Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers. Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million Read more

pressing technology

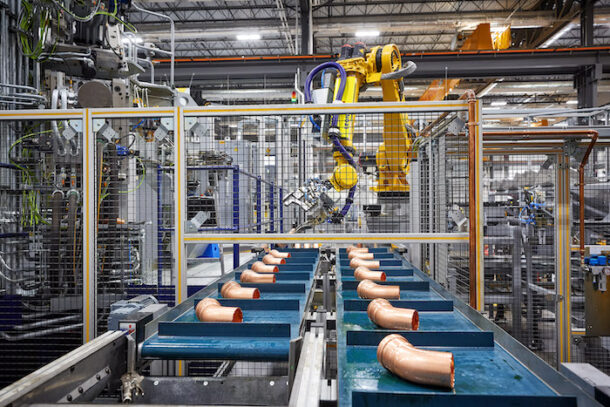

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers.

Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million and will increase the U.S. production of its industry-leading ProPress® products.

“As we continue to grow the business, we are bringing more production to the United States,” said Markus Brettschneider, CEO and President of Viega LLC. “These investments in our U.S. footprint will further support demand and leverage the talented U.S. manufacturing workforce, starting with the expansion of production capacity in Kansas.”

The McPherson manufacturing and distribution center is currently around 1 million sq. ft, with the facility more than doubling its footprint and workforce since opening in 2008. The new ProPress equipment is expected to be in production by the end of Q3 2023, with additional investments to come.

“We are proud to produce our fittings right here in Kansas. As we increase our U.S.-made products, we remain committed to creating highly skilled jobs in America, building out more sustainable manufacturing processes, and developing tomorrow’s workforce,” said Marki Huston, Head of Manufacturing for Viega LLC.

In addition to its McPherson, Kansas facility, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with further North American expansion planned for 2024 and 2025.

When premium wholesale plumbing supplier, Winston Water Cooler, decided to build a large training and distribution center in Phoenix, not only did they choose to stock Viega products, but they chose to show them off in their own plumbing and piping as well. The 35,000-square-foot building was recently completed for use with customer training. “The Read more

When premium wholesale plumbing supplier, Winston Water Cooler, decided to build a large training and distribution center in Phoenix, not only did they choose to stock Viega products, but they chose to show them off in their own plumbing and piping as well.

The 35,000-square-foot building was recently completed for use with customer training. “The Workbench” gives tradespeople the opportunity to do hands-on product demos and learn about the situations they might find on the job, as well as learn about products they can use.

“This is all live fire,” explained Phillip Clark, Partner of Winston Water Cooler in Phoenix. “There is water pumping through the heaters, gas running to the heaters, that sort of thing. We can simulate certain problems by putting different parts in and having people troubleshoot to find the issues. It’s all hands-on, which makes it valuable in our industry for these guys. We want them to be comfortable with the products, and it gives them a comfort level so they can come up here and screw up something instead of potentially screwing up their customer’s stuff!”

Clark said the training center includes products seen in multifamily buildings, plus parts of a mechanical room setup, including boilers, booster pumps and mixing valves. The building contains equipment supplied by a variety of manufacturers. Originally a data center, Winston remodeled the space into a training center.

All the water in the building is piped with ProPress, and gas lines are run with MegaPressG. About 200 feet of 2½” and 3” copper lines connect to storage tanks, where water can be circulated through heating and pressure-boosting segments. The gas lines have 1½” MegaPressG fittings.

“We wanted to become a stocking distributor for Viega for years, and in 2019 we jumped at the opportunity when it came,” Clark said. “We phased out Apollo as we brought in Viega. We realize the value in the product and know it’s good – and that a lot of customers only trust Viega.

“The product line with Viega is more diverse with the larger-diameter fittings, and Viega has some fittings in configurations and tighter tolerances. It’s just a good market presence that speaks for itself. We’ve had issues with other [brands], where we’re responsible for going back and taking care of the customer after hours. But Viega’s track record for quality and consistency is far superior to the competitors’ and it makes our customers happy.”

Clark said it’s a great advantage to hold training classes and show products at work that they also have in stock on their shelves. Attendees can see how Viega fittings work and that they’re a clean installation. All the piping in the facility is exposed on the walls and anchored so it can be used for show-and-tell.

The economy in Utah is booming, and Blue Line Plumbing and Mechanical has a lot of jobs to stay on top of. Viega products are coming in quite handy to help speed things along. Blue Line recently ran gas lines for an office complex with warehouses in American Fork, Utah, running MegaPressG lines to each Read more

The economy in Utah is booming, and Blue Line Plumbing and Mechanical has a lot of jobs to stay on top of. Viega products are coming in quite handy to help speed things along.

The economy in Utah is booming, and Blue Line Plumbing and Mechanical has a lot of jobs to stay on top of. Viega products are coming in quite handy to help speed things along.

Blue Line recently ran gas lines for an office complex with warehouses in American Fork, Utah, running MegaPressG lines to each of the 22 units. There is also a two-inch water main in ProPress, about 1,000 feet long with tees and ball valves, providing water to each unit. Using Viega products made it all possible.

“Basically, I first thought, ‘Wow, this looks so easy,’” Bryce Mannek, president of Blue Line, said. “Time is of the essence in Salt Lake City, and Marty Ellis from Viega had come out to do a demo. I borrowed a press gun from him and got the materials; and on a project in Herriman that I thought was going to take about a week, we did it in two days. It saved us a ton of time.”

The office complex owner estimated that there’s about a mile of one-inch pipe in the building, the first of three similar buildings in the same complex. Mannek said that besides saving time and money using Viega, one of his favorite things is the simple, clean look of the product.

Read more here