Trusted manufacturers will present their high-efficiency, high-performing products at Canada’s top mechanical and plumbing event in Toronto March 22-24 Bradford White Corporation, an industry-leading manufacturer of water heaters, boilers and storage tanks, will showcase innovative products offered by its Bradford White Water Heaters and Laars® Heating Systems brands at the Canadian Mechanical and Plumbing Exposition (CMPX) in Toronto March 22-24. “Professionals Read more

LAARS Heating Systems

Trusted manufacturers will present their high-efficiency, high-performing products at Canada’s top mechanical and plumbing event in Toronto March 22-24

Bradford White Corporation, an industry-leading manufacturer of water heaters, boilers and storage tanks, will showcase innovative products offered by its Bradford White Water Heaters and Laars® Heating Systems brands at the Canadian Mechanical and Plumbing Exposition (CMPX) in Toronto March 22-24.

“Professionals in our rapidly evolving industry are looking for the kind of reliable, high-efficiency and high-performance solutions Bradford White is known for,” said Neal Heyman, director of marketing for Bradford White. “CMPX is one of Canada’s biggest and best events for plumbing and mechanical professionals, and we’re looking forward to connecting with them to share first-hand demonstrations of our proven and trusted products.”

Representatives from Bradford White Water Heaters and Laars Heating Systems will be available at Booth 517 during CMPX, along with the following products:

- Bradford White AeroTherm® Series Heat Pump Water Heater: With 50-, 65- and 80-gallon capacity units available, the Bradford White Water Heaters ENERGY STAR®-certified AeroTherm® Series offers value, efficiency and versatility. AeroTherm® Series water heaters are easy to install and maintain and feature the AeroTherm® integrated smart control panel plus five operating modes (heat pump, hybrid, hybrid plus, electric and vacation).

- Bradford White ElectriFLEX HD™: With available advanced features such as rugged Incoloy® low-watt density elements, field conversion kits to fit demanding application needs, Bradford White’s proprietary Vitraglas® lining with Microban® antimicrobial product protection, and a Hydrojet® sediment reduction system, ElectriFLEX HD™ water heaters are designed for heavy-duty commercial applications.

- Bradford White Infiniti® GR Tankless Water Heaters: The ENERGY STAR®-certified Infiniti® GR tankless water heater offers energy efficiency, high performance and cutting-edge features, including a robust stainless steel heat exchanger, high temperature setting of 180 degrees, cascade rack installation and multiple venting options.

- Bradford White eF Series® Ultra High Efficiency Commercial Gas Water Heater: The ENERGY STAR®-certified eF Series® Ultra High Efficiency Gas Water Heaters feature BMS integration, protective powered anodes, thermal efficiency up to 97%, ICON HD® controls, direct spark ignition, three-pass fire-tube heat-exchanger system, and an installed T&P relief valve.

- Laars FT Series Floor Boiler and Combi: The Laars® FT Series floor standing condensing boiler comes in combi or heat only models. This powerhouse comes equipped with built-in low loss header, top connections, multiple access panels for easy install and a stainless-steel heat exchanger for ultra-high efficiency. The combi offers industry-leading 6-plus gallon first-minute DHW delivery.

- Laars FT Series Commercial Wall Hung Boiler: FT Series commercial wall-hung boilers are available in 301 and 399 MBH sizes, have a stainless steel firetube heat exchanger, 10:1 turndown, and 95%-plus efficiency. These robust boilers can be wall-hung or floor mounted, common-vented and are BMS compatible.

- Laars LT Series Tankless Water Heater: Ideal for residential or light commercial applications with a high temp output setting (185 degrees) and the ability to cascade up to 16 units. The newest member of Laars’ water heating lineup, the LT Series has 0.95 AFUE, a unique SS heat exchanger design with 15-year warranty, and gas-fired models that are capable of meeting Title 24 requirements.

CMPX is one of North America’s largest trade shows for the mechanical and plumbing industry. Attendees can source products, information, equipment and applications for industry professionals who want one-on-one access to the latest information and hands-on opportunities to come face-to-face with tomorrow’s trends.

For more information about CMPX, visit https://www.cmpxshow.com/.

For more information about Bradford White Water Heaters, visit https://www.bradfordwhite.com.

For more information about Laars Heating Systems, visit https://www.laars.com/.

The latest evolution of the leading U.S. designer and manufacturer’s reliable and efficient NeoTherm line delivers enhanced functionality and easy installation for a variety of applications Laars® Heating Systems, a leading U.S. designer and manufacturer of boilers, water heaters, and pool heaters used in residential, commercial, and industrial applications, announces the release of the new NeoTherm® XTR Read more

The latest evolution of the leading U.S. designer and manufacturer’s reliable and efficient NeoTherm line delivers enhanced functionality and easy installation for a variety of applications

Laars® Heating Systems, a leading U.S. designer and manufacturer of boilers, water heaters, and pool heaters used in residential, commercial, and industrial applications, announces the release of the new NeoTherm® XTR commercial boilers and volume water heaters.

The NeoTherm XTR is available as a condensing boiler or volume water heater, with venting up to 150 equivalent feet, has top water and gas piping connections, and can be common-vented, offering increased installation flexibility. NeoTherm XTR units have AHRI certified 96%-plus thermal efficiencies, a reliable low pressure-drop stainless steel heat exchanger, and 10:1 combustion turndown.

“The NeoTherm XTR marks the evolution of our field-proven NeoTherm product line,” said Chuck O’Donnell, director of marketing for Laars Heating Systems. “Listening to feedback from our heating professionals, we kept the features in the NeoTherm they liked and added new features that make the NeoTherm XTR even better — more robust, easier to install, and with enhanced control functionality that better serves a wide variety of installation requirements.”

Each NeoTherm XTR uses the powerful LaarsLinc® icon-driven control system that includes Laars Vari-Prime® pump control. Laars Vari-Prime controls a variable speed boiler pump to maintain a fixed, user-selectable, boiler temperature rise, maximizing total installed efficiency.

The Laars Linc intuitive control system with color touchscreen has an easy to navigate control structure that displays key performance measures, a quick start option, and a USB input for parameter upload. It easily connects to building automation systems via on board BACnet or Modbus protocols and has many other features, including the ability to cascade up to eight units.

NeoTherm XTR boilers and volume water heaters are available in six sizes, from 399 to 1500 MBH for natural gas applications.

For more information about Laars® Heating Systems, visit www.laars.com.

Leading U.S.-based manufacturer’s new light commercial boilers offer versatility, high performance and efficiency for a wide range of applications Laars® Heating Systems, a leading U.S. designer and manufacturer of boilers, water heaters, and pool heaters used in residential, commercial, and industrial applications, announces the release of the new FT Series light commercial boilers available in 301 Read more

Leading U.S.-based manufacturer’s new light commercial boilers offer versatility, high performance and efficiency for a wide range of applications

Laars® Heating Systems, a leading U.S. designer and manufacturer of boilers, water heaters, and pool heaters used in residential, commercial, and industrial applications, announces the release of the new FT Series light commercial boilers available in 301 and 399 MBH sizes.

Laars® Heating Systems, a leading U.S. designer and manufacturer of boilers, water heaters, and pool heaters used in residential, commercial, and industrial applications, announces the release of the new FT Series light commercial boilers available in 301 and 399 MBH sizes.

These robust boilers have a stainless steel firetube heat exchanger, operate with up to 10:1 turndown, can be used with either natural gas or propane fuel, and run at an ultra-high 95%+ thermal efficiency.

“These versatile additions to the Laars® FT Series product line meet or exceed the high standards our customers have for heating equipment,” said Chuck O’Donnell, director of marketing for Laars® Heating Systems. “The FT Series 301 and 399 MBH units provide optimal performance and ultra-high efficiency while also responding to a wide range of operational demands. We’re always looking for ways to maximize value for our customers and end users by providing top-performing heating equipment that’s built to last.”

Each FT Series unit is equipped with onboard high- and low-temperature zone control, DHW Smart PriorityTM functionality that allows simultaneous space and domestic water heating, BMS compatibility, and can cascade up to four units. Additionally, a sensor actively monitors incoming air for cross-contamination from exhaust flue gases. This unique feature issues an alert when cross-contamination is present, indicating that the vent system should be evaluated to help keep the boiler running trouble-free.

The FT Series 301 and 399 MBH units can be wall-hung or floor-mounted with optional stand package. Top and bottom gas and water connections and venting up to 150 equivalent feet offer increased installation flexibility.

For more information about Laars® Heating Systems, visit http://www.laars.com.

The new floor-standing FT Series Combination Boiler and Water Heater is the only residential combi boiler that delivers uninterrupted home heat and on-demand hot water simultaneously. Laars Heating Systemsannounces the launch of its powerful, ultra-high efficiency floor-standing FT Series Combination Boiler and Water Heater, the only residential combi boiler that simultaneously supplies abundant home heat Read more

The new floor-standing FT Series Combination Boiler and Water Heater is the only residential combi boiler that delivers uninterrupted home heat and on-demand hot water simultaneously.

Laars Heating Systemsannounces the launch of its powerful, ultra-high efficiency floor-standing FT Series Combination Boiler and Water Heater, the only residential combi boiler that simultaneously supplies abundant home heat and endless hot water without interruption.

“Home heat and hot water are critical to health and comfort in our daily lives,” said Chuck O’Donnell, director of marketing for Laars Heating Systems. “The Laars floor-standing FT Series Combination Boiler and Water Heater, like the rest of the FT Series of products, is built to meet the needs for space heating and domestic hot water reliably, efficiently and economically.”

“Home heat and hot water are critical to health and comfort in our daily lives,” said Chuck O’Donnell, director of marketing for Laars Heating Systems. “The Laars floor-standing FT Series Combination Boiler and Water Heater, like the rest of the FT Series of products, is built to meet the needs for space heating and domestic hot water reliably, efficiently and economically.”

The FT Series Combination Boiler and Water Heater includes a unique, integrated domestic hot water mini-indirect tank that delivers stable hot water on demand. Advanced smart technology coordinates uninterrupted space heating with domestic hot water demand and ensures continuing hot water supply for multiple heating events.

With industry-leading capacity, the FT Series Combination Boiler and Water Heater can deliver six gallons per minute of hot water in the first minute and 5.2 gallons per minute continuous delivery at a 70°F temperature rise. Other features include domestic hot water recirculation compatible; built-in low loss header for ease of installation; robust stainless-steel fire-tube heat exchanger; top piping connections for flexible installation; and large front access for service and maintenance.

“The Laars floor-standing FT Series Combination Boiler and Water Heater offers a unique combination of performance, efficiency and convenience,” O’Donnell said. “Based on extensive feedback from heating professionals, multiple features have been incorporated that make installation and service straightforward and accessible, and also provide options for homeowners.”

For more information, visit http://www.laars.com.

Mechanical Hub recently talked with Tod Hebert, manager, customer relations, and Chuck O’Donnell – director of marketing, LAARS Heating Systems, Co. regarding the benefits—and differences—in condensing and non-condensing boilers in residential installations. The following is information garnered from that Q&A. MH: It would seem that condensing boilers would be the right choice for an install in Read more

Mechanical Hub recently talked with Tod Hebert, manager, customer relations, and Chuck O’Donnell – director of marketing, LAARS Heating Systems, Co. regarding the benefits—and differences—in condensing and non-condensing boilers in residential installations. The following is information garnered from that Q&A.

MH: It would seem that condensing boilers would be the right choice for an install in terms of energy efficiency and energy savings. Perhaps there is more than meets the eye here. What are the pros and cons of each?

LAARS: Both condensing boilers, with Annual Fuel Utilization Efficiencies (AFUE) in the 95% range, and mid-efficiency boilers, with AFUEs in the mid-80% range, have their place depending on the home and homeowner’s goals when purchasing a new boiler.

Condensing boilers do offer higher efficiencies and can greatly reduce heating bills. However, they must be installed correctly and controls set up so that the boiler will condense as often as possible throughout the year. Condensing boilers work best when low return water temperatures of roughly 130F or lower are seen, otherwise the boiler’s installed efficiency will drop considerably. Low temperature heat emitters such as in-floor radiant, air handlers, or low temperature baseboards are ideal as they are designed for low boiler water temperatures.

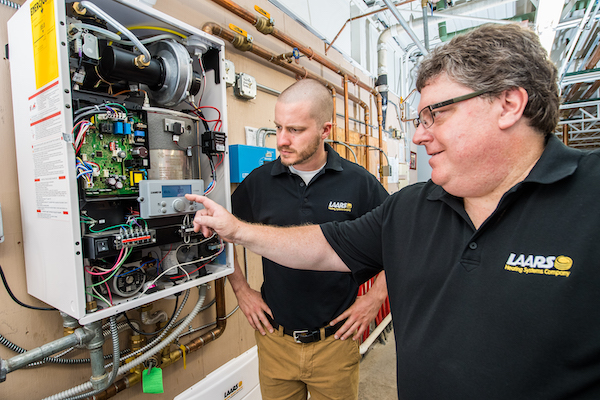

A tech conducts a service check on a LAARS NeoTherm condensing boiler.

However, even standard high temperature baseboard can return cold enough water for condensing to happen if, for example, outdoor reset is used. During the course of a heating season a modulation condensing boiler with outdoor reset can maximize efficiency by matching its heat output with the heating needs of a home. Outdoor reset changes a boiler’s outlet temperature based on the outdoor temperature. Milder outdoor temperatures experienced in the fall and spring results in cooler boiler water temperature that will still keep a house warm. Cooler boiler water temperatures promote condensing and that results in higher efficiency.

However, non-condensing boilers may be the better choice when home heat loss calculations in conjunction with the use of high temperature heat emitters indicate that low return water temperatures will not occur often. In many cases a modern mid-efficient boiler can offer considerable savings when replacing an older mid 70% or low 80% efficient boiler. There are also venting installation requirements that should be considered. A condensing boiler cannot be vented into a standard chimney unless it is lined with stainless steel or high temperature rated plastic such as polypropylene or CPVC vent materials. This can be costly to the homeowner, especially if placed inside a long chimney run.

MH: What is typical lifespan on each? Does one outlive the other?

LAARS: If maintained properly both condensing and non-condensing boilers can provide many years of efficient, reliable home heating. However, as a general statement, non-condensing boilers tend to have slightly longer life spans in the 20 year or longer range where condensing products typically have lifespans of 15 years or longer. This, of course, is often dependent on site-specific run time and installation practices.

Checking the the high ffficiency Mascot FT (Fire Tube) combi condensing boiler.

MH: How often does each unit need to be serviced?

LAARS: It is recommended that all residential boilers undergo yearly inspection and servicing. However, condensing boilers can be compared to a high-performance vehicle that may need more attention at service time vs. a non-condensing boiler that may not need as much work come service time. Again, these are general statements, and much depends on how boilers are installed and run time based on a homeowner’s thermostat settings per zone in their homes.

MH: You may have touched upon this in question 1, but is there a big difference in energy efficiency, savings and a reduction in carbon footprint?

As with any boiler, the key to longevity is proper maintenance. Here a service tech performs a combustion analysis.

LAARS: The less fuel consumed results in a lower carbon footprint and therefore a condensing boiler in general will result in a lower carbon footprint as compared to standard efficient boilers. In addition to lower carbon footprint, NOX emissions (pollutants) are normally lower on modern condensing boilers, due to advanced burner technologies that optimize the combustion process.

MH: In terms of initial and long-term costs, what is the investment in both units?

LAARS: A typical condensing boiler installation will cost between $10,000 to $15,000. However, the number may be higher or lower depending on the size of the home and thus boiler size, number of zones, and if major corrections need to be made to the piping in a replacement job. We see non-condensing installations come in around $8,000 to $12,000, again lots depend on job site specifics to land on a final number.

Condensing units typically have lower fuel costs than mid-efficiency boilers over the life of each unit. However, non-condensing units tend to last a few years longer and have lower maintenance costs. These should be looked at when doing any ROI calculation.

MH: What is the warranty on heat exchanger, parts and labor?

LAARS: Condensing boilers typically have a 10 to 12-year heat exchanger warranty and 2 -5-year parts coverage. Noncondensing boilers typically have a 20-year heat exchanger warranty and 1-year part coverage.

MH: What are the differences in installation? (venting, for example)

LAARS: Non-condensing units can be vented directly into standard chimneys without much additional cost (sometimes older chimneys need upgrade or liners). Condensing units must be vented with materials that can withstand the corrosive nature of condensing flue products. These materials include PVC (residential appliances), CPVC, or polypropylene venting materials. Federal, state, and local venting codes must always be followed as allowable materials change depending on the authority having jurisdiction in any given area. Condensing products also must have a condensate neutralizer kit installed and a drain line installed to dispose of the condensate generated during combustion. In some homes, there is not a drain near the boiler installation, and this can complicate a high-efficiency boiler installation.

LAARS: Non-condensing units can be vented directly into standard chimneys without much additional cost (sometimes older chimneys need upgrade or liners). Condensing units must be vented with materials that can withstand the corrosive nature of condensing flue products. These materials include PVC (residential appliances), CPVC, or polypropylene venting materials. Federal, state, and local venting codes must always be followed as allowable materials change depending on the authority having jurisdiction in any given area. Condensing products also must have a condensate neutralizer kit installed and a drain line installed to dispose of the condensate generated during combustion. In some homes, there is not a drain near the boiler installation, and this can complicate a high-efficiency boiler installation.

MH: Is there an advantage with condensing in terms of corrosion control?

LAARS: Non-condensing boilers use various heat exchanger materials such as copper, steel, or cast iron. Condensation can attack these metals, so effort needs to be made to protect them from sustained low temperature return water, which causes condensation. Most condensing boilers will have stainless steel heat exchangers to handle the corrosive condensate that is produced via high efficiency combustion. Low return water temperature is not a concern, and in fact optimizes the efficiency of these units.

MH: Approximately when were condensing boilers introduced into the market?

LAARS: Condensing boilers found their start in the late 1990s; however, their popularity did not gain traction until the early to mid-2000s.

MH: Finally, is one more popular than the other currently? Is condensing gaining traction?

LAARS: Condensing boilers have grown in popularity, and their rate of use has grown quickly over the past ten years. However, there are still more non-condensing boilers installed each year vs. condensing, but the gap is closing.