Like most add-ons and accessories, the boiler fuel conversion kit is another easy to forget item that stretches out the installation. In the third and final installment on Alta gas-adaptive technology, we’ll cover why fuel conversion is necessary, what was required to accomplish this in the past, and how simple it is to set the Read more

oil

Like most add-ons and accessories, the boiler fuel conversion kit is another easy to forget item that stretches out the installation. In the third and final installment on Alta gas-adaptive technology, we’ll cover why fuel conversion is necessary, what was required to accomplish this in the past, and how simple it is to set the Alta up for either natural or LP gas.

Like most add-ons and accessories, the boiler fuel conversion kit is another easy to forget item that stretches out the installation. In the third and final installment on Alta gas-adaptive technology, we’ll cover why fuel conversion is necessary, what was required to accomplish this in the past, and how simple it is to set the Alta up for either natural or LP gas.

As with most things in life, it’s best to start with the basics. Propane has roughly twice the BTU/ft3 when compared to natural gas. As such, the technician was historically required to replace or adjust certain gas train components to configure the boiler to operate safely, reliably, and efficiently with the selected fuel. Take cast iron boilers for example. The main orifices, pilot, and sometimes even the gas valve were replaced when transitioning from NG to LP, or vice-versa.

On 5:1 turndown condensing boilers such as the U.S. Boiler Alpine, technicians are required to adjust the throttle screw, and then set up combustion appropriately by tuning the boiler with an analyzer, and on occasion adjust the offset screw as well. On other 10:1 high efficiency, condensing products, a venturi replacement was required to switch from NG to LP, or vice versa. After the venturi replacement, combustion tuning is still required to verify optimal combustion settings.

With the Alta boiler, this conversion process is dramatically reduced to two easy steps, with no component replacement or kits required.

When purchasing a boiler, fuel selection is certainly a primary consideration, and there are a few options when ordering a boiler. Some models are available from the factory set up either for natural gas or propane, while others are shipped set for natural gas and must be converted to operate with propane in the field. The latter is true of all Alta boilers, but lucky for you, fuel conversion on the Alta is super simple!

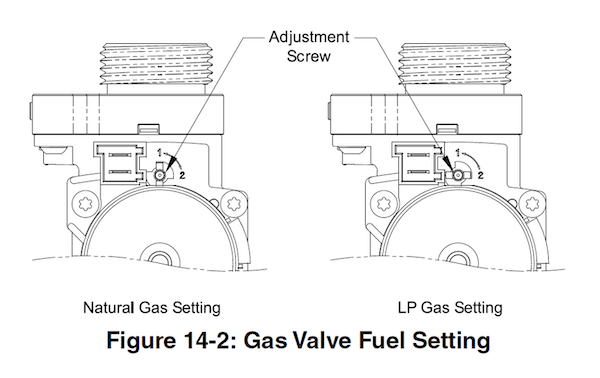

To convert an Alta from natural gas to LP, the technician must turn the fuel screw on the gas valve 1/4 turn to the LP position. Note that on the fuel screw position one is for natural gas, position two is for LP.

Next, simply follow the process listed in the manual to make adjustments on the control.

At this point you may begin looking around for your fuel conversion kit, but as the Alta boiler begins tuning itself for optimal combustion you can simply sit back and relax. The Alta’s gas adaptive system will ensure that your boiler is set for the highest efficiency operation, and all you need to do is press a button.

Is this the end of the gas analyzer?! Don’t put yours up for sale on eBay quite yet. Once your Alta boiler has completed the tuning sequence, we recommend a combustion check just to be sure there is nothing wrong with the venting, combustion air intake, or any other field variables.

So as you prepare for this week there will be hundreds of things to worry about. Are the boiler installs natural gas or LP? Who cares? Skip the conversion kits. Just put in an Alta by U.S. Boiler Company and it will take care of itself.

As soon as Viega LLC introduced its MegaPressG fitting system for joining gas and fuel oil pipes, contractors began asking for it in larger sizes. The original lineup included fittings for carbon steel pipes from ½” to 2″. They were the first fittings approved for use in gas and fuel oil applications and they quickly Read more

As soon as Viega LLC introduced its MegaPressG fitting system for joining gas and fuel oil pipes, contractors began asking for it in larger sizes.

The original lineup included fittings for carbon steel pipes from ½” to 2″. They were the first fittings approved for use in gas and fuel oil applications and they quickly proved popular among contractors for their speed, reliability and ease of use. However, the 2″ limit restricted the number of applications in which they could be used.

In February, Viega introduced MegaPressG fittings for 2½”, 3″ and 4″ pipe, creating a comprehensive lineup of fittings approved for use in gas and fuel oil applications. And it’s the only system on the market that allows secure press connections on gas lines 2½” to 4″ in 16 seconds or less.

Constructed of carbon steel with a corrosion-resistant zinc nickel coating and first-of-its-kind graphite separator ring in larger sizes, MegaPressG is suitable for use with ASTM Schedule 5 to Schedule 40 carbon steel pipe

Using MegaPressG means no open flames, faster connections and labor savings, resulting in safer and more efficient projects that come in on time and on budget. It can reduce labor costs by as much as 60% to 90% over traditional methods.

Configurations include elbows, couplings, no-stop couplings, reducers, tees, reducing tees, adapters, reducing adapters, caps and flanges.

Combining productivity with peace of mind, MegaPressG fittings are equipped with Viega Smart Connect® technology, which allows installers to easily identify unpressed connections during pressure testing.

MegaPressG fittings offer the same proven quality and durability as all Viega products, bringing complete confidence to every job.

For more information on the new line of MegaPressG fittings, click here.

Energy Kinetics’ 90+ Resolute Boiler can be chimney vented with 3″ flexible polypropylene for quicker, easier, and less expensive installations than stainless steel liners. The 90+ Resolute is a non-condensing heat and hot water system up to 91 AFUE, and it’s oil or gas fired providing long term fuel flexibility. The 3″ flexible liner is really the Read more

Energy Kinetics’ 90+ Resolute Boiler can be chimney vented with 3″ flexible polypropylene for quicker, easier, and less expensive installations than stainless steel liners. The 90+ Resolute is a non-condensing heat and hot water system up to 91 AFUE, and it’s oil or gas fired providing long term fuel flexibility. The 3″ flexible liner is really the only way to go when a chimney needs to be lined. The 90+ Resolute runs as quietly as a small microwave with a proven 30 year boiler backed by a lifetime limited warranty.

Energy Kinetics’ 90+ Resolute Boiler can be chimney vented with 3″ flexible polypropylene for quicker, easier, and less expensive installations than stainless steel liners. The 90+ Resolute is a non-condensing heat and hot water system up to 91 AFUE, and it’s oil or gas fired providing long term fuel flexibility. The 3″ flexible liner is really the only way to go when a chimney needs to be lined. The 90+ Resolute runs as quietly as a small microwave with a proven 30 year boiler backed by a lifetime limited warranty.

With over 6 years of installations from New England and Mid-Atlantic States to Alaska, the 90+ Resolute delivers consistent fuel savings results and cuts installation time by 3 to 5 man hours with its pre-piped and pre-wired package. Contact Energy Kinetics for direct to contractor purchase. Parts and support are available to all heating professionals.

https://youtu.be/TBdLs8FEVmA Mechanical Hub gives you an exclusive look at the 2015 OESP Show in Hershey, Pa Read more

https://youtu.be/TBdLs8FEVmA

Mechanical Hub gives you an exclusive look at the 2015 OESP Show in Hershey, Pa.