Taco Comfort Solutions is pleased to announce the appointment of Tony Furst as its newest Commercial Trainer. With over 40 years of distinguished experience in mechanical engineering and a comprehensive background in overseeing multimillion-dollar projects, Tony brings a wealth of knowledge and expertise to the Taco team. Tony’s career spans significant roles across renowned organizations Read more

pumping

Taco Comfort Solutions is pleased to announce the appointment of Tony Furst as its newest Commercial Trainer. With over 40 years of distinguished experience in mechanical engineering and a comprehensive background in overseeing multimillion-dollar projects, Tony brings a wealth of knowledge and expertise to the Taco team.

Taco Comfort Solutions is pleased to announce the appointment of Tony Furst as its newest Commercial Trainer. With over 40 years of distinguished experience in mechanical engineering and a comprehensive background in overseeing multimillion-dollar projects, Tony brings a wealth of knowledge and expertise to the Taco team.

Tony’s career spans significant roles across renowned organizations within the HVAC industry, including Armstrong Fluid Technology, where he served as the US Director of Application Engineering. His responsibilities included providing extensive application engineering support and developing technical education content for commercial HVAC systems. Tony’s commitment to excellence and innovation has consistently resulted in the successful completion of projects on time and within budget.

“We are thrilled to welcome Tony to Taco Comfort Solutions,” said Cheryl Merchant, CEO of Taco Family of Companies. “His deep understanding of mechanical systems and his passion for educating others will be invaluable as we continue to enhance our training programs for the commercial sector,” added Merchant.

Tony holds a BS in Mechanical Engineering from the University of Dayton and an MS in Education from Michigan State University. He is certified in Plumbing Design by the American Society of Plumbing Engineering (ASPE) and is a LEED Accredited Professional with the US Green Building Council. Throughout his career, Tony has been a dedicated member of ASPE and ASHRAE, contributing significantly to technical education committees and serving as a speaker at various industry events.

“I truly enjoy sharing knowledge with others to make modern hydronic systems better,” said Furst. His commitment to advancing industry standards aligns perfectly with Taco Comfort Solutions’ mission to provide innovative and efficient solutions for HVAC systems.

In his new role at Taco, Tony will join a team of esteemed trainers, including Brett Zerba and Rich Medairos, enhancing the company’s capability to deliver comprehensive training programs tailored to the needs of commercial clients.

“It’s rare when you get the opportunity to add someone with Tony’s background, experience, and knowledge to your team,” said John Barba, Director of Training at Taco Comfort Solutions. “Adding Tony to our commercial training team is like having three Hall of Famers in your outfield. I’m looking forward to seeing Tony, Brett, and Rich share their wit, wisdom, and knowledge with our industry,” concluded Barba.

Furst’s appointment marks a significant addition to Taco Comfort Solutions, reinforcing its commitment to excellence in commercial HVAC training and education.

It’s that time of year again where media, prognosticators and media prognosticators try to look into the immediate future to predict, and make sense of, the short-term economy. And, yes, even in this uncertain climate. Mechanical Hub will be featuring a series of exclusive Q & A sessions with industry leaders and players to get Read more

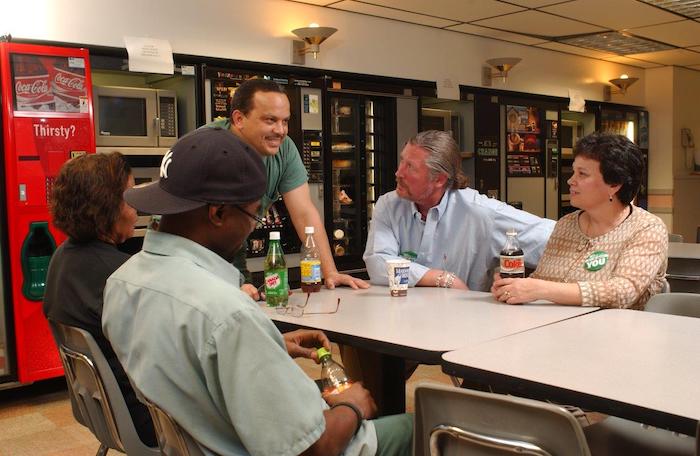

It’s that time of year again where media, prognosticators and media prognosticators try to look into the immediate future to predict, and make sense of, the short-term economy. And, yes, even in this uncertain climate. Mechanical Hub will be featuring a series of exclusive Q & A sessions with industry leaders and players to get their views on the future, and living in a COVID world. The first in our series, we feature Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

MH: When it comes to 2021 industry forecasts, the most resonant word I hear is optimistic. But that word can become hollow if it doesn’t have any substance backing it up. Now I’ve read reports that residential service repair and remodel may remain constant with a slight increase in early 2021. On the other hand, according to AIA info, for example, there is a predicted 5.7% decrease in construction spending—hotels, office buildings, recreation—for 2021, with pent-up demand leading to anticipated growth in 2022. What does the short-term economy look like as it relates to Taco?

CHAFFEE: There’s one certainty: it’ll be a bumpy road, but there’s no surprise in that. We’re sure to see regional variances in economic challenge, and recovery. Business climates shifted in response to COVID-19. The tremors are still being felt, so the trend is: more shifting and variation. Though, gradually, our economy has made every attempt to adjust to the turmoil. So yes, there’s optimism in that.

We’re optimistic because we’ve built a resilient, responsive organization. As a family-owned company with more than 100 years of experience to draw on—through plenty of economic turmoil, and even world wars—Taco Comfort Solutions has found strength even in the worst of times. We’re nimble, flexible and entrepreneurial, characteristics that continue to position us well for the long term. We invest in people and opportunity.

This year we also had to invest substantially to protect the health and safety of the Taco family, including employees, partners and customers. We quickly adapted our business model and the way we manufacture products so we could remain open and able to supply products.

I can’t understate the importance of these things: Taco’s health and longevity; its future, our future and the future of America’s economy depends of strengths like these and resilience that stems from smart, diligent, deliberate action—each and every day, one step at a time. We spin and pivot.

Just one example of how we’ve responded to the pandemic’s trauma and stress: our training programs have strengthened. Of course, we used to conduct more live, hands-on training at Taco and at Rep and Distributor locations, though now our online training has intensified with unexpected results. Our trainers—John Barba, Dave Holdorf, Rick Mayo, and Rich Medairos and Brett Zerba on the commercial side—have developed an incredibly strong outreach among customers. Customers are engaged and responsive, so it seems that even in the midst of challenge, we’ve managed to strengthen ties with installing contractors, system designers, engineers and specifiers. Of course, we’re eager to get back to a full slate of personal, boots-on-the-ground, hands-on and factory-based training with customers.

Undoubtedly, there are some areas in the market that have been severely impacted—hospitality is perhaps the biggest example of this. The international crisis of COVID-19 has been a huge disruption to hotel construction and renovation work. Architects and designers, general contractors and mechanical systems installers—especially those who tailored their work specifically to hospitality work—are forced to wait, with lots of business on hold. Another part of the market that’s similarly depressed is commercial office construction and remodeling.

Professionals in these fields are unpleasantly faced with the need to examine the financial and technical hurdles of how to keep existing buildings in operation. Following this, there are then considerations about whether or not to downsize operations, or at least—“How can we better use the space we have, safely?”

Out of these concerns, two key issues emerge: efficiency, and ventilation.

If buildings are to remain in operation, then it’s with a greatly heightened awareness of the financial importance of improving energy efficiency in concert with maintaining the health and well-being of anyone who steps inside the building. Luckily our industry has the answers, solutions to these rather complex challenges. So in that respect, there’s a silver lining to the crisis we now face

MH: What are some indicators you look at to determine trends, movements, etc.?

CHAFFEE: We track a number of standard data sets like the consumer confidence level, stock market, and the strength of housing starts, construction and remodeling. We also watch the way people spend the money they have.

One promising change we’ve seen in response to COVID-19 has been that people are far better acquainted with their own comfort, or lack of it, at home. So, there’s a greater awareness of how to live with comfort systems, what’s involved, and how they can be improved if there are concerns. After all, families are brought together in ways that no one could have expected prior to the pandemic.

So now in the midst of winter conditions, people are responding to their own comfort or discomfort. Understandably, one of those reactions may be a desire to improve the comfort of a home. As we know, hydronic heat stands tall in that category. And, with their inherent flexibility, hydronic systems can be improved with relative ease. Not only the delivery of comfortable heat, but also the energy efficiency of system. Many Americans have chosen to invest in improvements and renovations as opposed to a vacation they can’t take. We’re seeing evidence of this every day.

For the commercial market, we use different services to track projects through the engineering, design, specification and release of jobs. Of course, hotel and office space starts are down, though other commercial categories are still moving, though gradually and with huge variation based on geography. Interest rates remain low, money’s cheap and the underlying economy continues to chug along.

As for trends, we see the continuing expansion of strategic electrification. These initiatives are supported by more local utilities, state regulators, and fits with the new administration’s environmental stance as indicated by President Biden’s early executive actions.

For our industry, that means more heat pumps. We’ve already seen the seismic market shift to mini-splits and commercial VRF systems; but these systems use distributed refrigerant, where refrigerant lines are run throughout the building to terminal units. Adding pounds of additional refrigerant into a system where the global warming potential (GWP) of 410A is 2,088 will not be sustainable under the new climate goals Already in Europe we are seeing the move to “low GWP” refrigerants where the goal is to get under a GWP of 700. But the options for A3 and A2L refrigerants come with the risk of being flammable, along with not being retrofittable into existing 410A systems.

This is where we see the continued growth of geothermal heat pumps, especially in community based projects, along with hydronic-based air-to-water heat pumps having a major impact in future-proofing a house or building’s HVAC system while delivering heating, cooling and domestic hot water production. The best part is that the GWP of water is 0! Sure, you still need the refrigerant for the heat pump, but it’s kept at a bare minimum, is factory sealed and outside.

MH: I read somewhere that at the rate the U.S. is distributing the vaccine, we should be back to “normal” by 2024. Perhaps that’s a bit overly dramatic, but how does (has) Taco positioned itself from the “fallout” of COVID-19?

CHAFFEE: We’re cautious, but as I’ve said, we’re also optimistic. Taco continues to invest in its future.

Very important to Johnny White and Cheryl Merchant have been investments in the company and its ability to meet market demand, with products and technology that exceed expectation.

Investment in our training capability and outreach among customers is a very important part of that. Of course, Taco also invests in its people. As we’ve said on many occasion, Taco’s employees are Johnny’s family. He and Cheryl, and Johnny’s sons Ben and John—each, now with key management roles—see Taco’s stability as the continuation of a long dream, a tradition that’s grown and improved through the years only because of a genuine sense of belonging that Taco’s employees have with each other, and at all levels of company management. Our future is in their hands, so it’s easy to understand this very real emphasis.

MH: Is the only certainty heading into early 2021 uncertainty? How do you forecast and budget for such uncertainty? Or is it fairly certain at this point during the pandemic? (Certainly, a lot of certainty here, lol)

CHAFFEE: Again, we’re cautiously optimistic. And yes, some measure of uncertainty is guaranteed. We continually review and evaluate business conditions. People’s habits are changing in response to the pandemic; some of them may be altered forever. So, these become trends.

Because the HVAC industry was designated as an essential critical infrastructure workforce during the early stages of the pandemic, Taco Comfort Solutions and its suppliers were able to continue operations. Our strong, long-term relationships with suppliers, as well as our logistic partners, helped minimize supply disruptions.

Our investment in inventory, combined with a comprehensive plan to ensure the health and safety of our workforce, has enabled us to continue to provide our customers with vital heating, cooling, and hot water products. We anticipate the capacity in the logistics industry will remain tight through the first half of 2021 due to labor shortages caused by COVID-19 cases as well as the prioritization of vaccine distribution.

MH: Without getting overly political, does a change at the presidential level (and congress) change the outlook for your company, if at all? (Infrastructure, regulations, green energy initiatives, etc.)

CHAFFEE: Under the Biden presidency, underscored by the renewed involvement in the Paris Accord, it seems certain that there will be an emphasis on the environment, where the improvements to existing buildings through energy efficiency is key. But there’s also an appetite on both sides of the political isle for increased infrastructure spending. This isn’t just roads and bridges but will also focus on our aging water infrastructure including significantly increased investment in state revolving funds. And, as part of that, there will be added attention to energy and operational efficiency.

We’re sure to see more incentives for energy conservation in the form of Federal rebates for the purchase and installation of energy-conserving and IAQ technologies. This will also incentivize manufacturers to develop more energy-efficient technologies.

Attention to commercial and industrial building improvements will lead to increased recognition of the importance of pumping systems and improved hydronic systems and their role in improving the energy efficiency of buildings, coast to coast.

Taco’s ahead of the curve here. We were deeply involved in DOE’s effort to bring about the labeling of commercial pumps … and now, we believe, the emphasis will again return to accomplishing the same for residential circulators. This will again focus attention on the need to replace remaining non-ECM pumps and circulators, with far more efficient ECM-powered equipment.

Many years ago, Taco also recognized the need to invest in and develop ECM technology. Those early efforts led to our role today as the nation’s leading sources of ECM technology. Taco now offers ECM circulators and pumps, from the smallest residential circulator, to pumps that serve the commercial and industrial markets.

That’s not to say there isn’t room for improvement; there is. We plan to expand our ECM product lines substantially. There’s great strategic value in this as we maintain our leadership role in helping to continue the market’s transformation toward better, more efficient pumping.

Mark Chaffee, is Vice President of Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

Mark Chaffee, is Vice President of Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

Epoch Senior Living Inc. operates 10 Bridges by Epoch Memory Care Assisted Living Facilities throughout New England. Over the years, management has sought to provide the highest level of resident comfort and environmental sustainability. Partnering with architects, designers and mechanical system installers that understand these priorities has lead the company to continuous growth. At nearly Read more

Epoch Senior Living Inc. operates 10 Bridges by Epoch Memory Care Assisted Living Facilities throughout New England. Over the years, management has sought to provide the highest level of resident comfort and environmental sustainability. Partnering with architects, designers and mechanical system installers that understand these priorities has lead the company to continuous growth.

At nearly all the Bridges locations, consulting engineer Wozny Barbar & Associates (WB&A) has been hired for the mechanical system design. The 27-year-old firm specializes in assisted living facilities, with an impressive list of projects completed throughout the Northeast.

“We have 37 employees,” said Casey Archacki, PE. “As the market has changed and grown, so has our stake in the industry. We’ve done work for EPOCH specifically since 2011.”

In 2016, construction began on the newest facility, Bridges by EPOCH at Sudbury (MA). With help from manufacturer’s representatives at Emerson Swan, WB&A specified a mechanical system that has performed exceptionally well at other EPOCH properties: a cooling tower and boiler system providing heating and cooling capacity to a variable-speed loop for water source heat pumps, along with an extensive ventilation system.

Comfort and control

“The heat pump systems provide a high level of control and zoning throughout the building,” said Archacki. “At EPOCH, comfort is the main priority, followed by efficiency and lifecycle cost.”

Bridges at Sudbury is a 45,000 square-foot, single-structure facility with 54 resident apartments. An 85-ton cooling tower and two redundant 650 MBH condensing boilers serve the collection of water source heat pumps. Whalen vertical-stack heat pumps are used in tenant rooms, while horizontal heat pumps made by Florida Heat Pump are used in common areas.

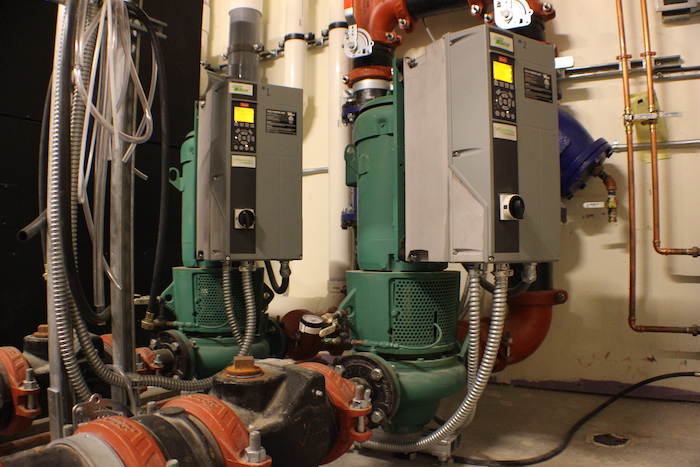

The building loop serving the heat pumps is served by a pair of redundant Taco SelfSensing pumps, with a max 210 GPM and 70 ft. head. The use of SelfSensing pumps eliminates the need for pressure sensors within the hydronic loop, and speeds up the commissioning and balancing process.

“To improve the indoor air quality of the building, the owners request that all of the spaces be mechanically ventilated,” said Archacki. “In order to accomplish this, all the bathroom exhaust has to be mechanically balanced with ventilation air. Since each resident has a private bathroom, this means that outdoor air and exhaust air requirements are quite high for the building. In order to maximize the energy load, we provided a single energy recovery ventilator to handle all of the outdoor and exhaust air.”

EPOCH has hired WB&A for numerous projects in part because the engineering firm comes highly recommended by architects. Their systems continuously perform. Each time they’ve approached a new EPOCH design, WB&A has drawn on the experience of Emerson Swan.

Smart choice in pumps

Emerson Swan has supplied the pumps, cooling towers and heat exchangers, along with assistance during specification, since WB&A was founded.

Emerson Swan has supplied the pumps, cooling towers and heat exchangers, along with assistance during specification, since WB&A was founded.

“Wozny Barbar is self-sufficient, but we help in any we can,” said Bill Arscott, sales engineer at Emerson Swan. “WB&A has been installing these heat pump systems before my time at Swan, and precedes the release of the Taco SelfSensing pumps that have simplified installation of the systems. Back then, conventional pumps with pressure sensors were used.”

Taco’s SelfSensing line of VFD-driven pumps not only eliminate the need for pressure sensors, but the VFDs are pre-programmed at the factory.

“The challenge we faced when using conventional circulators with sensors was picking a location for the sensor early on in the design phase,” said Archacki. “This was tough because the piping was subject to change, meaning sensor placement would no longer be ideal. Not needing sensors has been a big advantage.

Because Taco installs the VFDs on the pumps at the factory, on-site programming is not needed. The engineer provides a nominal pressure drop measurement, and the factory programs the units to 10 steps below nominal. Once installed, a balancing team fine tunes the pumps.

“We’ve always specified Taco in part because they’re a local company,” said Archacki. “When the SelfSensing product line came out, I attended a lunch-and-learn hosted by Rich Medairos at Taco. “That was several years ago, and we’ve now installed the pumps at nine properties without a single issue.”

Modulation

Because the SelfSensing line of pumps can sense and respond to pressure changes within a hydronic system, DDC controls are eliminated from the picture. The big advantage is that the capability is all found in a single pump, as opposed to fishing wires, paying the set-up and maintenance contract for controls, and installing pressure sensors throughout the loop.

Because the SelfSensing line of pumps can sense and respond to pressure changes within a hydronic system, DDC controls are eliminated from the picture. The big advantage is that the capability is all found in a single pump, as opposed to fishing wires, paying the set-up and maintenance contract for controls, and installing pressure sensors throughout the loop.

When compared to fixed-speed, centrifugal pumps – which are specified for maximum flow rate – the savings provided by SelfSensing pumps are even greater. Fixed-speed pumps spin literally non-stop, regardless of whether there’s a call or not. By slowing or stopping the pumps, literally millions of revolutions per heating season are eliminated. This dramatically extends the life of pumps, seals and bearings and translates into a very big savings in wear and tear.

A 1750 RPM design pump will save at least 225,000,000 cycles every heating season.

From a design standpoint, SelfSensing pumps provide more leeway in pump selection, since the pump will adjust to the need.

Continuing success

“At most senior living facilities, residents don’t pay utilities, so they expect a lot, and that typically means very warm spaces,” said Archacki. “In addition to the high ventilation rate, we must be able to maintain 80°F at an outdoor design temp of 0°F.

Bridges By EPOCH has considered installing a VRF system at one of the properties in place of the heat pump design, but the systems typically have lower performance in the middle of winter. Discharge air temperatures can drop, resulting in lower comfort levels.

“In general, natural gas costs in this area have been stable and very cheap when compared to electricity,” said Archacki. “Massachusetts pays some of the highest electricity rates in the country. This, along with high comfort levels, is one of the main reasons we continue installing heat pump systems for EPOCH.”

The success that EPOCH has had since its inception is evident. Roughly one new property is constructed and occupied each year. Currently, WB&A is designing systems for two coming EPOCH facilities simultaneously, one in MA and one in NY.