NIBCO INC. has announced the promotion of Dawn Bloch to vice president, customer engagement. In her new role, Bloch will oversee the marketing communications department in addition to continuing to manage business development and customer service. She will report to Ashley Martin, executive vice president, NIBCO. Bloch joined NIBCO in 2000 as a customer service representative Read more

NIBCO

NIBCO INC. has announced the promotion of Dawn Bloch to vice president, customer engagement.

In her new role, Bloch will oversee the marketing communications department in addition to continuing to manage business development and customer service. She will report to Ashley Martin, executive vice president, NIBCO.

Bloch joined NIBCO in 2000 as a customer service representative. She held several positions of increasing responsibility including technical specialist, radiant heating advisor; radiant heat technical coordinator; customer service supervisor; customer service manager, director retail sales; manager, HR services; and director, business development and customer service.

Bloch was named to Supply House Times, “20 Women in Industry” in March 2017, an acknowledgement of women decision makers in the PHCP-PVC industry. At NIBCO, she was recognized in 2015 with the Rex Martin award, given to recognize achievement in cost reduction, safety, or an increase in sales, and in 2018, the Alice A. Martin award, given to recognize women who demonstrate philanthropy, community service, mentorship, and support the development of other women.

She has been a member of the American Supply Association Women in Industry since 2013, a board chair for Habitat for Humanity of Elkhart since 2019, and she volunteers for the United Way of Elkhart.

She holds a bachelor’s degree of Science in Business Administration from Indiana Tech, Fort Wayne, Indiana. Bloch also holds a master’s degree in Business Administration from the University of Northern Alabama and a certificate in Digital Marketing from Cornell University.

She resides in Elkhart, Indiana.

NIBCO’s Wrot Racer® C8 Corvette kicks off its tour at AHR Expo 2022 before visiting qualified distributors throughout the United States to celebrate the introduction of Wrot Racer push fittings. NIBCO INC. announces its Wrot Racer® “Start Me Up” promotion to celebrate its next generation of push fittings that it recently launched. The multi-faceted promotion centers on Read more

NIBCO’s Wrot Racer® C8 Corvette kicks off its tour at AHR Expo 2022 before visiting qualified distributors throughout the United States to celebrate the introduction of Wrot Racer push fittings.

NIBCO INC. announces its Wrot Racer® “Start Me Up” promotion to celebrate its next generation of push fittings that it recently launched. The multi-faceted promotion centers on the Wrot Racer C8 Corvette that will tour the U.S., making stops at distributor locations that have qualified.

The “Start Me Up” promotion provides a quick and easy way for distributors to take on immediate inventory of the new Wrot Racer copper push fittings. Distributors who meet the minimum stocking order requirement will receive a free marketing kit that includes POP merchandising.

NIBCO’s Wrot Racer Corvette began its tour at AHR Expo in Las Vegas on January 31, before moving to the West Coast, making various stops along the way, including Phoenix and Los Angeles. The “Start Me Up” promotion runs through 2022.

“We’re excited for our Wrot Racer Corvette to head out on the road to visit qualifying distributors across the U.S.,” said Ashley Martin, executive vice president, NIBCO INC. “This is a great opportunity for distributors to create additional coverage for their businesses and for everyone attending to have fun!”

Introduced in 2021, Wrot Racer push fittings are a line of premium copper push fittings that are engineered to join copper, CPVC-CTS, PEX and PE-RT (with stiffeners) for easy transition between piping systems. With a patented fitting design, installations are easily made within seconds.

Wrot Racer push fittings are made with 99.9 percent pure wrot copper. Naturally lead free, the fittings feature antimicrobial properties and are dezincification resistant, providing for safe, clean drinking water connections for both residential and commercial applications.

Available in 1/2″ to 1″ sizes, the lightweight and compact Wrot Racer fittings are able to be installed wet or dry and can handle applications up to 200 psi and 200 degrees. The new fittings feature stainless steel gripper rings to ensure a secure connection. Wrot Racer fittings are ideal for tight-space installations and can also be removed and reused, avoiding wasted materials.

To learn more about how NIBCO’s Wrot Racer Corvette can make an appearance, contact your local NIBCO sales representative, visit nibco.com/wrotracer/ or email Customerservice@nibco.com. Contractors should contact their local distributor to see if it is on the Wrot Racer tour list.

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter. https://youtu.be/pmZaip09_kA The drain makes it simple Read more

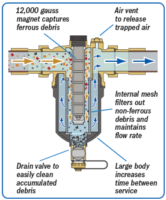

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter.

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter.

The drain makes it simple to remove accumulation, with a strapped cap that can be used to actuate the drain valve and a large filter body that increases time between service. A service tool is also included to help install and maintain the filter with ease. G-threads make it simple to swap out your choice of press, MIP, FIP, or sweat G-union end connections in sizes 1¼” or 1½”. The MBF XL can withstand 250°F and 145 PSI CWP.

Whether installing a new boiler or maintaining an existing one, it’s important to consider the inherent issues that can befall a hydronic system and impact the performance of its components. Anticipating these pitfalls and planning accordingly will result in a smarter installation. By choosing your boiler accessories wisely, you can extend the life of your Read more

Whether installing a new boiler or maintaining an existing one, it’s important to consider the inherent issues that can befall a hydronic system and impact the performance of its components. Anticipating these pitfalls and planning accordingly will result in a smarter installation. By choosing your boiler accessories wisely, you can extend the life of your boiler and maintain its efficiency while guarding against potential problems down the road.

One of the most common issues comes in the form of ferrous debris, a result of normal metal pipe wear that, when left unchecked, can cause major problems. Over time, rust particles and other debris in the heating loop build up, creating an iron sludge that reduces boiler efficiency or even stops it altogether from working. The resulting damage can require expensive repairs, increase heating costs, and reduce the overall lifespan of the boiler.

To combat the accumulated sludge in the pipes, a system flush may be required. Depending on the severity of the issue, this could be a costly and time-consuming process. Moreover, doing so will not reverse any damage that’s already been done to the boiler. By the same token, boiler manufacturers are becoming more stringent about their warranty claim requirements. Installing a boiler accessory as a precautionary measure is the most consistent way to ensure due diligence is being done. The best protection from iron sludge is to prevent it from ever reaching the appliance.

To combat the accumulated sludge in the pipes, a system flush may be required. Depending on the severity of the issue, this could be a costly and time-consuming process. Moreover, doing so will not reverse any damage that’s already been done to the boiler. By the same token, boiler manufacturers are becoming more stringent about their warranty claim requirements. Installing a boiler accessory as a precautionary measure is the most consistent way to ensure due diligence is being done. The best protection from iron sludge is to prevent it from ever reaching the appliance.

To protect the boiler, consider the Magnetic Boiler Filter (MBF) from Webstone®, a brand of NIBCO. It captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet. Its internal filter knocks out sediment as it enters the unit, breaking down the sludge and maintaining optimal flow rate. The build-up is captured in the body, which has a large storage capacity to increase time between service. The strapped cap is also used to actuate the integrated drain valve, making it simple to remove accumulation when needed, and a service tool is included to help remove the filter housing with ease.

The MBF bodies feature G-thread ends for connection to your choice of MIP, FIP, sweat, or press union fittings. Unions and bodies can be purchased as an installation kit or as separate components depending on the installer’s preference. Optional lead-free dezincification-resistant brass isolation valves are also available to simplify future service. When installed in conjunction with a circulator pump, the flanged ball valve saves space, labor, and leak paths compared to the off-the-shelf assemblies that would normally be required to connect the two appliances. It also mitigates the risk of electrolysis and galvanic corrosion, while allowing virtually no air into the system upon pump replacement. For more simple isolation needs, Webstone offers straight and angled G-union ball valves with reversible handles.

For smaller systems, the ¾” and 1” models feature a universal diverter that allows the MBF to be used in both horizontal and vertical piping orientations on the system return line. For horizontal installations on the system run, the Magnetic Boiler Filter XL model is now available in sizes 1¼” or 1½”. Introduced in 2021, the patent-pending MBF XL is ideal for larger residential and light commercial boiler applications, with a robust 2-layer metal mesh filter and manual air vent.

For smaller systems, the ¾” and 1” models feature a universal diverter that allows the MBF to be used in both horizontal and vertical piping orientations on the system return line. For horizontal installations on the system run, the Magnetic Boiler Filter XL model is now available in sizes 1¼” or 1½”. Introduced in 2021, the patent-pending MBF XL is ideal for larger residential and light commercial boiler applications, with a robust 2-layer metal mesh filter and manual air vent.

Webstone offers a wide array of system performance products designed to support efficient operations and protect components. To learn more about how you can work smarter, visit WebstoneValves.com.

In a hydronic system, every installation is an opportunity to improve efficiency. The products you select for the job not only impact the installation of today but the performance of tomorrow. This is especially true when installing a boiler; the components you pair with the unit can mean the difference between a simple installation and Read more

In a hydronic system, every installation is an opportunity to improve efficiency. The products you select for the job not only impact the installation of today but the performance of tomorrow. This is especially true when installing a boiler; the components you pair with the unit can mean the difference between a simple installation and a smarter installation.

Auxiliary boiler accessories range in both form and function. The best products for the job should be designed to save time, space, and labor during installation. They should also provide controls to ease future maintenance and should protect the boiler and system components over time.

With these goals in mind, Webstone has developed the most complete selection of under boiler solutions available today. Its under boiler program is a single source for better installations, with products that also simplify and reduce the number of maintenance callbacks.

The Hydro-Core™ manifold simplifies the installation and service of the primary heating loop. This solution combines closely-spaced tees with isolation valves to achieve hydraulic separation for the heating loops, isolates the components within the loop, and purges the system. A T-Flow ball directs the flow into either the boiler or the drain, which can be configured in a number of ways to assist with purging, filling, and descaling/cleaning. Its compact, forged-brass body replaces up to 17 individual components, eliminates 16 leak paths, and saves over two hours of labor.

To improve overall system performance, the Air Separator uses a unique stainless-steel coalescing medium that captures both microbubbles and static air. The separated air collects in the top of the unit, where it forces a pin-guided float to drop down and open a vent. Once the air is released, the float rises once again and closes the vent. This reduces noise as well as wear on system components caused by trapped air in the pipes. The vertically mounted model is ideal for installing on the boiler outlet, where the air can be separated and vented before it reaches the rest of the system.

To protect the boiler from iron sludge that can accumulate in a hydronic system, consider the Magnetic Boiler Filter. Installed on the system return line, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter. The drain makes it simple to remove accumulation, with a strapped cap that can be used to actuate the drain valve. A universal diverter allows the Magnetic Boiler Filter to be used in both horizontal and vertical piping orientations. The service tool is also included to help install and maintain the filter with ease.

Both the vertical mount Air Separator and Magnetic Boiler Filter are outfitted with removable G1 threaded end connections (available in sizes ¾” and 1”, with MIP, FIP, SWT, or Press ends), offering added versatility to any installation. These threads allow the installer to easily add isolation valves for future service, or a temperature gauge to verify boiler output right at the source.

A full-featured under the boiler installation from Webstone requires no more than 22” of space and delivers cleaner, more professional-looking results. Solutions are also available for boilers with external pumps and combi domestic hot water connections from the E-X-P™ Series of Tankless Water Heater Service Valves. To find all of these products and more, visit www.webstonevalves.com.

Founded in 1954, Webstone now operates as a brand of NIBCO INC. and is recognized as an industry leader for innovative design of residential and commercial valves used in plumbing, hydronic, radiant, solar and geothermal applications. These designs focus on time and space-saving concepts that simplify future maintenance and upkeep of all piping systems. Some of the Webstone trademarked and patented items include Hydro-Core™, The Isolator®, E-X-P™, Pro-Connect™, and Pro-Pal® step-saving valves.