- Apply heat to the parts to be joined, preferably with an oxy-fuel torch with a neutral flame. Heat the tube first, beginning about one inch from the edge of the fitting, sweeping the flame around the tube in short strokes at right angles to the axis of the tube (Figure 7.18, Position 1 [see below]). It is very important that the flame be in motion and not remain on any one point long enough to damage the tube.

- Switch the flame to the fitting at the base of the cup (Figure 7.18, position 2 [see above]) and heat the fitting cup around the bottom 2/3rds of the joint.

- As the fitting cup rises to brazing temperatures, begin to heat both the tube and the fitting by sweeping the flame (Figure 7.18, position 3) [see above] from the fitting to the tube until both the tube and the fitting reach the temperature at which the brazing metal begins to melt when applied to the copper-iron surface. Avoid excessive heating of cast fittings, due to the possibility of cracking.

- For 1-inch tube and larger, it may be difficult to bring the whole joint up to temperature at one time. It frequently will be found desirable to use an oxy-fuel, multiple-orifice heating tip to maintain a more uniform temperature over large areas. A mild preheating of the entire fitting is recommended for larger sizes, and the use of a second torch to retain a uniform preheating of the entire fitting assembly may be necessary in larger diameters. Heating can then proceed as outlined in the steps above.

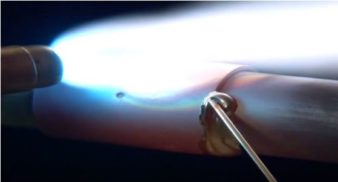

- Apply the brazing filler metal at a point where the tube enters the socket of the fitting, near the bottom portion of the assembly. When the proper temperature is reached, the filler metal will flow readily into the space between the tube and fitting socket, drawn in by the natural force of capillary action. Keep the flame away from the filler metal itself as it is fed into the joint. The temperature of the tube and fitting at the joint should be high enough to melt the filler metal.

- Keep both the fitting and tube heated by moving the flame back and forth from one to the other as the filler metal is drawn into the joint and move the flame and filler metal smoothly and continuously up one side of the joint assembly. Once you reach the top, move back to the bottom of the joint on the other side and repeat the process, overlapping filler metal addition at both the bottom and top of the joint.

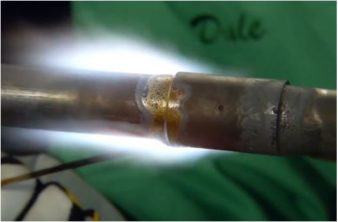

- When the joint is properly made, filler metal will be drawn into the fitting socket by capillary action, and a continuous fillet of filler metal will be visible completely around the joint. To aid in the development of this fillet during brazing, the flame should be kept slightly ahead of the point of filler metal application. Inspect to make sure there is a complete fillet around the joint, if necessary you can reheat the face of the joint and add additional filler metal to complete the fillet.

- For vertical joints, the starting point (bottom of the horizontal joint) is irrelevant but the same heating and brazing process should be followed.

- Cleaning is not a requirement once the brazing process is completed. If flux was used, the residue should be removed. This can most easily be done with hot water and brushing.

- Your joint is now complete! For additional information related to brazing copper-iron alloys and copper piping in HVAC systems, check out CDA’s Copper Tube Handbook.

Copper-iron alloy’s effectiveness under high pressure distinguish it as a top material for HVAC&R applications. The development of copper-iron alloy is a huge step forward in creating piping applications that are fit for the future environment. For more information about proper installation techniques for copper-iron, check out the video: Copper-iron Piping for HVAC, Lightweight but Strong as Iron.

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from. The shortage of skilled workers in the trades is severe and getting worse. Seventy percent of construction companies nationwide are having trouble finding qualified workers, according to the Associated General Contractors of Read more

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from.

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from.

The shortage of skilled workers in the trades is severe and getting worse. Seventy percent of construction companies nationwide are having trouble finding qualified workers, according to the Associated General Contractors of America.

And if Congress ever does approve a much-needed infrastructure package, the need will be even greater.

We in the trades can hope parents will stop pushing the necessity of a four-year degree to every child, regardless of interest or qualifications, but there are more practical measures we can take in the meantime.

Last year, Viega LLC launched the Viega Trades Education Network (VTEN) to boost the ranks and skills of students studying the design, installation and function of plumbing and hydronic systems. Viega is partnering with trade schools, community colleges and the UA in the United States and Canada to subsidize and provide training on mechanical systems.

VTEN is about providing a better education for those already enrolled and supporting the schools and instructors that are training the next generation of workers. Like all educational institutions, these schools don’t have the budgets and resources to deliver everything they’d like to give their students.

As members of VTEN, schools get comprehensive curriculum modules that easily integrate into existing programs. The modules include Hydronics 101, Piping & Controls, Radiant Design, Trades Math, Blueprint Reading, CAD and BIM, and more. In addition, Viega provides functional demonstration units supported by lesson plans and projects and a complete tooling package.

Educators receive admission to an annual VTEN conference in Colorado or New Hampshire, including hotel, airfare, food and admission; Viega and direct vendor support of BlueVolt® eLearning platform; hands-on tool demonstrations and LoopCAD® license options and instructor training.

The LoopCAD package includes on-site orientation to the network and a Zoning Demonstration Board and Mixing Demonstration Board to give students hands-on experience in troubleshooting systems.

And, of course, VTEN offers credentialed classes for Viega products, including ProPress® and MegaPress®.

But the program doesn’t stop there. Schools also receive a RIDGID® RP-340 tool or Milwaukee M18® Force Logic Press Tool with a set of jaws for metal and PEX, as well as samples of various types of pipe and couplings for each student.

The first students in VTEN will graduate soon and we welcome them to the ranks of the trades. We invite other companies to follow suit and join us in building the workforce of the future.

Lino Santoro is Viega Trades Education Network (VTEN) Manager.

Lino Santoro is Viega Trades Education Network (VTEN) Manager.

Affordable Digital Device Combines Thermal Imaging with Precision Electrical Measurement FLIR announces the FLIR DM166 thermal imaging multimeter with Infrared Guided Measurement (IGM™), the industry’s most affordable digital multimeter/thermal imager combination. The FLIR DM166 features 80×60 thermal resolution, broad multimeter test functions, and the flexibility for use in both high and low voltage applications. Designed Read more

Affordable Digital Device Combines Thermal Imaging with Precision Electrical Measurement

FLIR announces the FLIR DM166 thermal imaging multimeter with Infrared Guided Measurement (IGM™), the industry’s most affordable digital multimeter/thermal imager combination. The FLIR DM166 features 80×60 thermal resolution, broad multimeter test functions, and the flexibility for use in both high and low voltage applications.

FLIR announces the FLIR DM166 thermal imaging multimeter with Infrared Guided Measurement (IGM™), the industry’s most affordable digital multimeter/thermal imager combination. The FLIR DM166 features 80×60 thermal resolution, broad multimeter test functions, and the flexibility for use in both high and low voltage applications.

Designed to provide faster troubleshooting in applications such as electrical distribution, electro-mechanical systems, HVAC/R, and electronics, the FLIR DM166 features a FLIR Lepton® thermal microcamera core that visually guides users to the precise location of a problem. The feature-packed multimeter helps users pinpoint issues faster, and then troubleshoot complex electrical distribution and electro-mechanical systems more effectively and efficiently.

Thermal imaging is a non-contact temperature measurement method, allowing the user to more safely scan for overheating system components. Additionally, with a rugged, drop-tested design and the safety rating electrical and HVAC professionals’ need, the FLIR DM166 is field-ready for even the most demanding applications.

The FLIR DM166 carries a 10-year warranty on both the product and the thermal detector. It will be available in fourth quarter 2017 for $499.99. For more information visit www.flir.com/professionalDMMs.

Every year, here in the U.S., we have the AHR Show, one of the largest HVACR trade shows in the world. Well, every other year, the ISH Show in Frankfurt—organized by our friends from Messe Frankfurt—is the plumbing and HVACR granddaddy of them all. This week—March 10-14—the 2015 ISH Show kicks off, featuring the latest Read more

Every year, here in the U.S., we have the AHR Show, one of the largest HVACR trade shows in the world. Well, every other year, the ISH Show in Frankfurt—organized by our friends from Messe Frankfurt—is the plumbing and HVACR granddaddy of them all.

This week—March 10-14—the 2015 ISH Show kicks off, featuring the latest innovations and new products from the water and energy sectors. Over 2,400 exhibitors from over 50 countries are taking part in The World’s Leading Trade Fair for The Bathroom Experience, Building Services, Energy, Air Conditioning Technology and Renewable Energies.

With 10 exhibiting pavilions, you really need a week to see, well, most of it. Drawing from past experiences at ISH, the show allows visitors to talk business right at the booth with libation in hand.

I have been told that there should be around a 4% attendance contingent from the U.S. Interesting. I know plenty of friends from the industry making the jump over the pond this year. Nonetheless, it will be a great opportunity for us here to see the latest and greatest from the brightest minds in Europe, and all across the world. Check back on mechanical-hub.com this week for more updates on the show.

ISH 2015

‘Comfort meets Technology’ is the motto of ISH 2015, which reflects the latest topics and developments in the sector and puts the focus on innovative technologies for individual ease of use and operation in buildings, as well as the latest trends for ecological, design-oriented bathrooms.

Today, Barbara Hendricks, German Federal Minister for the Environment, Nature Conservation, Building and Nuclear Safety, will open ISH.

The German sanitation, heating and air-conditioning sector can look back over 2014 with satisfaction; industry, the wholesale trade and the installation trades achieved a consolidated yearly turnover of € 52.3 bn (2013: € 51.3 bn). That represents growth of two per cent. Domestic turnover amounted to € 43.2 bn (2013: € 42.3 bn). As a result, the sector was able to continue the upward trend of the previous few years. At 51,316 (2013: 51,520), the number of companies continues at a relatively constant level; the skilled trades, with 50,350 businesses (2013: 51,520), comprise the vast majority of these, by a very wide margin. When it comes to the number of people employed in the sector, the figures show a persistent upwards trend.

In all, the building services engineering industry, which is dominated by medium-sized businesses, recorded some 509,000 employees in 2014, making it a round 8,000 more than in 2013. “These positive figures for the sector are reflected at ISH. 2,465 well known exhibitors (ISH 2013: 2,436) from 59 countries amount to a new record on the part of the manufacturers. For five whole days, they will be presenting their innovations to trade and professional visitors from all over the world at the trade fair. With some 260,000 square metres of exhibition space occupied, ISH will also be recording renewed growth in floor space for the show and a fully booked exhibition centre,” says Wolfgang Marzin, President and Chief Executive Officer of Messe Frankfurt.